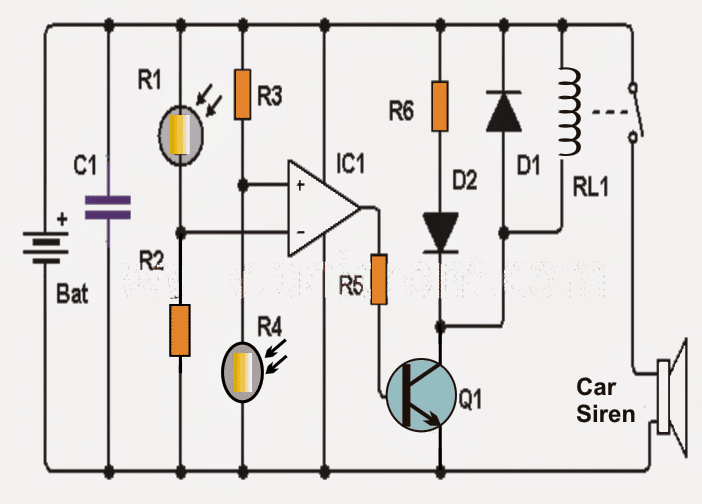

Simple Shadow Sensor Alarm Circuit

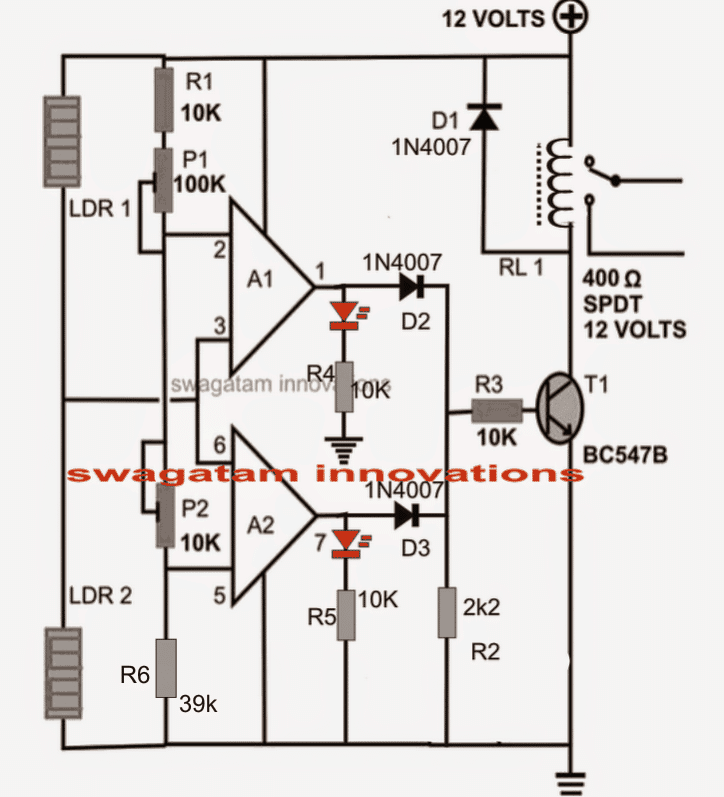

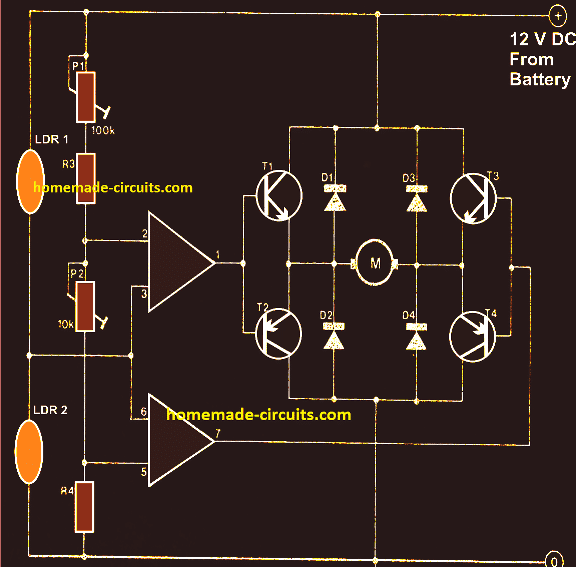

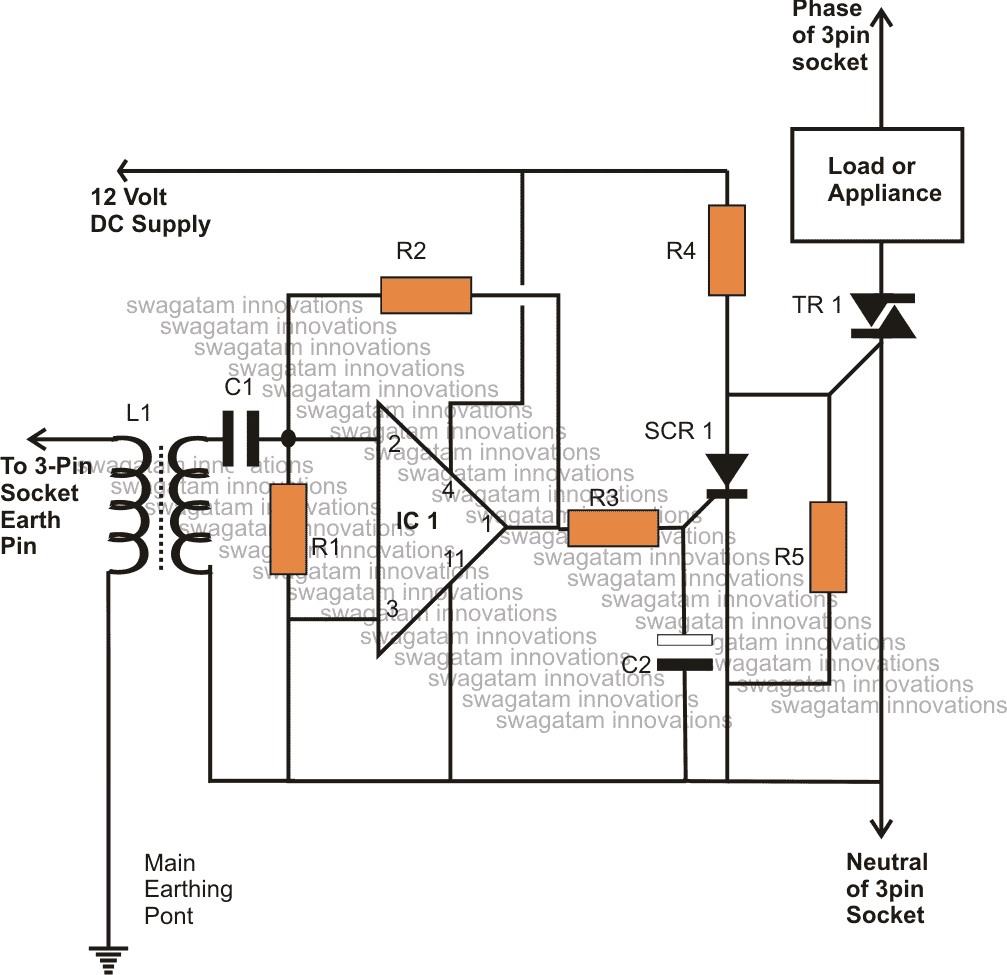

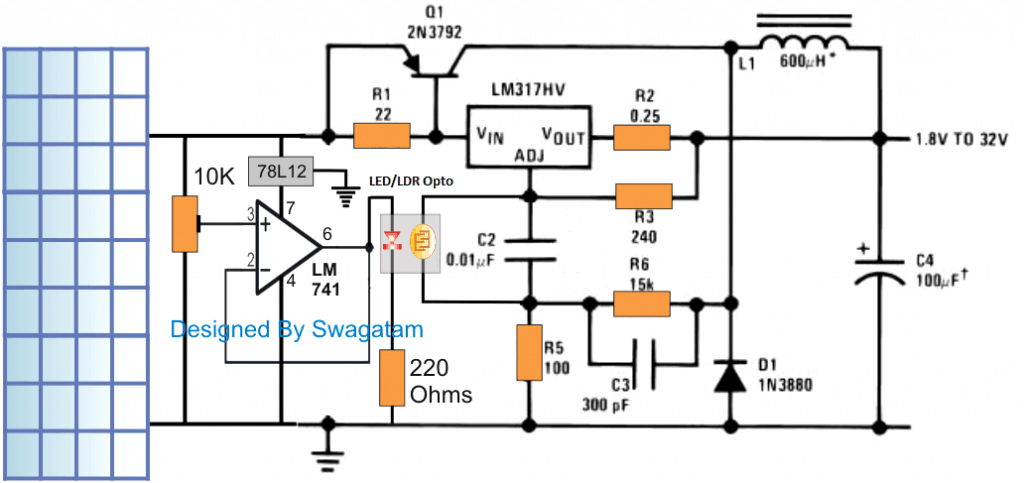

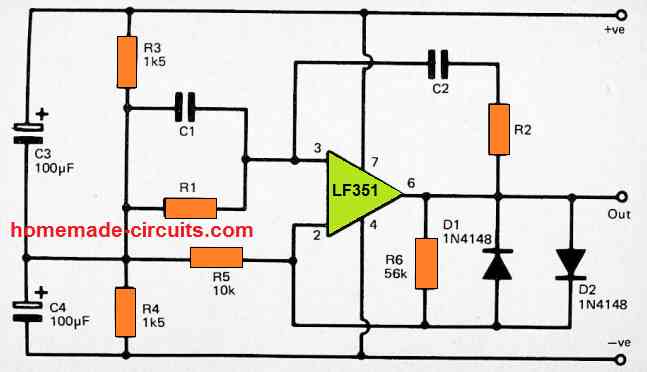

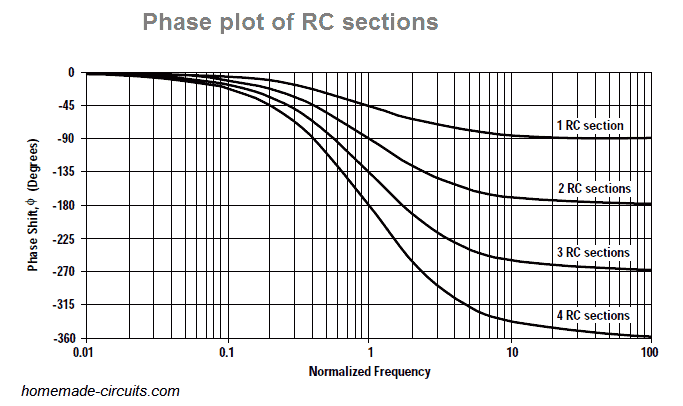

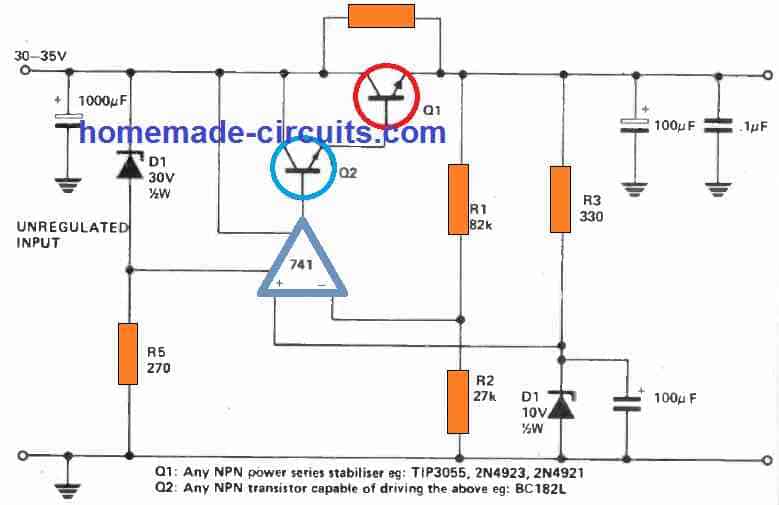

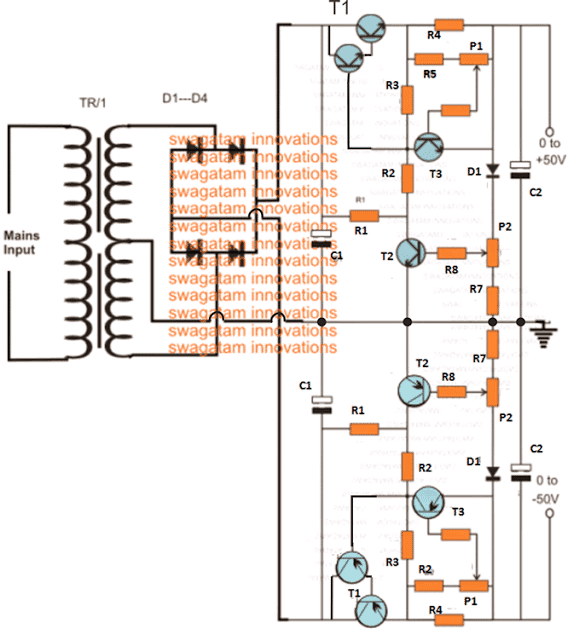

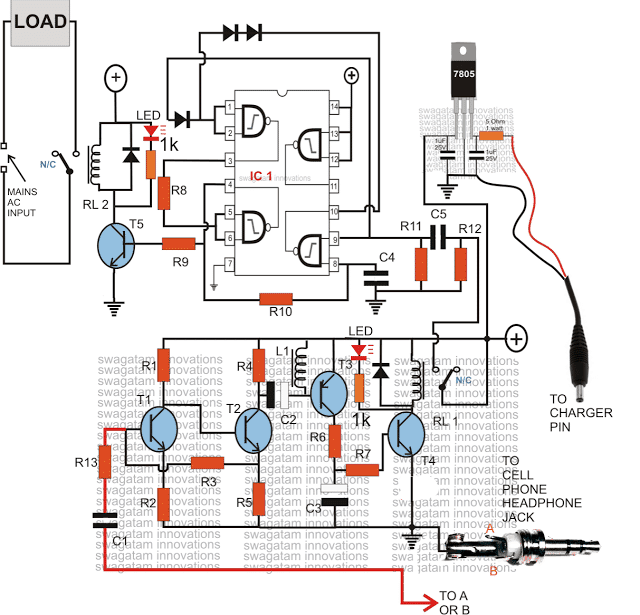

This shadow detector circuit operates using two LDRs and effectively detects the difference between the light levels and triggers a loud audible warning siren. In circuits which uses a single LDR (photoresist), the detection may not be as sharp as with two LDRs discussed here.Operational details of the shadow detector circuit may be studied as follows: The key elements of this circuit are the two LDRs and the active operational amplifier, which functions as a comparator.Circuit Operation

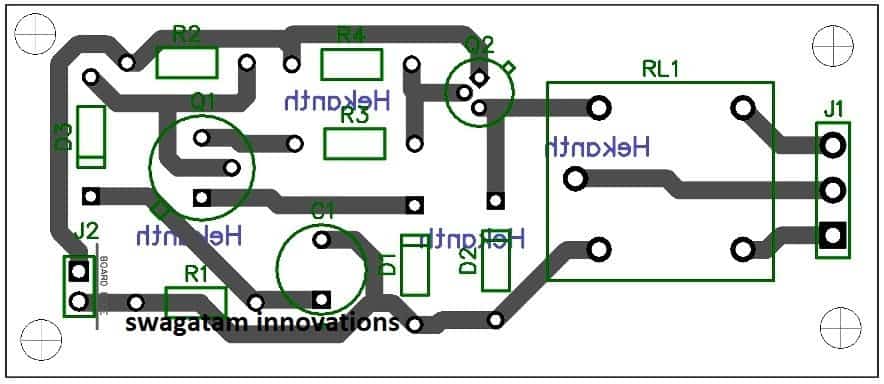

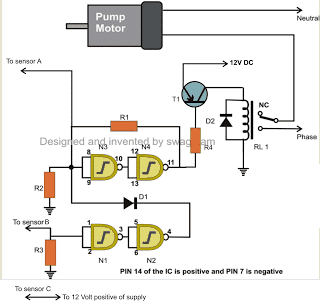

As may be seen in the diagram, the inputs of the opamp are carefully balanced using alternately positioned LDRs across the corresponding supply rails in conjunction with the respective resistors. The two resistors may be possibly replaced with presets for getting a fine adjustment option and for ensuring an optimum balance and a perfect zero logic at the output of the opamp. In normal light situations that is with no shadow detected (no shade) the two LDRs are able to receive the same amount of light across the sensing input of the opamp which renders a low logic level at the output of the IC. In an event when one of the LDRs (for instance R1) experiences a shadow or less light than the other (R4), causes the voltage at the inverting input of opamp to go lower than in the non-inverting counterpart, causing the logic at the output of IC to switch to a high logic. The above action activates transistor Q1, which in turn activates the LED and the relay. The LED allows to acquire a visual warning while the relay activates a siren device. Preferably you may want to place a semiconductor diode (D1) in parallel with the relay, as shown in the diagram, to protect the transistor Q1 from the relay reverse EMFs.Circuit Diagram

Things to be notes:

- The circuit is powered by 9 volt lead acid battery or any similar SMF battery.

- The LDRs should be placed with a separation of about 3cm.

for an optimal response and to avoid incorrect triggering.

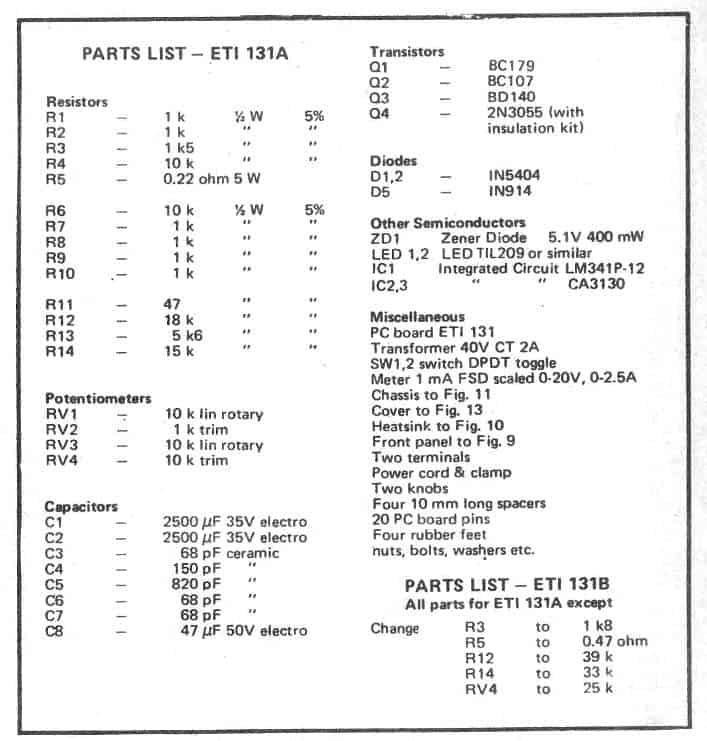

Parts list for the proposed shadow detector circuit

- 1 Operational amplifier: LM741 (IC1)

- 2 LDRs (photoresistor / LDR) (R1, R2)

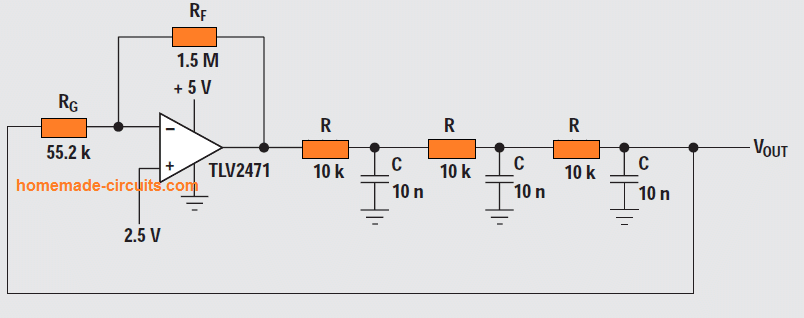

- 1 NPN transistor 2N2222 or similar (Q1)

- 1 1N4007 diode (D1)

- 1 red LED diode (D2)

- 9 volt relay (RL1)

- Two 10K resistors (R3 and R4)

- 1 1K resistor (R5)

- 1 resistors 470 (R6)

- 1 100 nF capacitor (C1)

Things to be notes:

- The circuit is powered by 9 volt lead acid battery or any similar SMF battery.

- The LDRs should be placed with a separation of about 3cm.

for an optimal response and to avoid incorrect triggering.

Parts list for the proposed shadow detector circuit

- 1 Operational amplifier: LM741 (IC1)

- 2 LDRs (photoresistor / LDR) (R1, R2)

- 1 NPN transistor 2N2222 or similar (Q1)

- 1 1N4007 diode (D1)

- 1 red LED diode (D2)

- 9 volt relay (RL1)

- Two 10K resistors (R3 and R4)

- 1 1K resistor (R5)

- 1 resistors 470 (R6)

- 1 100 nF capacitor (C1)

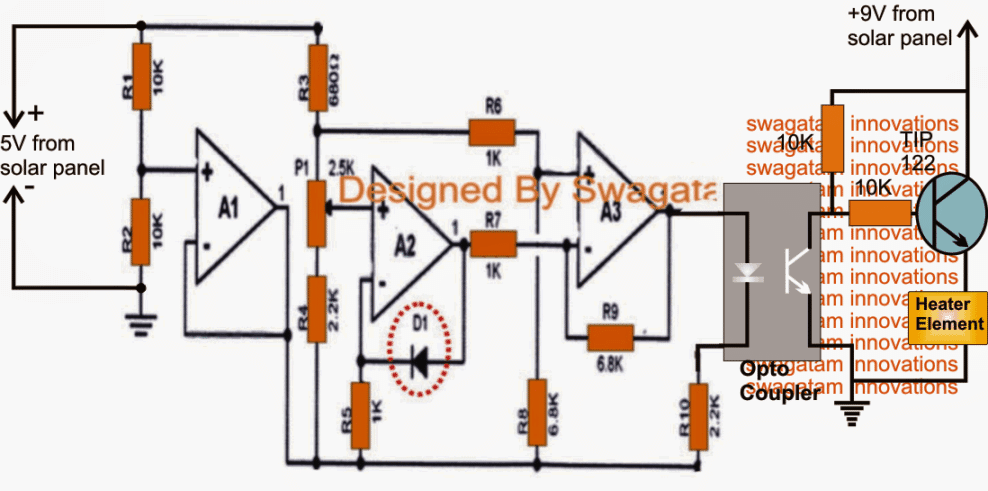

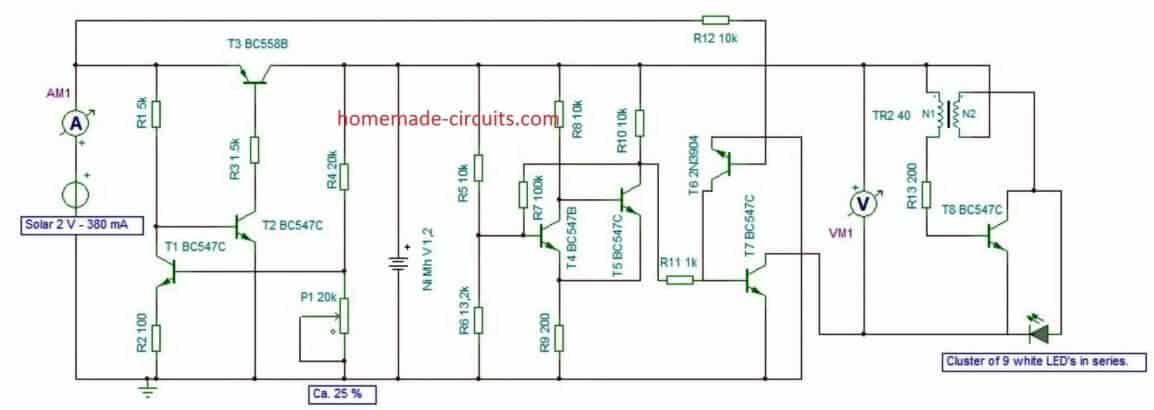

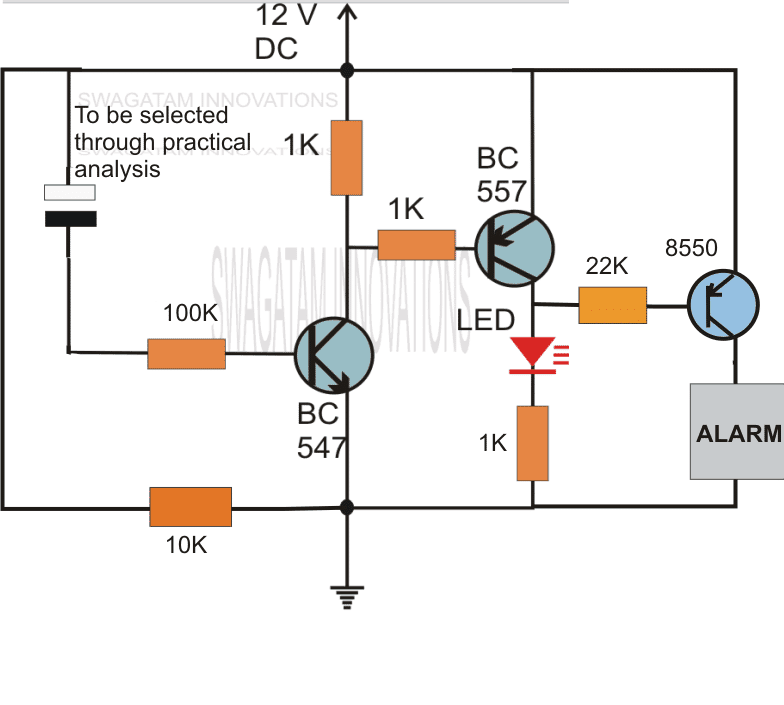

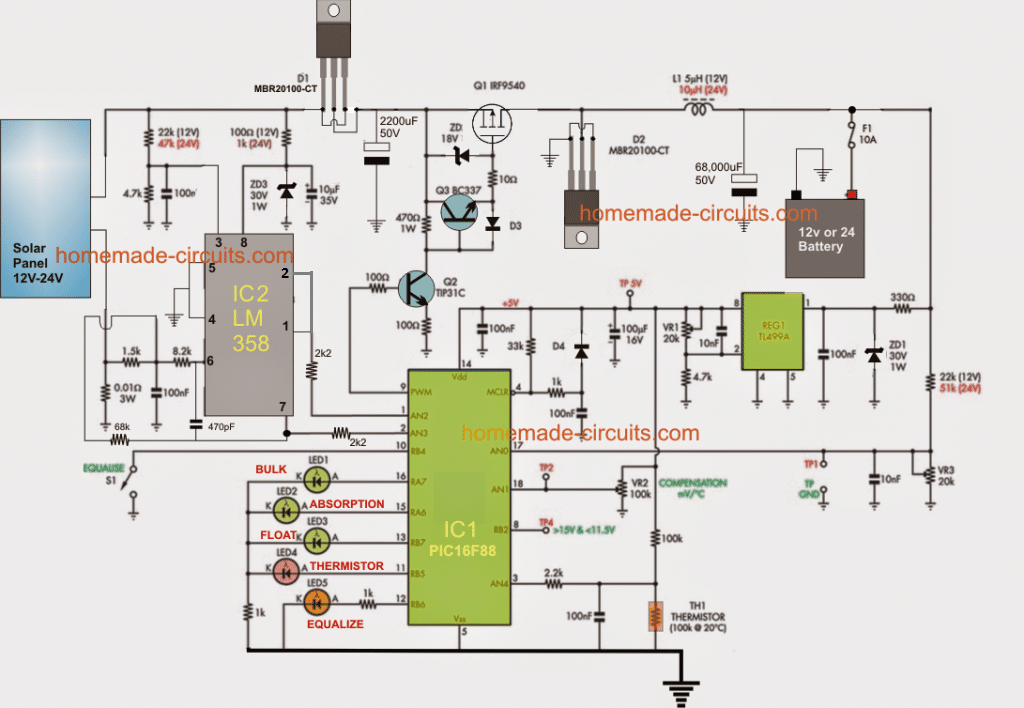

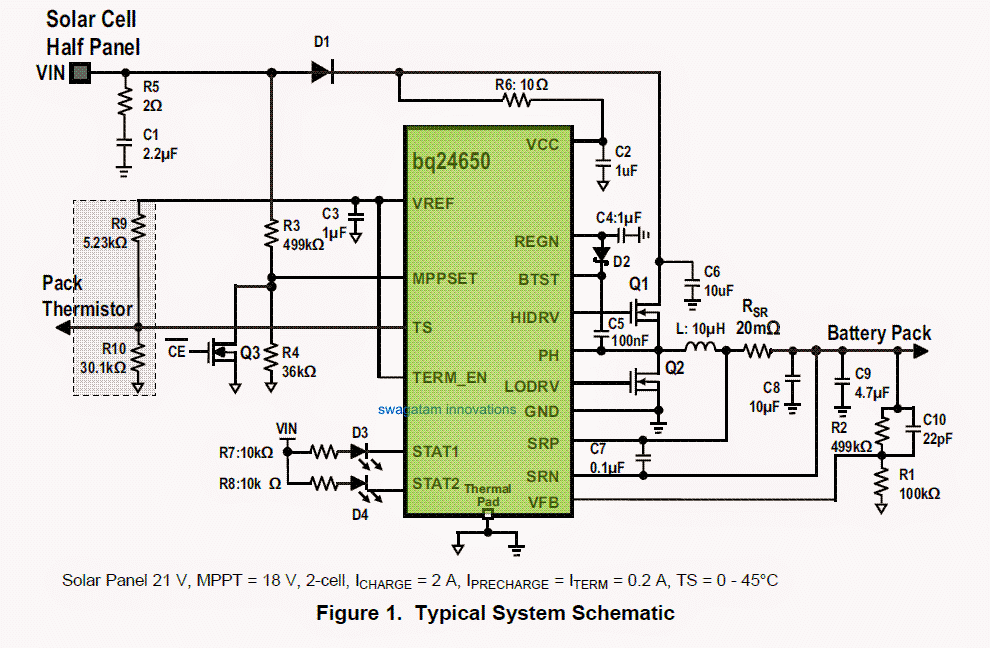

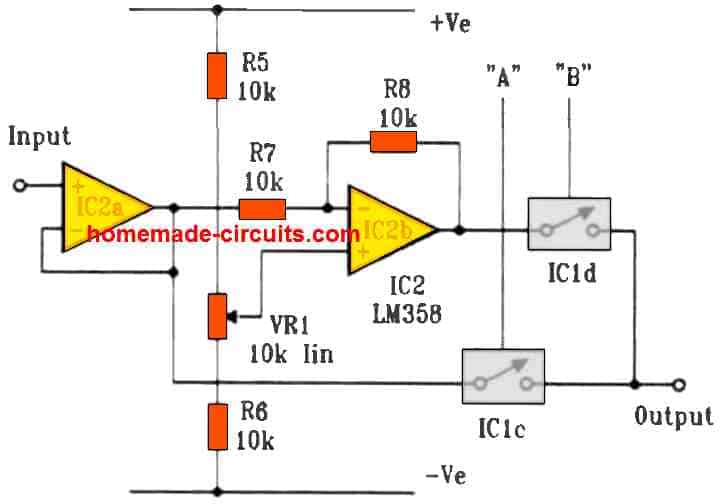

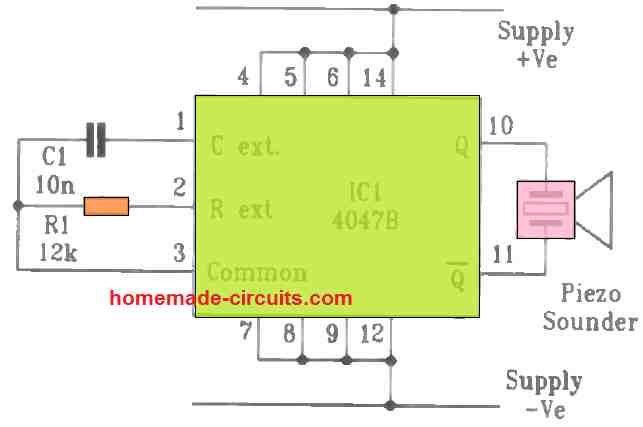

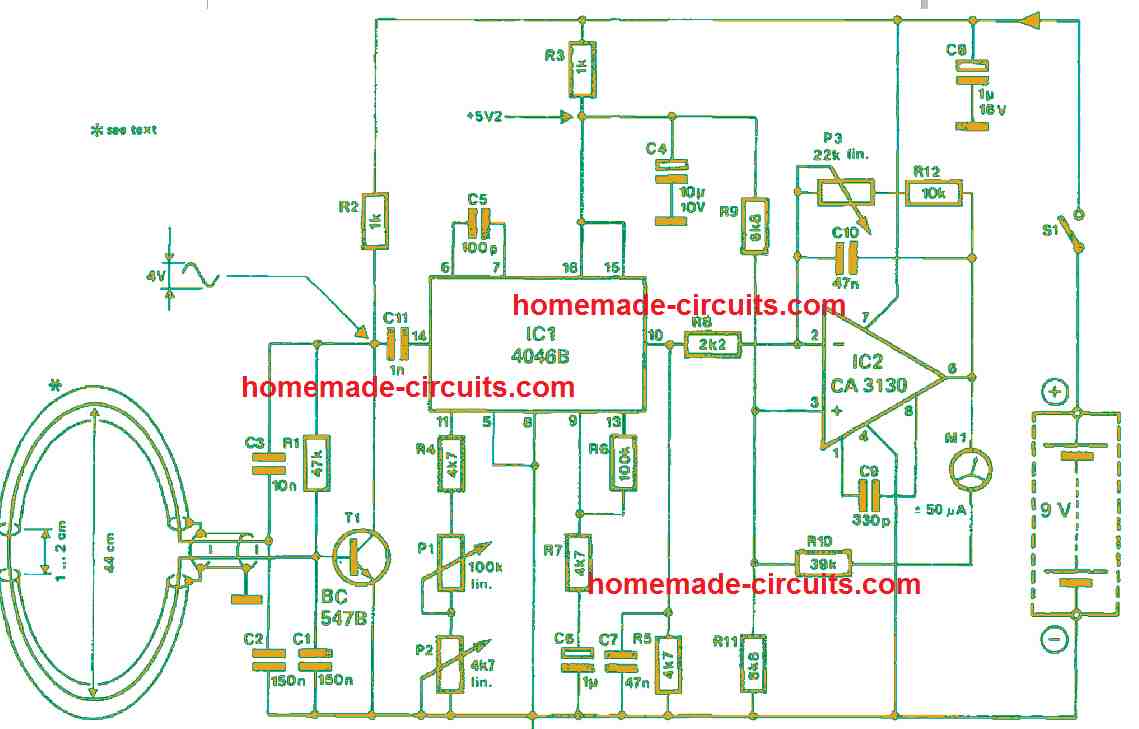

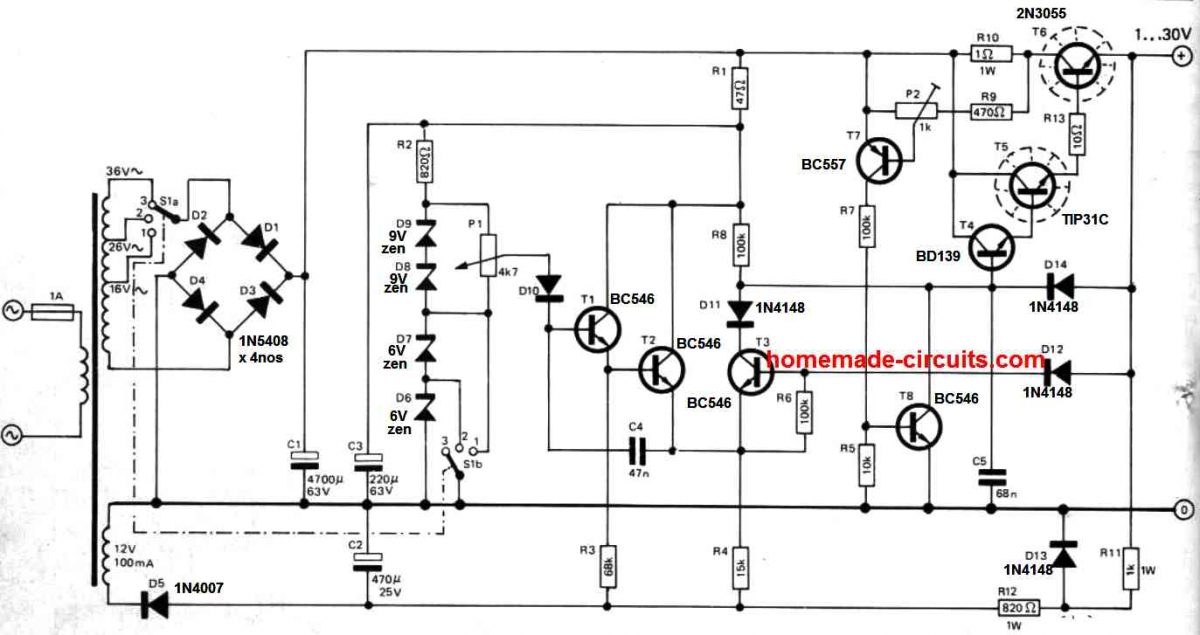

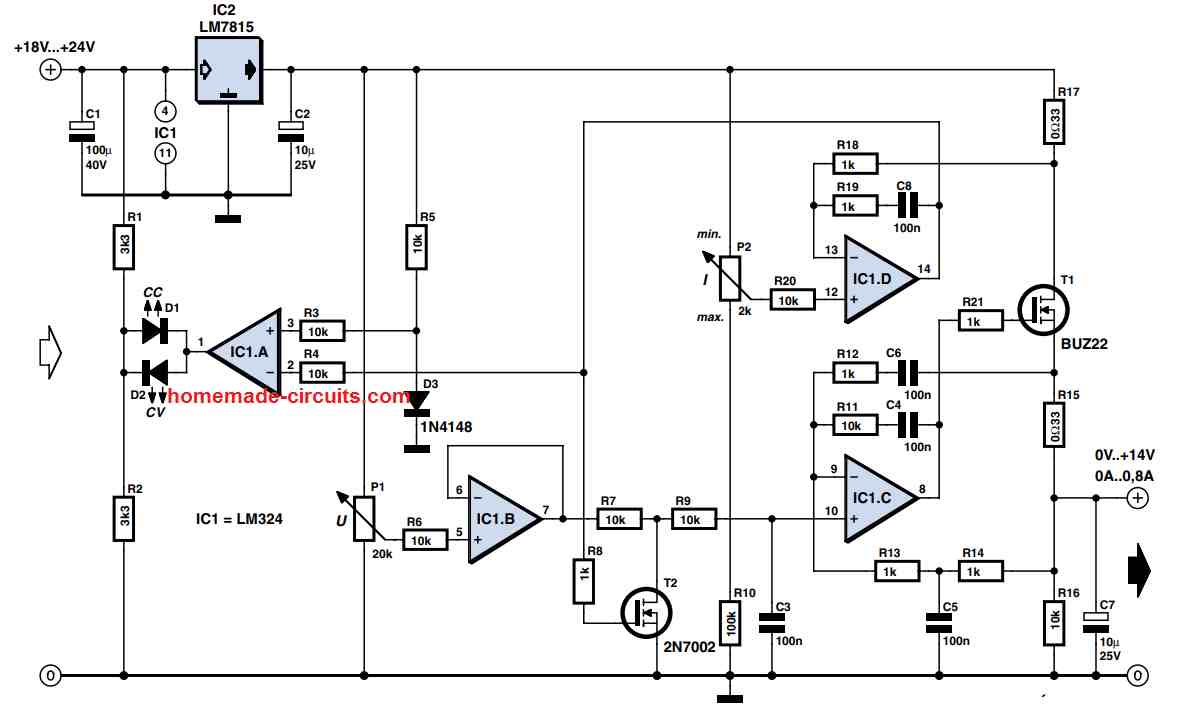

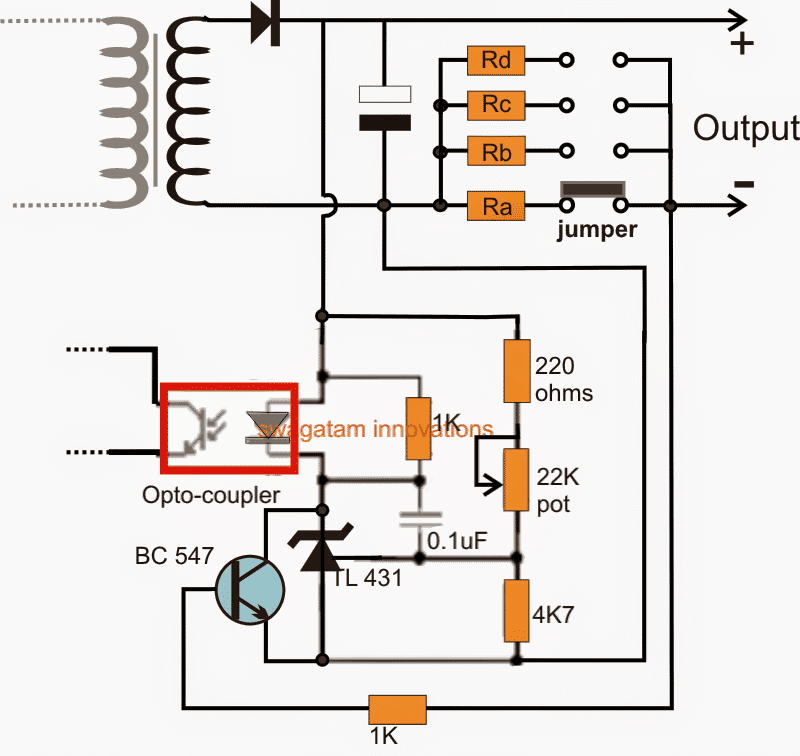

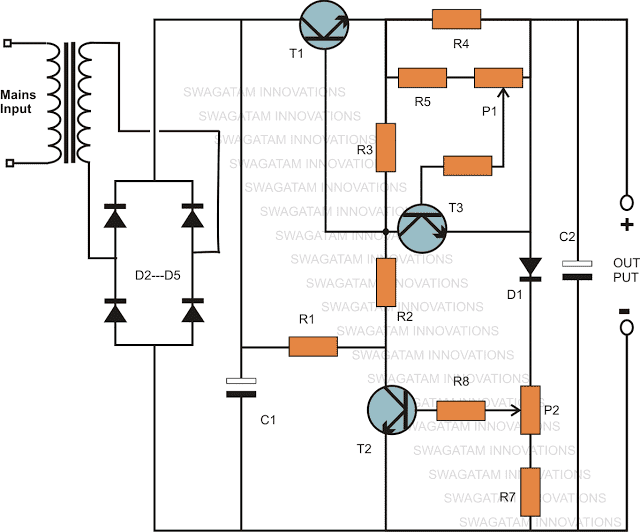

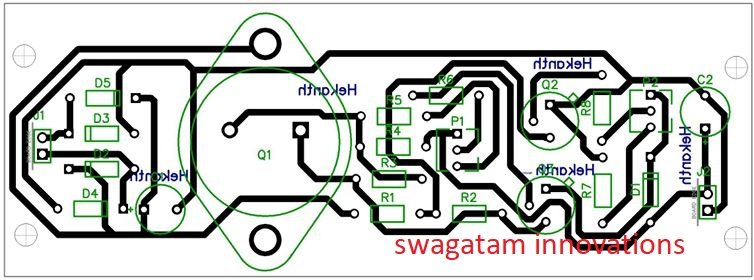

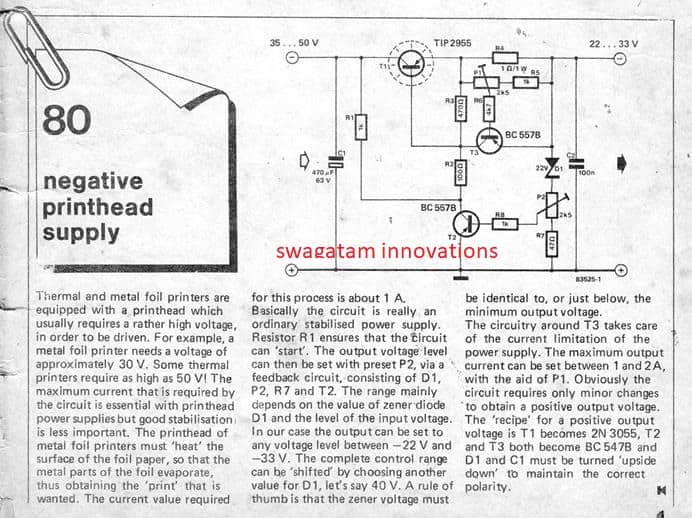

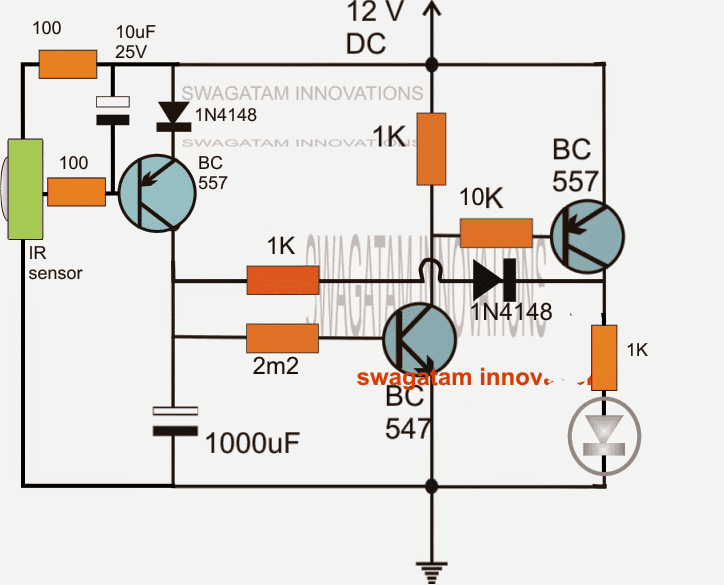

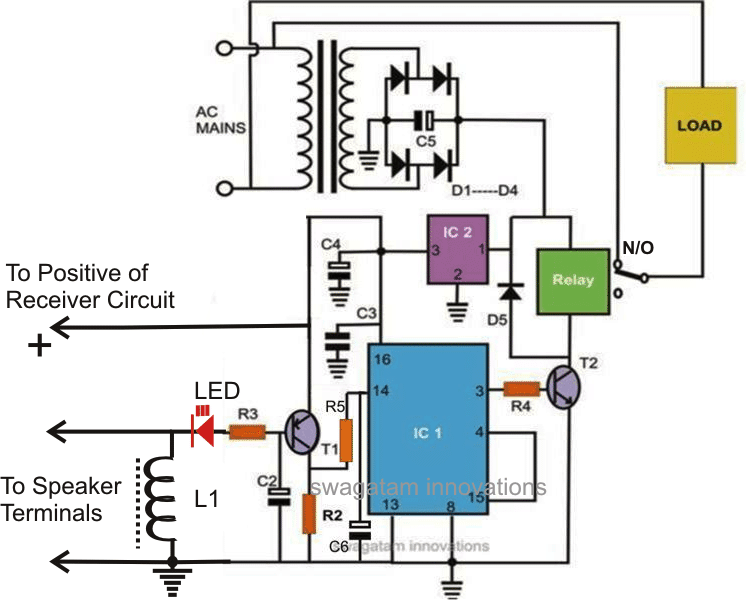

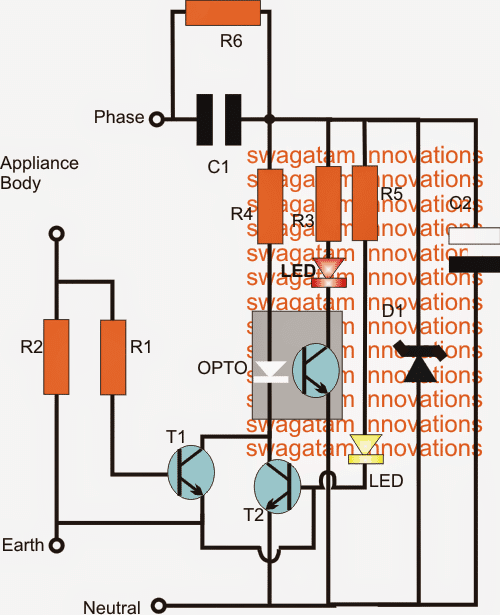

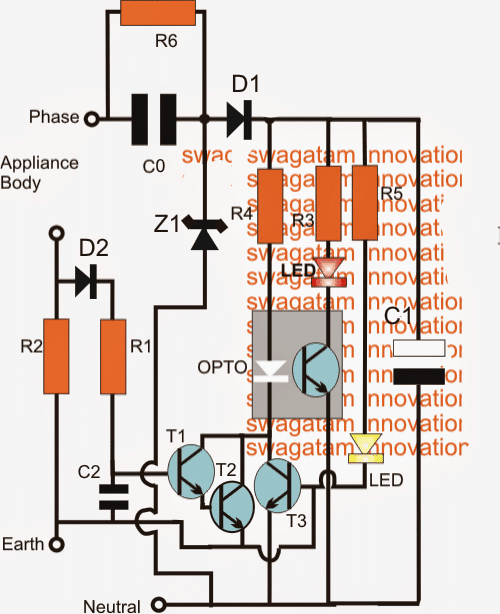

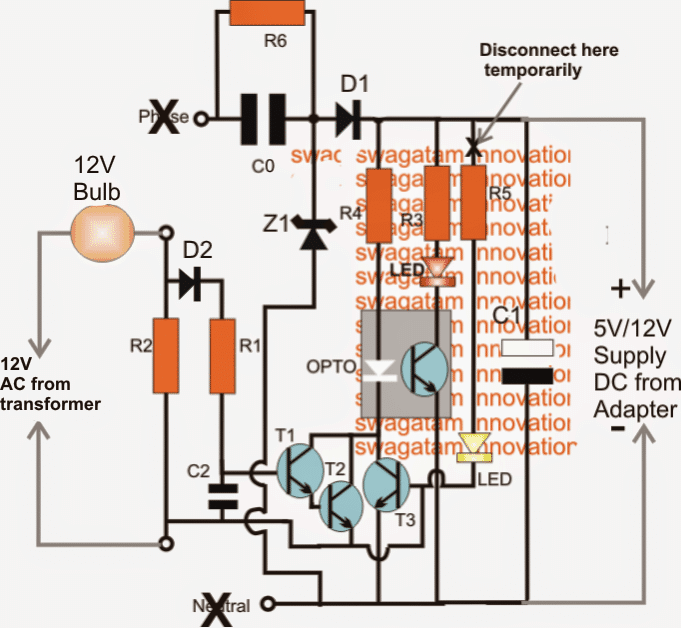

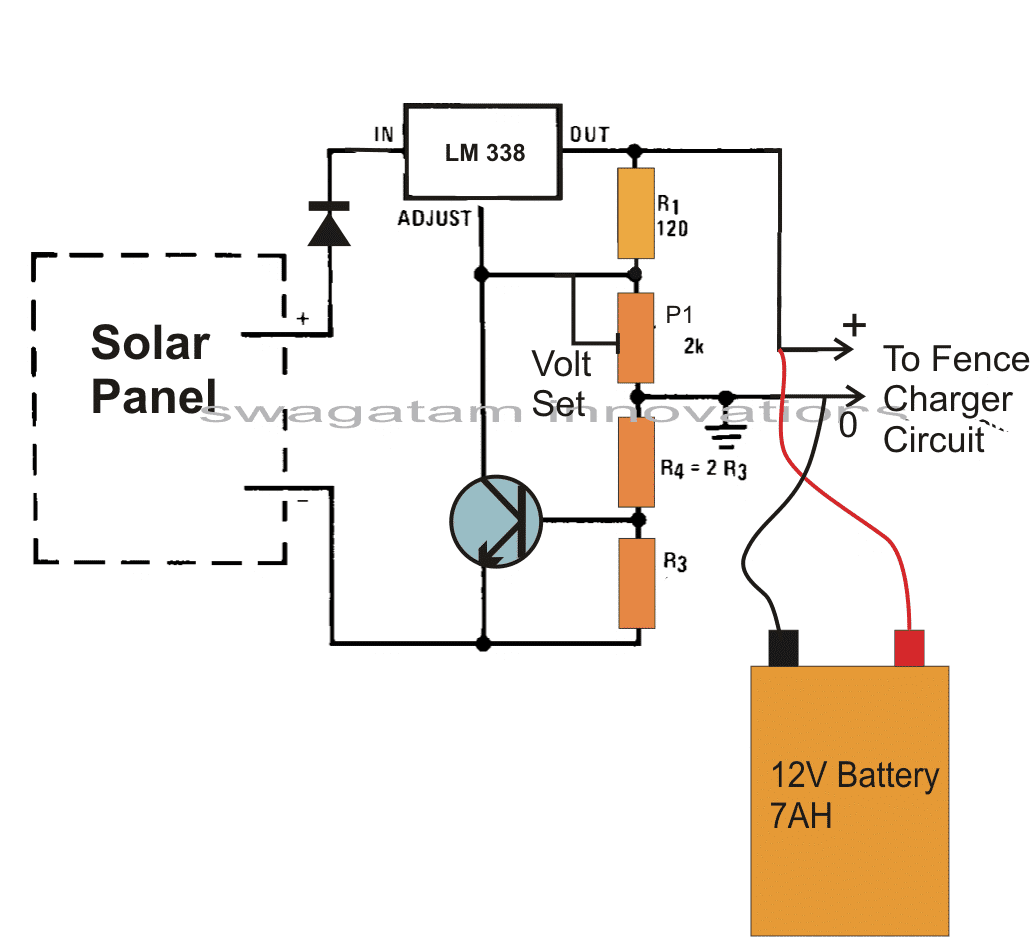

Simple Greenhouse Temperature Regulator Circuit

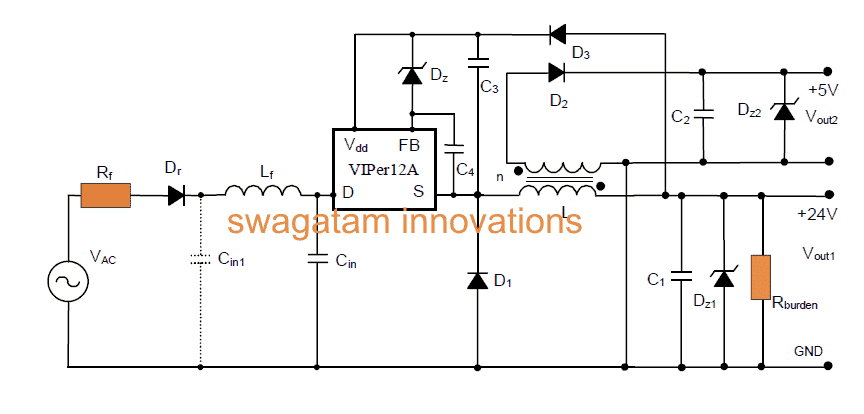

The post discusses a simple electronic temperature regulator circuit which could be specifically used for regulating greenhouse temperatures. The idea was requested by Mr. Leo.Technical Specifications

I am looking for a guide to build a basic temp regulator circuit. I have a solar charger bought from lidl,(SLS 2200 A1) which has outputs for 5, 7.5 & 9.5v DC 0.5A. it will be used for soil heating in a greenhouse. My idea is to use black drip irrigation pipe as a 'solar panel' to heat the water and with a low volume pump regulate the temp under a propagation tray. Any advise is greatly appreciated. I have seen similar setups for egg incubators , fridge temp controls, etc. but need it at an allotment, so only power source is small panel. also if possible would it be possible to increase capacity of internal battery and have a heating element added. Thank once again. LeoIntroduction

Before getting into the main circuit concept, it would be interesting to learn regarding a few of the parameters expressed in the above request, as given below:What is "black" drip irrigation:

We all probably have heard a lot about drip irrigation, a method in which water is fed to the crops across the entire allotted field through a network of narrow pipe lines wherein water is allowed to drip directly at the bottom of the stem of the crop for a sustained period of time. The method helps to save water and allows the water to reach the crucial areas such as the roots of the crop resulting in a better growth and efficiency. Here an identical approach is implemented but the conventional pipes are replaced with black coiled PVC pipes. The back coiled pipe helps to absorb the heat from the sun rays naturally and allow the water passing through it to become warm naturally without depending on costly artificial utility electricity. The warm water ultimately helps to heat up the soil deep inside for acquiring the intended greenhouse effects.What's a Propagation Tray:

These could be arrays of plastic plantation pots arranged in a large tray like fashion for allowing deeper soil content to the seedlings over minimal spaces, it's specifically designed for optimizing indoor plantations.What's Allotment:

It may refer to a small garden or a plot of land as explained here: https://en.wikipedia.org/wiki/Allotment_%28gardening%29 The Solar Panel: The specified solar panel is a self contained unit which includes a solar panel with outputs at 5, 7.5 & 9.5v DC (0.5A). It also includes a 4-step charge indicator circuit and most interestingly it includes a built-in 2200mAH Li-ion battery so that you don't have to bother about external battery integrations, rather would be able to use the existing facility under overcast conditions.

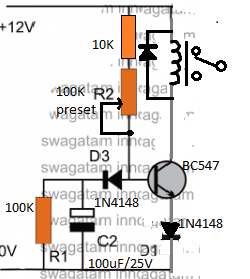

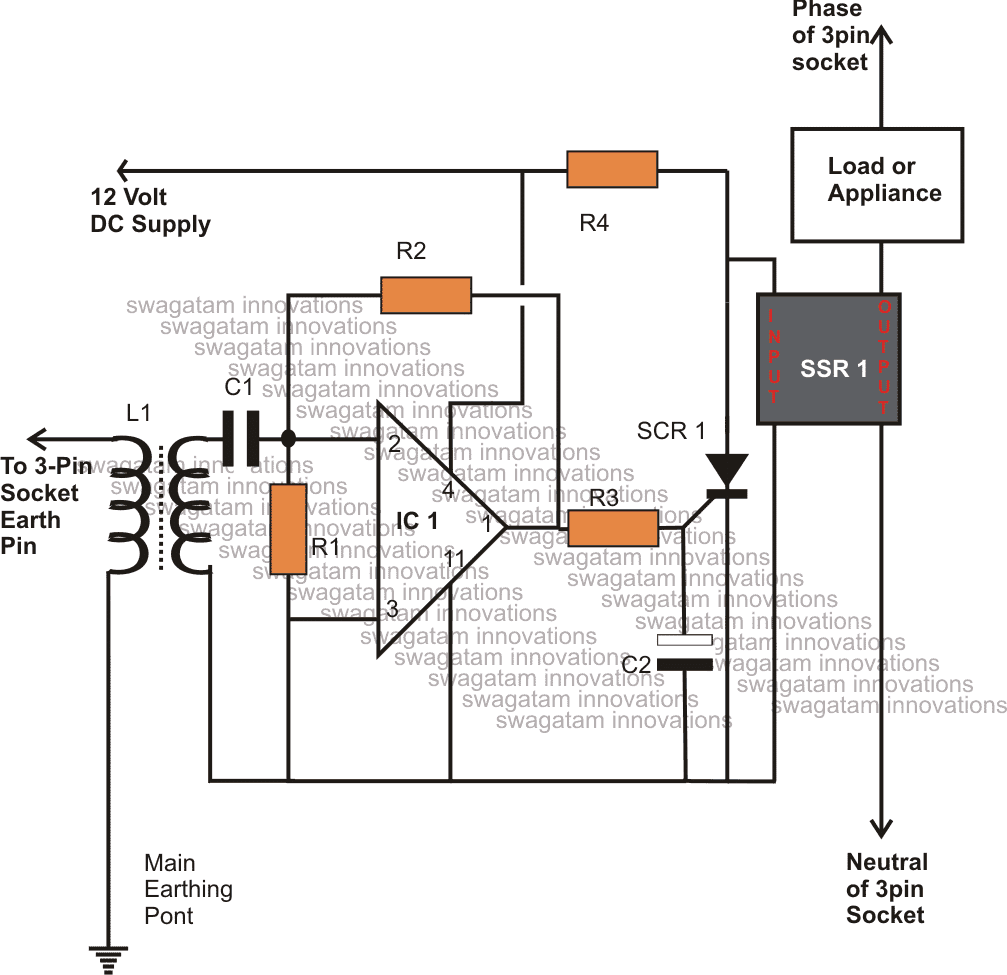

Basic Requirement for the Green House Effect

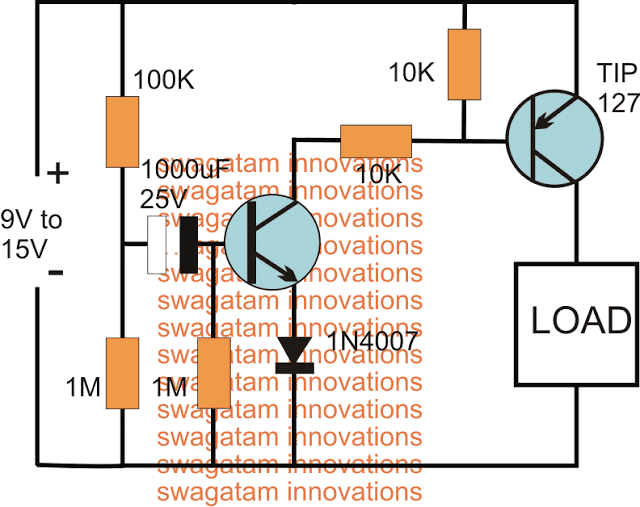

Now let's return to the actual requirement of the proposed greenhouse temperature regulator circuit, the idea here is to sustain a raised temperature of the soil by 10 to 20 degrees Celsius above the atmospheric temperature for boosting or enhancing seed germination. Because seeds normally germinate faster in soils that are warmer than the atmosphere, which in turn results in an initial stronger root development instead of bigger leaf development. Generally, heat mats are used below the propagation trays for heating the soil but in the present application the drip water is itself heated and used for generating the same results, which looks much impressive, since heat mats could at times get messy causing sparks, fire or over heating of the soil (if the attached thermostat fails). Nevertheless, the electronic temperature controller circuit discussed below could be used with any heating system, including heat mats. In the proposed design, the natural heating of the water within the black pipes is aided by an external heating element until the temperature of the water reaches the optimal point. As soon as this threshold is sensed the heater is switched off by the regulator circuit and held at that position until the temperature falls back to a relatively cooler level. Parts List

D1 = 1N4148,

A1---A3 = 3/4 LM324,

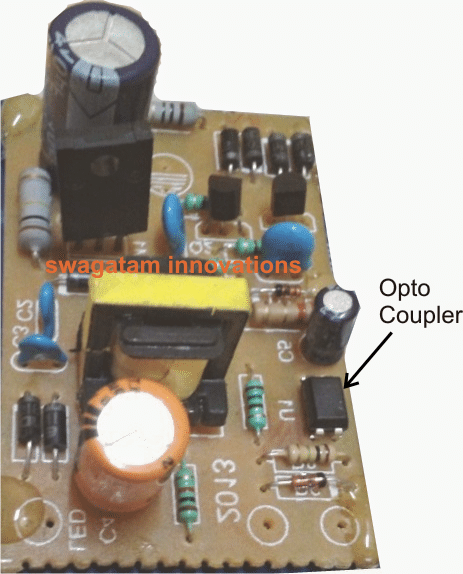

Opto = 4n35

Parts List

D1 = 1N4148,

A1---A3 = 3/4 LM324,

Opto = 4n35

Circuit Operation

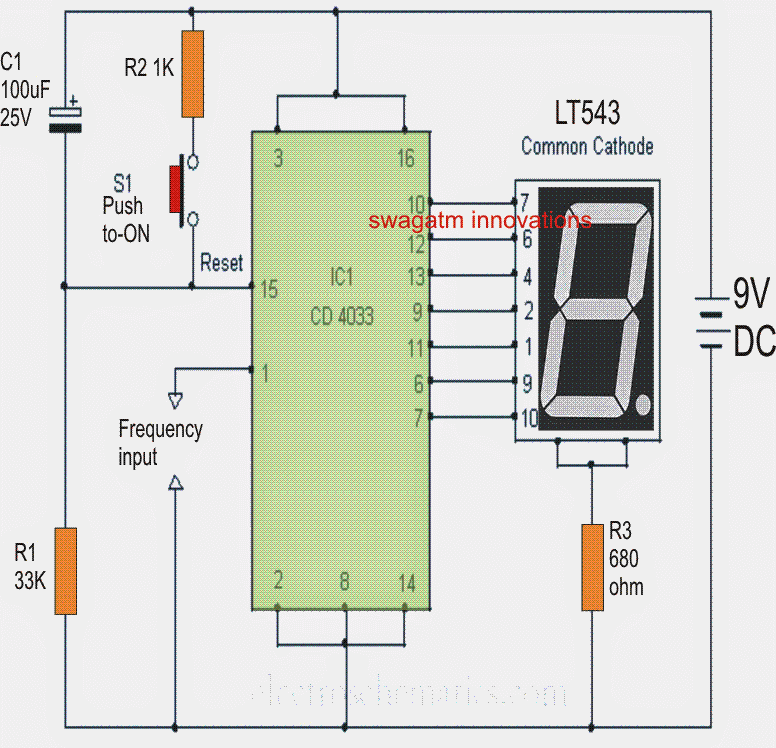

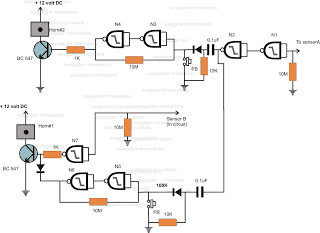

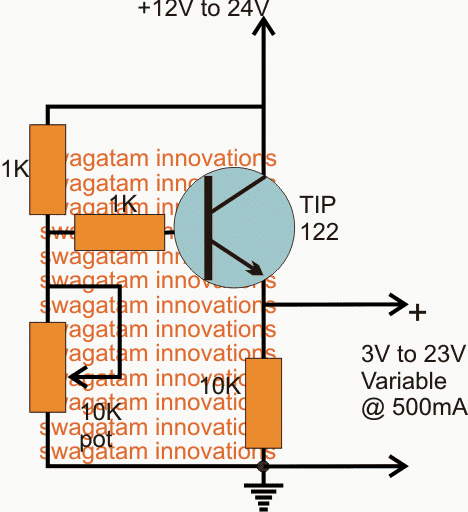

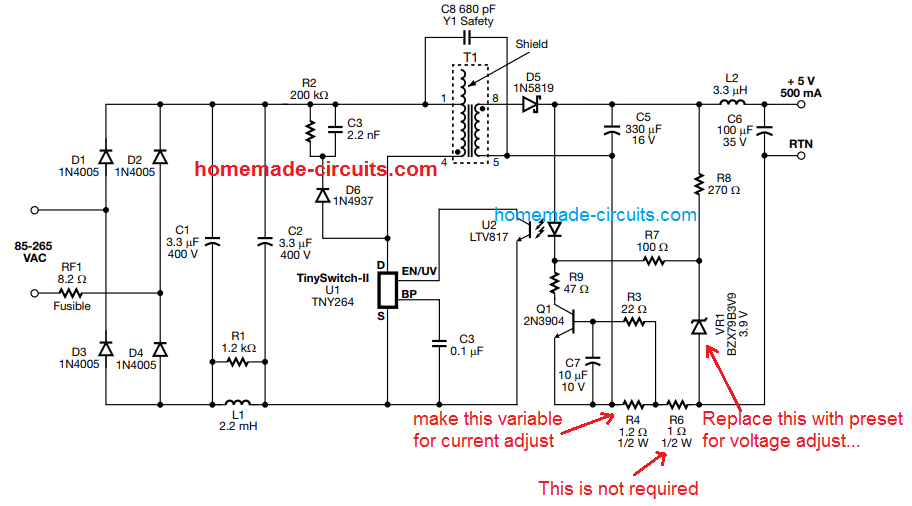

Referring to the diagram above which is actually a simple temperature controller circuit, could well be used for regulating the soil temperature in the proposed greenhouse application. Here the temperature sensor D1 is our very own "garden" diode (no pun intended ) 1N4148 which translates every one degree (C) rise in the ambient temperature into a 2mV drop across itself. The opamp A2 is specifically arranged to detect this change in voltage across D1 and feed the difference to A3 such that the result illuminates the LED inside the attached opto coupler IC. The threshold at which the above action takes place could be preset with the help of P1. The output of the opto is connected with a NPN driver stage which is responsible for switching off the heater as soon as the above threshold is reached. The sensor and the heater may be placed across any desired position, as per the user preference. For example the heater could be positioned below the propagation tray, or inside the water tank from where the water is being supplied to the black pipes. On same grounds the sensor may be placed anywhere around, could be below the propagation trays, inside the soil, inside the pipe or simply inside the water tank. The capacity of the unit could be upgraded as per the application, simply by employing a heavier rated solar panel and by replacing the TIP122 with a higher rated mosfet. The heater may also be upgraded as per the requirements.Simple Walkie Talkie Circuit

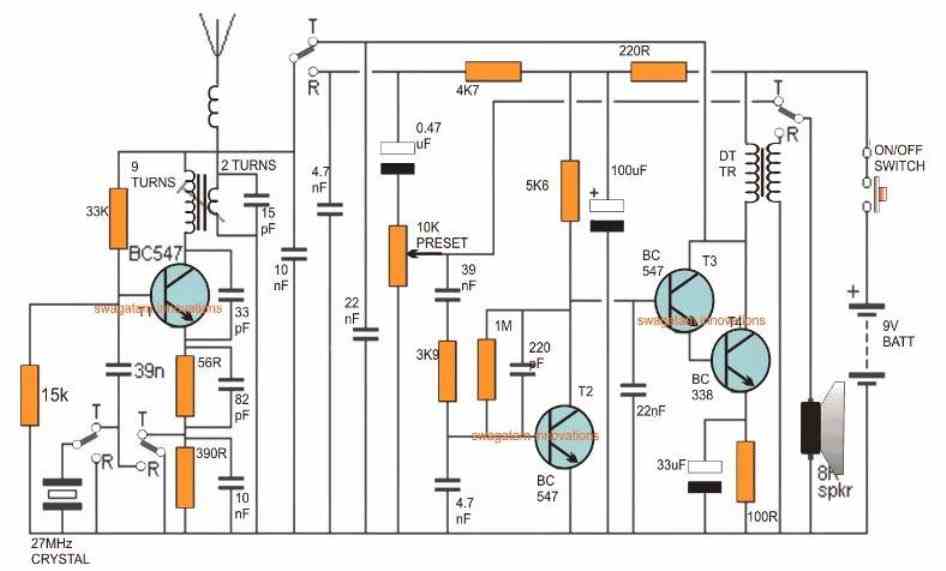

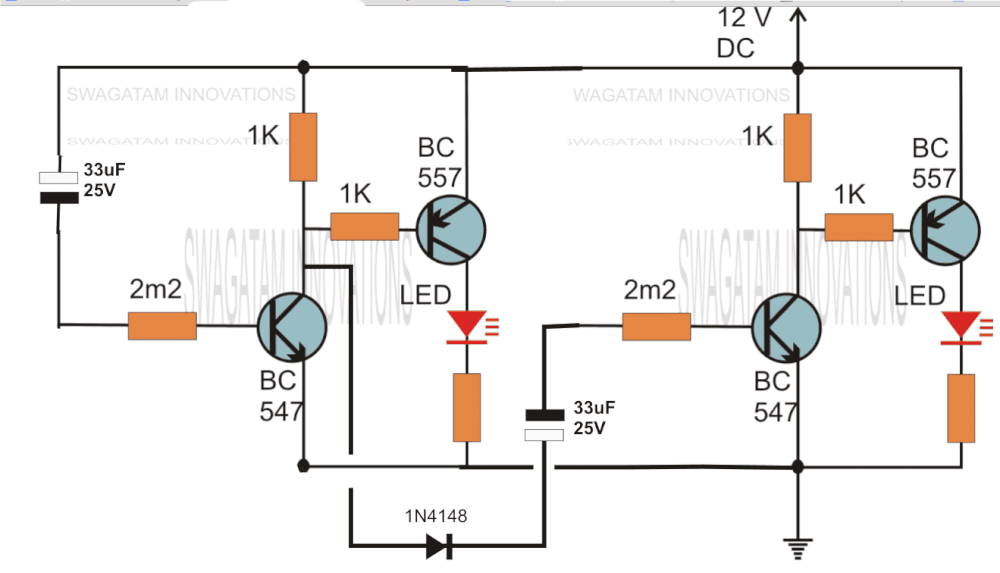

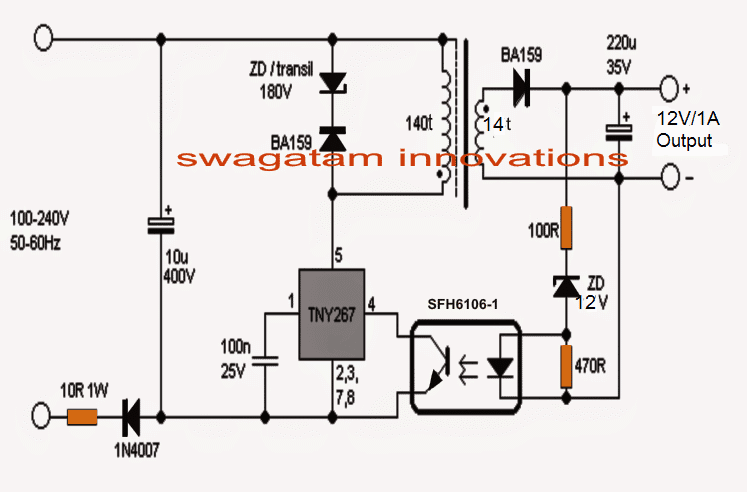

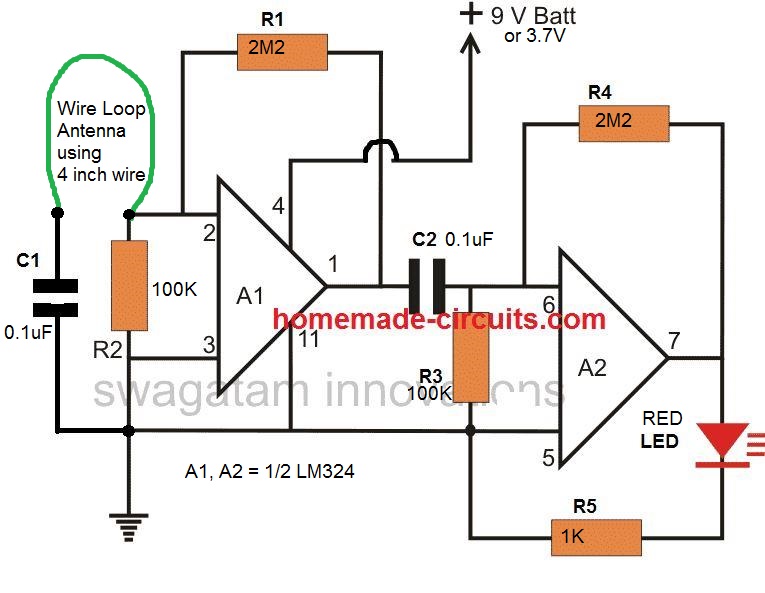

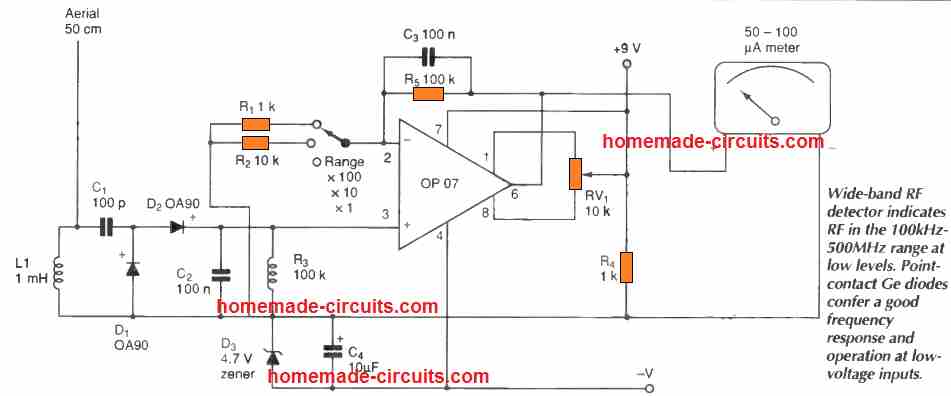

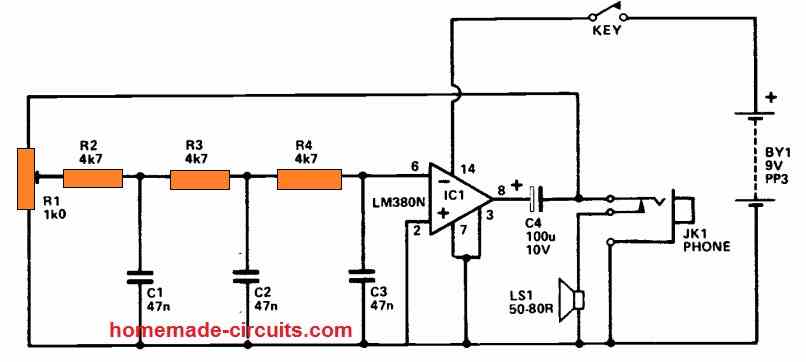

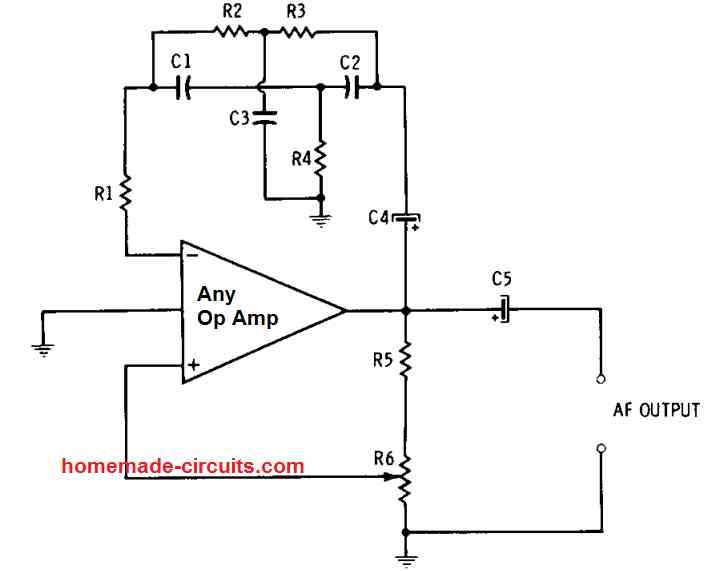

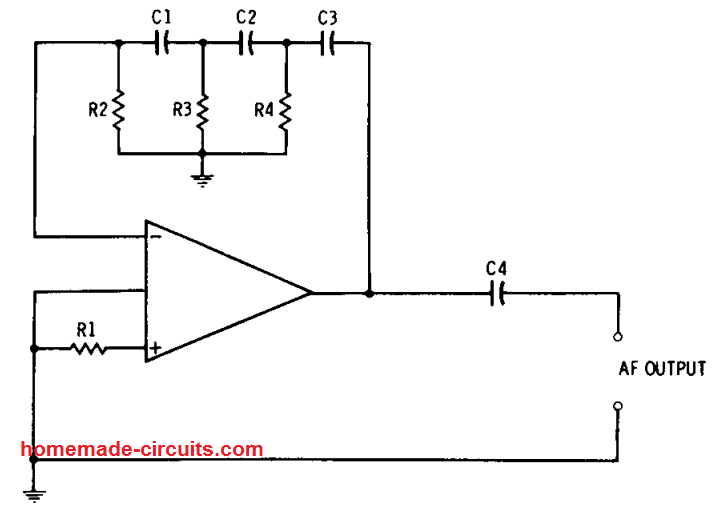

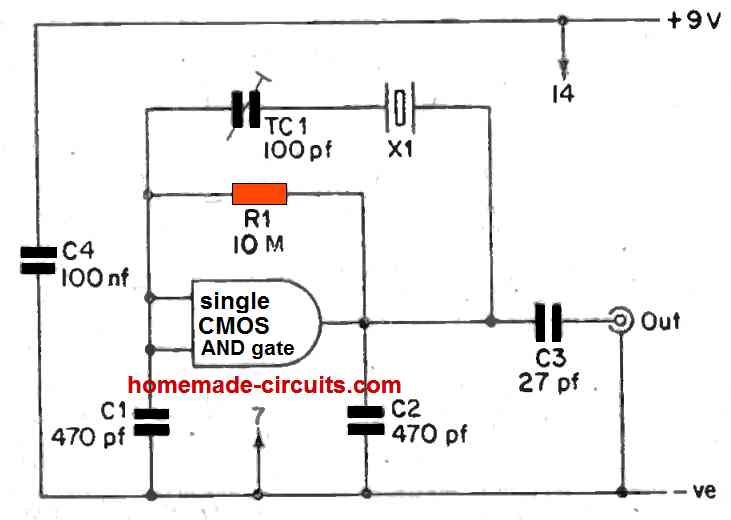

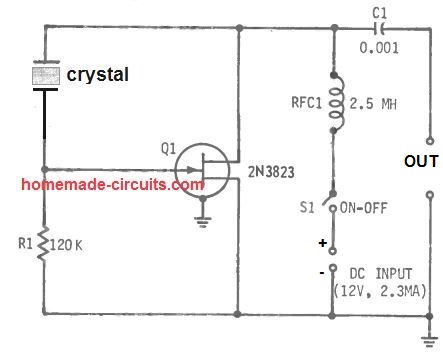

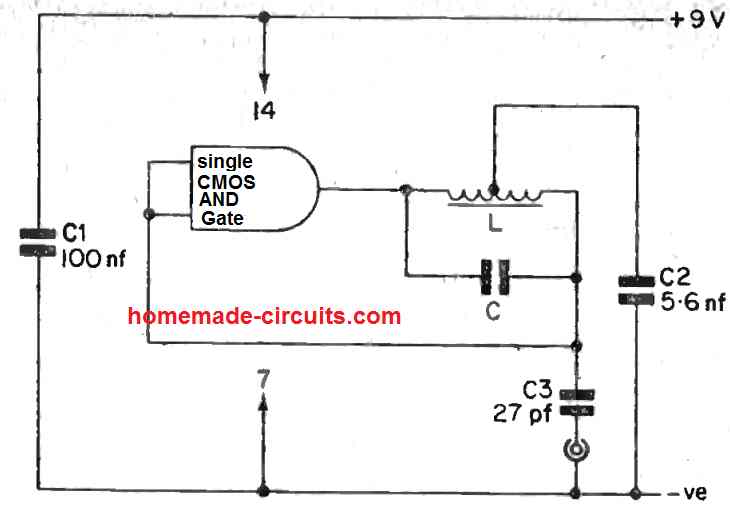

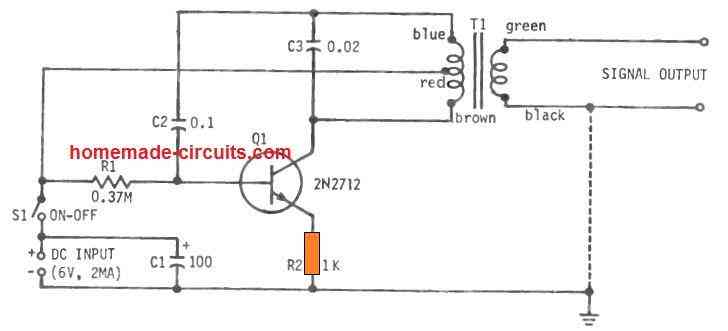

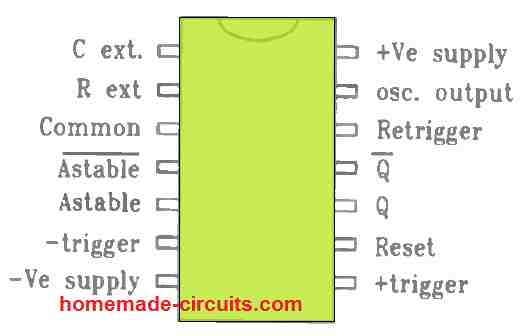

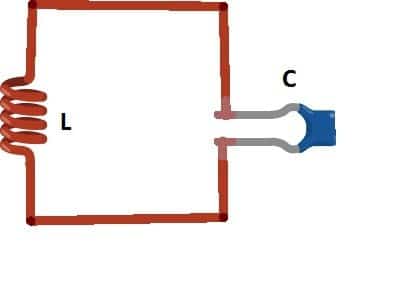

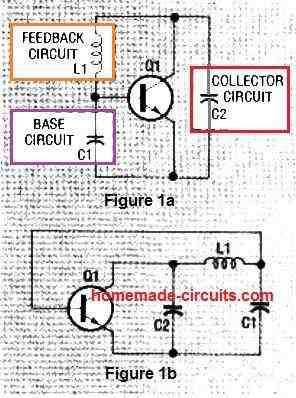

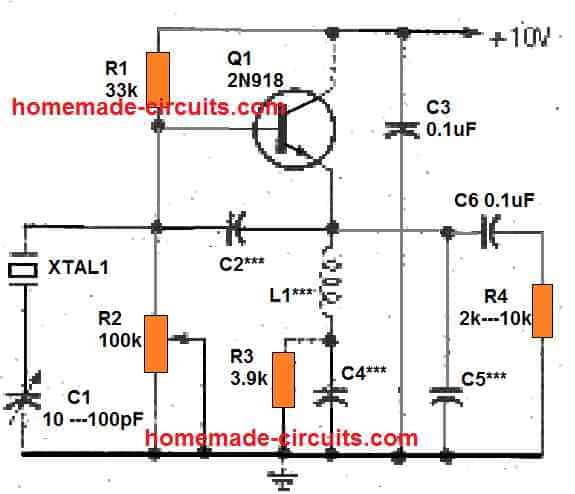

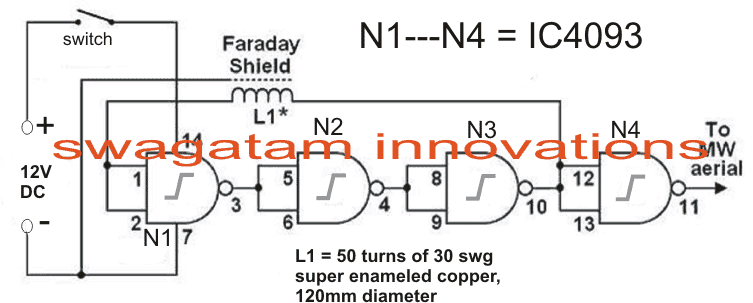

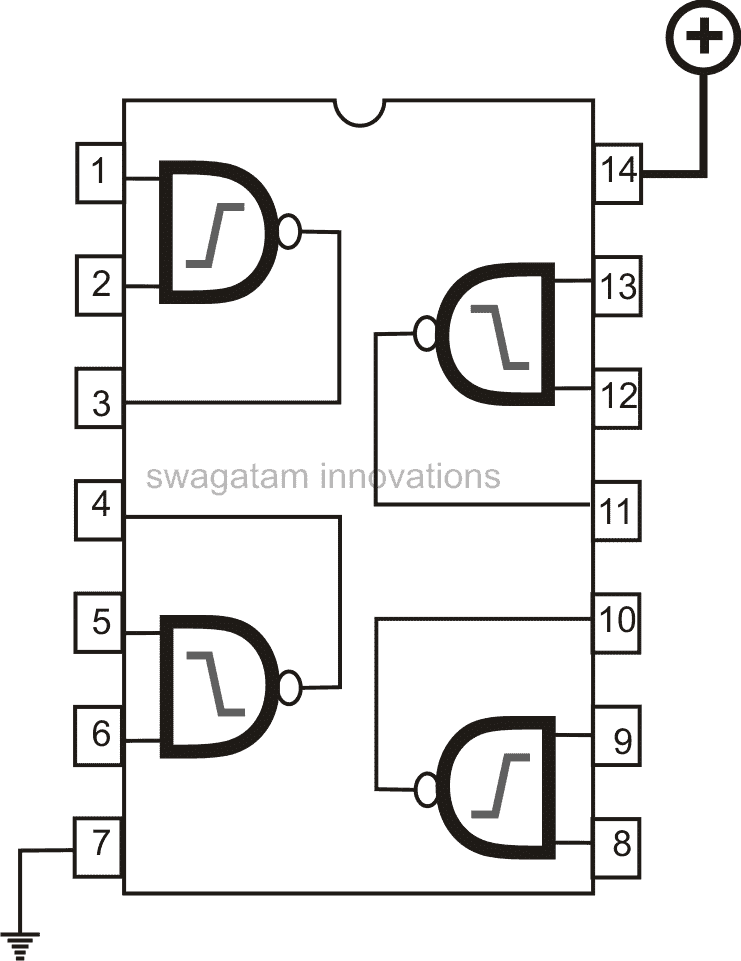

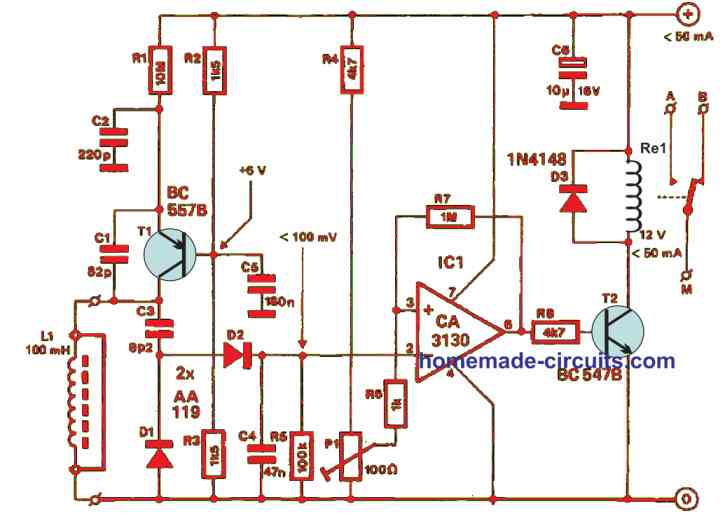

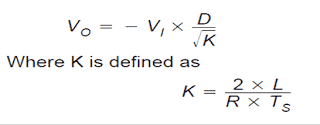

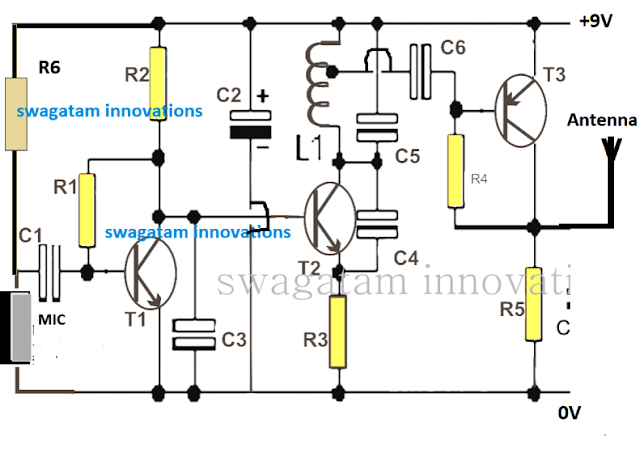

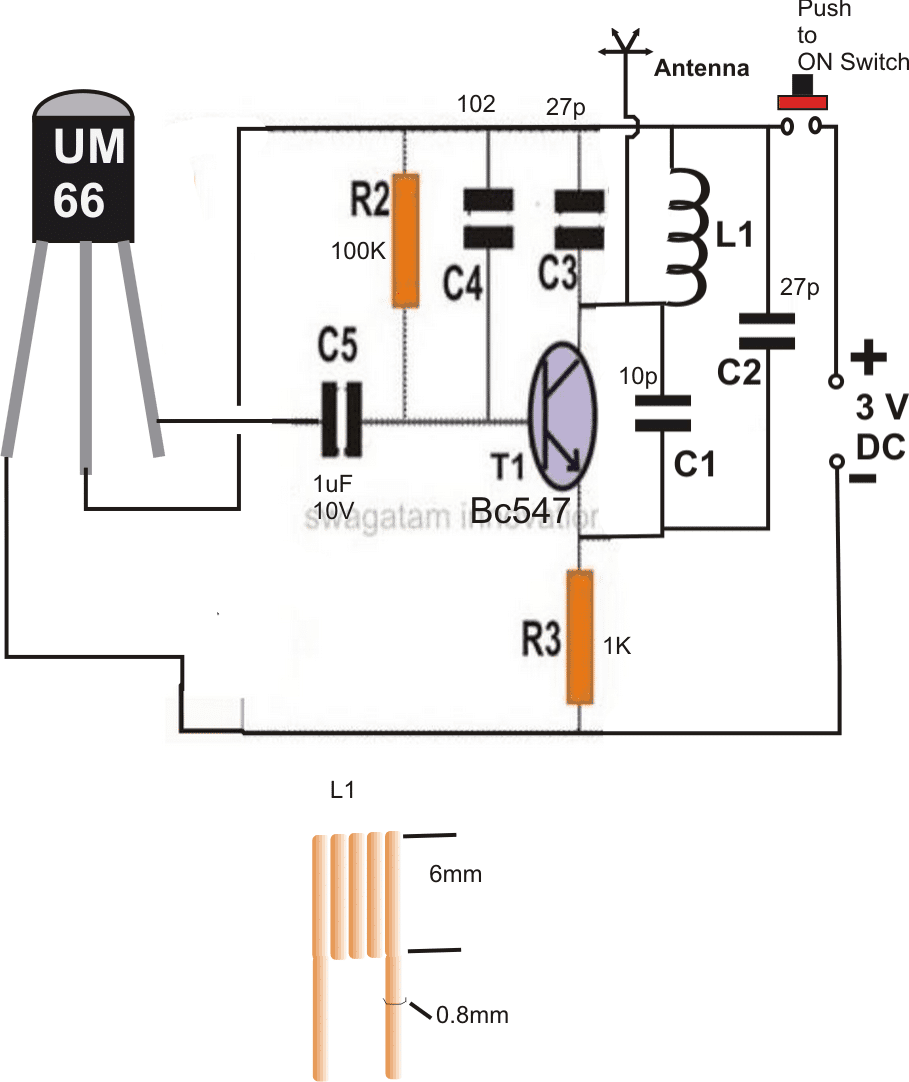

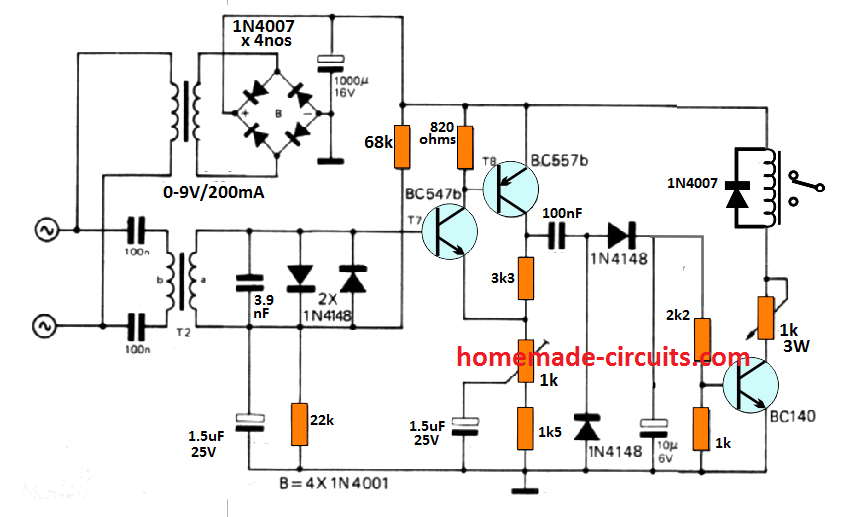

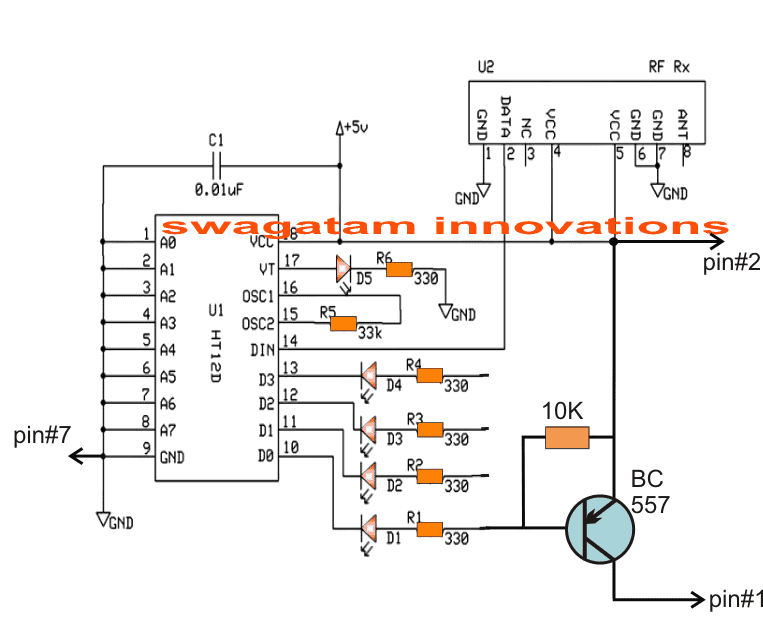

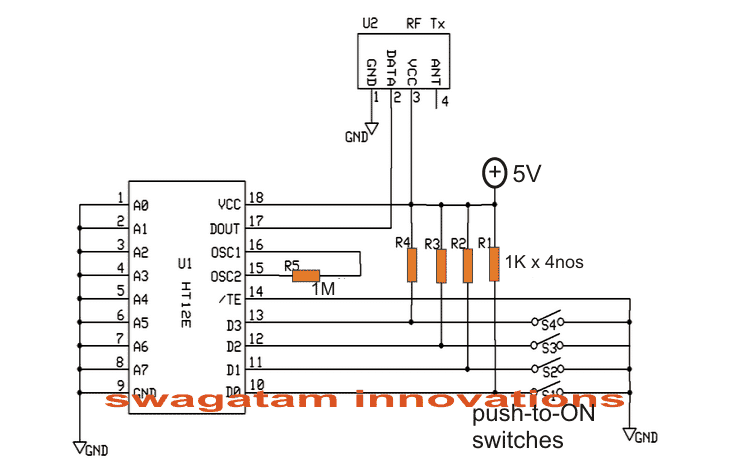

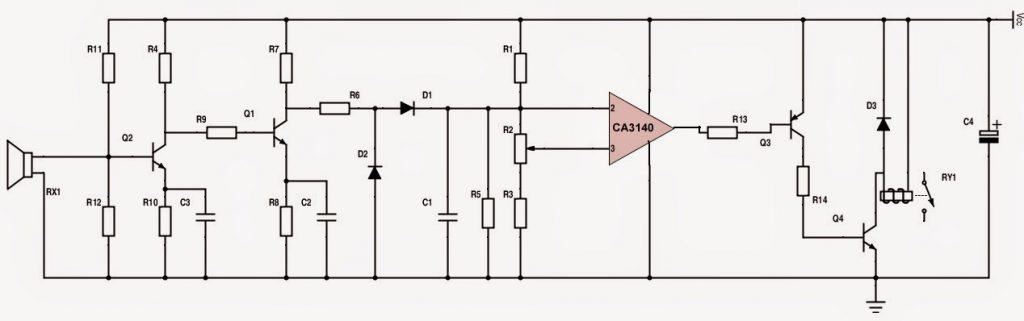

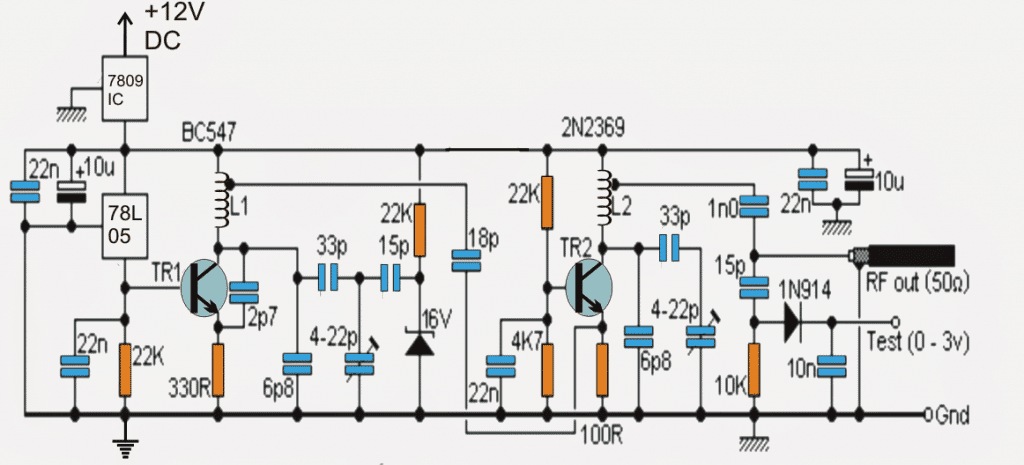

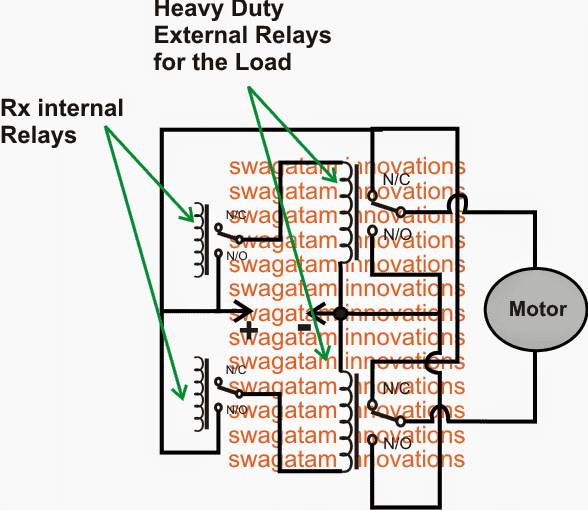

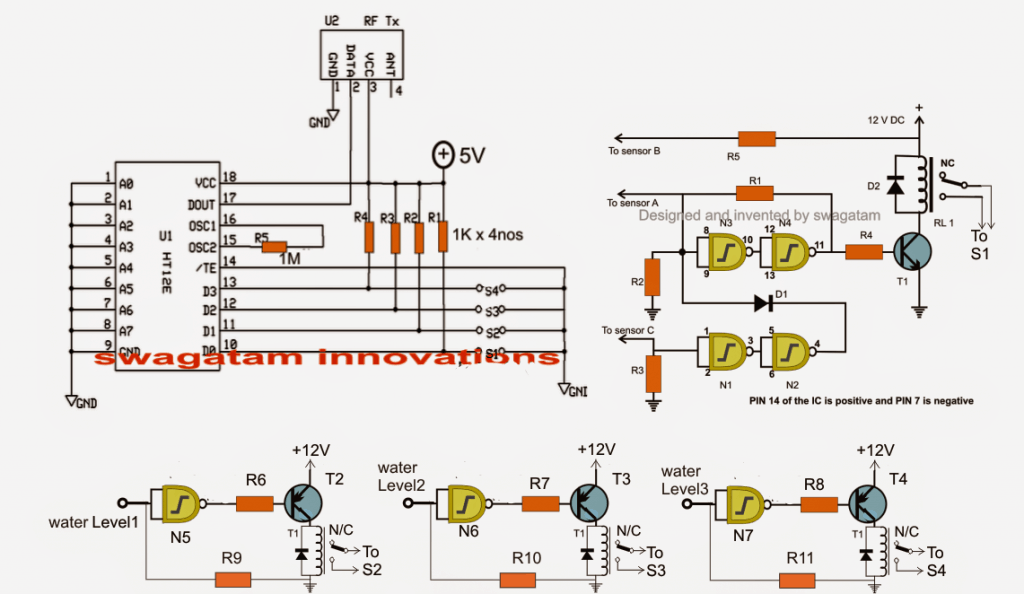

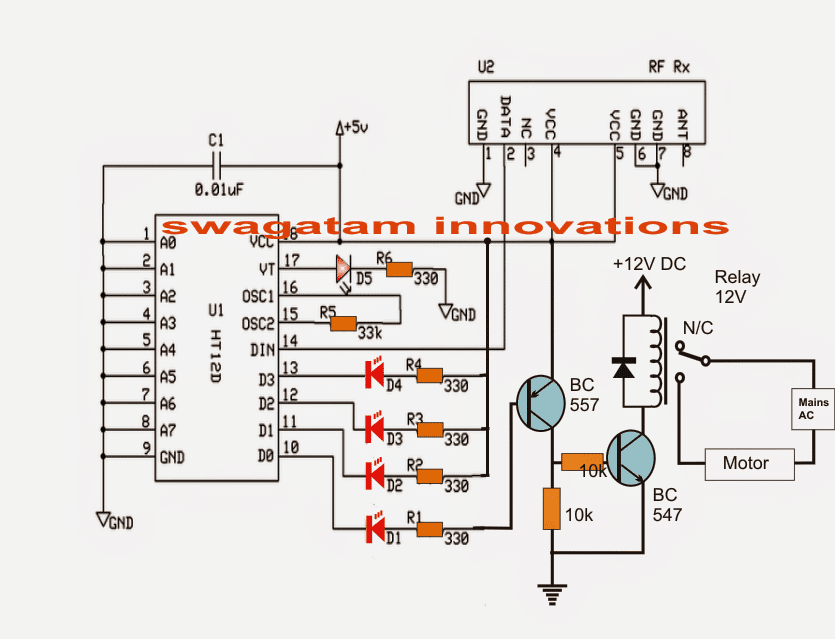

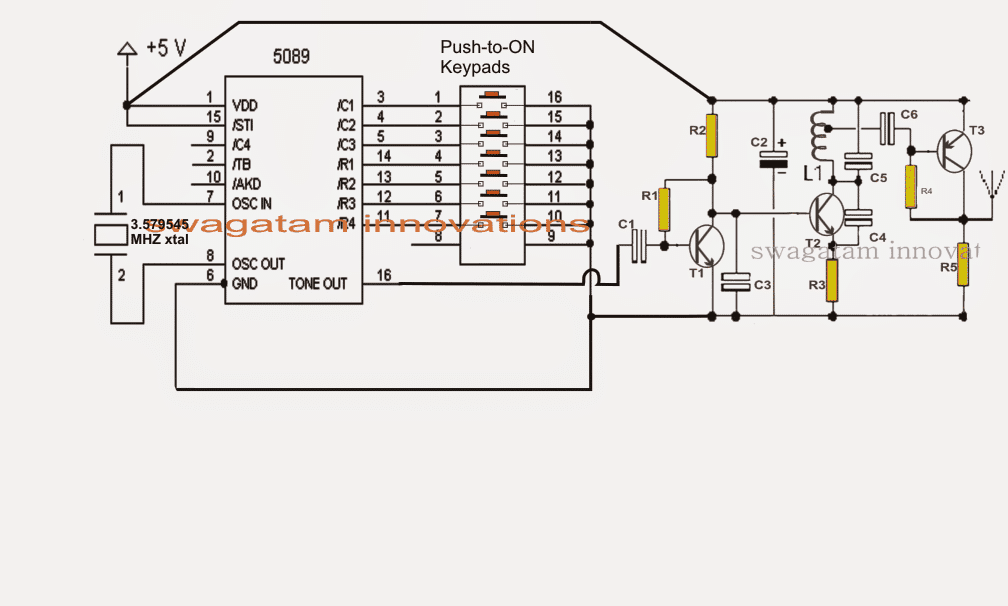

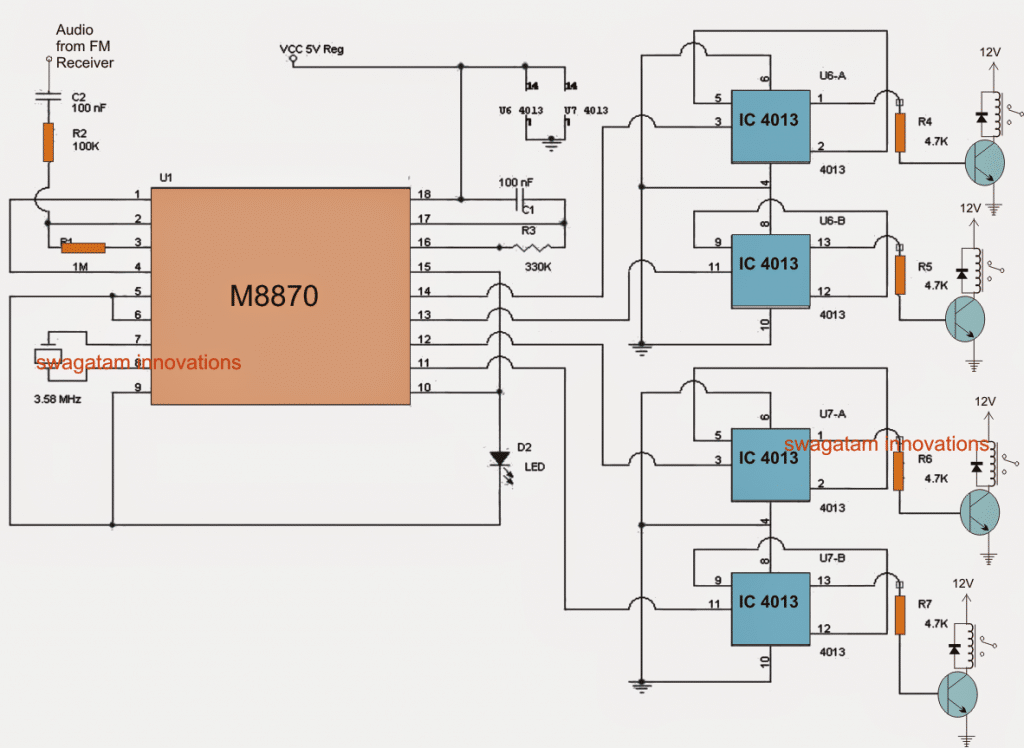

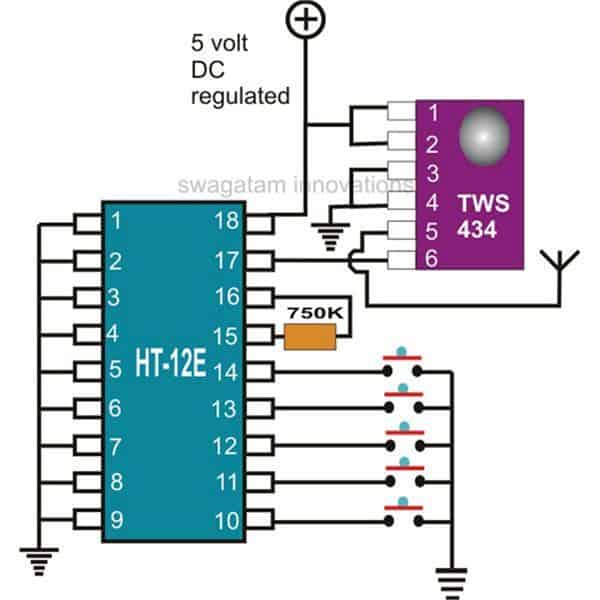

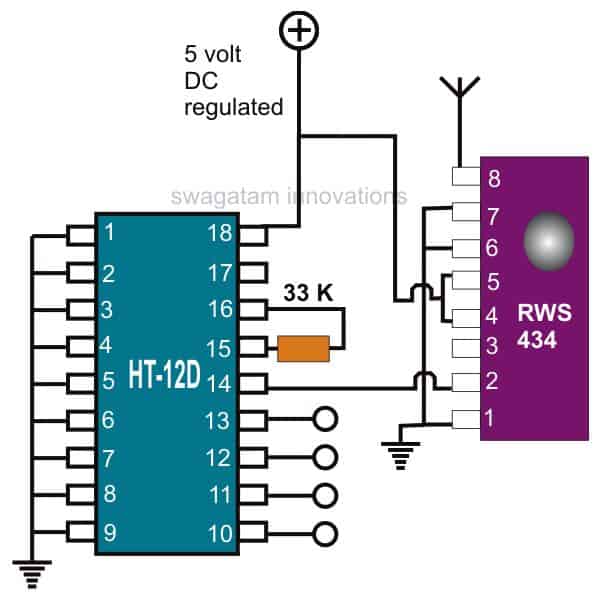

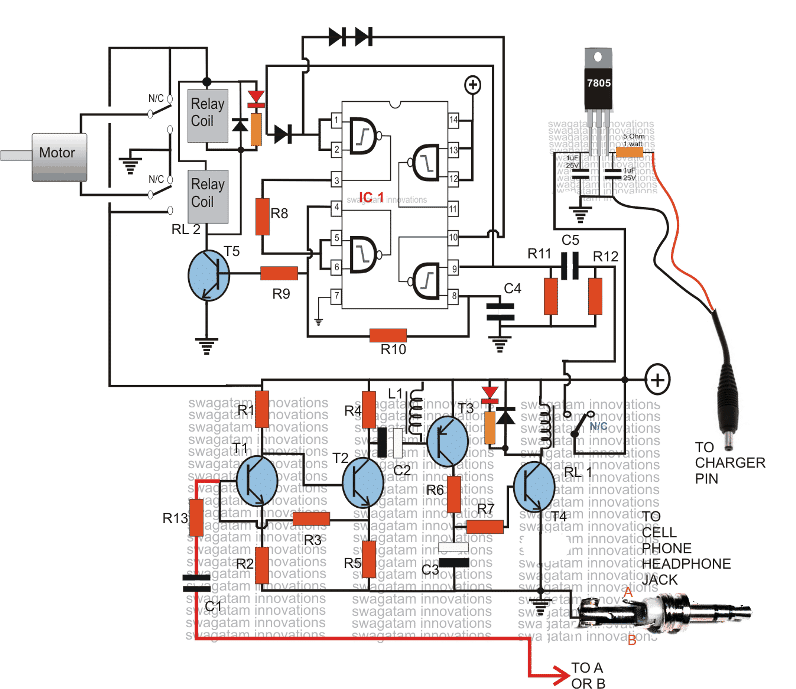

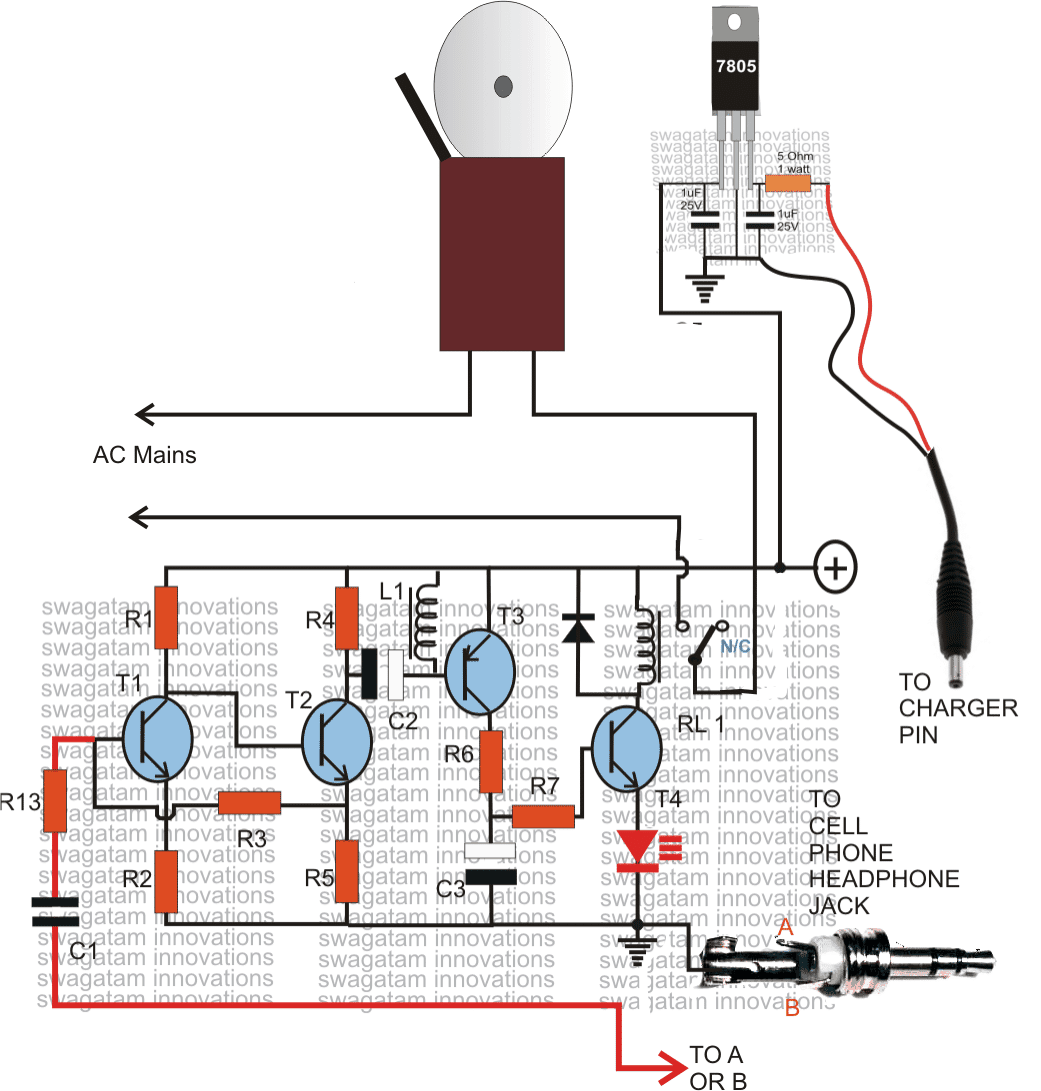

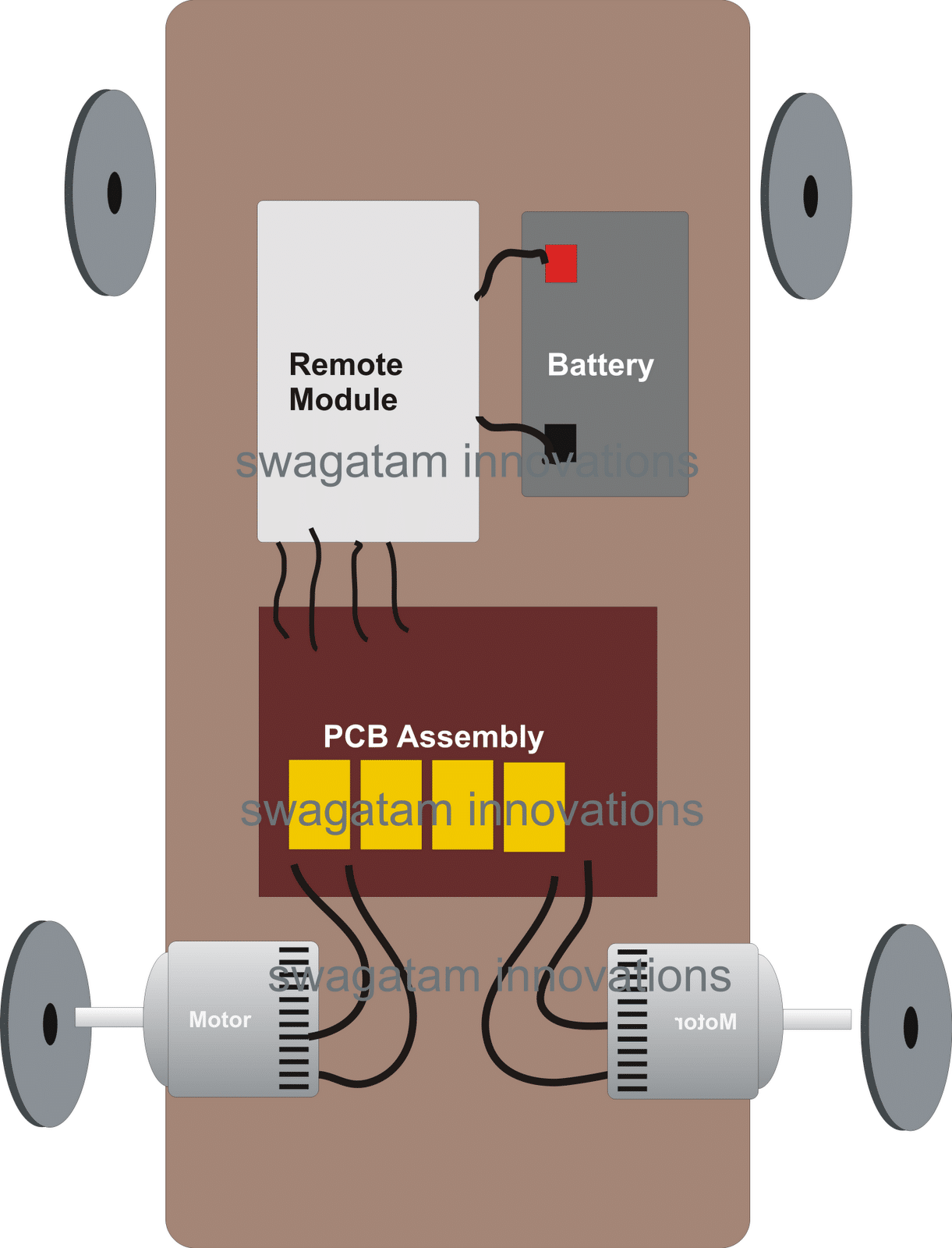

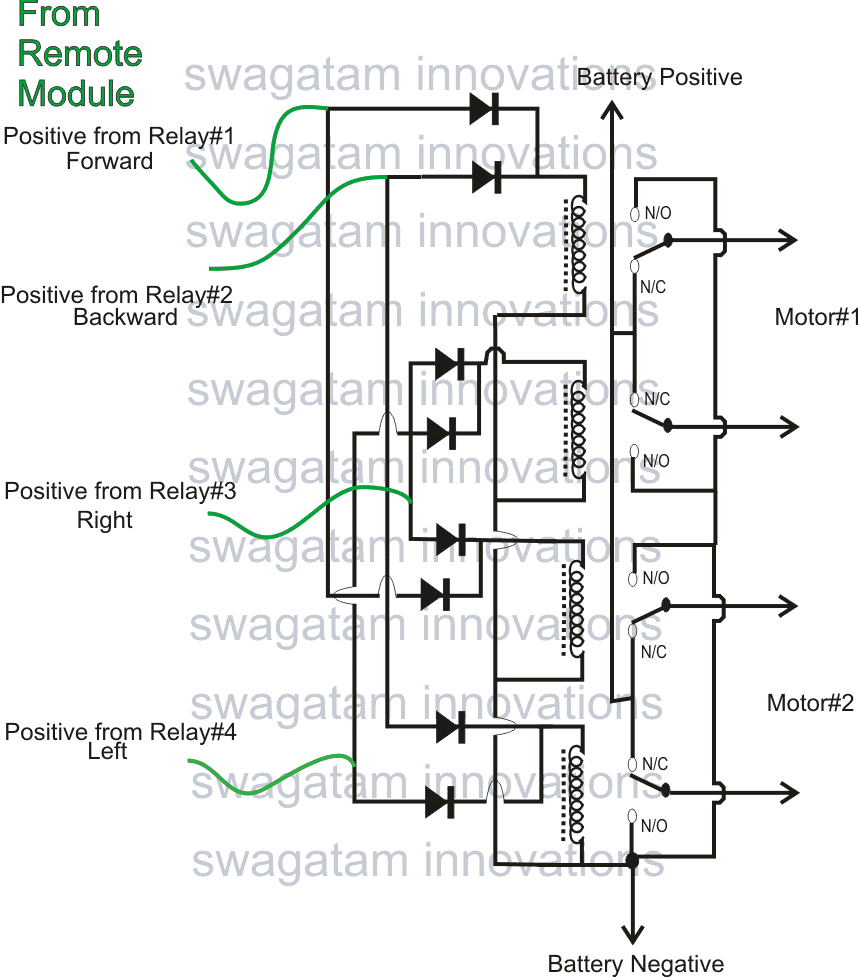

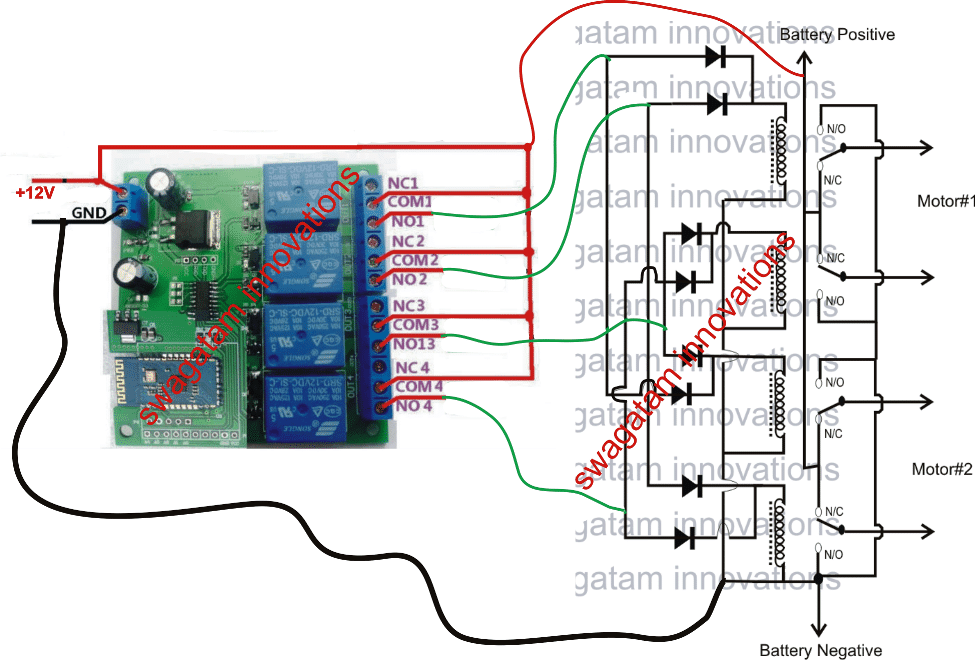

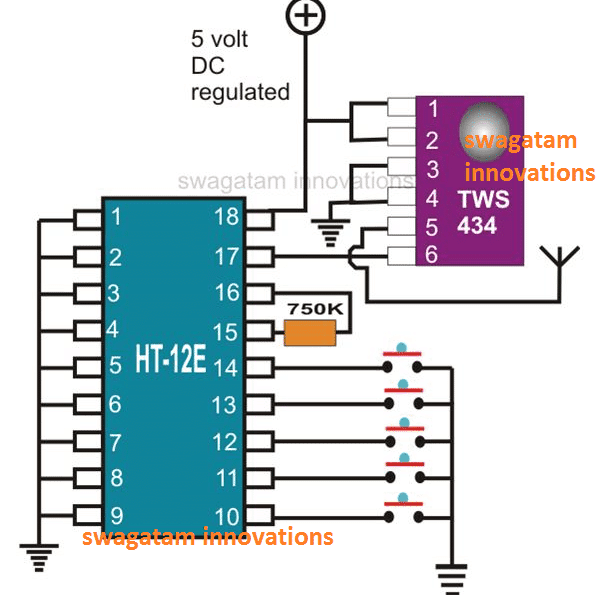

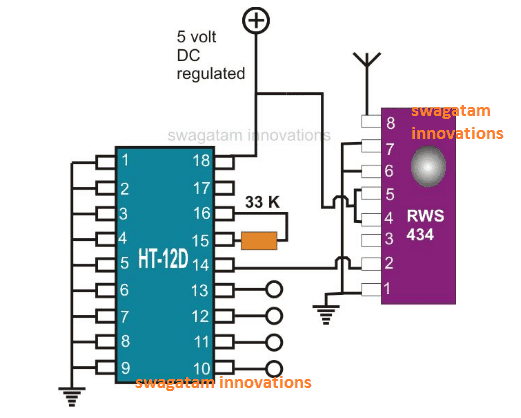

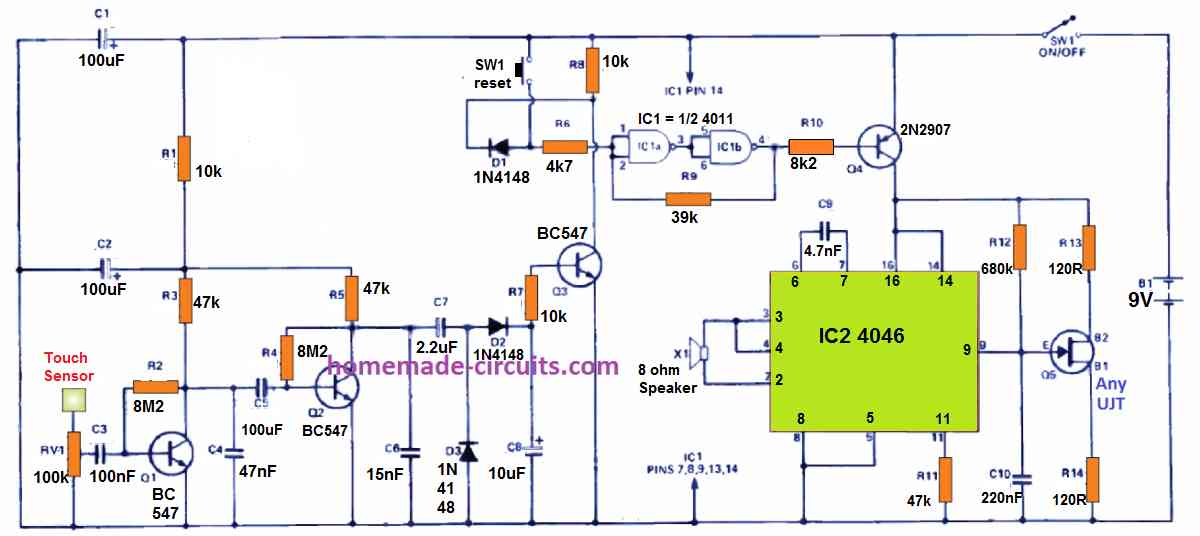

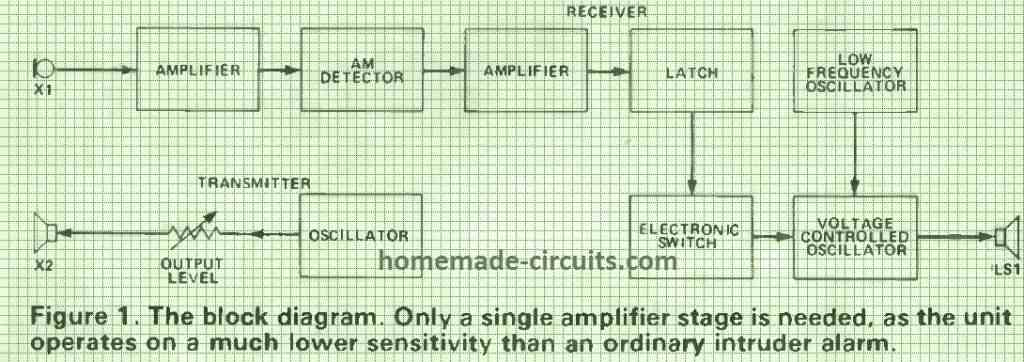

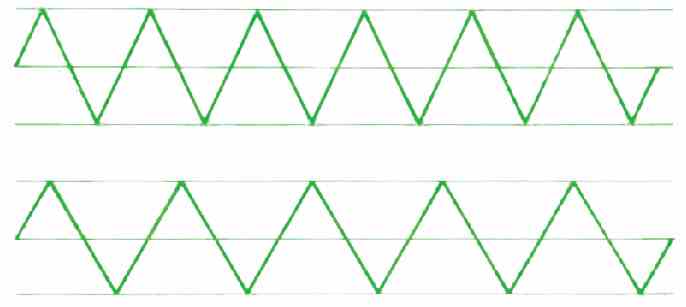

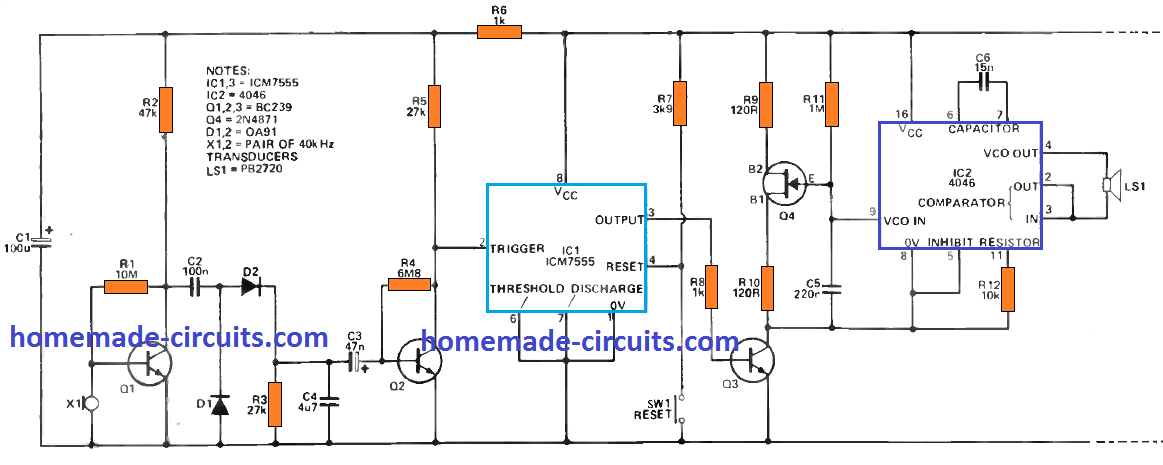

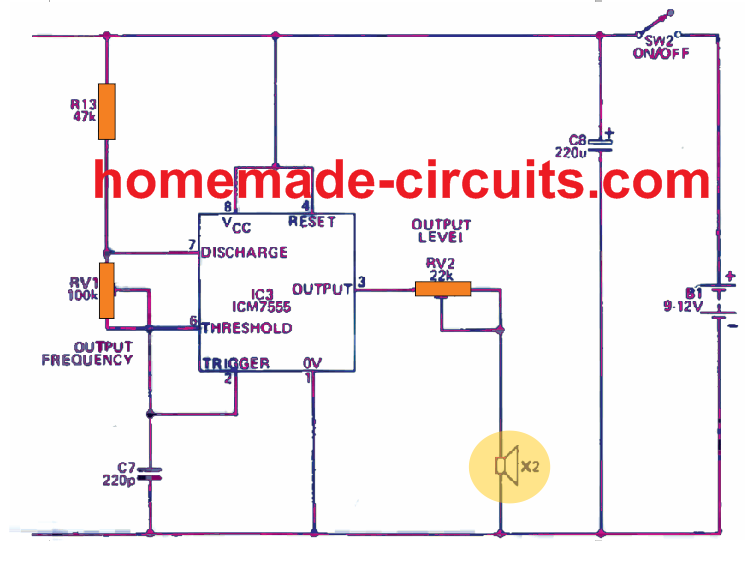

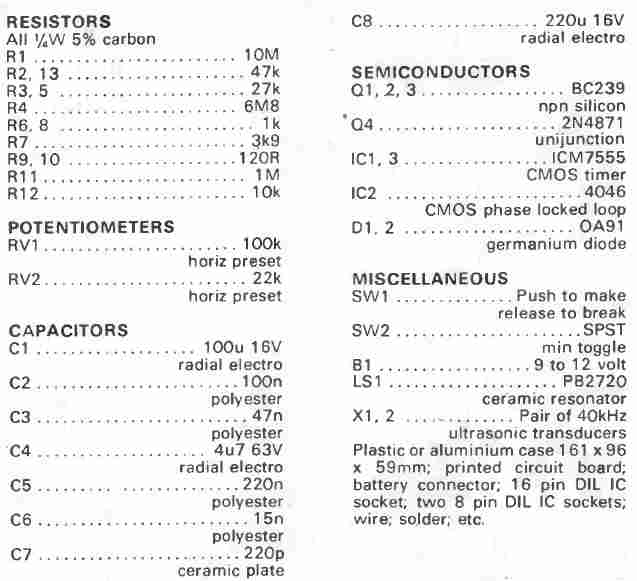

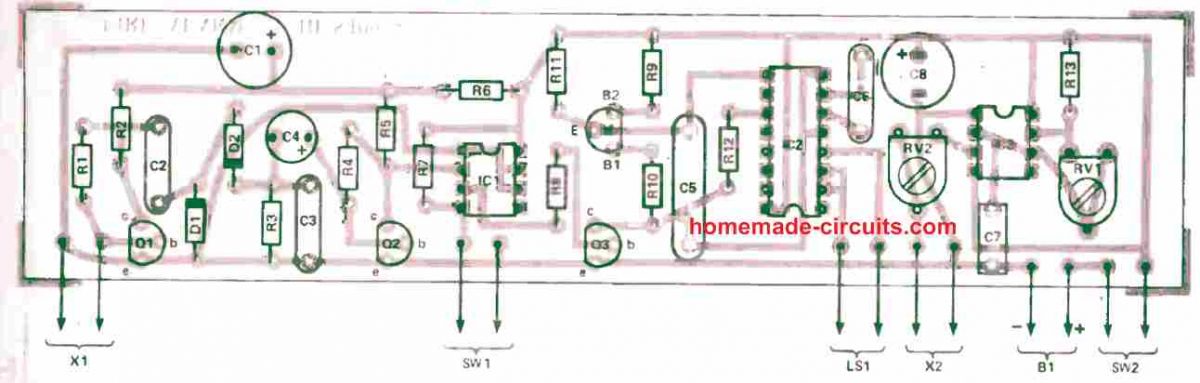

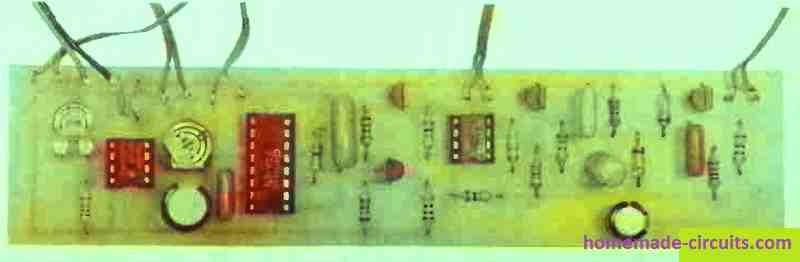

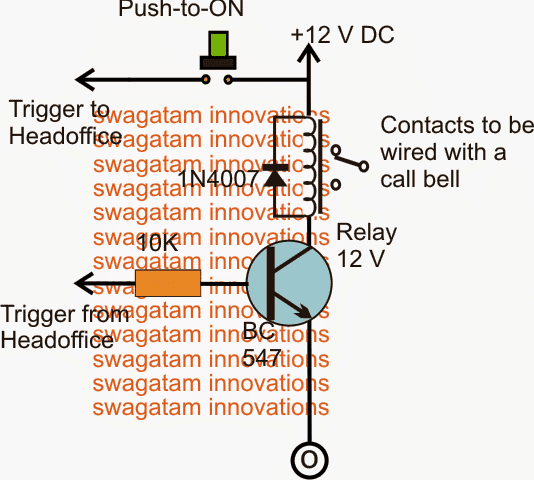

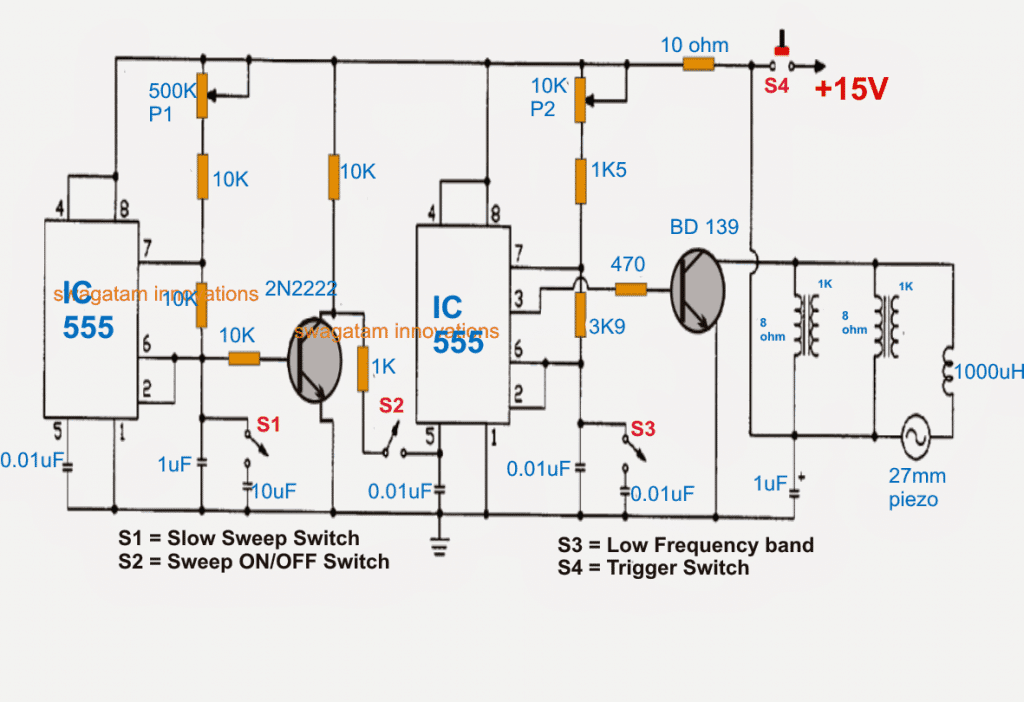

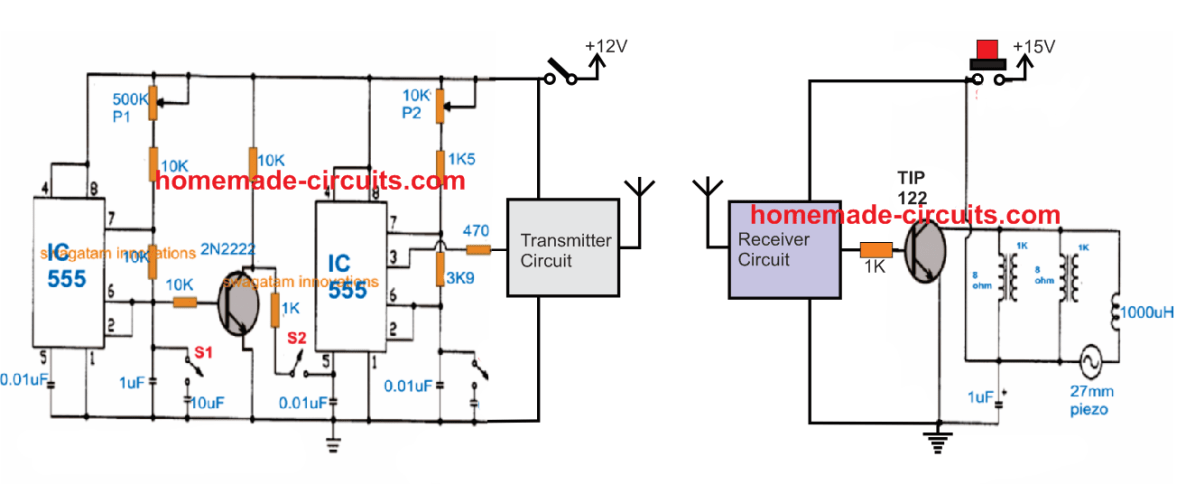

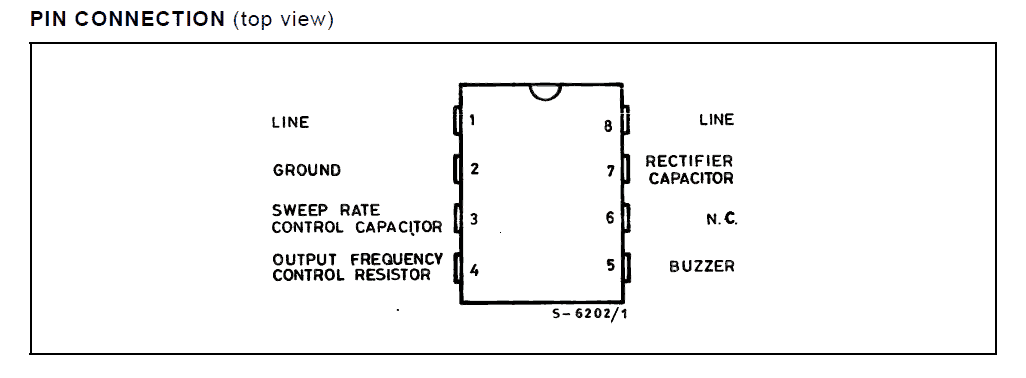

The article explains a simple walkie talkie circuit that can be easily built by any hobbyist and used for communicating between rooms or floors or simply for having some fun across neighbors and friends. The range of this system is around 30 meters. Awalkie-talkie, also commonly referred to as handheld transceiver is a small, portable hand-held two-way radiotransceiver, which enables voice communication across a specified radial distance without using physical wire connections across the devices. The initial research on walkie talkie concept during the 2nd world war era, has been variously credited toDonald L. Hings, Alfred J. Gross, and engineering experts atMotorola. Walkie talkies were first supplied for infantry use, and soon it also became indispensable among field artillery and tank units. Due to their outstanding wireless communication ability, these units quickly became popular among the masses and became a commercial product for the various manufacturers.Circuit Operation

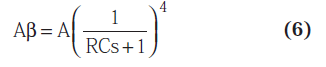

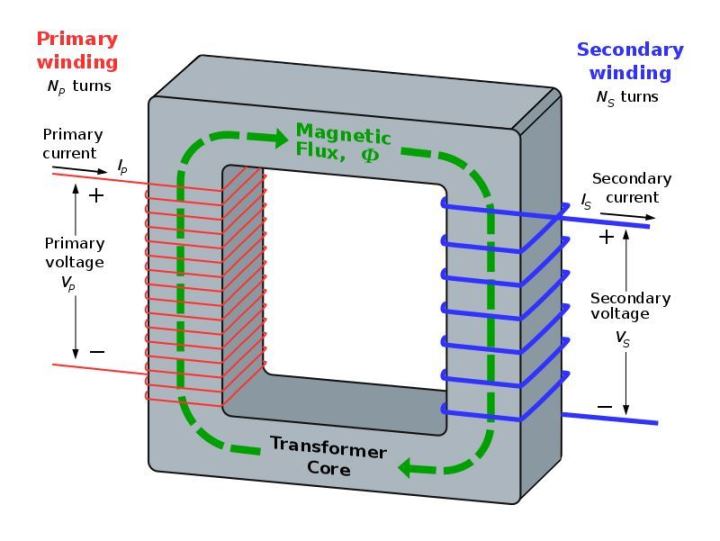

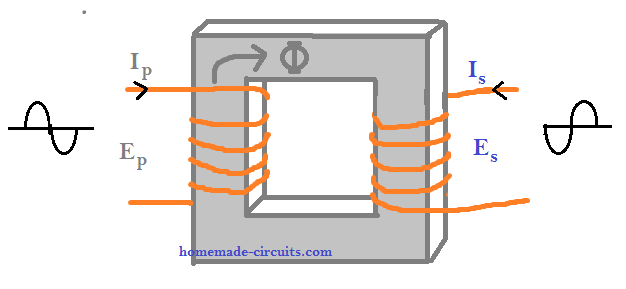

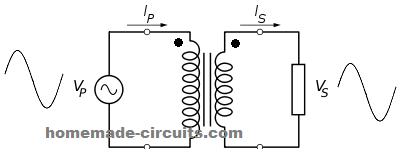

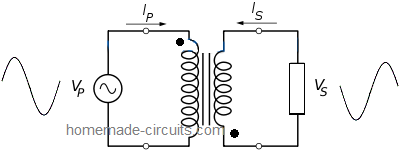

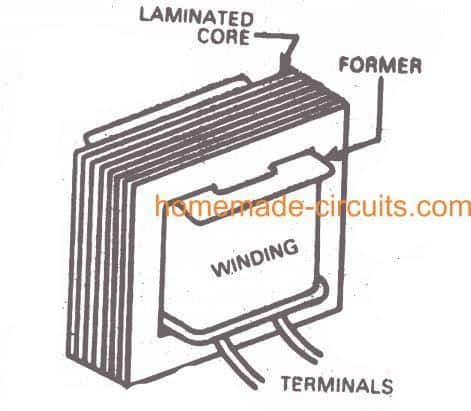

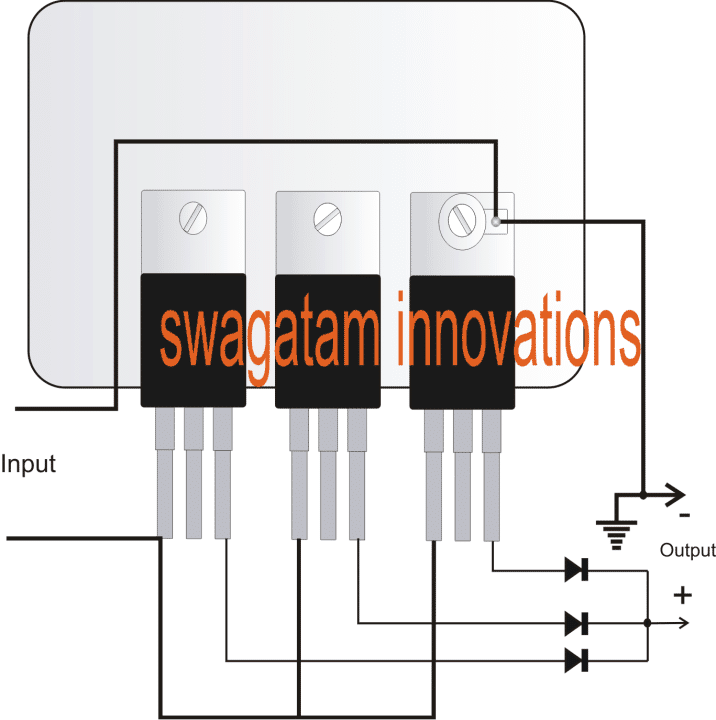

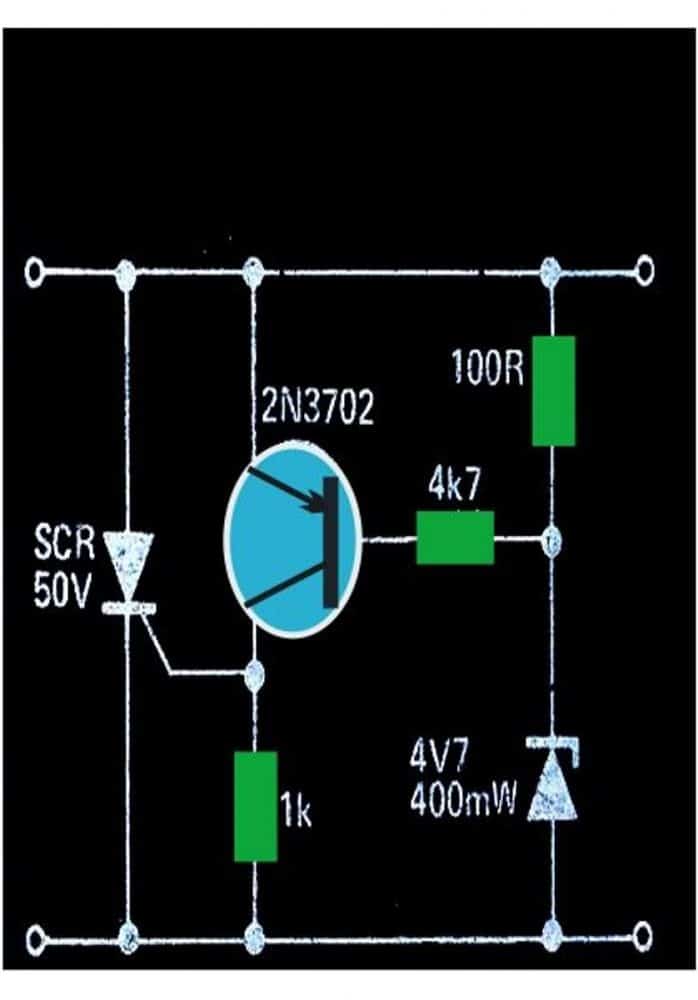

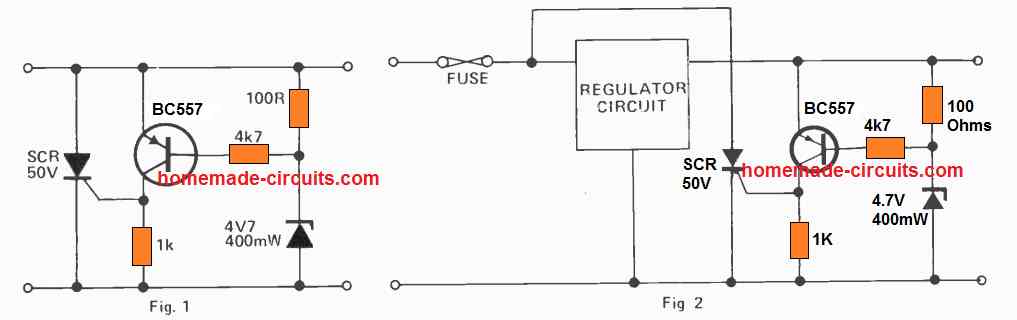

The figure shows a four stage transistorized circuit which behaves both like a transmitter and a receiver unit, making the design very economical and versatile. An ordinary ※4-pole double throw§ switch serves the purpose well for transforming the unit either to a transmitter or a receiver while communicating with another identical transmitter/receiver set. As can be seen in the diagram three transistors are directly coupled for making an audio amplifier stage set to operate at a significantly high gain. The first transistor functions as a pre-amplifier which pulls the minute voice signals to some higher level and feeds to the next high gain Darlington stage which further amplifies the received audio frequencies and dumps it across the primary of a driver transformer.How Driver Transformer Works

The driver transformer steps up the level of the signals such that it becomes clearly audible over the connected loudspeaker. The speaker may be salvaged from an old small transistor radio or from a landline phone (earpice). The speaker in the shown design is configured in an interesting manner. Depending upon the position of the walkie talkie switch, the speaker works like a sound reproducer when it*s in the receiver mode and like a super dynamic microphone when the switch is toggled in the transmitter mode. While the speaker is being used as a sound reproducer or simply in the receiver mode, the first transistor acts like a signal receiver, picking up the audio across the 4k7 load resistor through the 0.47uF capacitor. The signals then has to pass through a connected volume control stage to finally reach the three transistor amplifier stage discussed above. However while the proposed walkie talkie circuit is flipped in the transmitter mode, the speaker gets rigged right at the input of the amplifier stage such that the spoken voice hits the speaker diaphragm and gets amplified by the same transistor stage. This amplified voice signal is now applied in the form of supply voltage for the circuit in the transmitter mode. The switch also makes sure that the 27 MHz crystal gets connected with the first stage while the transistor gain is uplifted by eliminating the 390 ohm resistor and using a 59 ohm resistor at the emitter of the transistor. In the transmitter mode the speaker transformer secondary now has no connection with the voltage step-up function rather simply acts like a series inductor for coupling the output of the audio amplifier with the supply rail and for sending the signal across the winding to the transmitter stage in the form of a fluctuating supply voltage. As the above signal witnesses a rise and fall in response to the spoken voice, the gain of the first transistor stage is forced to change correspondingly which in turn results in a varying amplitude for the carrier waves transmitted by this stage over the attached antenna. Thus the spoken voice now gets converted to an amplitude modulated (AM) RF 27MHz signal which may be picked by another identical unit placed in the vicinity for the same reason.

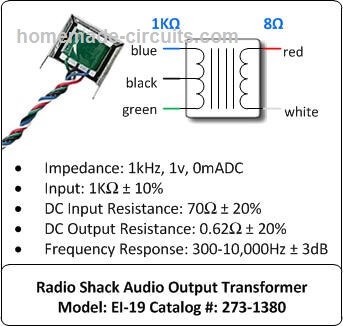

Parts List

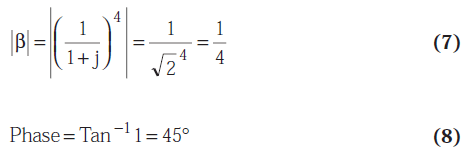

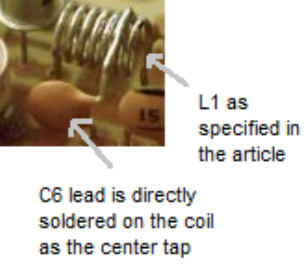

All resistors are 1/4 watt 5% CFR 100 ohm - 1 220 ohm - 1 5.6K - 1 4.7K - 1 3.9K - 1 1M - 1 15K - 1 33K - 1 56 ohms - 1 390 ohms - 1 10 k preset - 1 Capacitors Electrolytic 33uF/25V 100uF/25V Capacitors ceramic disc 0.47uF - 1 22nF -2 220pF- 1 4.7nF - 2 10nF - 2 82pF - 1 33pF - 1 15pF - 1 39nF - 1 Transistors BC547 - 2 BC338 - 1 Miscellaneous Crystal 27MHz - 1 TPTT 3 pole triple throw switch - 1 Audio transformer - 1 small speaker 8 ohm 1 watt - 1 9V battery - 1 Inductor as explained belowHow to Wind the Antenna Coil

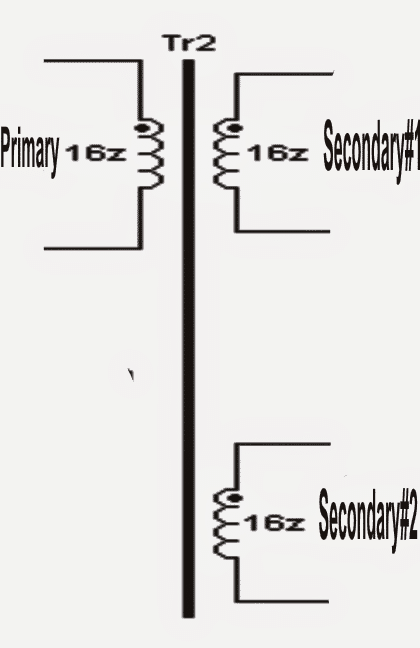

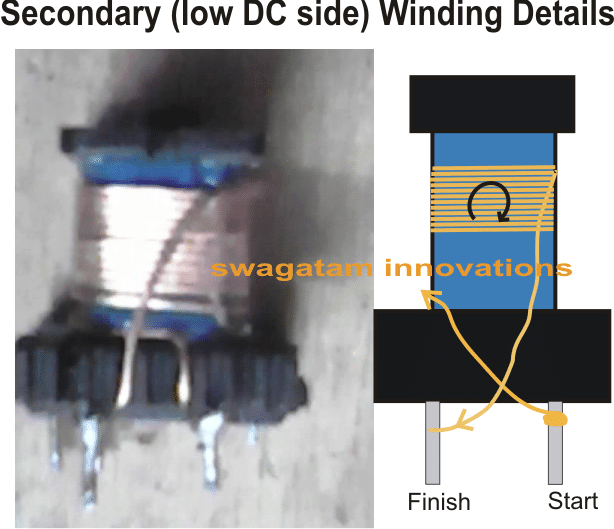

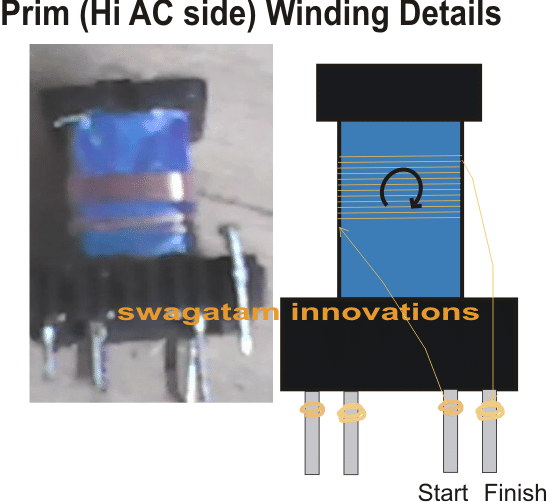

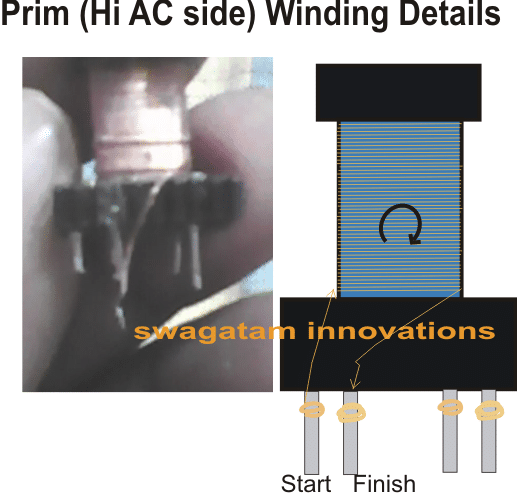

The coil associated with T1 (BC547) collector is the antenna coil. It is constructed over a ready made variable inductor slug (see image below) having an approximate 3mm diameter and around 7 to 10mm height. The wire used is a 0.3 to 0.5mm super enameled copper.

Start with the primary 9 turns first, directly on this wind the secondary 2 turns.

The coil in series with the antenna is s simple air core coil made by winding 5 turns of 0.3mm with 5mm diameter.

The wire used is a 0.3 to 0.5mm super enameled copper.

Start with the primary 9 turns first, directly on this wind the secondary 2 turns.

The coil in series with the antenna is s simple air core coil made by winding 5 turns of 0.3mm with 5mm diameter.

How to Wind the speaker coil

You may use a small audio transformer for the shown speaker transformer, or alternatively build it by winding around 70 turns for the primary (left side), and 500 turns at the secondary (speaker side). The wire may be a 0.2mm super enameled copper wire wound over a 3 inch long iron screw.How to Set up the Circuit

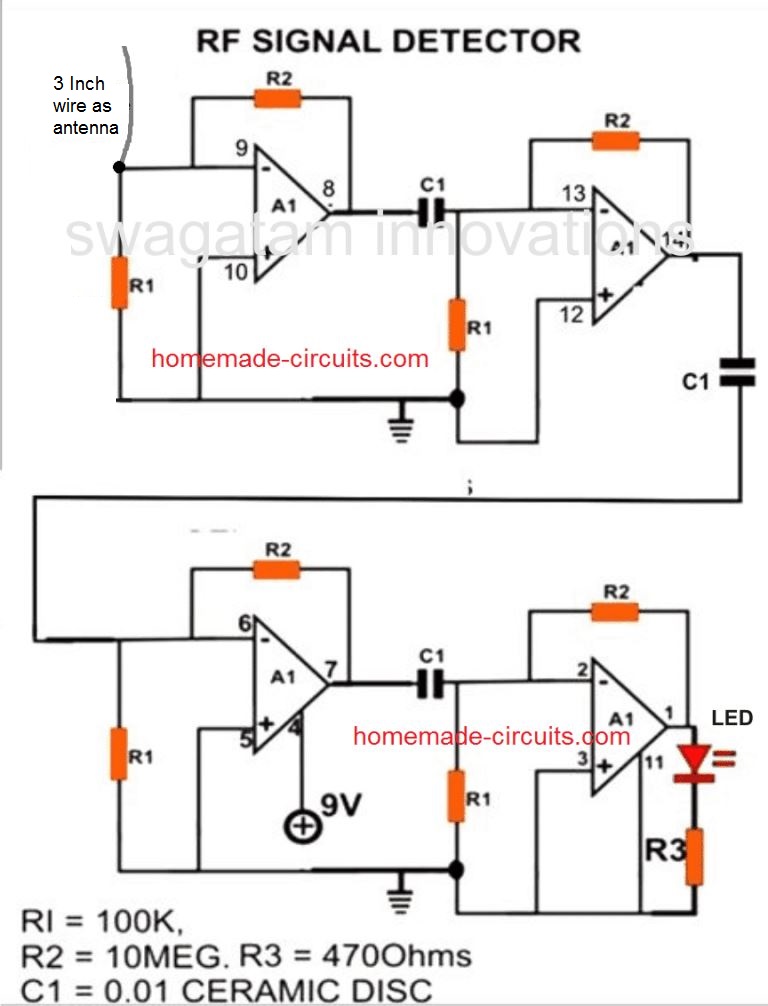

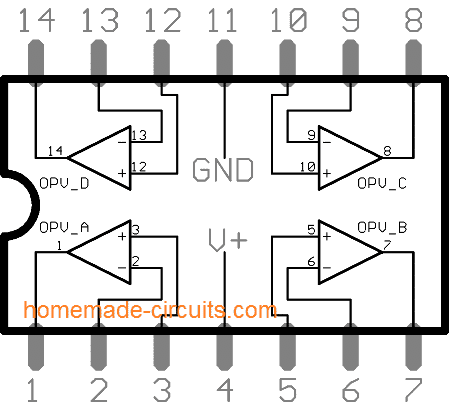

After you have built the above explained walkie talkie circuit it's time to check its response by powering it with a 9V PP3 battery. Initially let the switch contacts be positioned for activating the transmitter stage. For knowing whether the transmitter is generating the required 27MHz frequencies or not you will first need to make an RF sniffer circuit as explained HERE Switch ON both the circuits, position the above RF detector circuit about 10 inches away from the walkie talkie antenna, and begin adjusting its variable inductor slug gently using an insulated screw driver which are typically used for adjusting FM radio GANG trimmers. If every thing's done correctly you'll hopefully see the RF detector LED glowing brightly at some point of the adjustment process. Seal and glue the variable inductor at this position, and you can assume your walkie talkie to be all set for having some great time with your friends. However you would need to build another identical set for exchanging the conversations with the other guy, otherwise a single unit wouldn't have much of an importance.What's the Range of this Walkie Talkie

The range of this 27 MHz walkie Talkie can be around 1 Km, provided the trimmers are correctly adjusted and the antenna is long enough for the wide radial transmission.Simple Automatic Plant Watering Circuit for Monitoring Soil Moisture

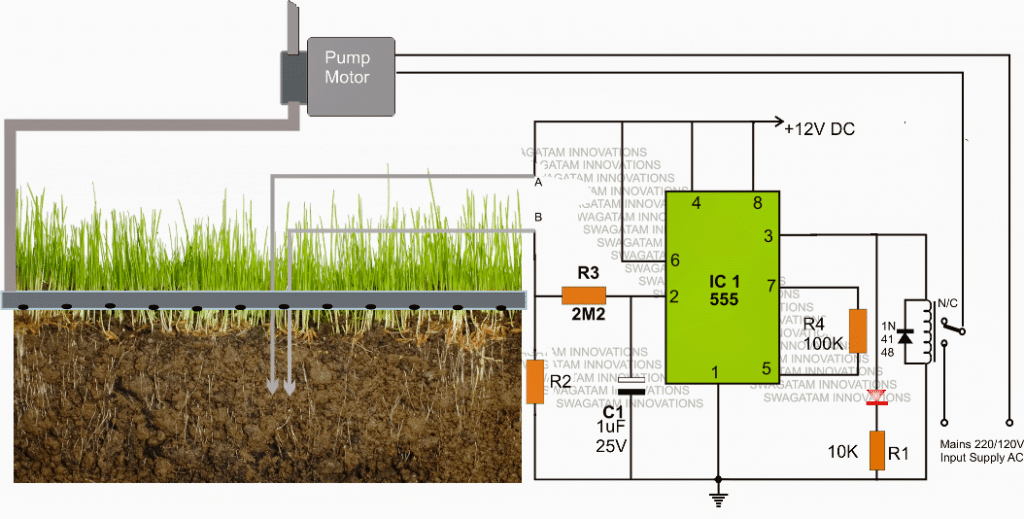

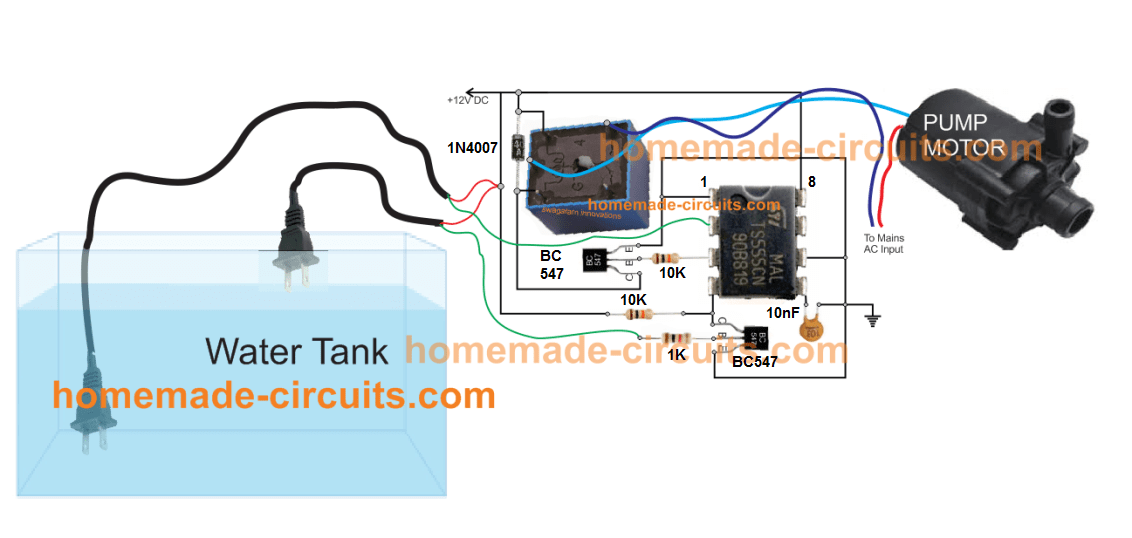

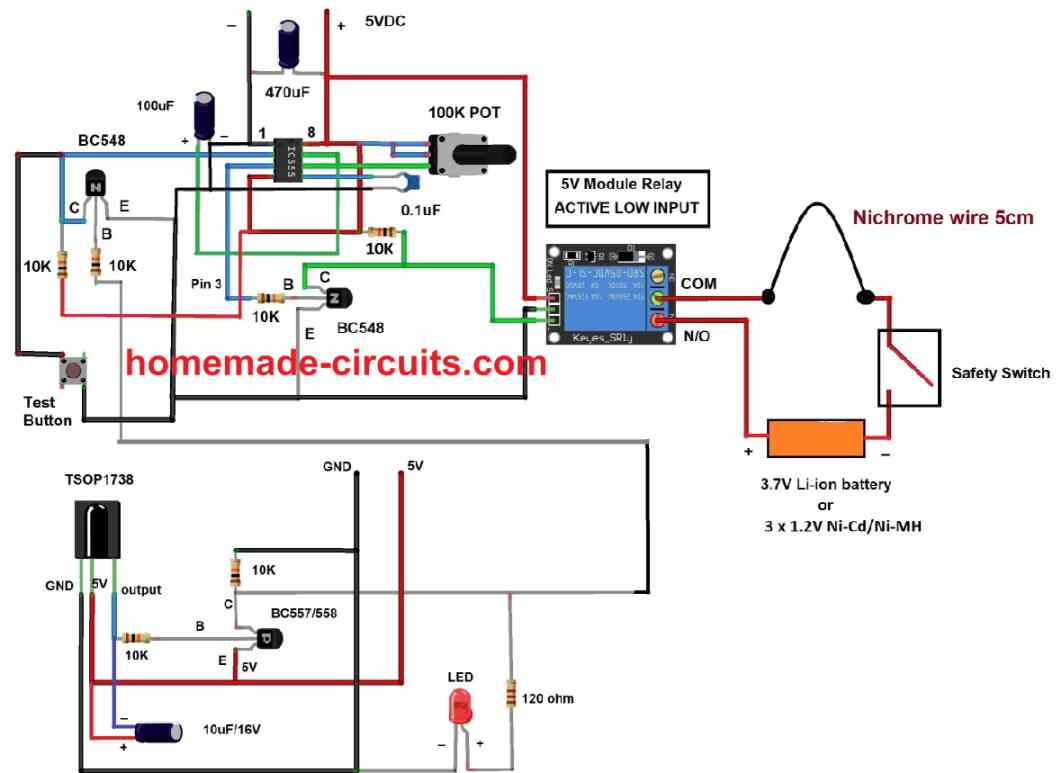

This automatic plant watering circuit can be used for automatically sensing soil humidity and triggering a water pump when the ground gets parched below a predetermined level (adjustable).Circuit Operation

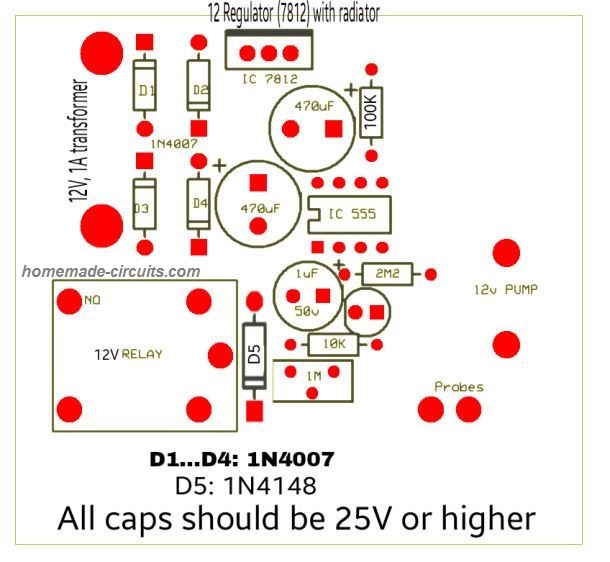

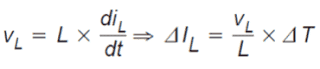

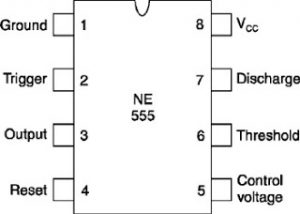

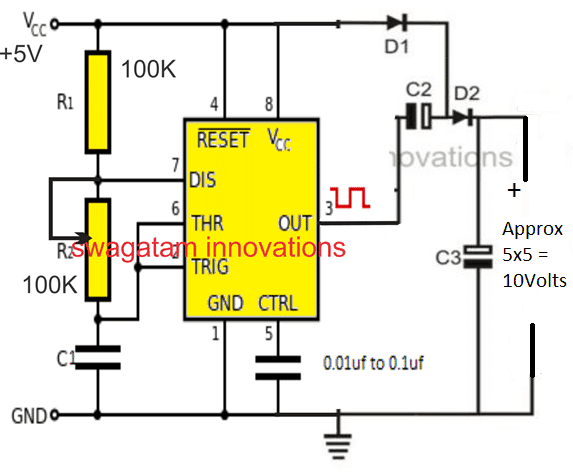

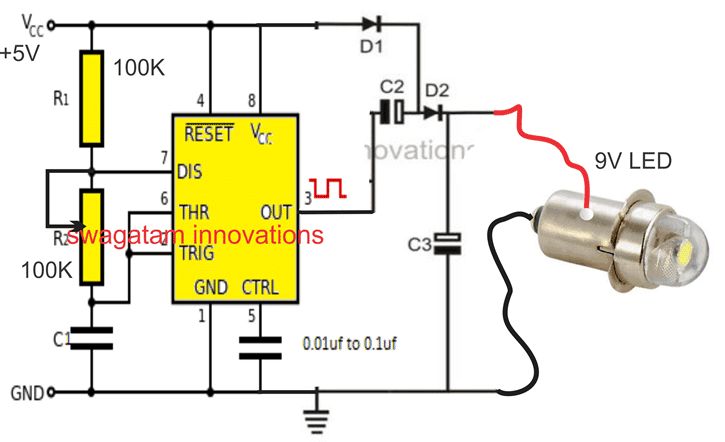

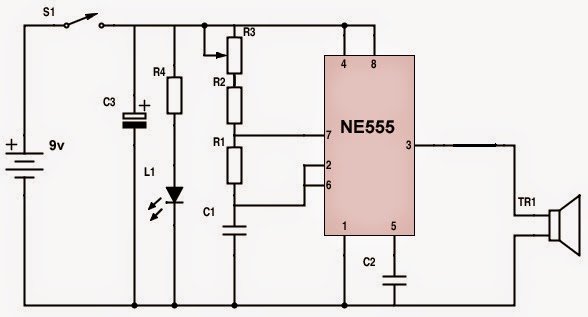

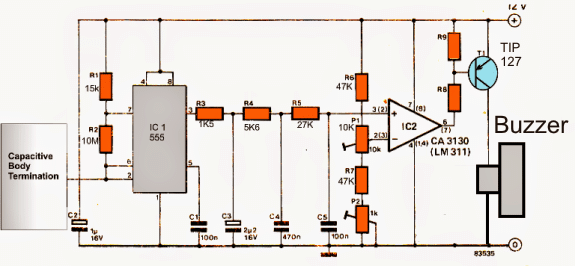

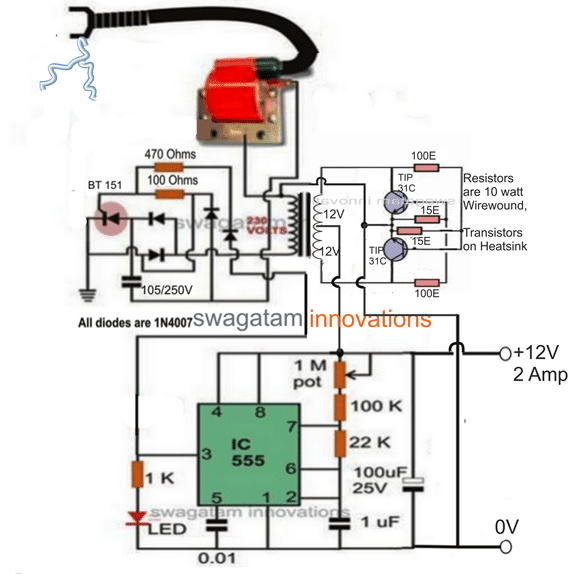

The circuit is rather straightforward and uses a single IC 555 as the main active component.Referring to the automatic plant irrigation circuit shown below we can see the IC 555 is wired in a completely unique and in the quickest possible mode. Here it's configured as a comparator, and works better than an opamp because the IC 555 has built in opamps which are at par with any single opamp and also the output of a 555 IC is able to sink sufficient current in order to drive a relay without a transistor driver stage. The above features particularly makes the above design very simple, low cost and yet too effective with its functions. The pin#2 here becomes the sensing pinout of the IC, and is held at ground level via R2 which must be calculated as per the desired soil humidity triggering threshold. The points A and B can be seen fixed inside the soil which needs to be monitored for the intended automatic watering from the water pump. As long as the points A and B senses some level of humidity corresponding to a resistance value which may be lower than R2, the IC 555 output is held low, which in turn keeps the relay deactivated. However as the soil tends to get dryer, the resistance across the probes starts getting higher and at some moment of time it becomes higher than R2, creating a potential below 1/3rd supply voltage at pin#2 of IC555. The above situation instantly prompts pin#3 of the IC to become high, triggering the connected relay. The relay activation switches ON the water pump which now starts pumping water to the particular area of the soil via a distributing water channel. As this happen, the soil gradually gets wetter and as soon as the predetermined level is reached, the probes immediately sense the lower resistance and revert the IC ouput pin#3 to a low again switching OFF the relay and the water pump consequently. C1 ensures a slight hysteresis in the operations ensuring that the relay triggering is not sudden or abrupt, rather it switches only after sensing a genuine response from the soil conditions.Circuit Diagram

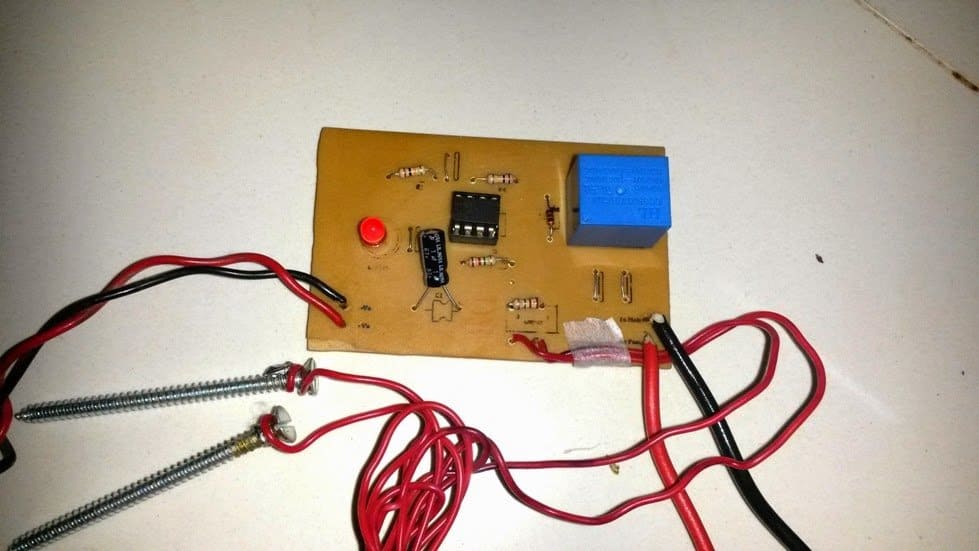

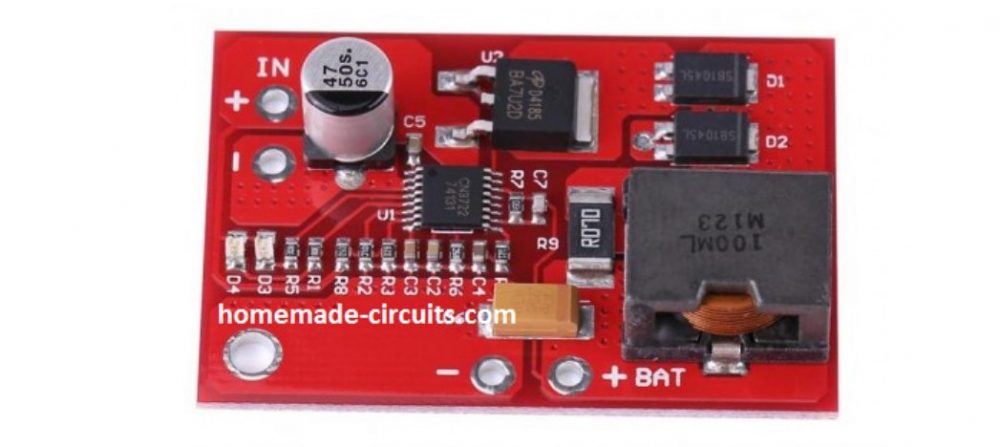

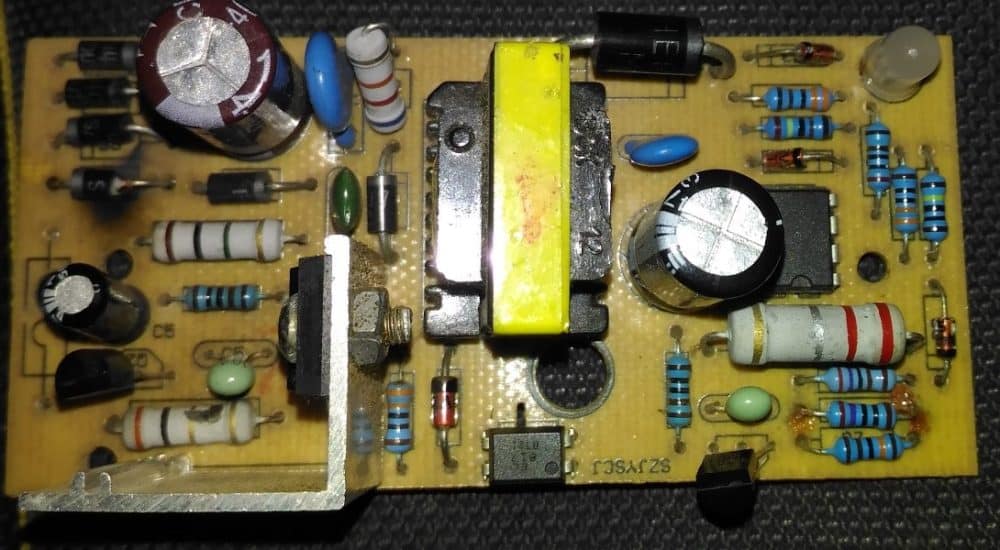

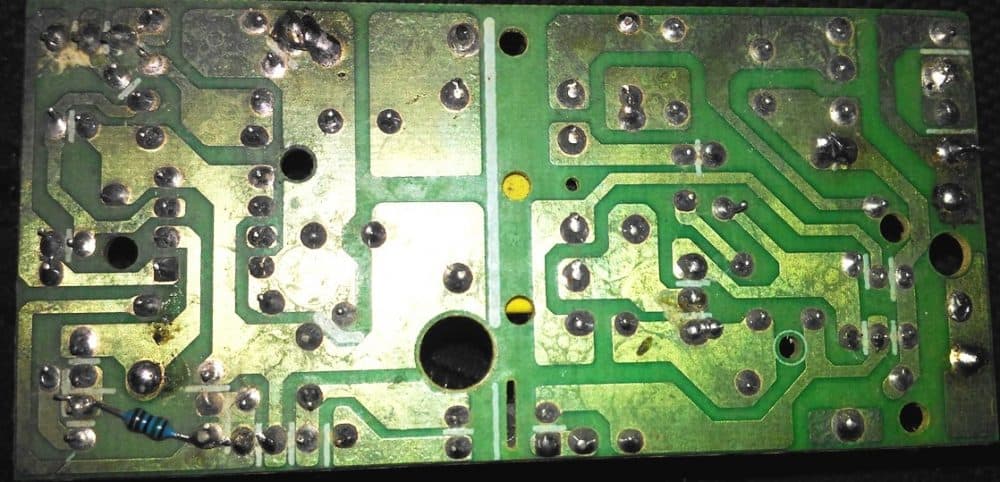

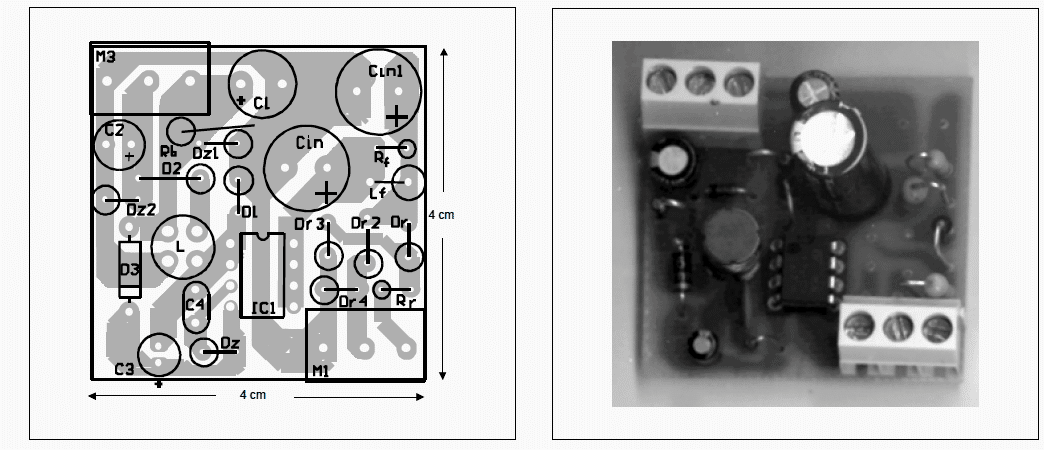

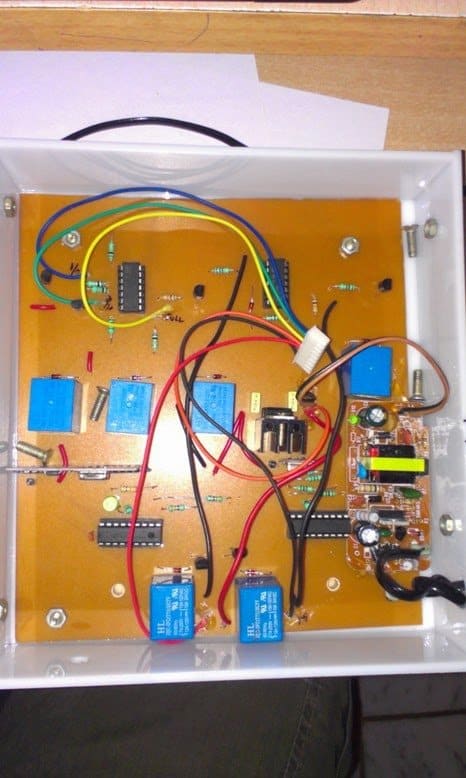

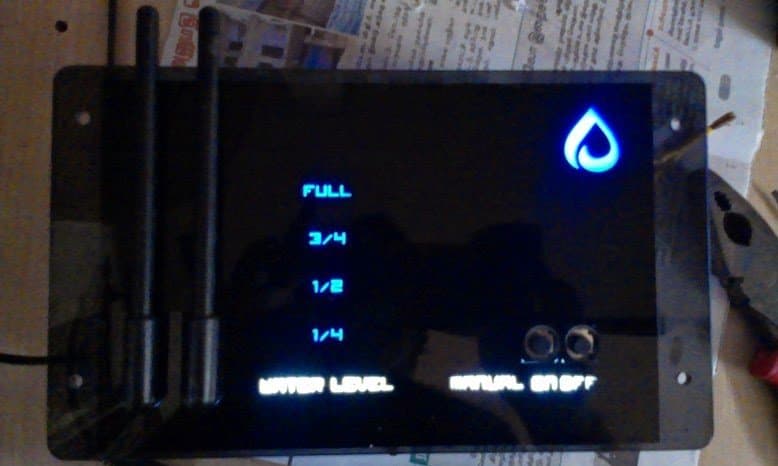

The above explained automatic plant irrigation circuit was successfully built and tested by Mr.

Ajay Dussa.

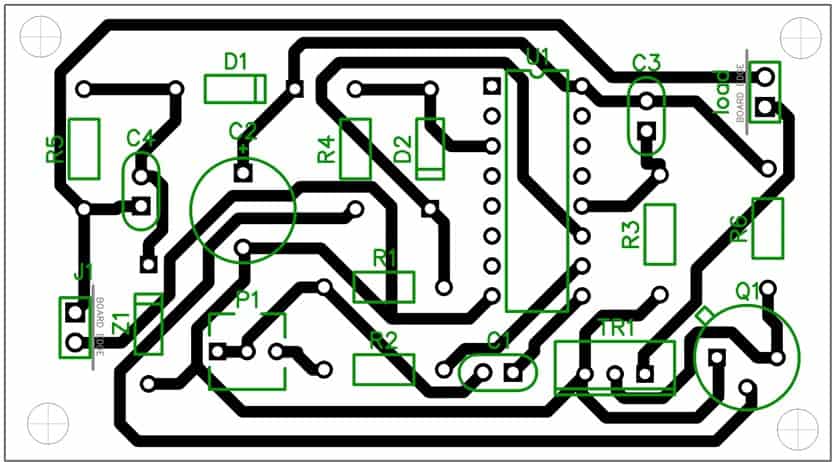

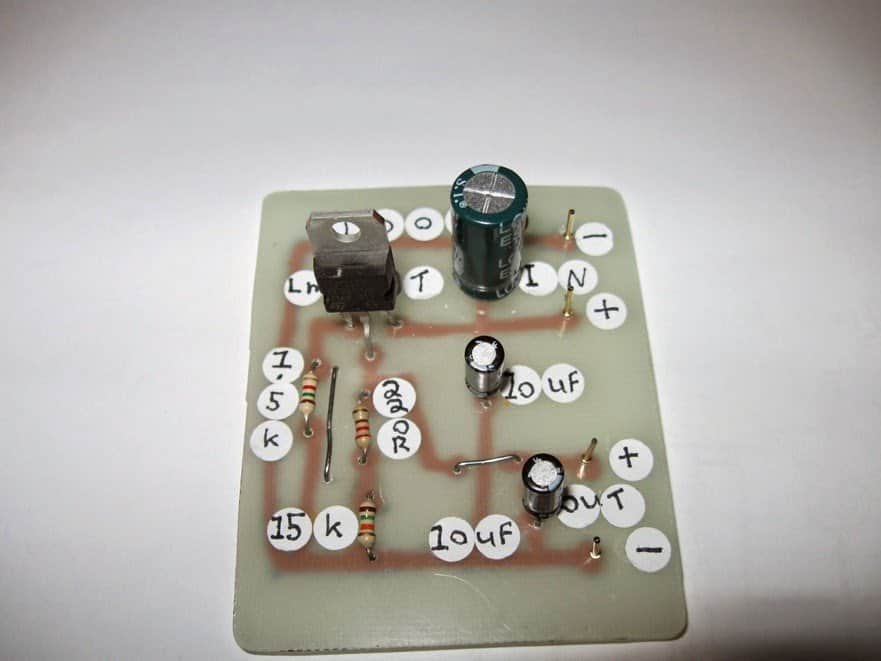

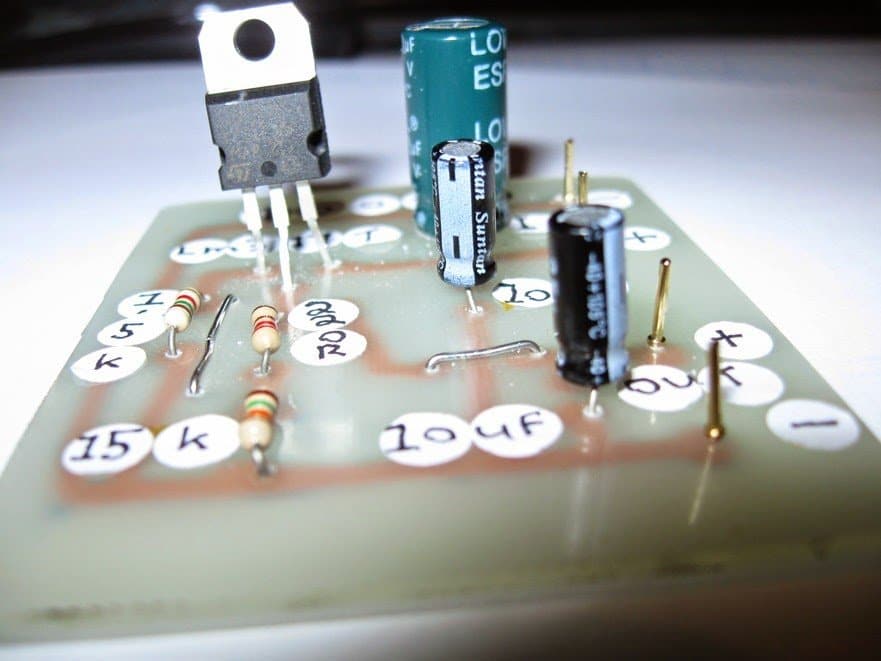

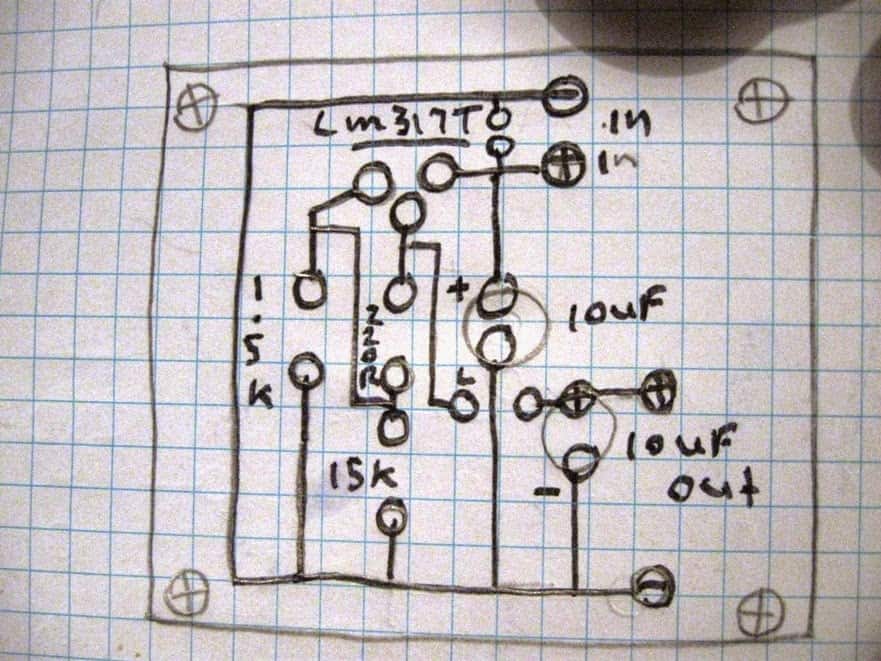

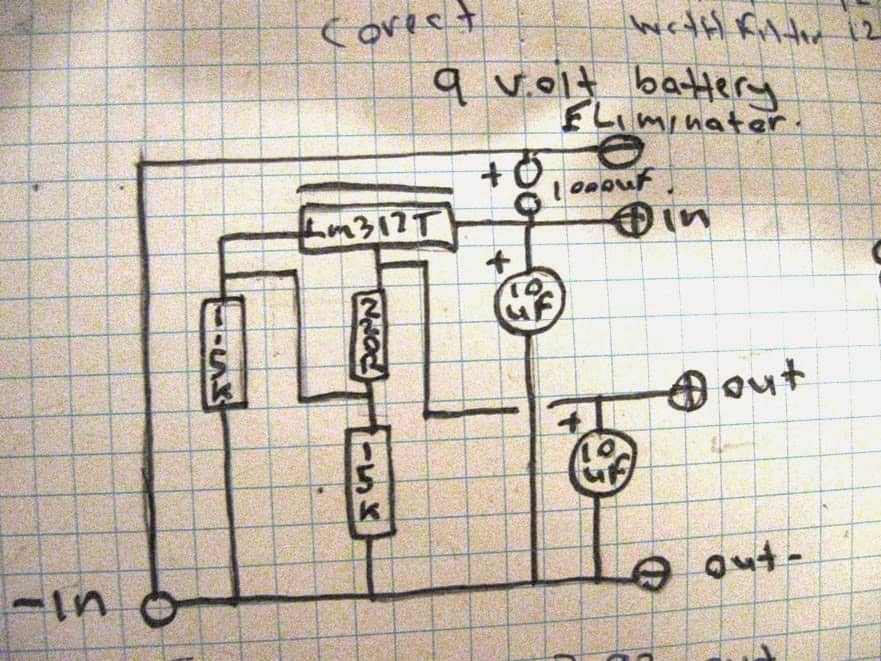

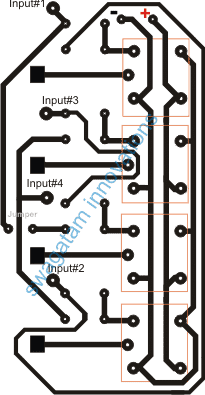

The following images show the prototype unit and the PCB design built by Mr.

Ajay.

The above explained automatic plant irrigation circuit was successfully built and tested by Mr.

Ajay Dussa.

The following images show the prototype unit and the PCB design built by Mr.

Ajay.

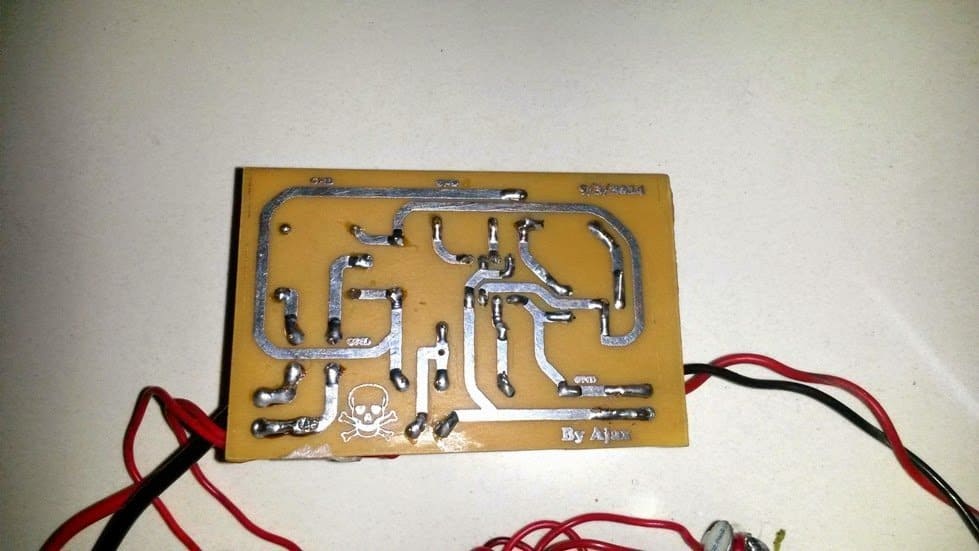

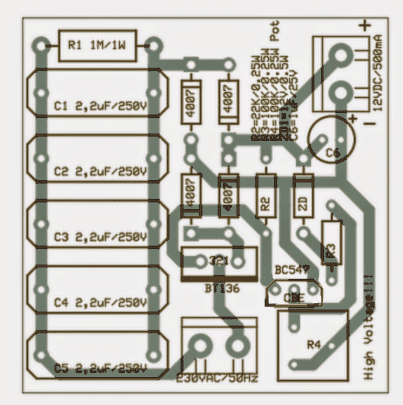

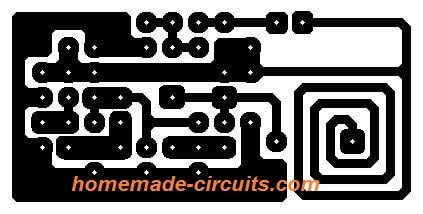

PCB Design

PCB Design

FOR A 741 OP AMP BASED CIRCUIT, YOU CAN REFER TO THIS ARTICLE.

FOR A 741 OP AMP BASED CIRCUIT, YOU CAN REFER TO THIS ARTICLE.

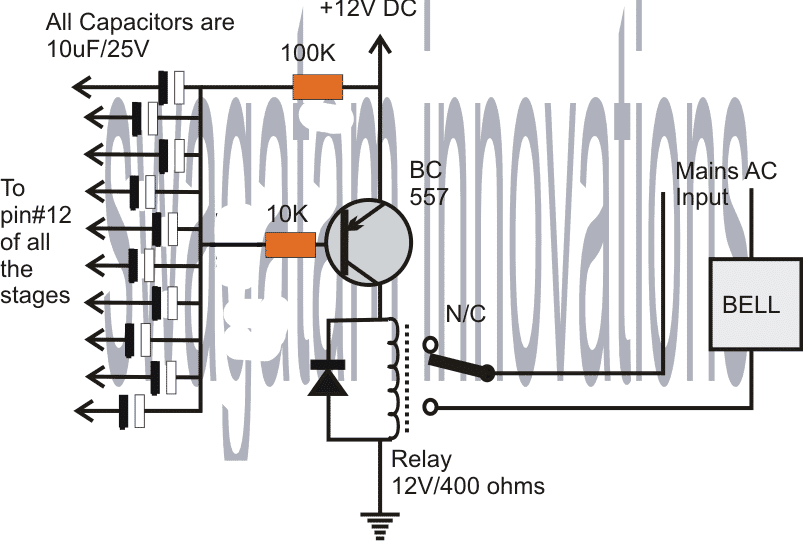

Parts List

All resistors are 1/4 watt 5% CFR R1 = 10K R3 = 2M2 R4 = 100K R2 = 1M preset or cermet C1 = 1uF/25V optional for creating delay effect on the relay Relay = 12V, 400 ohm SPDT Supply input = 12V/500mA DC Another version of the PCB design is shown below. It was designed an contributed by: Alireza Ghasemi

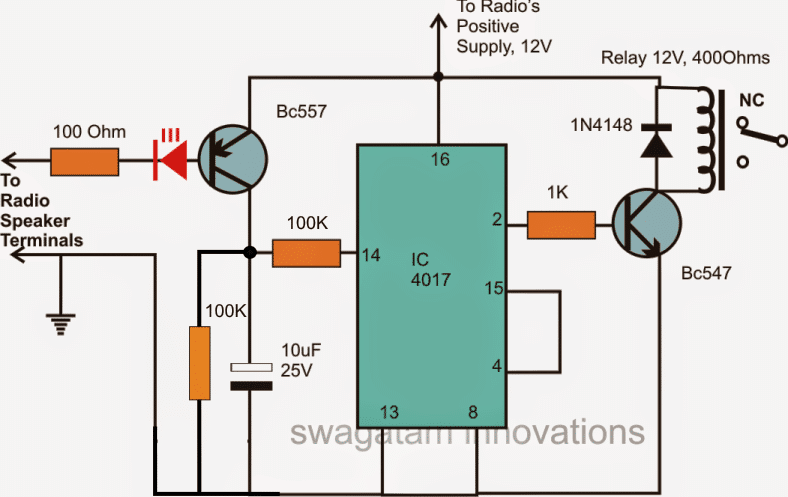

Soil Moisture Sensor with Automatic Water Sprayer

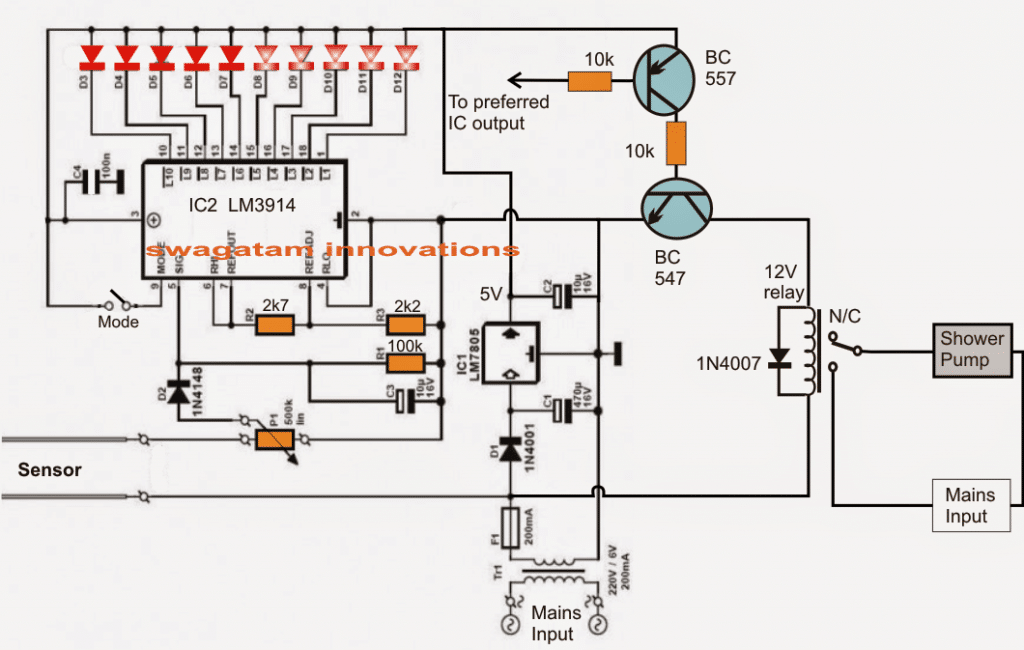

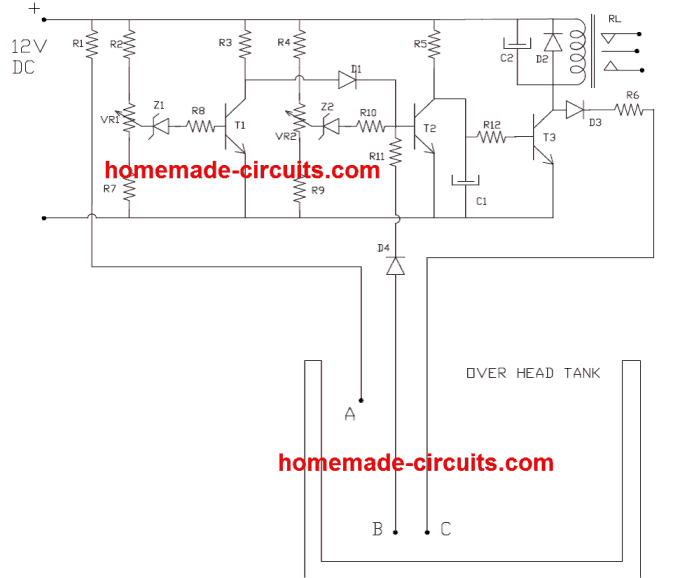

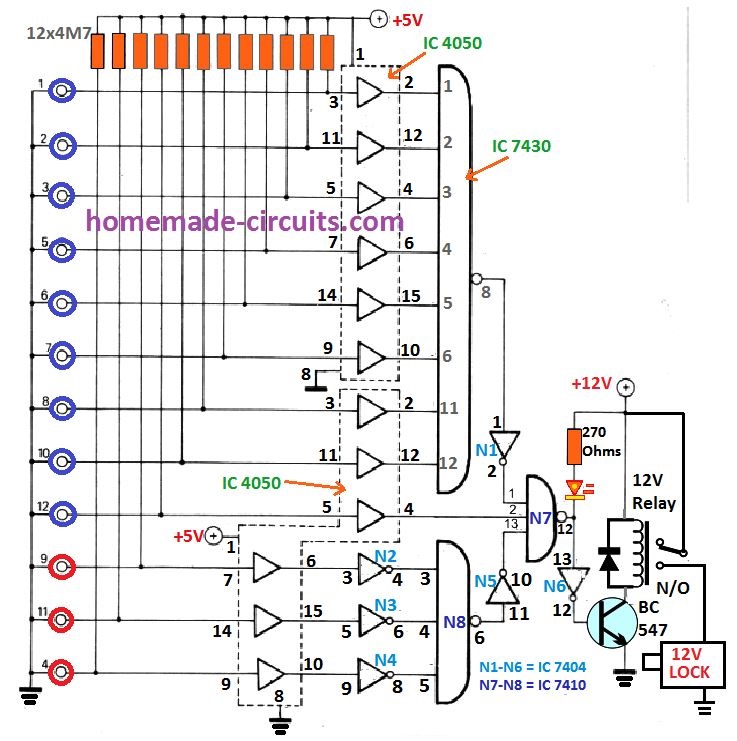

The next article explains a 10 stage soil moisture sensor circuit with an integrated automatic water sprayer mechanism for restoring the critical condition of the soil. The idea was requested by Mr. Remy. I come today asking for help making an automatic watering circuit to water my tomatoes for me. I am requesting the use of a soil moisture sensor (cheap eBay style) to sense the moisture of the soil. Then the moisture value is compared to a set value from a potentiometer maybe. If level is too low then a relay is turned on for a settable amount of time. After a shower the soil is measured again. Rise repeat. The ability to daisy chain many together would be a great help. For wow factor I was thinking that having a few(3) leds light up as a scale to indicate the current moisture level would work well. Thank you for your time and experience. I have learned much from you and hope to add this to my knowledge. RemyCircuit Diagram

The Design

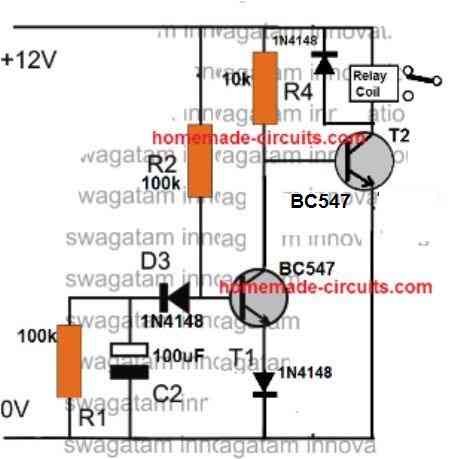

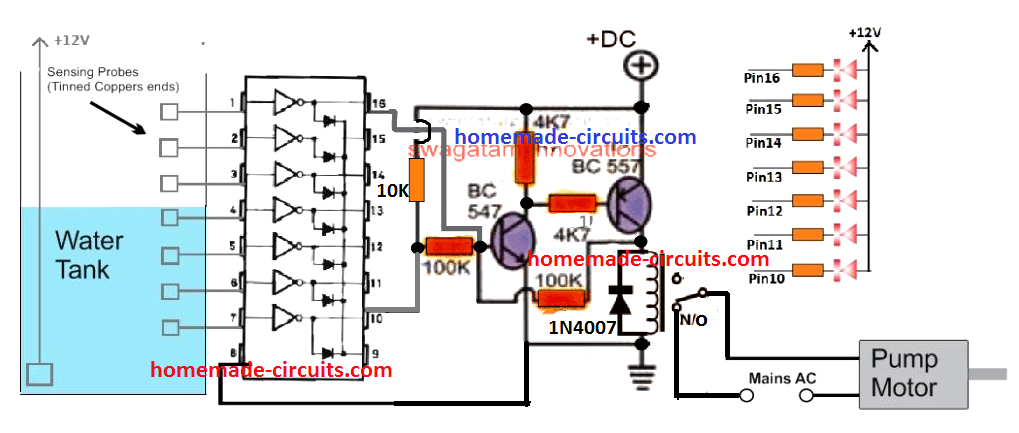

Referring to the given schematic we see a simple yet highly accurate soil moisture sensor circuit with an automatic preset water shower system for restoring the soil moisture level to optimum points. The design is based on a single voltage sensor/LED driver IC LM3914 or a LM3915. The shown sensor pins which are basically two brass rods are configured as voltage sensors across the critical soil area where it may be inserted. The voltage across these pins depend upon the level of moisture present across that particular soil area. This sensed voltage proportionate to the soil moisture level is applied across pin5 of the IC for the required comparison with an in-built reference voltage level. The threshold level at which the shower pump is supposed to be switched ON is set by P1. Depending upon this setting, the IC internal circuitry senses the soil moisture and produces a shifting sequential low logic across the shown 10 outputs starting from pin1 to pin10. This sensed output across the relevant IC outputs are indicated by 10 respective LEDs which light up in sequence in response to the rising or depleting soil moisture levels.Selecting Bar Mode and Dot Mode

The LED illumination sequencing style could be selected to simulate a bar mode or a dot mode by appropriately positioning the pin9 switch of the IC to either ON or OFF. The stage comprising BC547 and BC557 constitute the relay driver stage for controlling the motor pump switching as per the user preference. The base of the PNP transistor is appropriately integrated with any of the output pins of the IC depending at what moisture threshold the user wants the motor to be started or stopped. For example suppose pin15 determines a particular moisture threshold level of the soil and the user feels it to be the unsafe level at which the motor needs to be started in order to restore the soil moisture, then this pinout could be chosen and hooked up with the base of the BC557 transistor for the discussed motor switching. Once the motor is switched ON the soil is showered until its moisture level is restored to the desired level and this prompts the IC to revert its sequence from pin15 to pin14 and toward pin10, switching OFF the motor and the shower. The above process keeps repeating making sure that the soil moisture level never goes down below the undesired parched condition.Simple Transistorized Soil Watering System

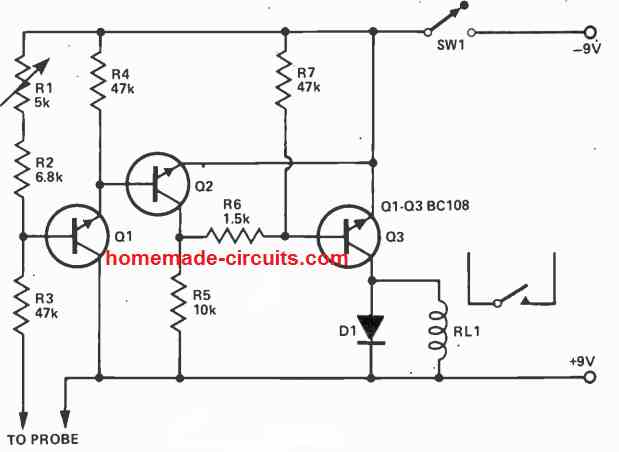

Here's another automatic soil watering system that you can build. Its working mode is mainly the nonstop checking of soil moisture, and then responding to a drop beneath a preadjusted degree to set off the plant watering action. This design consists of a straightforward trigger circuit, that switches ON the relay RL for a degree of moisture in the soil and its conductivity which may be beneath the fixed level as adjusted by the 5 k preset. The conductivity inside the soil or mud is detected through a pair of probes coupled to the terminals as indicated in the diagram.

The idea really is easy and very reliable, and will can work by using any supply voltage between 6 and 12 volts or even more, only if the supply voltage is perfectly compatible with the working voltage spec of the relay.

The relay contacts can be appropriately wired with a water pump or a water sprayer device for initiating the required automatic watering of the plant, each time a dry soil is detected and the relay is switched ON.

The conductivity inside the soil or mud is detected through a pair of probes coupled to the terminals as indicated in the diagram.

The idea really is easy and very reliable, and will can work by using any supply voltage between 6 and 12 volts or even more, only if the supply voltage is perfectly compatible with the working voltage spec of the relay.

The relay contacts can be appropriately wired with a water pump or a water sprayer device for initiating the required automatic watering of the plant, each time a dry soil is detected and the relay is switched ON.

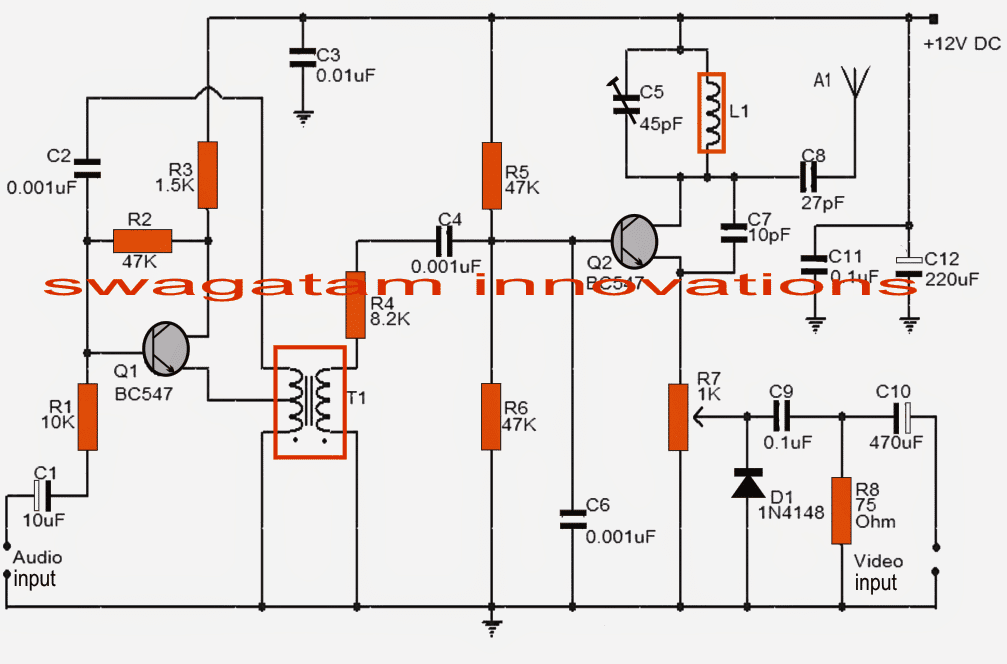

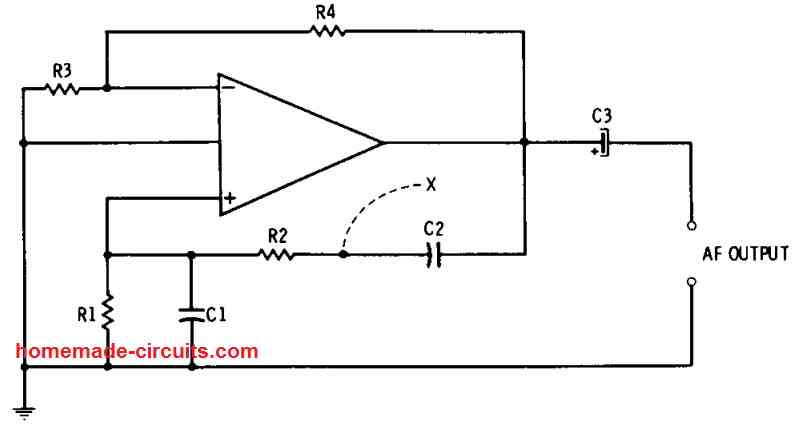

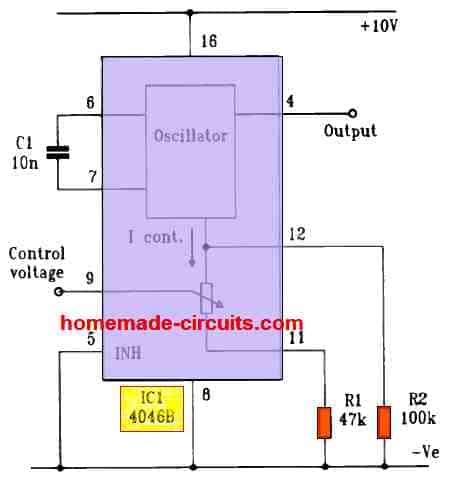

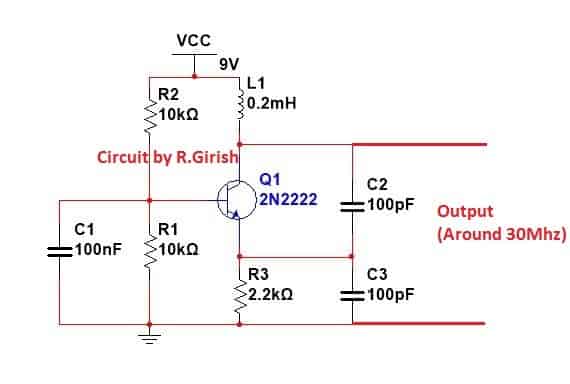

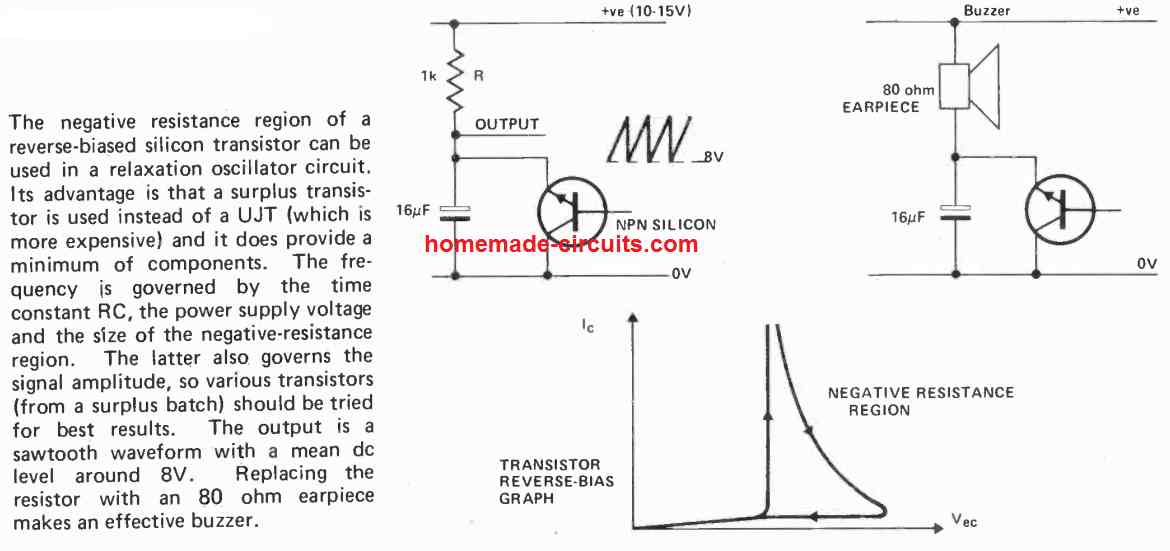

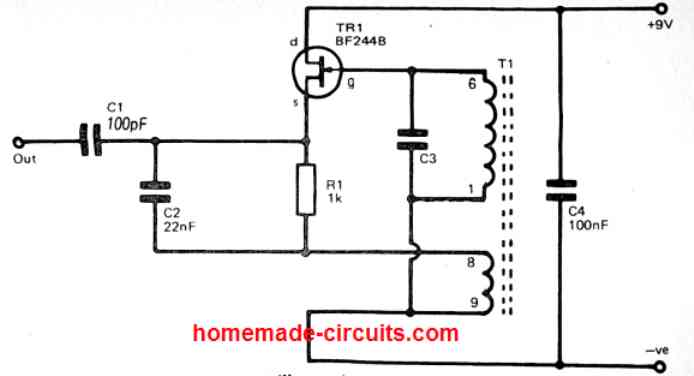

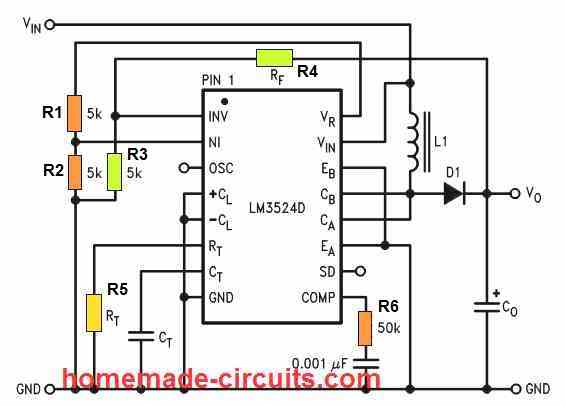

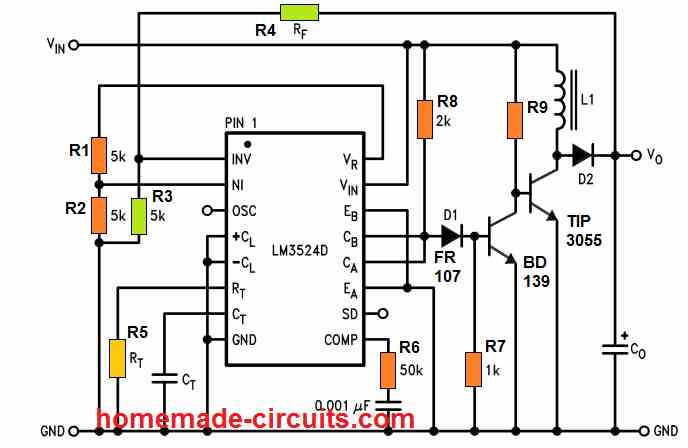

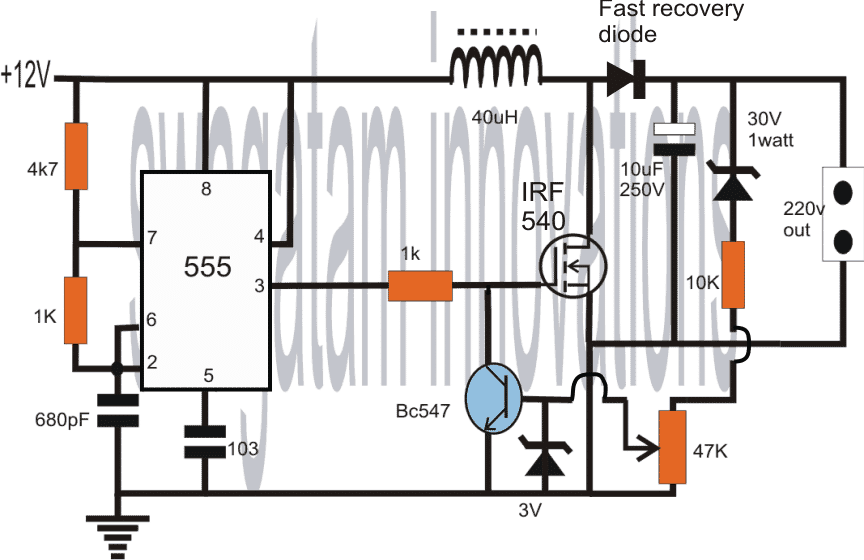

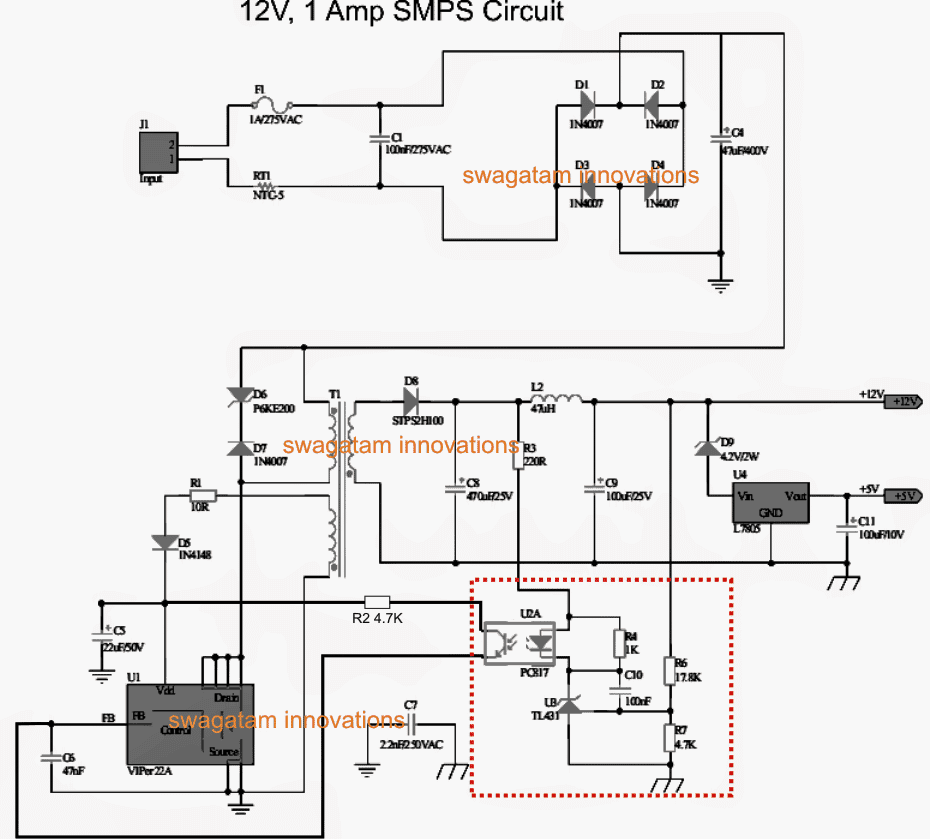

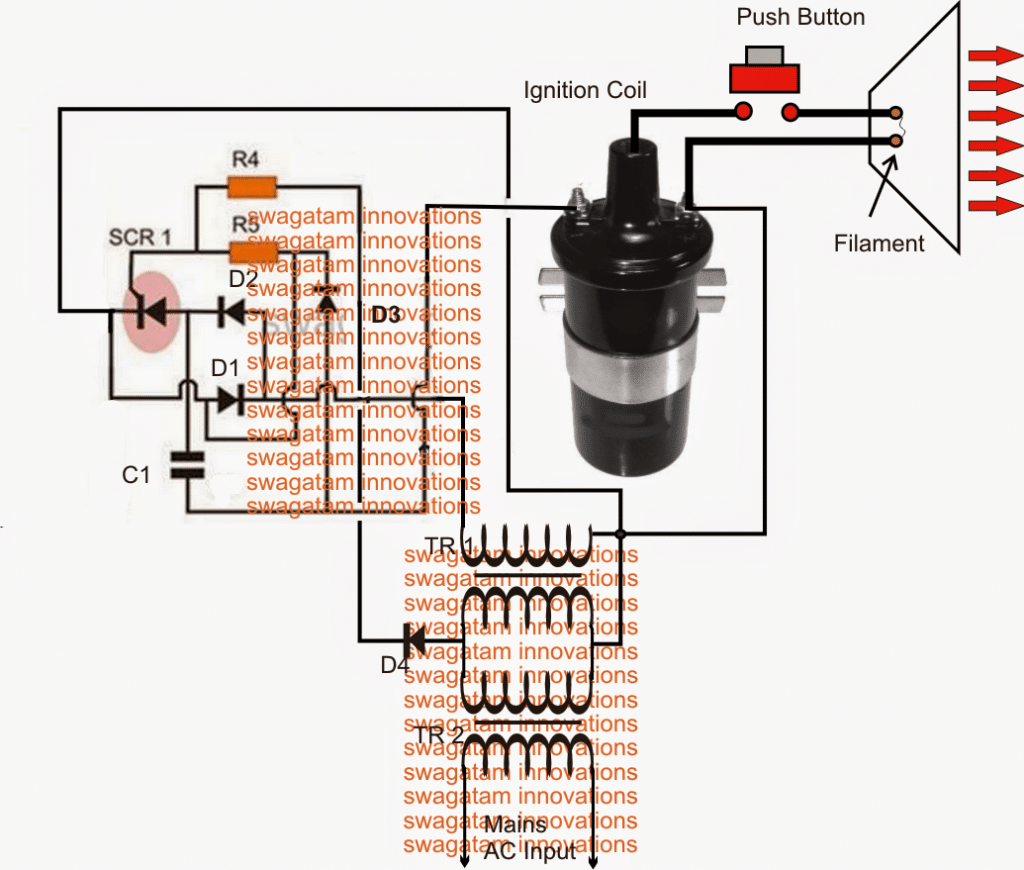

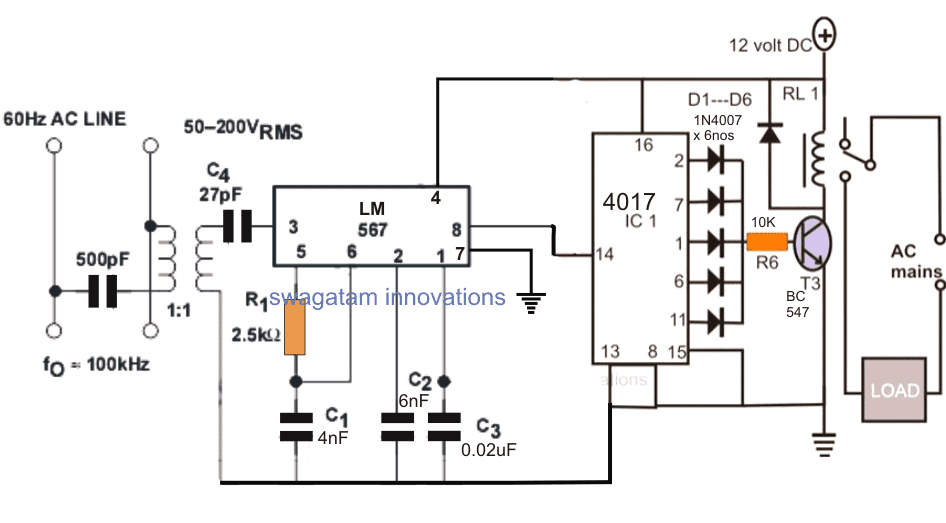

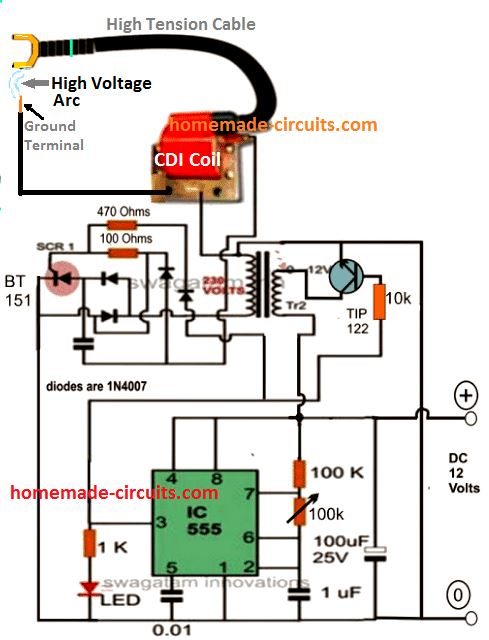

Simple TV Transmitter Circuit

The TV transmitter circuit presented in this post incorporates the European standard FM frequency for audio and Videoup-links. Referring to the circuit below, Q1 is configured as a preamplifier for amplifying the audio input to be modulated.Circuit Description

Q2 is fundamentally responsible for conducting a couple of important functions: It amplifies the carrier frequency generated by the tank circuit, and also modulates the input over this carrier waves. The preamplified audio signals from the Q1 stage is fed to the Q2 stage at its base for the intended modulation actions. As we know all transmitter circuits require a conventional "tank" circuit involving an inductor and few capacitors for generating carrier waves.Here too a tank circuit becomes imperative and is formed by the insertion of C5, L1. This network essentially generates the crucial carrier waves. The video signal which needs to be superimposed with the audio signal is applied to the emitter of Q2 through the variable resistor R7 for implementing the intended modulation process. The composite signal (audio/video) after modulation via the Q2 and the tank circuit stages is further applied to the connected antenna A1 for the final transmission into the atmosphere so that it can be received by a particular TV set in the vicinity. The proposed TV transmitter circuit requires a well regulated stabilized 12V supply for operating. Preferably a 12v battery would give better results due to a muchcleanerDC free from all possible ripples and noises.Circuit Diagrams

Some Important Points:

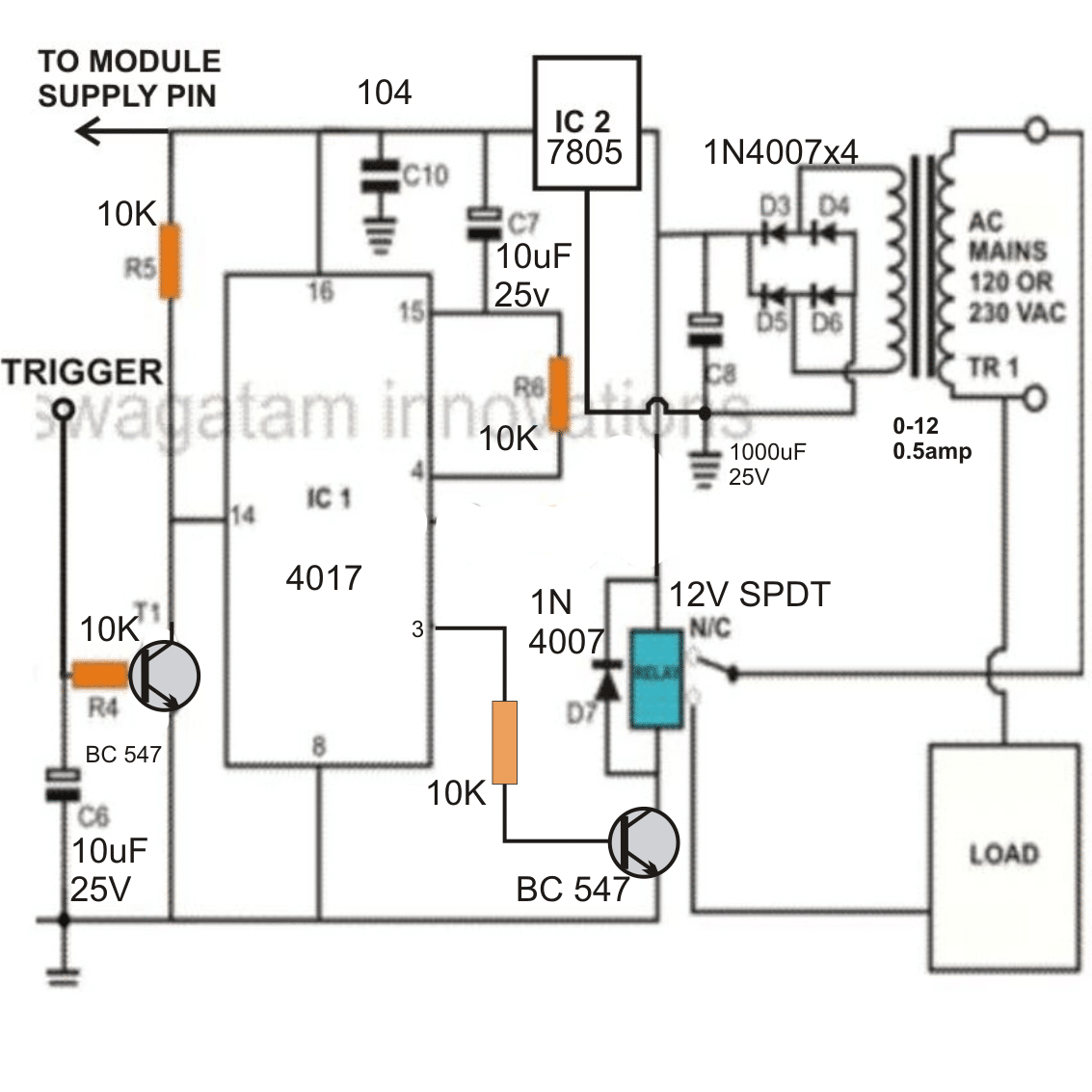

Things you need to consider while building this TV transmitter circuit at home: Preferably use a well designed glass epoxy PCB for this project. For the inductor L1 use a super enameled copper wire of 24SWG and wind 4 turns with 6mm diameter over any non conducting former such as paper or plastic. T1 may be replaced with any standard audio transformer the type which were commonly used in olden transistor sets and radios at the output amplifier stage. The antenna is not much critical, can be any good conductor of electricity, around a foot long, such as a copper wire. You may try different lengths until you get the optimal response from the TV transmitter circuit. The operating frequency of this unit could be within 50 and 210MHz.Thecompatibilityof this circuit is well with PAL B/C systems. You may have some fun with C8 which may be tweaked a bit for acquiring extreme accuracy with the performance of the circuit.Simple Adjustable Industrial Timer Circuit

The post discusses a simple and effective industrial timer circuit which can be universally used for most industrial and home timer based applications. The idea was requested by Mr. Vasilis K.Technical Specifications

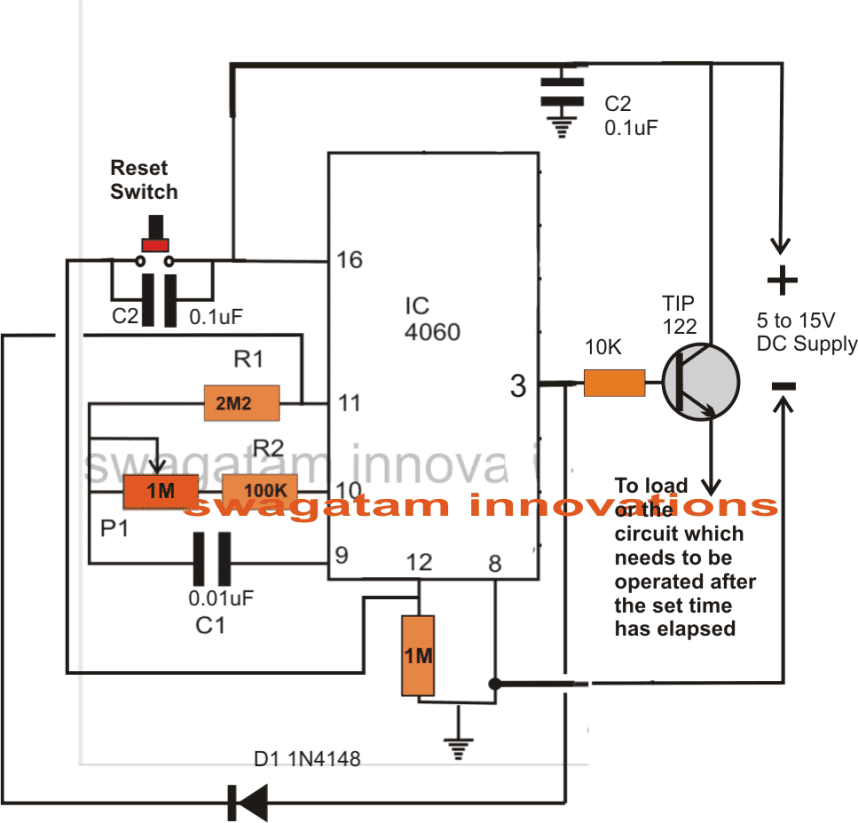

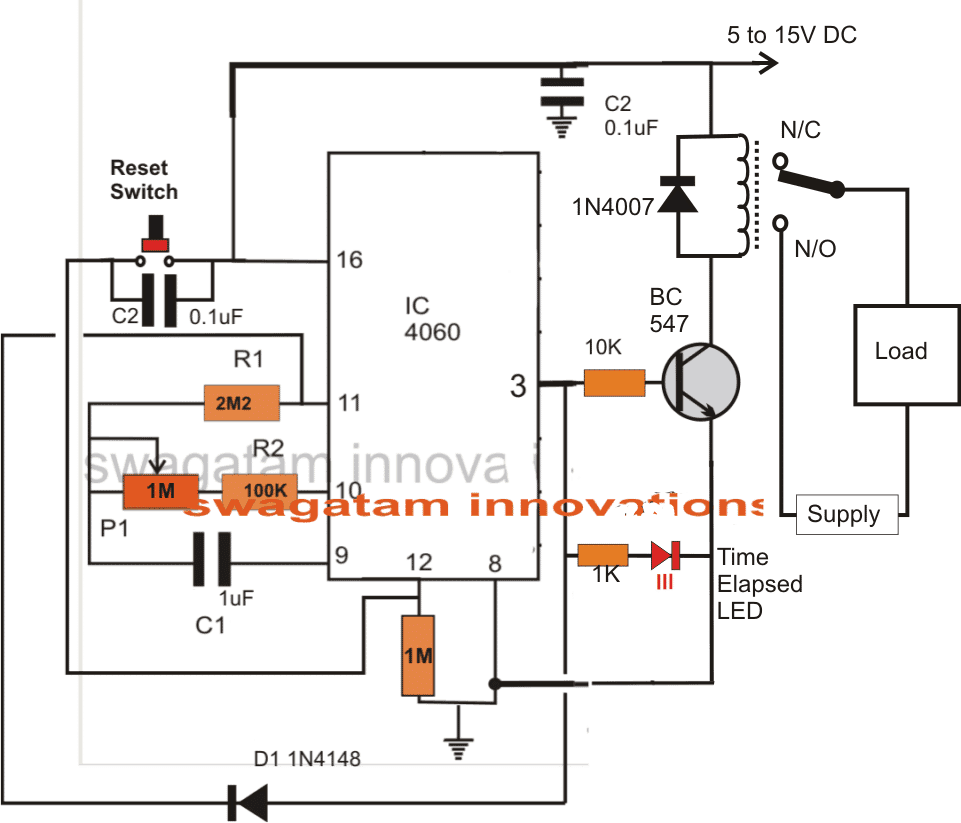

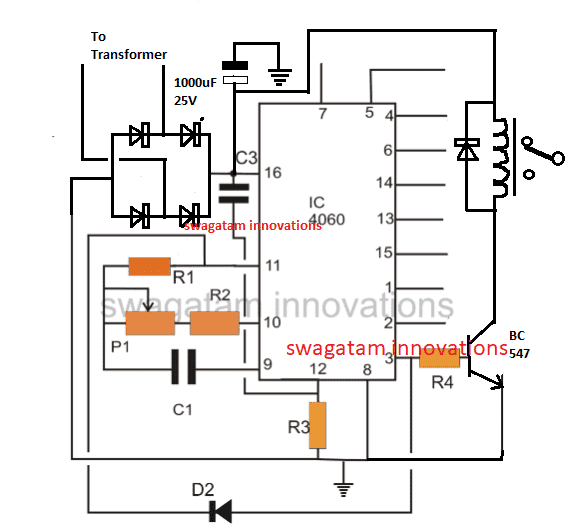

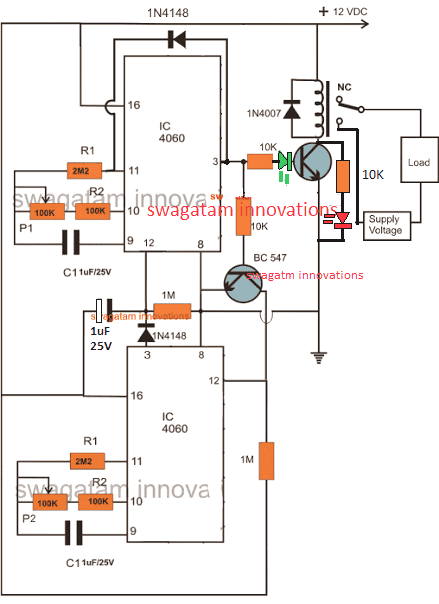

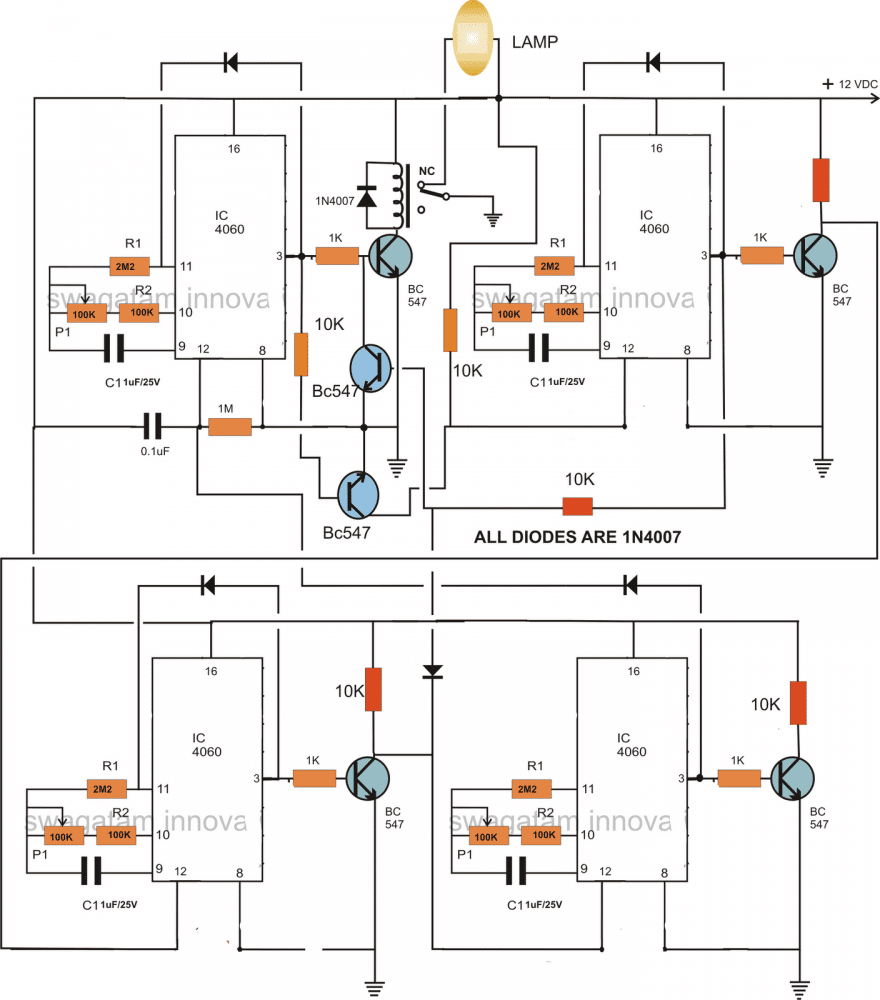

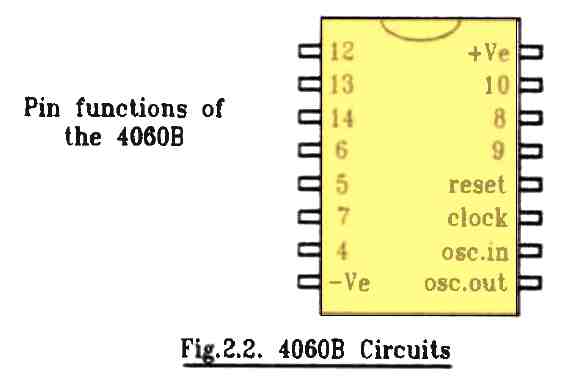

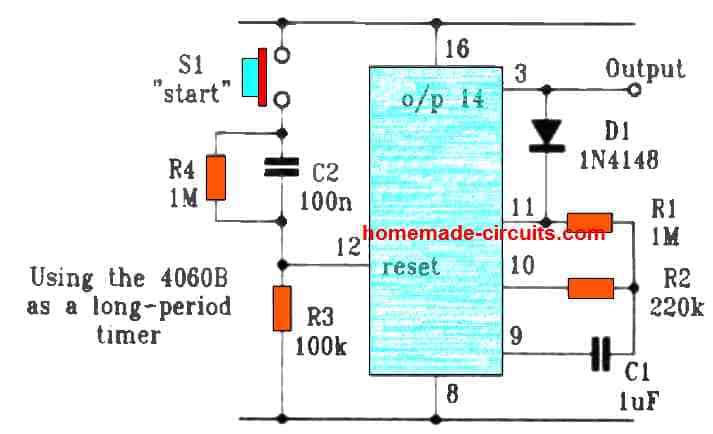

I have a question regarding the 4060 ic wired as "one shot timer." If it can power on the two monostables from the pellet burner circuit, output will be taken from pin #3 which is the last to count to the C1 stage, will that work? When power is applied to the circuit, the first 2 stages should stay low until the time has elapsed. Pin #3 should be set to activate the cycle, so when I leave home in the morning, I will be starting the timer via the thermostat. Then when I get home, the burner should be running. To be more precise, as per the circuit design there are 2 monostable circuits (Stage 1&2) when power is applied via a room thermostat it activates the cycle (Stage 1&2), My request is when power is applied after the predetermined time of the 4060 has elapsed, is to activate the cycle (Stage 1&2), as there is no need for the burner to run when no one is around, plus this would be ideal as it takes about an hour for the water temperature to reach at 75 Celsius.The Design

The IC 4060 is an excellent option when it comes to any timer based industrial or home project. This chip being a CMOS device is highly accurate, and is able to generate time delay periods of as high as upto 10 hours with reasonably good accuracy, after this limit the accuracy tends to drift a bit. Although the IC 4060 generates a fixed 50% duty cycle astable type of oscillations at its various outputs, it can be configured as a one shot timer, as explained in the present article. Referring to the shown simple industrial adjustable timer circuit, we can see the IC being the central main component of the whole design. When power is applied or switched ON, C2 momentarily pulses pin#12 of the IC and resets the timing so that the internal oscillator begins counting from zero, moreover the IC can be reset at any moment during the counting period by pressing the given reset switch. While the IC counts, the output which is being used (pin#3 here) is held at a low logic level or a zero voltage, which keeps the TIP122 switched OFF Now as per the setting or selection of R2, P1 and C1, as soon as the set timing elapses, pin#3 goes high, switching ON the transistor and allowing the power to pass to the connected circuit, which now activates. The feedback diode from pin#3 to pin#11 instantly locks the internal oscillator and latches the circuit so that the circuit freezes in that position until the reset switch is pressed for initiating a new cycle.Circuit Diagram

For heavier loads, the above circuit may be upgraded with a relay for identical results but with much higher load current handling capabilities.

For heavier loads, the above circuit may be upgraded with a relay for identical results but with much higher load current handling capabilities.

Feedback from Mr.

Vasilis:

Feedback from Mr.

Vasilis:

Vasilis Karastergios

Hello swagatam!

TESTED & WORKING, really happy with the outcome, i used the 2nd circuit with the relay as i didn't have that specific transistor, that would be my last request for you, i hope i wasn't that much of a pain, again really thankful for all the help and effort, god bless you!!

Regards

Vasilis K.

Vasilis Karastergios

Hello swagatam!

TESTED & WORKING, really happy with the outcome, i used the 2nd circuit with the relay as i didn't have that specific transistor, that would be my last request for you, i hope i wasn't that much of a pain, again really thankful for all the help and effort, god bless you!!

Regards

Vasilis K.

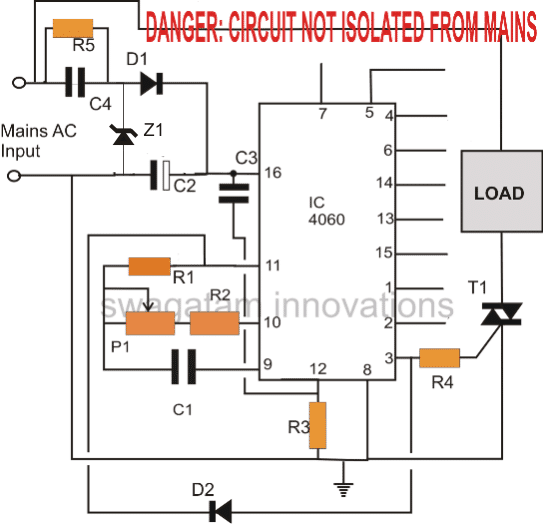

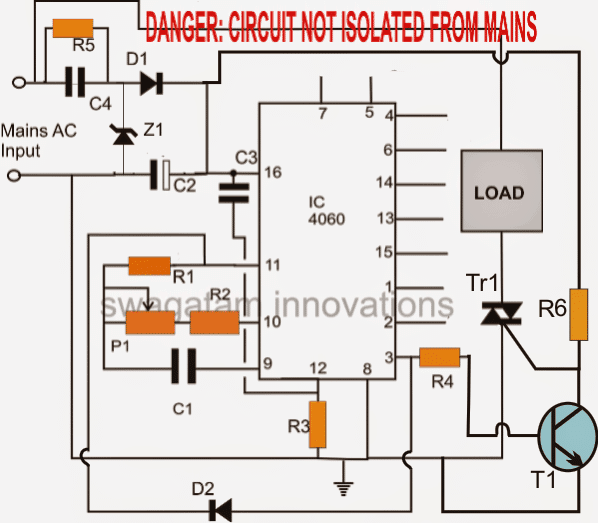

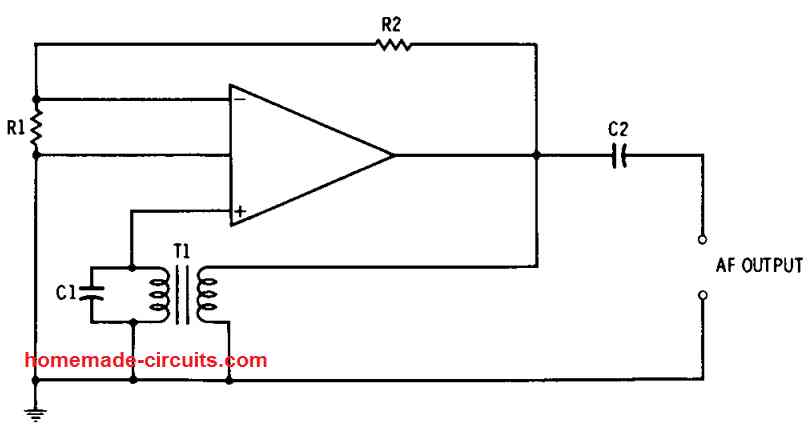

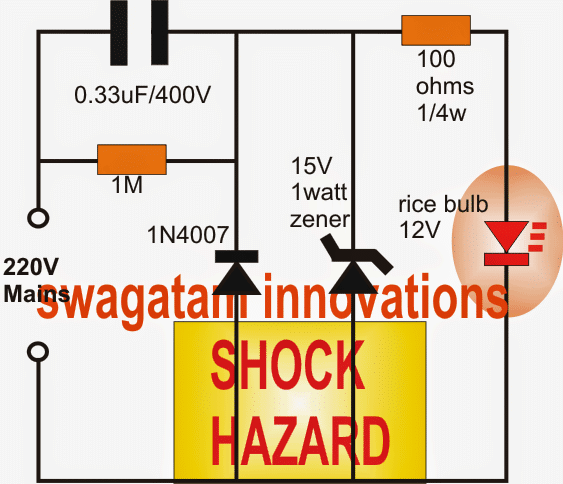

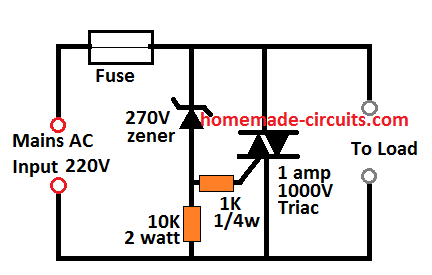

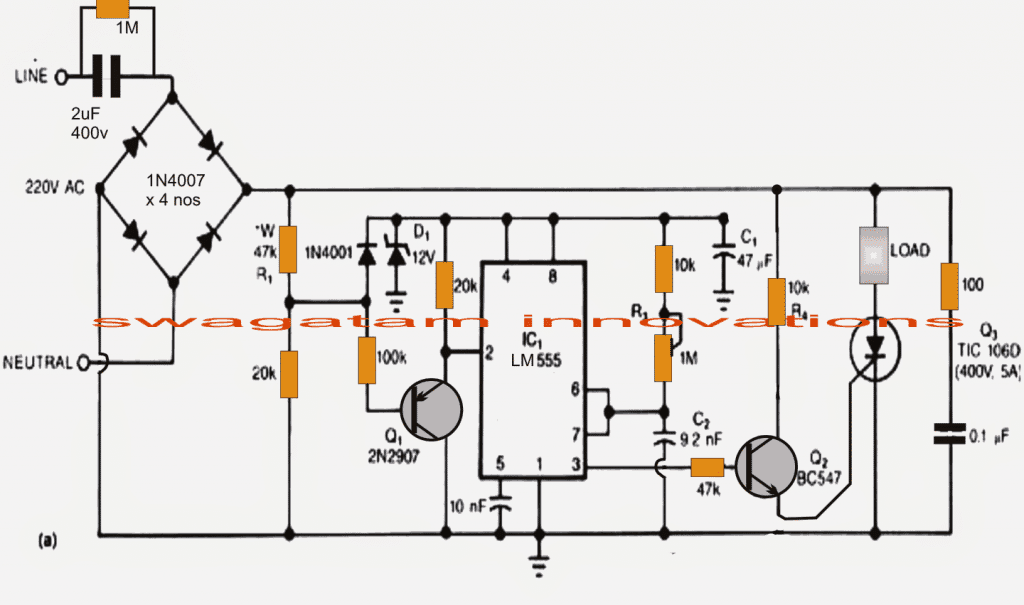

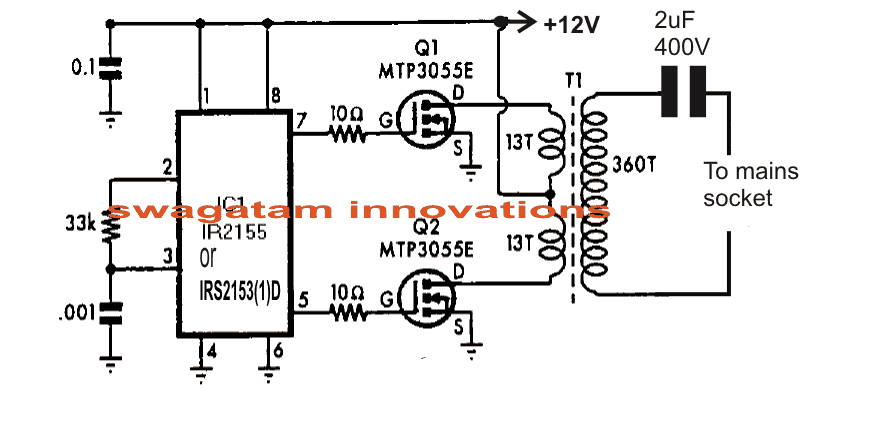

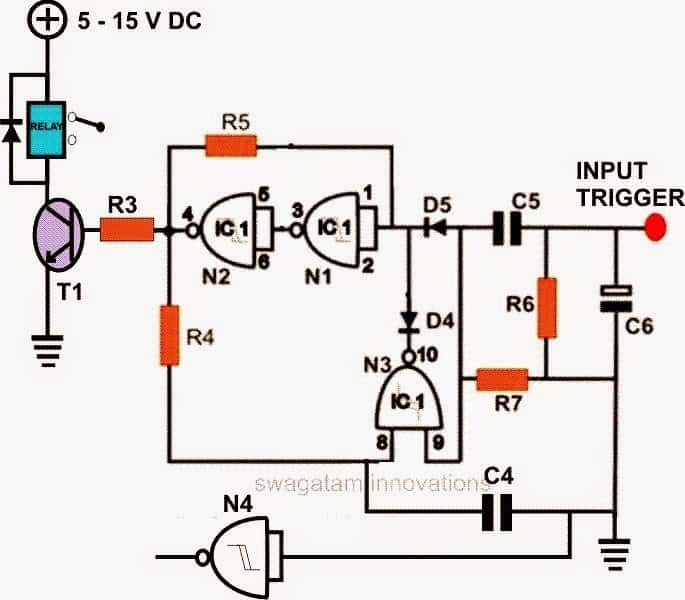

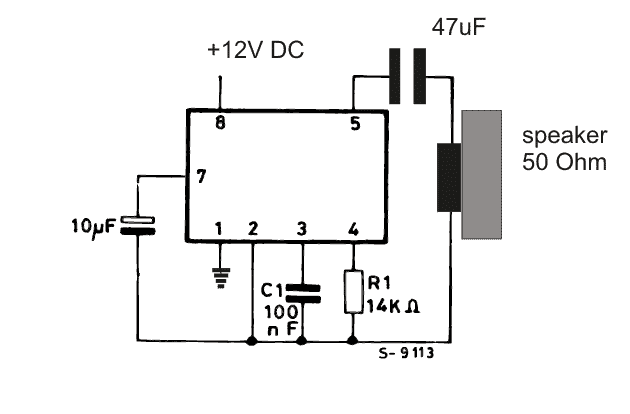

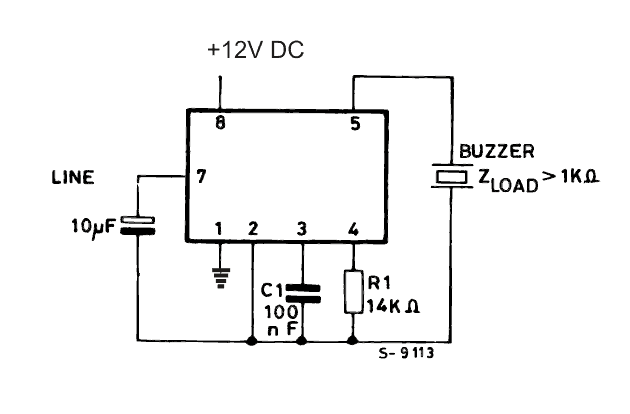

Simple Triac Timer Circuit

Here's a simple triac timer circuit which can be used for switching ON a particular device after a predetermined time, set through the given pot or the variable resistor. The shown circuit diagram of a simple triac timer can be understood by referring to the following explanation:How it Works

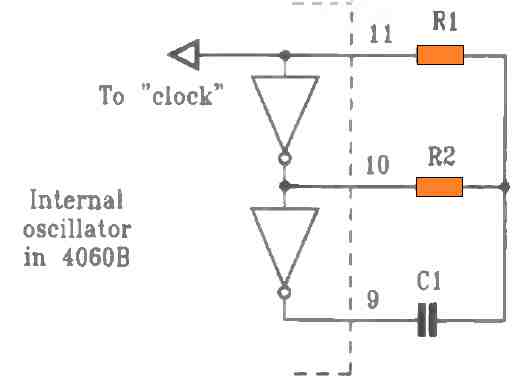

The left hand side section comprising the IC 4060 becomes the basic delay generator stage.As we all know, the IC 4060 is an extremely versatile time delay generator chip which has a built in oscillator for the required fundamental timing clocks. The components connected at the pin#9,10 and 11 form the time delay determining parts of the IC. Precisely, the resistor at pin#10 and the capacitor at pin#9 are responsible for fixing the delay period and may be adjusted for acquiring the required predetermined switching output. This IC has 10 discrete outputs which produce delays or oscillation periods which are twice to the previous pinout in the order. Here pin#3 produces the largest delay, followed by pin#2 and then pin#1 and so on as per the specified pinout order. So suppose pin#3 produces delay interval of 1 minute, then pin#2 would produce the same at an interval of 30 seconds, pin#1 at 15 seconds and so on. Since pin#3 is specified with the highest time interval, we use this pinout as the output. Therefore suppose we set the RC at pin#9 and 10 with a maximum delay of 2 hours, pin#3 would be assigned to generate alternately changing ON/OFF pulses, having equal delay intervals of 2 hours, meaning initially the output would be OFF for 2 hours, then ON for next 2 hours and so on as long as its powered. The above explains the IC 4060 configuration, now let's learn about the triac configuration. As we can see, the output pin#3 is directly connected to the gate of the triac, while the triac A1 and A2 are terminated with the load and the other specified parameters. When power is first switched ON, C3 at pin#12 of the IC4060 makes sure that the timing count initiates right from zero by resetting pin#12 with a short pulse. The output pin#3 now initiates with a logic zero output while the IC internal timer starts counting. Due to the logic zero, the triac stays switched OFF initially along with the load. Once the predetermined delay interval lapses, pin#3 instantly becomes high, triggering the triac and the load. The diode connected across pin#3 and pin#11 plays an important function of latching the IC counting process. If this diode is removed, the counting process will continue and after 2 hours the triac will be again become switched OFF, and this procedure will go on repeating every after 2 hours. The diode shuts off this operation, and lathes the IC to the ON position permanently. The above situation provides us with another interesting application of the proposed circuit, by removing the diode we can convert the above circuit into an AC lamp flasher circuit, the flashing rate being set by the RC components. Also note that irrespective of the RC parts you have the option of selecting/connecting the remaining outputs of the IC with the triac gate for getting a diverse range of time delays.Circuit Diagram for Delay ON Timer

The above triac controlled timer circuit becomes suitable for applications which requires a delay switch ON.

For applications which require a delayswitchOFF meaning in cases where a load needs to beswitched off after a predetermined time interval, the above circuit can be modified as given below:

The above triac controlled timer circuit becomes suitable for applications which requires a delay switch ON.

For applications which require a delayswitchOFF meaning in cases where a load needs to beswitched off after a predetermined time interval, the above circuit can be modified as given below:

Circuit Diagram for Delay OFF Timer

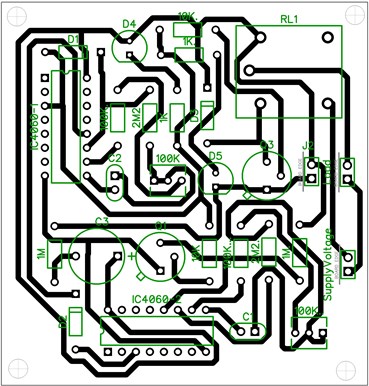

PCB Layout

Parts list for the above simple triac timer circuit

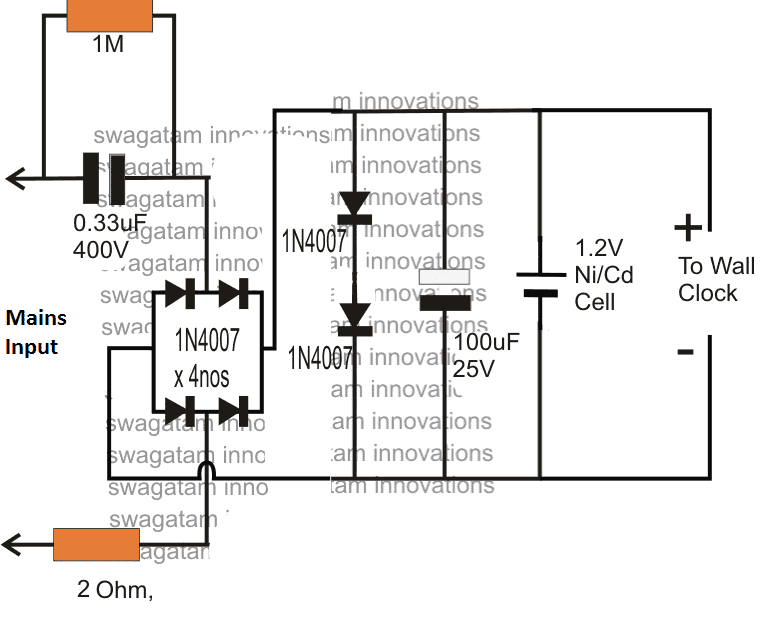

R1 = 2M2 R3 = 100K R2, R4, R6 = 1K R5 = 1M C1 = 1uF/25V (must be non-polar, use more in parallel for higher delays) C3 = 0.1uF disc C2 = 100uF/25V C4 = 0.33uF/400V Z1 = 15V 1watt zener Tr1 = BT136 T1 = BC547 D1, D2 = 1N4007 P1 = 1M potUsing a Transformer DC Supply

The above simple timer circuit can be also built using a transformer DC supply, as shown below: All diodes are 1N4007, and the relay is 12V/400 ohm, 10 amp

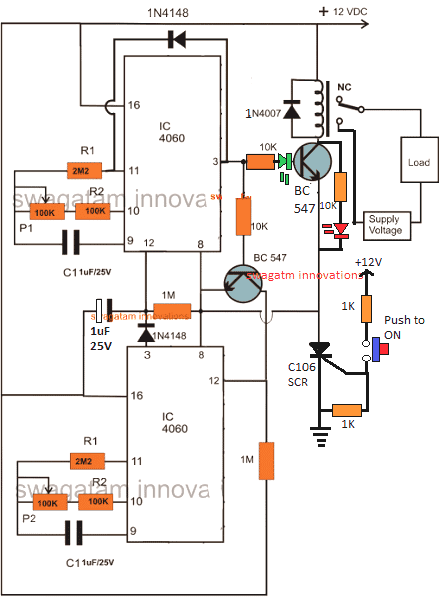

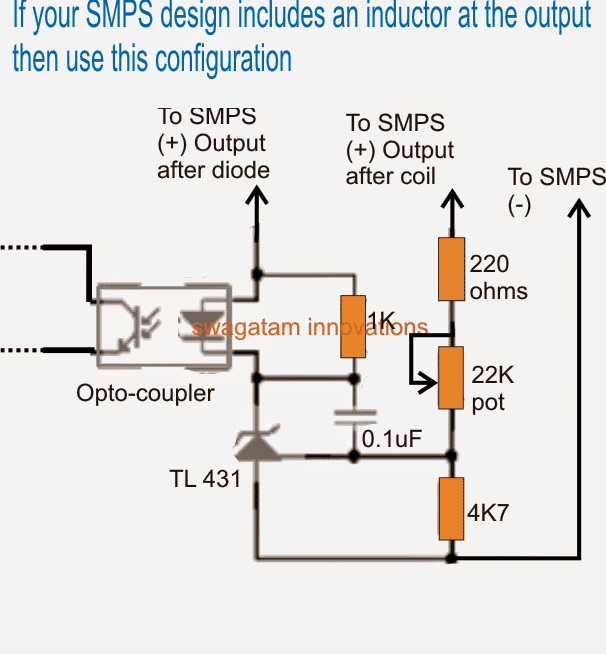

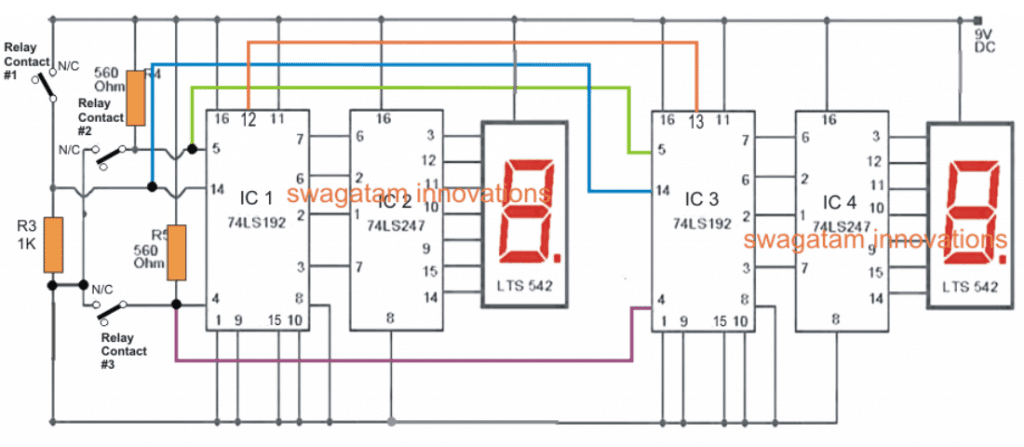

Simple School Bell Timer Circuit using IC 4060

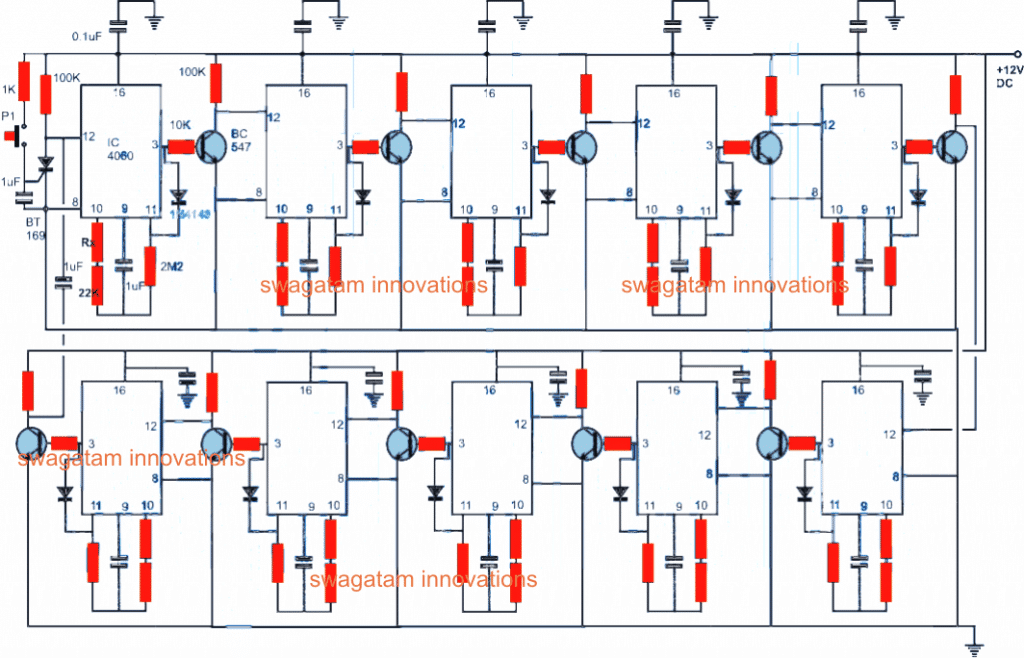

The post explains a very simple 10 stage long duration programmable timer circuit which can be used as a school bell timer circuit. All the 10 stages can be individually programmed from zero to 5 hours. The circuit can be modified in many different ways to suit other specific related applications. You may be also interested in a IC 4017 based School Bell systemThe Circuit Concept

Normally in most of the schools even today the period bells are rung manually by the concerned staff or the peon. Although the job is quite traditional and is carried out without much difficulty and reasonably accurately, the concerned person has to be always on a stand by position for implementing the actions. However with the help of a simple electronic circuit the above implementations could be made fully automatic, eliminating human intervention, thus saving a lot of inconvenience and time. The functioning of the proposed automatic school bell period timer circuit may be understood with the following points:Circuit Operation

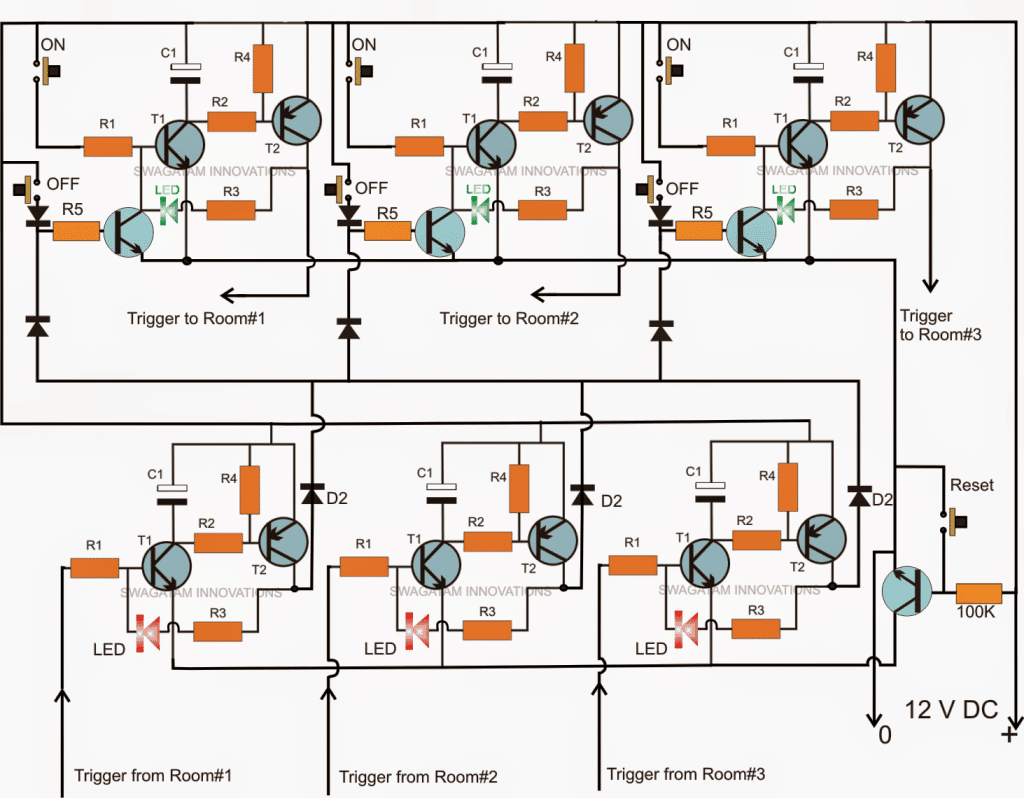

At the first glance the circuit might look quite complex, but seeing it closely shows that actually it's very simple, just a repetition of identical stages for the required number of times. We'll try to understand the top left stage and that will clarify the entire circuit within no time. The circuit is based on the timer/oscillator chip 4060. It's wired in its usual timer/counter mode with the help of the resistors and capacitors fixed over its pin#9, 10,11. Rx determines the time period for which the IC counts until its pin#3 becomes high. The value of this resistor may be determined through trial and error for acquiring the required time intervals for all the relevant subsequent stages. The design is repeated for all the stages. However the top left stage being the first power switch ON stage is rigged with additional components. When the push button P is pressed, the SCR latches, grounding pin#12 of the IC. This initiates the counting procedure within the IC. After the predetermined time lapses, pin#3 of the IC goes high and also the stage gets latched via the diode connected to pin#11. With pin#3 high, the associated transistor pulls pin12 of the next stage to ground, which in turn initiates the counting of the second stage. The procedure is repeated exactly the same way for the second stage also, and consequently all the corresponding stages get activated serially one after the other as per the set time for the individual stages. When the the time period for the last stage is elapsed (bottom left), the transistor at pin#3 momentarily grounds the anode of the SCR via the 1uF capacitor switching off the SCR and the entire circuit. The situation resets the whole circuit to its original state, until the push button is pressed the next morning for initiating yet another cycle. The second circuit shows the driver stage which is responsible for ringing the AC bell in response to the triggering of each subsequent stages in the given order. The diode ends are connected to pin#12 of the different stages. The moment these pins are pulled to ground by the BC547 transistors, sends a momentary biasing to the BC557 transistor which in turn activates the connected relay and the load for a brief period of time depending upon the values of the transistor base resistor and the capacitor (chosen arbitrarily here)

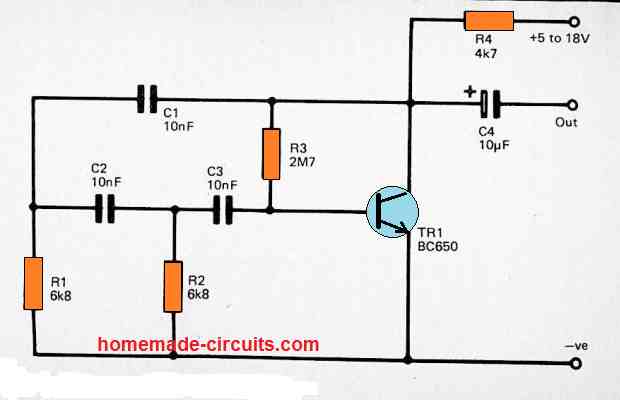

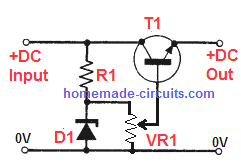

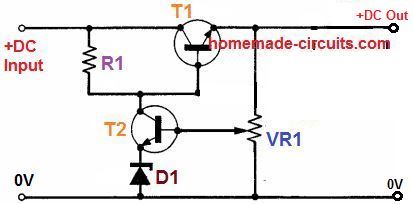

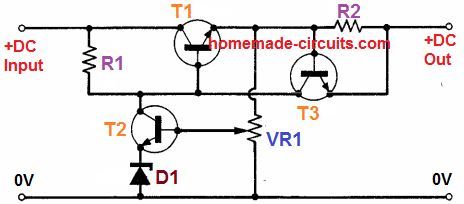

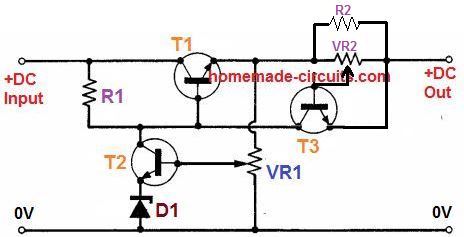

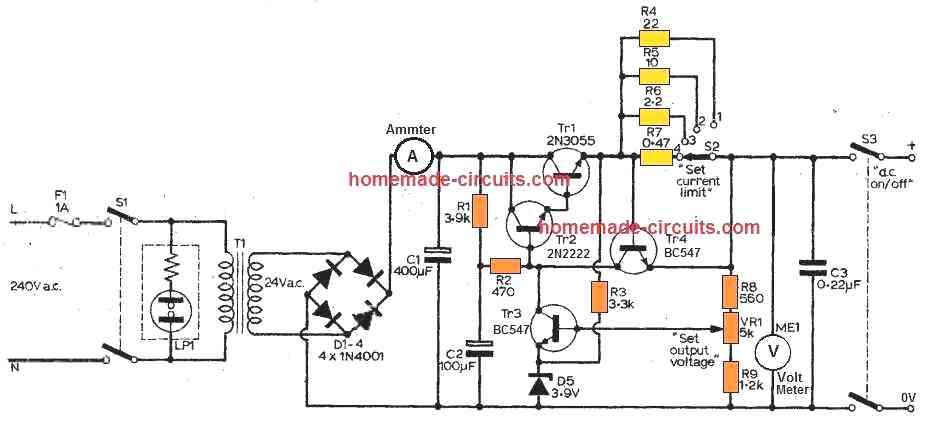

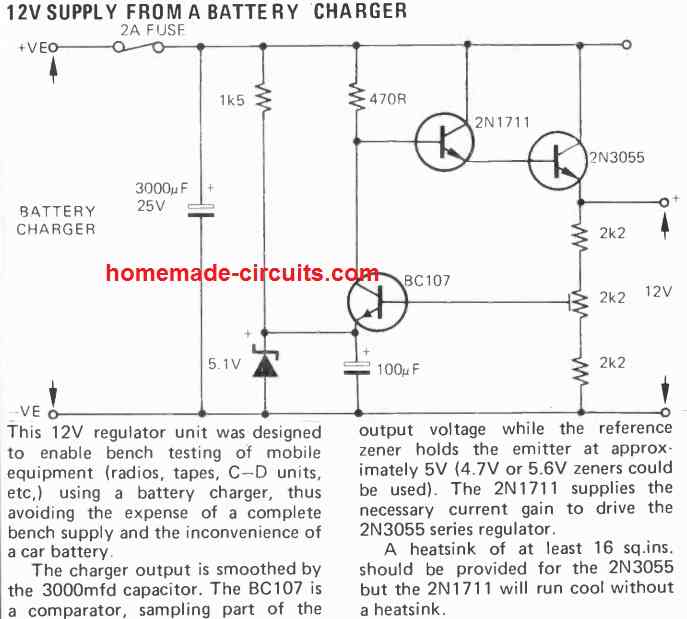

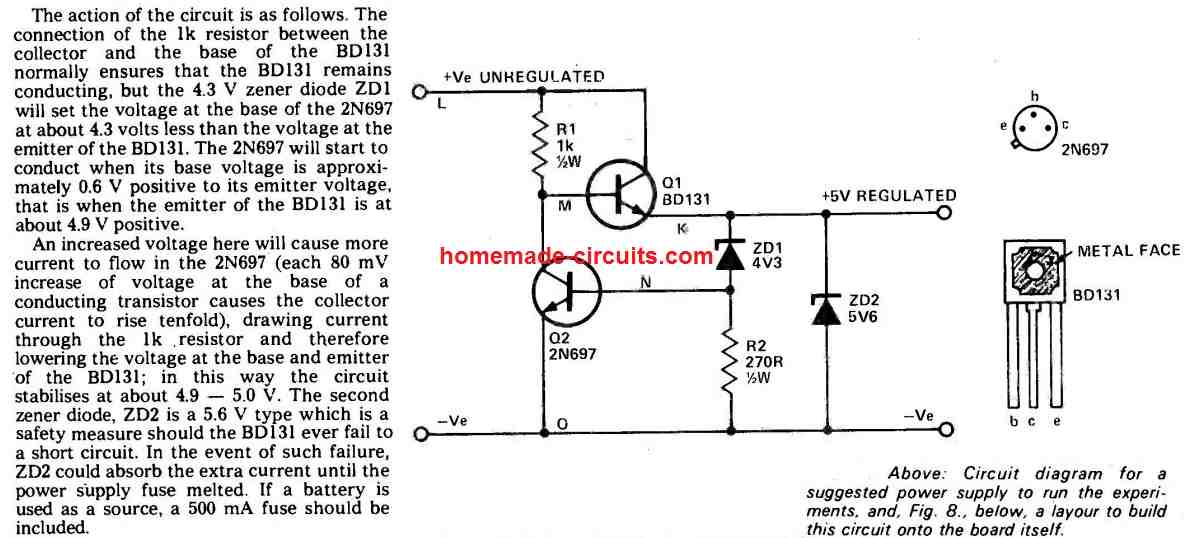

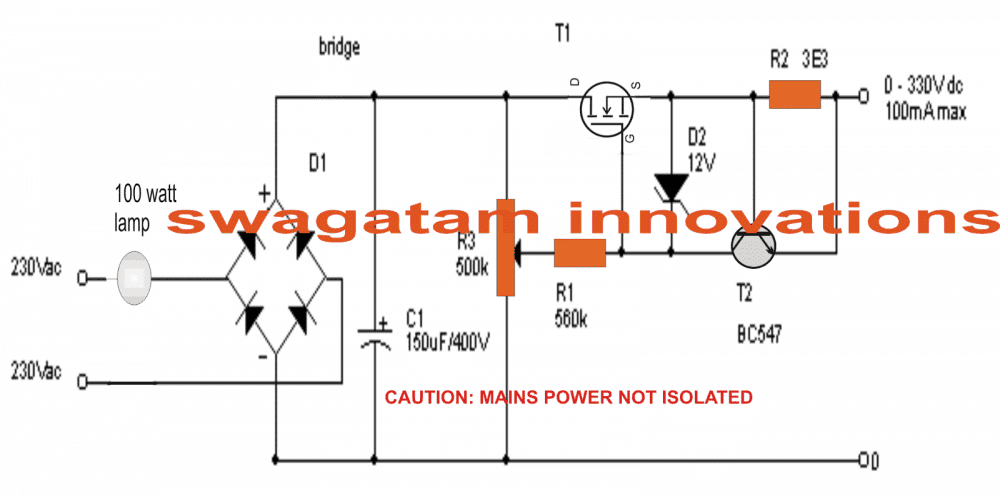

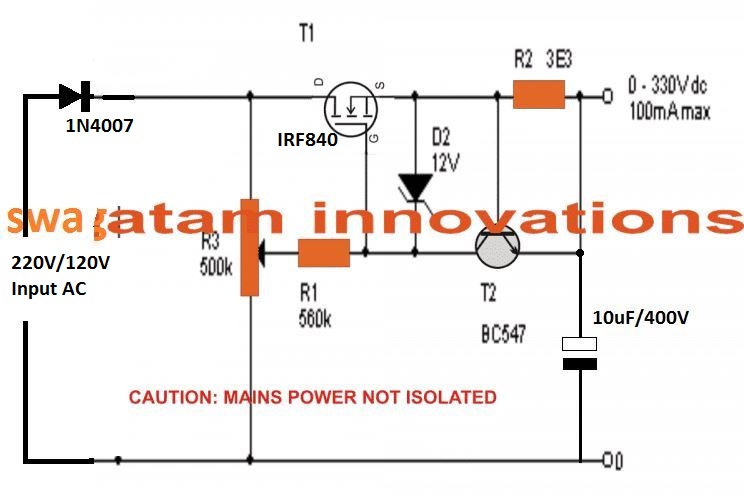

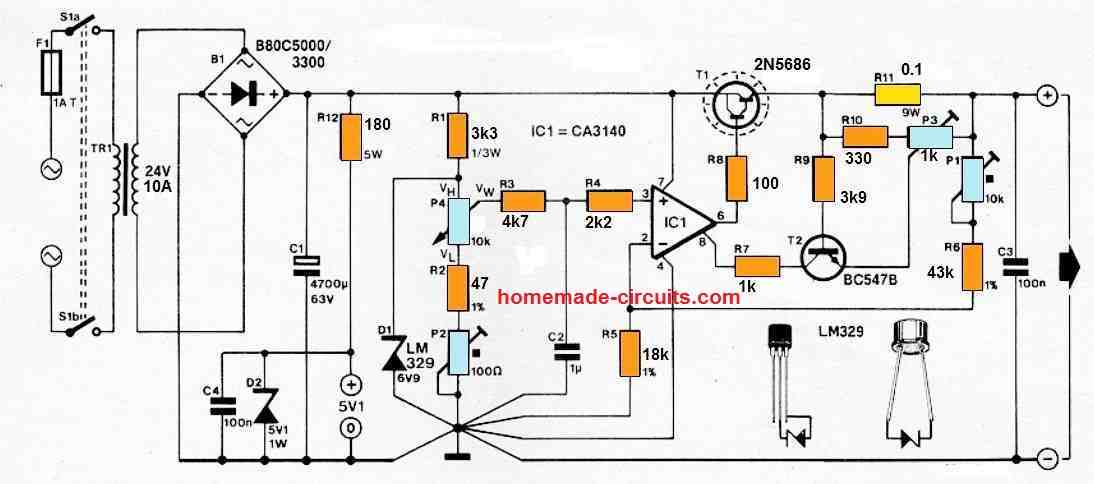

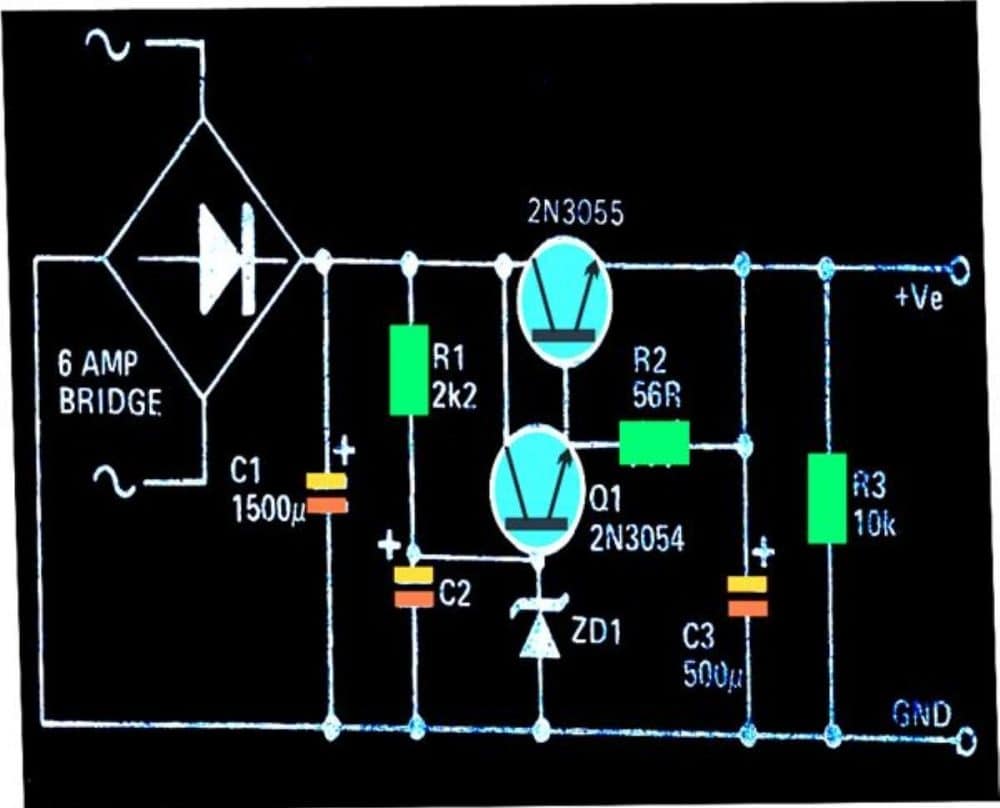

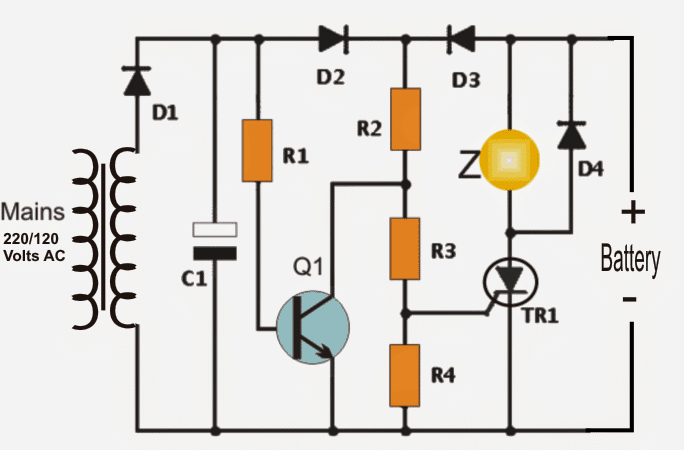

Simplest One Transistor Regulated Power Supply Circuit

The article explains a simple variable regulated voltage power supply circuit which utilizes just a single transistor. The design can be very handy for the new electronic hobbyistMain Features

The explained power supply includes an adjustable voltage feature which is an essential feature for every electronic enthusiast. However making one such power supply within minutes using a handful of components might look difficult. The circuit of a simple variable voltage power supply using just a single transistor referred here shows us how to build one such unit quickly using common parts from your junk box. This single BJT regulated Power Supply is easy to construct. It takes less than an hour on a piece of copper-laminate. All the components can be mounted as show in the aforesaid diagram, cutting the strips for placement. Moreover the board also acts as a heat-sink. Enamelled wires are used to connect the components and the transistor gets bolted to the board, acting as a cooling agent.Circuit Operation

The circuit is designed for use with old C," "D", and even lantern batteries. That*s the reason for no diodes or electrolytic. Get some old batteries and connect together to receive 12v 每 14v, at least. The power for this output is controlled by a 10v zener, made by following the characteristic of zener voltage of 8.2v in between the base-emitter leads of a BC547 transistor, in a reversed bias, and 1.7v approx. across one Red LED. The circuit is designed to deliver 0v-9v at 500mA. However the deliverance depends upon the life of the cells being used. The 10k pot works to adjust the output voltage and thereby the LED circuit goes in ON state. A good part is that the circuit is well designed to fetch the last leg of energy from old cells. Submitted By: Dhrubajyoti BiswasCircuit Diagram

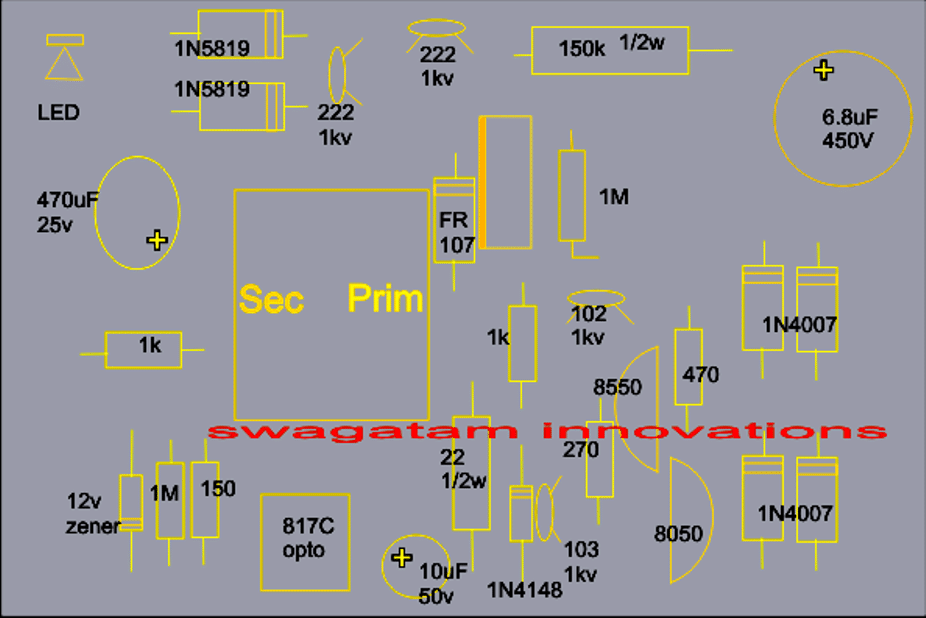

Simple Solar Garden Light Circuit 每 With Automatic Cut Off

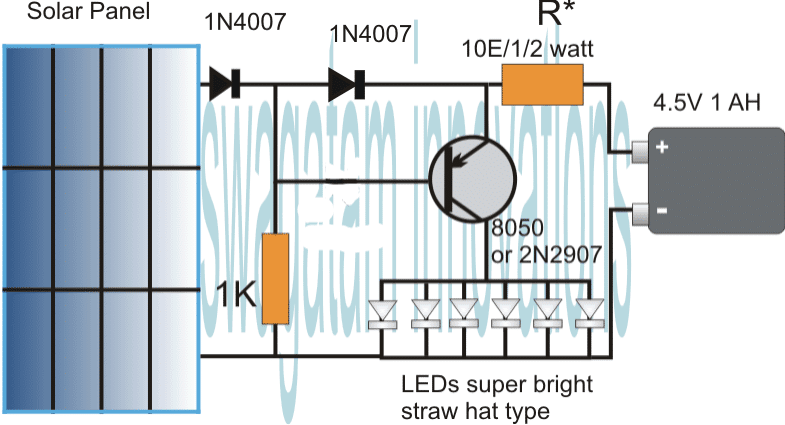

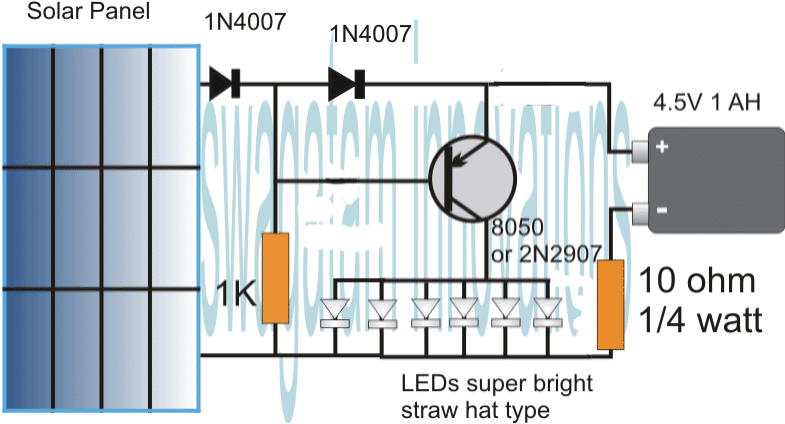

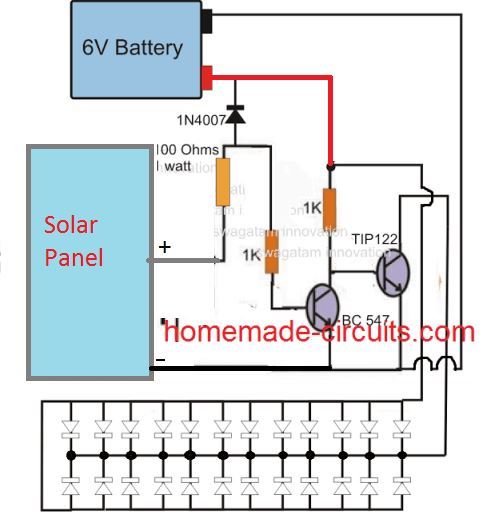

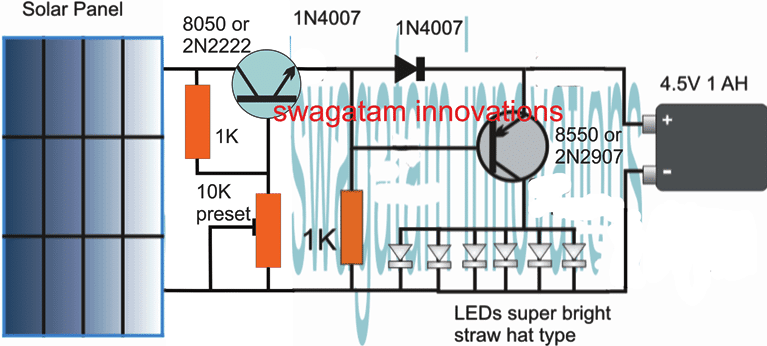

A very simple automatic solar light system for illuminating your garden passages can be built using some LEDs, a rechargeable battery and a small solar panel. The system automatically switches ON the lamps at dusk and switches them OFF at dawn.How it Works

The circuit design is extremely straightforward and may be understood with the following points: As can be seen in the given circuit diagram, the design basically consists of a solar panel, a PNP transistor, few LEDs, a battery and a few resistors. The transistor is the only active component which is positioned as a switch for preventing the battery voltage from reaching the connected LEDs during day time. During broad day light, the solar panel produces the required amount of voltage which is applied across the rechargeable battery via the 1N4007 diode and the resistor R*. This voltage charges the battery gradually from dawn to dusk.Selecting the Current Limiter Resistor

The resistor R* value should be adjusted as per the specs of the battery for limiting excessive current to it. The resistor also serves as the current limiting resistor for the connected LEDs when the transistor is switched ON. Here it hasbeencalculated as 10 Ohms. As long as the solar panel generates the optimal amount of power, the positive potential at the base of the transistor keeps it switched OFF. However when dusk sets in the solar voltage begins to drop, and when it drops below the zener diode rating, the transistor slowly starts conducting, illuminating the LEds gradually. With complete absence of sun light or when its completely dark, the transistor conductsfullywith the help of the 1K resistor, and produces full brightness over the LEDs. The next morning, thecyclerepeats all over again. The circuit can be modified in many different ways.Circuit Diagram

The above diagram may also be built in the following manner.

It looks more sensible now as the resistor is removed from the emitter for facilitating efficienttriggering of the transistor.

The above diagram may also be built in the following manner.

It looks more sensible now as the resistor is removed from the emitter for facilitating efficienttriggering of the transistor.

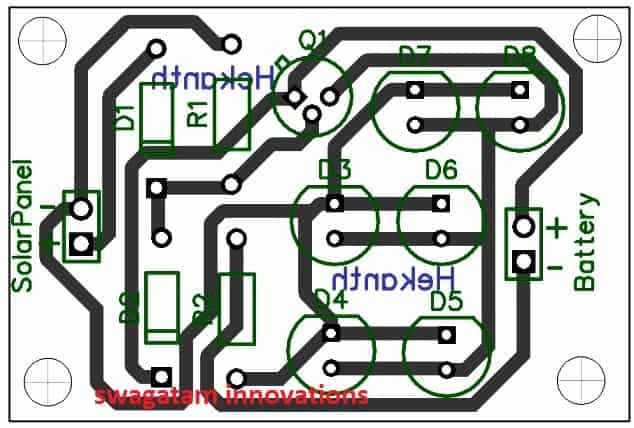

PCB Design

Pictorial Diagram

Parts List

The diagram shows an incorrect transistor number (8050), use 8550 instead.

Recommended Solar Panel Specs

6 to 8V/2 watt

Voltage - 6V

Current - 330 mA

Pictorial Diagram

Parts List

The diagram shows an incorrect transistor number (8050), use 8550 instead.

Recommended Solar Panel Specs

6 to 8V/2 watt

Voltage - 6V

Current - 330 mA

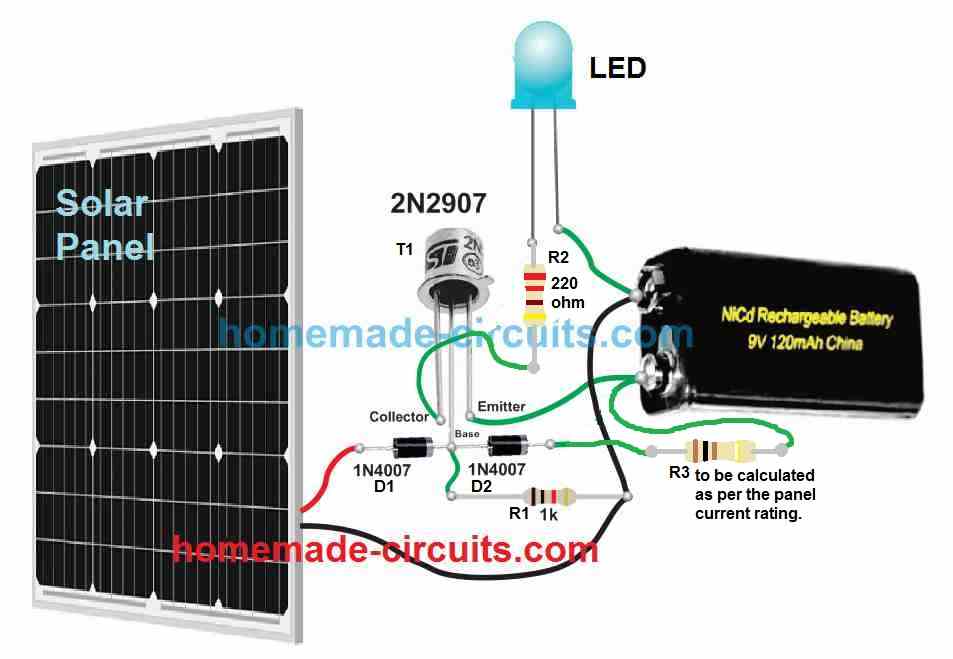

Using a 9 V Battery and High Bright White LED

The next shows an elaborate yet simple solar garden light diagram in pictorial form R2 is the LED current limiting resistor which can be calculated using the following formula: R2 = Battery Voltage - LED Fwd Voltage / LED Current R3 is the charging current limiter resistor for the battery, and it can be calculated using the following formula: R3 = Solar Panel Voltage - Battery Voltage / 10% of Battery mAH Rating The battery voltage must be at least 3 V higher than LED voltage. The panel voltage must be at least 3 V higher than the battery voltage.

Using NPN Transistors

The above explained designs can be also replicated using two NPN transistors as shown in the following diagram:

Solar Pathway Light Circuit with Constant Voltage

If a Li-Ion battery is intended to be used for the above explained circuit, a constant voltage feature becomes crucial for safeguarding battery life and prolonging it. The following circuit show how this may be done by adding a simple voltage follower regulator circuit: If a 3.7V Li-Ion battery is used, make sure to adjust the 10K preset to achieve precisely 4V across the output points where the battery is supposed to be connected, do this adjustment without connecting the battery.

The 4V level ensures that the battery is never overcharged (at 4.2V) and this also allows the circuit charge the battery without a constant current supply.

If a 3.7V Li-Ion battery is used, make sure to adjust the 10K preset to achieve precisely 4V across the output points where the battery is supposed to be connected, do this adjustment without connecting the battery.

The 4V level ensures that the battery is never overcharged (at 4.2V) and this also allows the circuit charge the battery without a constant current supply.

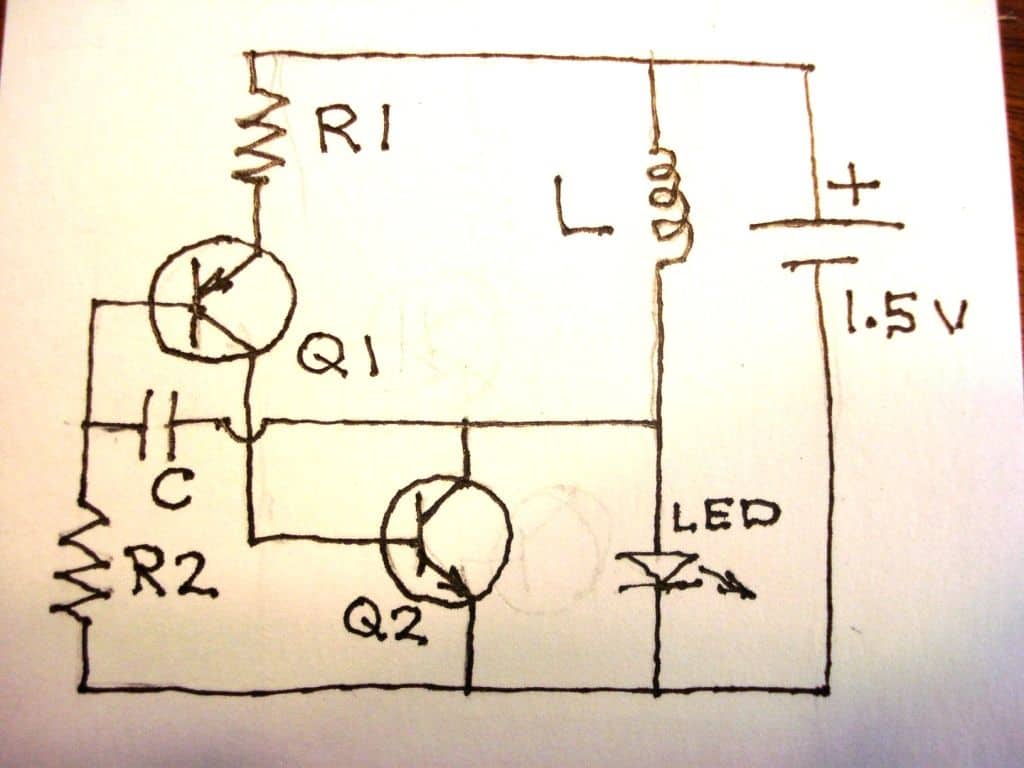

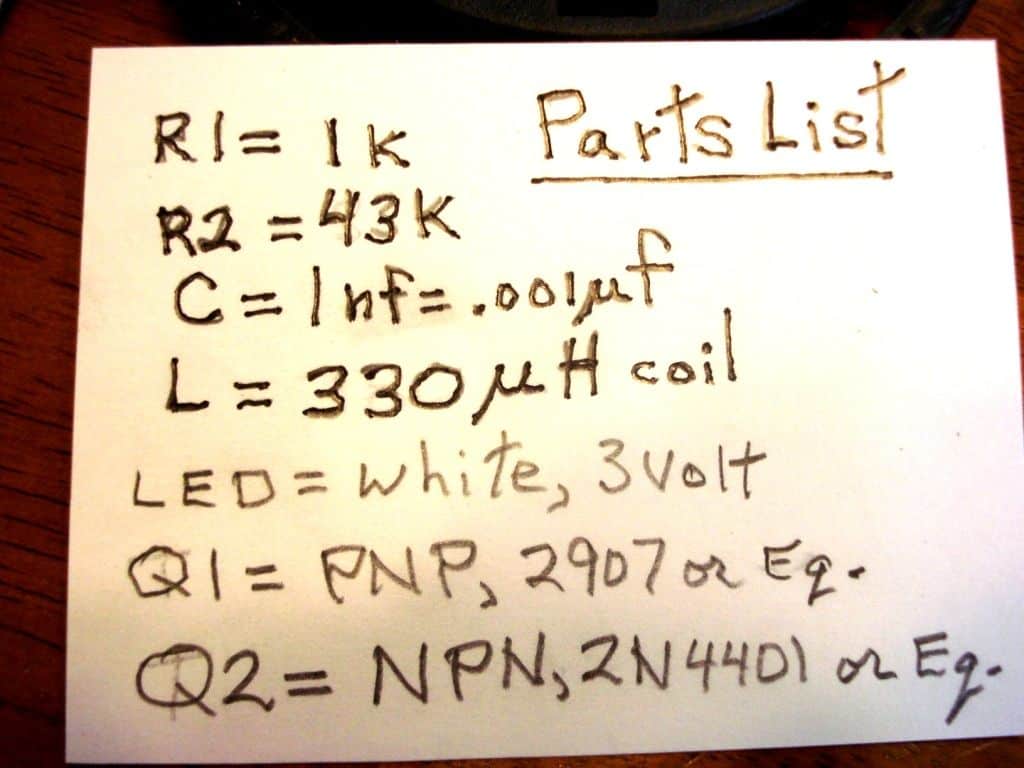

1.5V Solar Garden Light with Enhanced Features

The following solar powered garden light was designed by Mr. Guido which includes additional features such over charge and low charge cut off for the battery and with a Schmidt trigger. This ensures that the connected battery is never allowed to charge or discharge beyond unsafe levels. The main attraction of the circuit is the use of a single rechargeable AAA penlight cell, which is able to light up a 3.3V high bright LED through an attached Joule thief circuit.

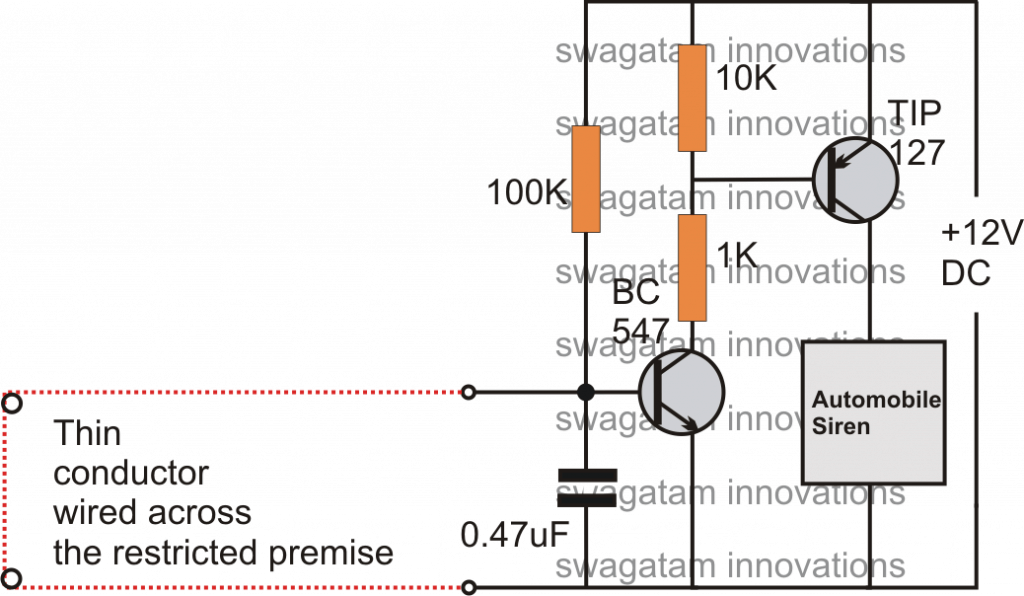

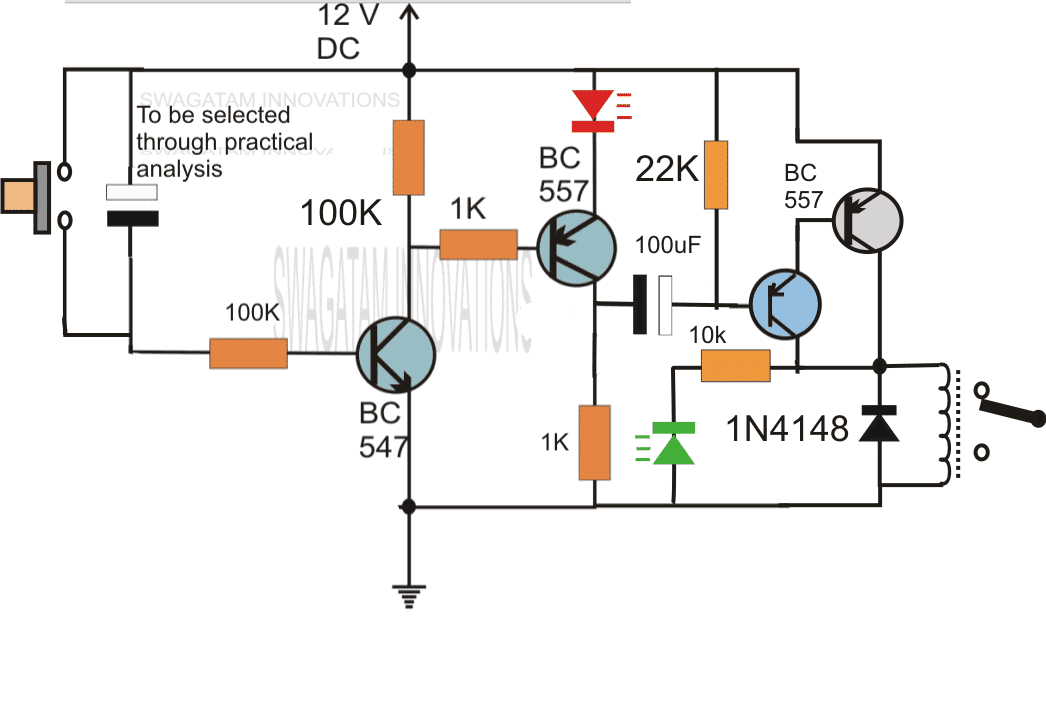

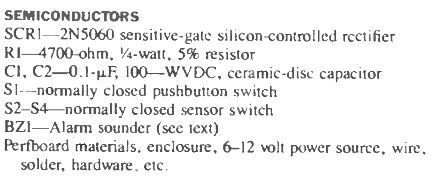

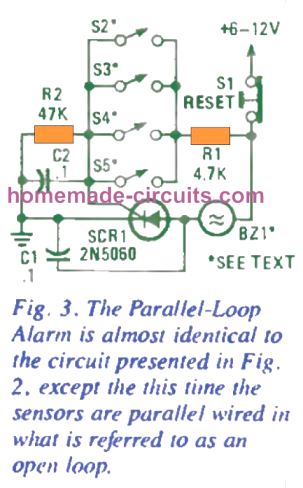

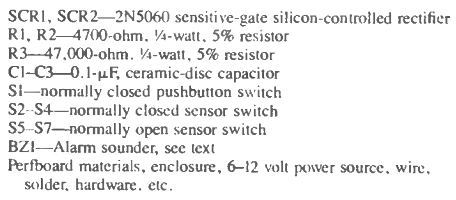

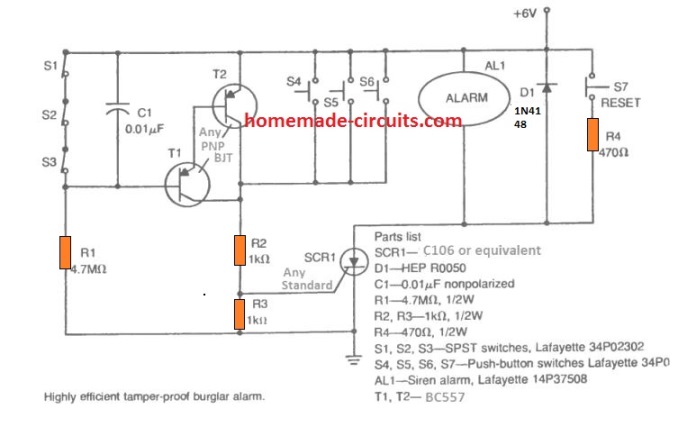

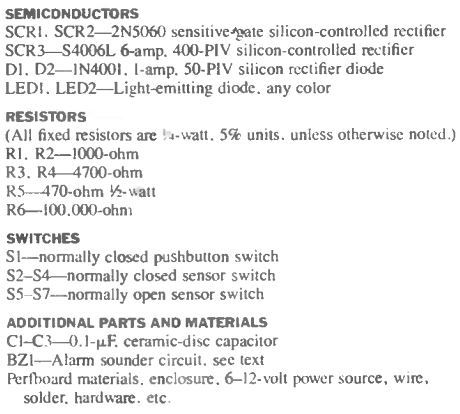

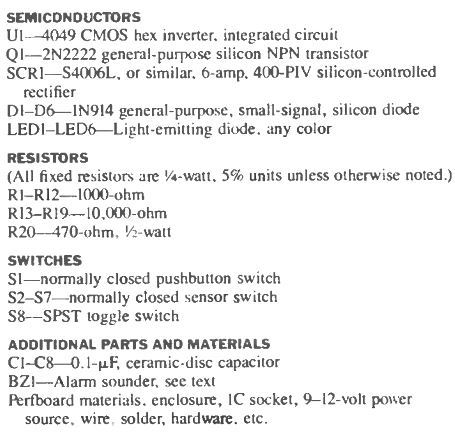

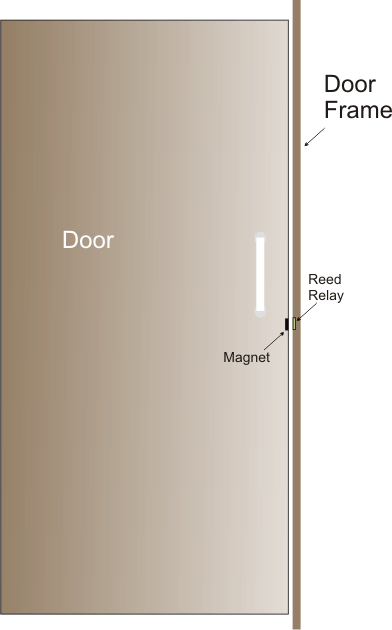

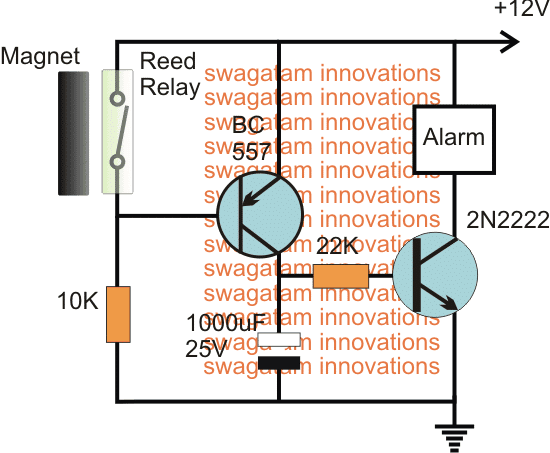

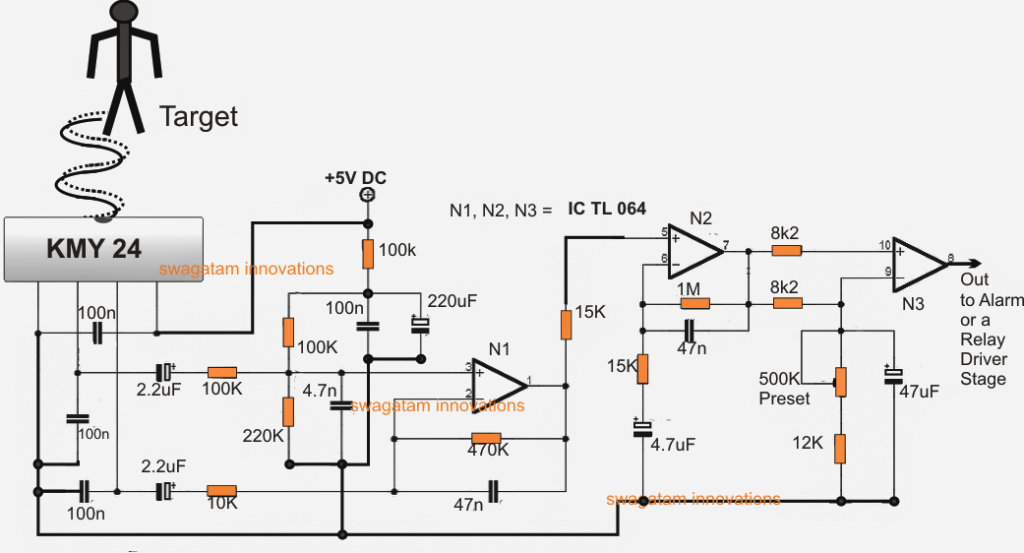

5 Simple Alarm Circuits for Protecting your Home/Office from Theft

The following article discusses a few very simple intrusion detector circuits, or ant-theft alarms. The presented designs are easy to build yet extremely effective with the functions.How the Circuits Works

An intruder alarm basically consists of a sensor and a trigger stages, which work together to produce the requireddetection. The sensor detects the presence of an intruder while the triggering stage responds to the sensor detection by instantly raising the alarm. The triggering stage may consist of a voltage/current amplifier stage rigged with a relay driver stage along with a timer stage for keeping the triggering switched ON even after the threat is eliminated, for increased safety. The sensor pat is generally more sophisticated because it's the main section responsible for detecting the threat. Generally infrared sensorswhichwork bydetectingbody warmth are incorporated in most hi-end types of anti-theft alarms, however here we'll try to implement reasonably similar results yet use ordinary arrangements for the sensor stage in the proposed circuits. You may also want to build this PIR burglar Alarm CircuitIntruder Alarm Using an Ordinary Conductor as the Sensor

This is probably the simplest one among all. As shown in the circuit diagram, the sensor is an ordinary thin wire conductor which is laid across therestrictedarea in such a way that anybody intruding the place gets caught up against the conductor and in the course breaks it up. Once the wire breaks, the transistor is allowed to receive the required base drive, ringing the attached alarm.

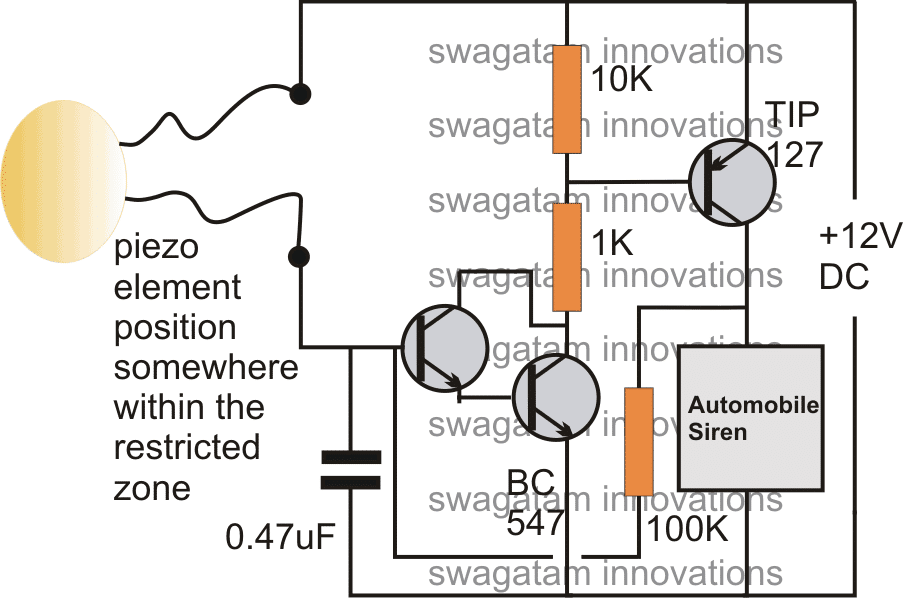

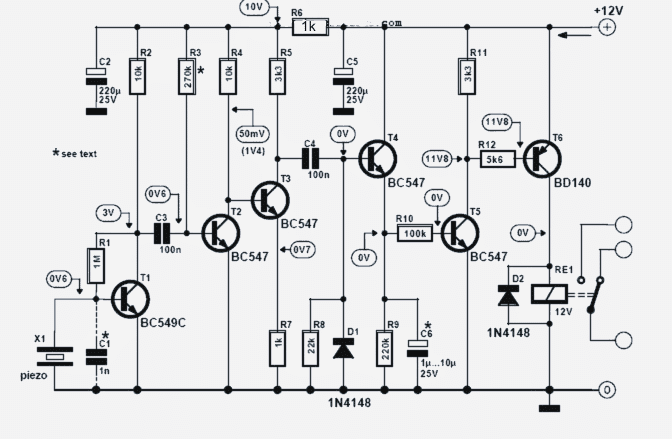

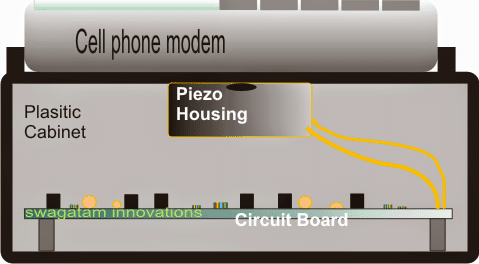

Intruder Alarm Using a Piezo Electric Sound Sensor

This circuit is based on a sound detection through an inexpensive piezo element. Theentiresystem may be fixed over the door or therestrictedentrance. If an intruder tries to break in, the door would be disturbed instantly activating the connected piezo sensor, and theprecedingalarm circuit.

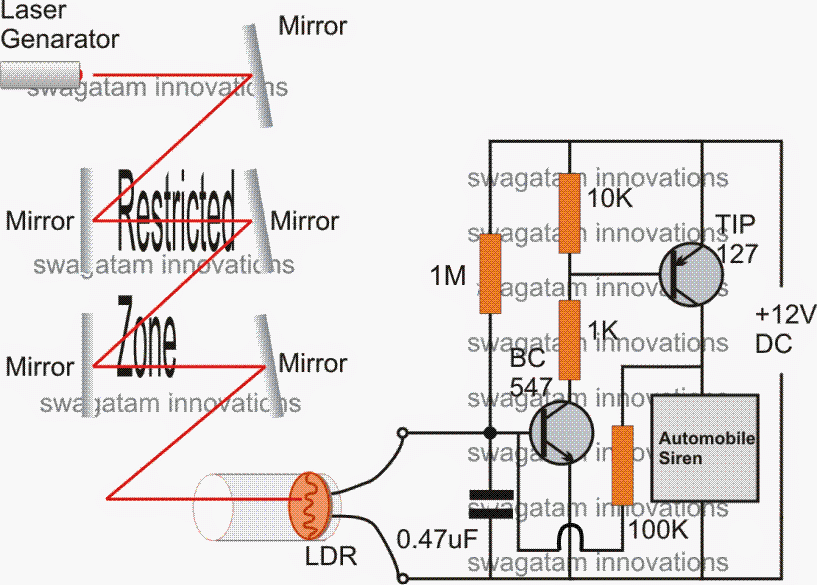

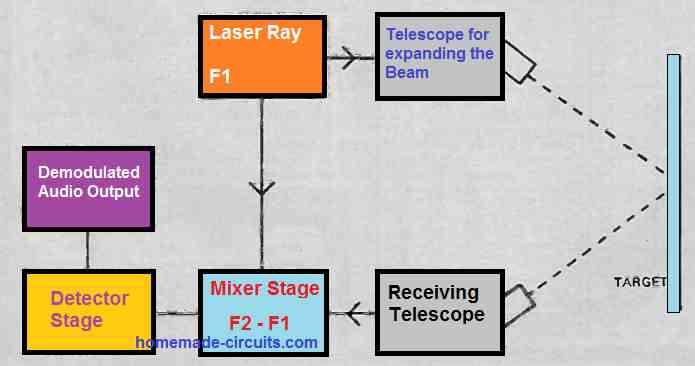

Intruder Alarm Using a Laser Beam.

Today toy laser beam generator devices are pretty popular, and can be easily procured ready made from the market. This toy laser beam can be effectively implemented as an alarm sensor. As shown in the figure, the restricted area may be swarmed by laser beams reflectedacrossthe area via accurately angled mirrors. The final reflection gets directed toward an LDR trigger circuit. In case an intruder tries to trespass the premise, the person would block at least one of the reflections, interrupting the laser passage over the LDR. This would result in an instant triggering of the connected driver circuits.

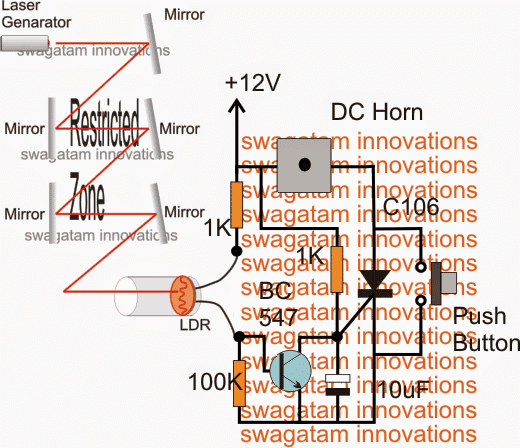

Intruder Alarm with Push Button OFF Feature

The above design of a latching laser activated alarm can be modified with a push button OFF feature. The following diagram shows how it's implemented using a single SCR, while the LDR, and the laser set up remains the same. The idea was requested by Mr. Kuldeep The 12V input power should be switched ON only after the laser point is set on the LDR.

The 12V input power should be switched ON only after the laser point is set on the LDR.

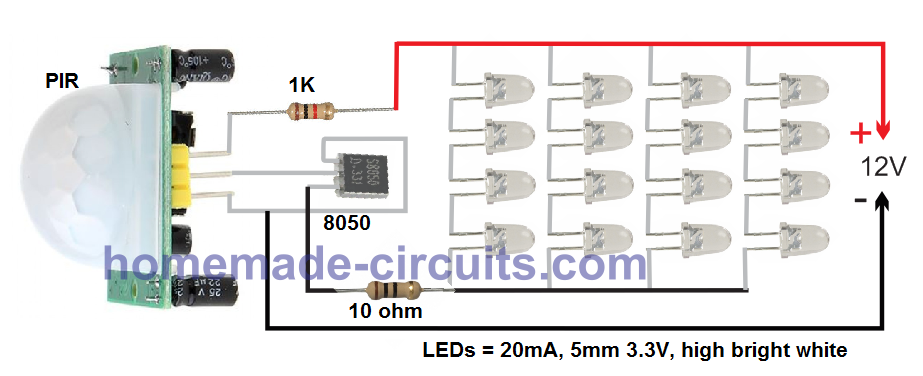

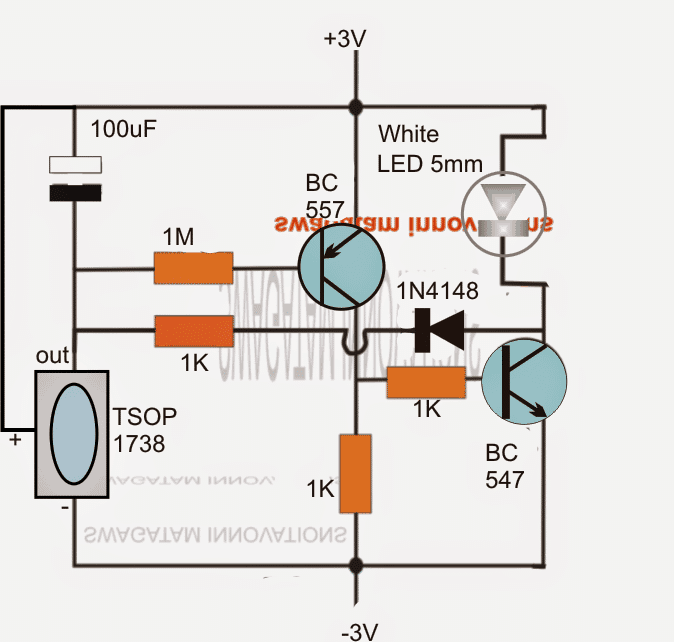

Simple PIR LED Lamp Circuit

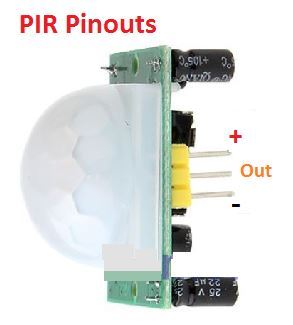

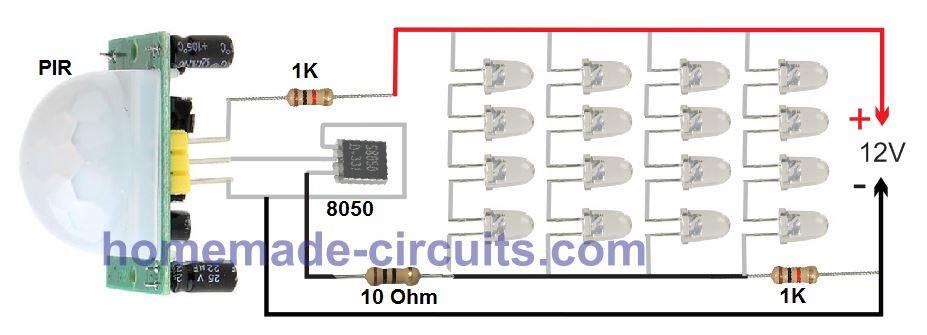

The following PIR LED lamp circuit wasdesignedby me for one of the followers of this blog Mr.Deepak upon his request. The circuit is a LED driver which responds to ambient lightas wellas to the presence of a human, person or intruder, and varies its illumination accordingly, let's know more. "I was looking to drive 20 LEDs of 0.06 watts. So total Output voltage is 12-17 volts and total current is 0.08 amps to drive 4 strings of 5 LEDs each each led is 3.4 volts and 20 mA. Can you help with this? Also I would like to have an ambient sensor to switch on and off and a proximity sensor to switch to full brightness if some one approaches and to switch to half or 30% brightness after 30 seconds. I need this for commercial use. I need asimplecost effective circuit. I have been following the blog and am sure that you know the subject. Please get back to me."Simple PIR Controlled LED Lamp Circuit

Before solving the above request, let's first see how we can build the design in its simplest form using a PIR module and some LEDs. PIR Module Datasheet The following circuit shows a simple PIR sensor which activates the connected LEDs in response to the presence of humans within the specified area. As you can see I have not used any voltage regulator here, since the 1K at the positive works good to limit the current and the voltage to the PIR.

This also avoids the base resistor for the transistor.

I have used 16 LEDs, however upto 64 EDs can be used.

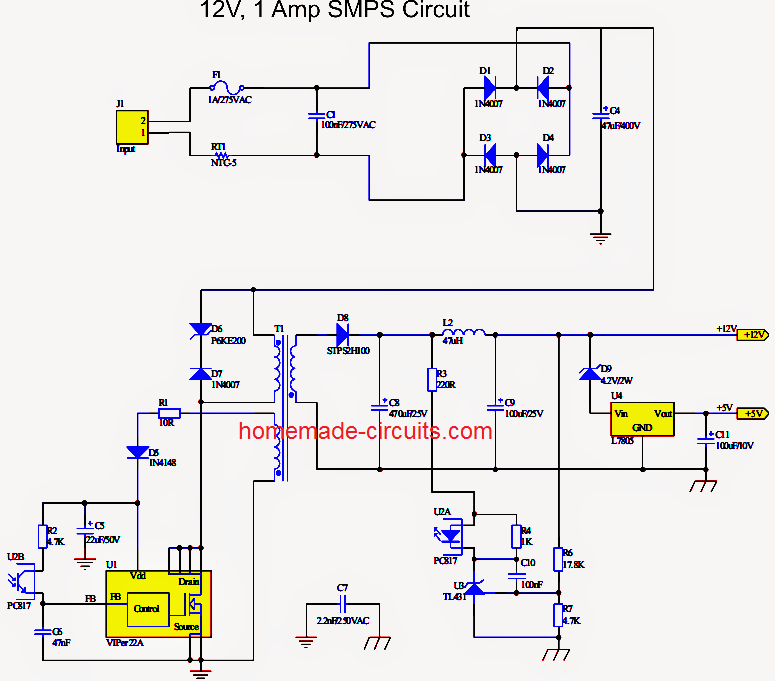

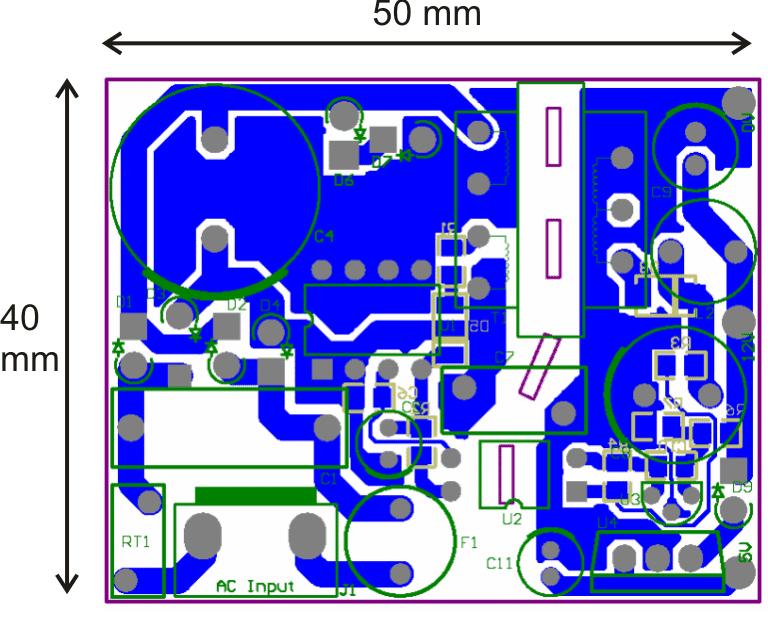

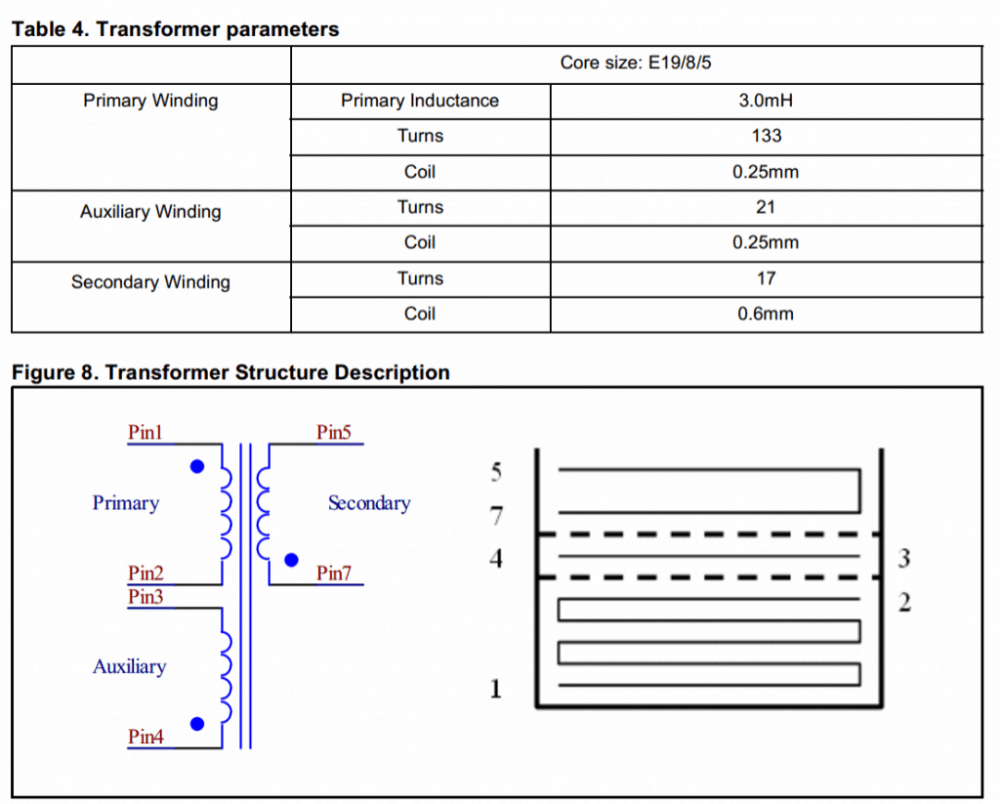

For the power supply you can use any cheap 12V 1 amp SMPS

As you can see I have not used any voltage regulator here, since the 1K at the positive works good to limit the current and the voltage to the PIR.

This also avoids the base resistor for the transistor.

I have used 16 LEDs, however upto 64 EDs can be used.

For the power supply you can use any cheap 12V 1 amp SMPS

Parts List for the above circuit:

PIR Module - 1 1K 1/4 watt - 1 Transistor 8050 - 1 LEDs 5 mA, 20 mA, 3.3V - 16nos, or upto 64 nos

Light Intensity Transition

As requested, the 30% light transition in the absence of a human can be implemented by simply adding a 1K or some other calculated resistor with the negative line of the LED as shown below:

Light Intensity Transition

As requested, the 30% light transition in the absence of a human can be implemented by simply adding a 1K or some other calculated resistor with the negative line of the LED as shown below:

Video Demo

Design# 2

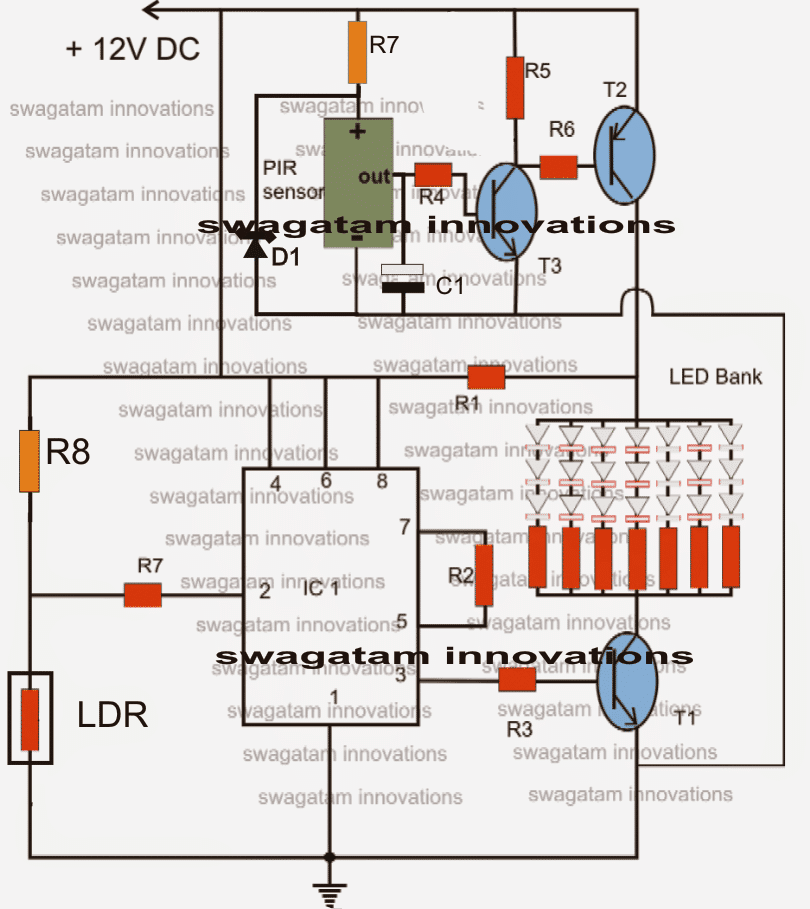

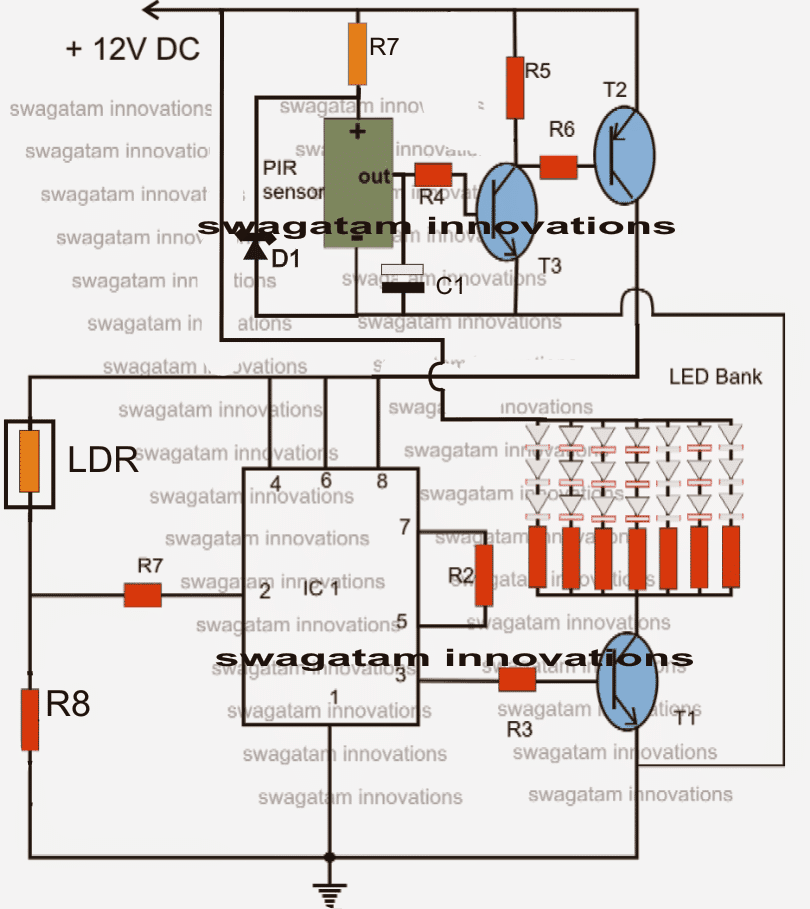

The next two PIR based sensor LED light circuits is similar but has an added feature of detecting the ambient light conditions also. Therefore the circuits will respond based on whether the atmospheric light is sufficiently dark or not and also whether the premise is occupied by a human. Let's try to understand the PIR based LED lamp circuit functioning from the following points:

The IC 555 isconfigured asa comparator, the LDR and R8 values are compared for generating anappropriateoutput.

As long as there's enough light over the LDR, pin#2 of the IC remains high and this keeps the output pin#3 of the IC high as well.

The highoutputat pin#3 keeps the transistor and the LED switched ON, until the ambient light falls below a predeterminedvalue setby P1.

This means during night or in the absence of light the LEDs too get switched OFF.

The uppersectionis aproximitysensor circuit.

The transistors T2 and T3 are configured as high gainamplifierand is able to sense even minute voltages from the PIR sensor.

In the presence of any human or animal in the specified vicinity, the PIR becomes active and triggers T3, which in turn switches ON T2.

T2 instantly shorts R1, such that the supply voltage reaches the LEDs directly instead of via R1.

This situation brightens up the LED illumination, indicating the presence of a passer by (as stated in the request).

The capacitor C1, ensures the LED brightness stays alive for many seconds, even after the PIR is deactivated.

Let's try to understand the PIR based LED lamp circuit functioning from the following points:

The IC 555 isconfigured asa comparator, the LDR and R8 values are compared for generating anappropriateoutput.

As long as there's enough light over the LDR, pin#2 of the IC remains high and this keeps the output pin#3 of the IC high as well.

The highoutputat pin#3 keeps the transistor and the LED switched ON, until the ambient light falls below a predeterminedvalue setby P1.

This means during night or in the absence of light the LEDs too get switched OFF.

The uppersectionis aproximitysensor circuit.

The transistors T2 and T3 are configured as high gainamplifierand is able to sense even minute voltages from the PIR sensor.

In the presence of any human or animal in the specified vicinity, the PIR becomes active and triggers T3, which in turn switches ON T2.

T2 instantly shorts R1, such that the supply voltage reaches the LEDs directly instead of via R1.

This situation brightens up the LED illumination, indicating the presence of a passer by (as stated in the request).

The capacitor C1, ensures the LED brightness stays alive for many seconds, even after the PIR is deactivated.

Parts List

R1 = 100 Ohms, R2,R4 = 100K, R3,R5, R6 = 10K, R7 (at IC 555 pin2) = 2M2, R7 at PIR positive = 10K R8 = 2M2, C1 = 470uF/25V LED resistors = 100 Ohms each, T1, T3 = BC547, T2 = BC557, D1 = 4.7V zener LDR = any standard type. PIR sensor = any standard type. IC1 = 555Darkness Activated PIR Circuit

The following circuit can be used for automatically detecting human presence, and activating the lights during night time.

Simple Delay Timer Circuits Explained

In this post we discuss the making of simple delay timers using very ordinary components like transistors, capacitors and diodes. All these circuits will produce delay ON or delay OFF time intervals at the output for a predetermined period, from a few seconds to many minutes. All the designs are fully adjustable.Importance of Delay Timers

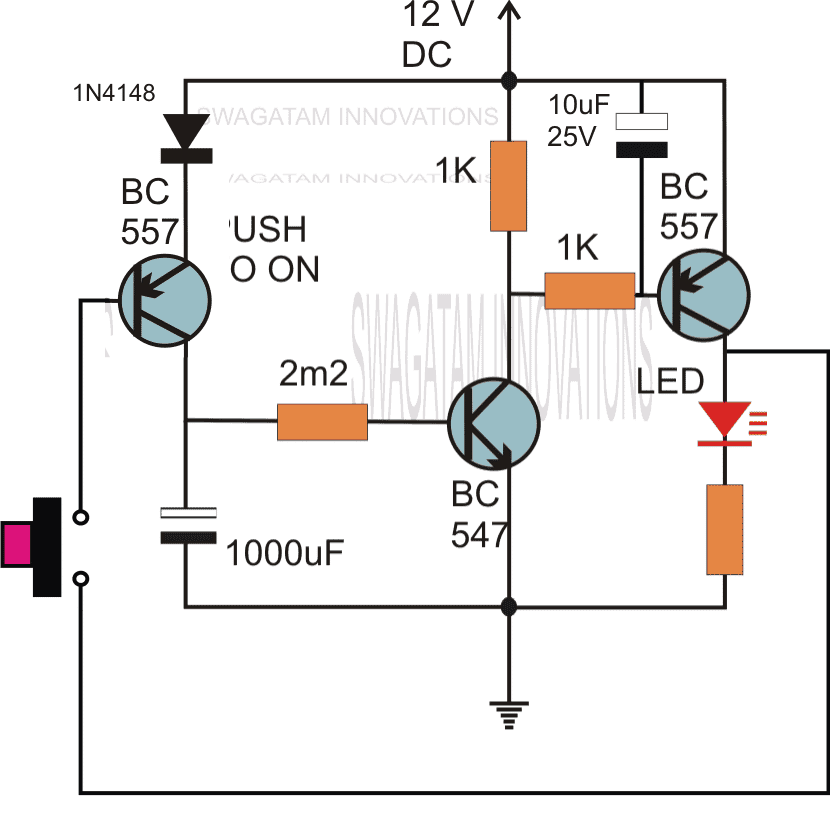

In many electronic circuit applications a delay of a few seconds or minutes becomes a crucial requirement for ensuring correct operation of the circuit. Without the specified delay the circuit could malfunction or even get damaged. Let's analyze the various configurations in details. You may also want to read about IC 555 based delay timers. Recommended for you!Using a Single Transistor and Push Button

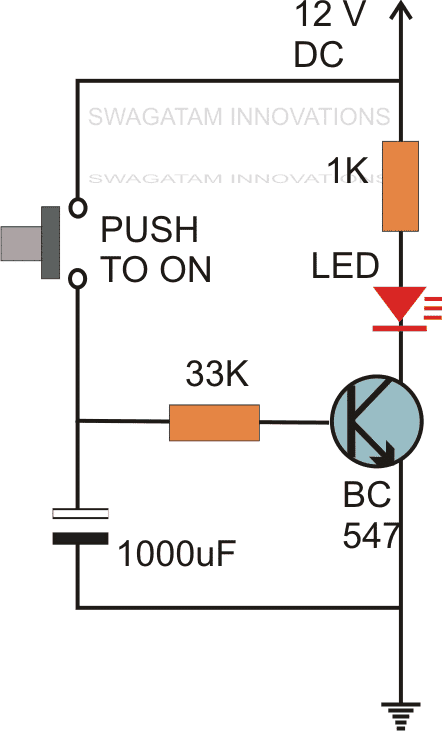

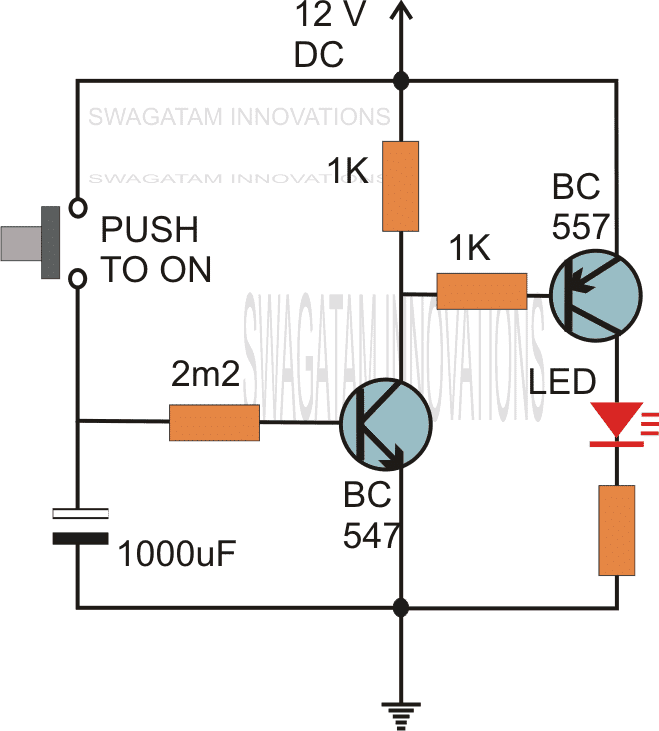

The first circuit diagram shows how a transistors and a few other passive components may be connected for acquiring the intended delay timing outputs. The transistor has been provided with the usual base resistor for the current limiting functions. A LED which is used here just indication purposes behaves like the collector load of the circuit. A capacitor, which is the crucial part of the circuit gets the specific position in the circuit, we can see that it's been placed at the other end of the base resistor and not directly to the base of the transistor. A push button is used to initiate the circuit. On depressing the button momentarily, a positive voltage from the supply line enters the base resistor and switches ON the transistor and subsequently the LED. However in the course of the above action, the capacitor also gets charged fully. On releasing the push button, though the power to the base gets disconnected, the transistor continues to conduct with the aid of the stored energy in the capacitor which now starts discharging its stored charge via the transistor. The LED also stays switched ON until the capacitor gets fully discharged. Te value of the capacitor determines the time delay or for how long the transistor stays in the conducting mode. Along with the capacitor, the value of the base resistor also plays an important role in determining the timing for which the transistor remains switched ON after the push button is released. However the circuit using just one transistor will be able to produce time delays which may range only for a few seconds. By adding one more transistor stage (next figure) the above time delay range can be increased significantly. The addition of another transistor stage increases the sensitivity of the circuit, which enables the use of larger values of the timing resistor thereby enhancing the time delay range of the circuit. PCB Design

PCB Design

Video Demonstration

Video Demonstration

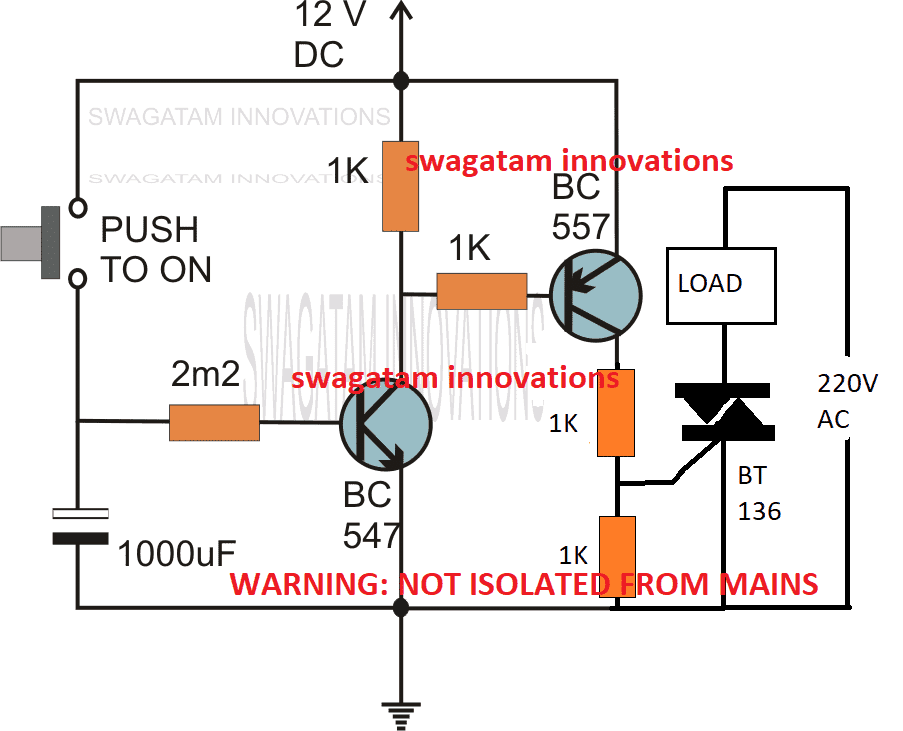

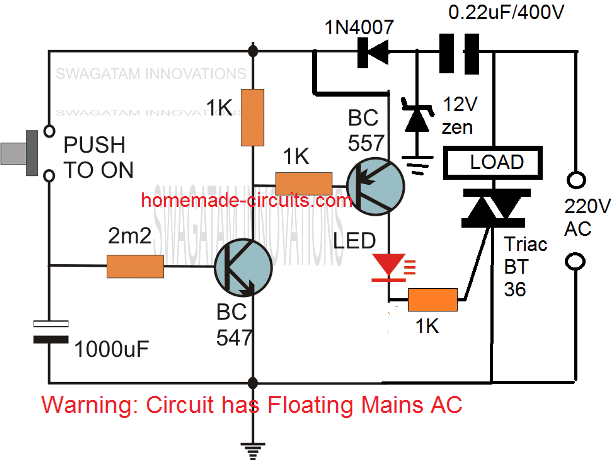

Using a Triac:

The following image shows how the above delay timer circuit may be integrated with a triac and used for toggling a mains AC operated load The above could be further modified with a self contained power transformerless power supply as shown below:

The above could be further modified with a self contained power transformerless power supply as shown below:

Without a Push-Button

If the above design is intended to be used without a push button, the same may be implemented as indicated in the following diagram: The above delay OFF effect without a push button can be further improved by using two NPN transistor, and by using the capacitor across base/ground of the left NPN

The above delay OFF effect without a push button can be further improved by using two NPN transistor, and by using the capacitor across base/ground of the left NPN

The following circuit shows how the associated push button may be rendered inactive as soon as it's pressed and while the delay timer is in the activated state.

During this time any further pressing of the push button has no impact on the timer as long as the output is active or until the timer has finished its delay operation.

The following circuit shows how the associated push button may be rendered inactive as soon as it's pressed and while the delay timer is in the activated state.

During this time any further pressing of the push button has no impact on the timer as long as the output is active or until the timer has finished its delay operation.

Delay from an External Trigger

Problem asked by Mr. Glen (one of the dedicated readers of this blog): I have a situation where I have a pulse of 12V that lasts about 4 seconds (from a rotary switch being turned by a slow motor) but I only want about half a second pulse (to trigger a mechanical bell/chime). Is there any way to take a long pulse into a circuit and send a much shorter pulse out? The solution to the above problem is provided in the following schematic:

Two Step Sequential Timer

The above circuit can be modified to produce a two step sequential delay generator. This circuit was requested by one of the avid readers of this blog, Mr.Marco. A simple delay OFF alarm circuit is shown in the following diagram.

The circuit was requested by Dmats.

A simple delay OFF alarm circuit is shown in the following diagram.

The circuit was requested by Dmats.

The following circuit was requested by Fastshack3

The following circuit was requested by Fastshack3

Delay Timer with Relay

"I am looking to build a circuit that would control an output relay. This would be done in 12V and the sequence will be initiated by a manual switch. I will need an adjustable time delay (possibly displayed time) after the switch is released, then the output would go on for an adjustable time (also possibly displayed) before shutting off. The sequence would not restart until the button was pressed and released again. The time after the button release would be from 250 milliseconds to 5 seconds. The "on" time for the output to turn on the relay would be from 500 milliseconds to 30 seconds. Let me know if you can offer any insight. Thanks!" So far we have learned how to make simple delay OFF timers now let us see how we can build a simple delay ON timer circuit which allows the connected load at the output to be switched ON with some predetermined delay after power switch ON.

The explained circuit can be used for all applications which calls for an initial delay ON feature for the connected load after the mains power is switched ON.

So far we have learned how to make simple delay OFF timers now let us see how we can build a simple delay ON timer circuit which allows the connected load at the output to be switched ON with some predetermined delay after power switch ON.

The explained circuit can be used for all applications which calls for an initial delay ON feature for the connected load after the mains power is switched ON.

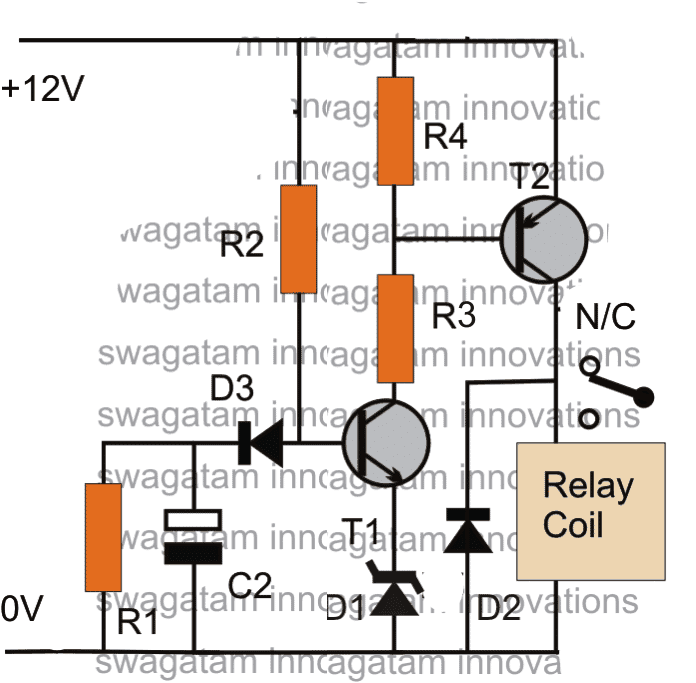

Delay ON Timer Circuit Working Details

The shown diagram is pretty straightforward yet provides the necessary actions very impressively, moreover the delay period is variable making the set up extremely useful for the proposed applications. The functioning can be understood with the following points: Assuming the load which requires the delay ON action being connected across the relay contacts, when power is switched ON, the 12V DC passes via R2 but is unable to reach the base of T1 because initially, C2 acts as a short across ground. The voltage thus passes through R2, gets dropped torelevantlimits andstartscharging C2. Once C2 charges up to a level which develops a potential of 0.3 to 0.6V (+zener voltage) at the base of T1, T1 is instantly switched ON, toggling T2, and the relaysubsequently....finally the load gets switched ON too. The above process induces the required delay for switching ON the load. The delay period may be set byappropriatelyselecting the values of R2 and C2. R1 ensures that C2 quickly discharges through it so that the circuit attains the stand by position as soon as possible. D3 blocks the charge from reaching the base of T1.

Parts List

R1 = 1o0K (Resistor for Discharging C2 when circuit is switched OFF)) R2 = 330K (Timing Resistor) R3= 10K R4 = 10K D1 = 3V zener diode (Optional, could be replaced with a wire link) D2 = 1N4007 D3 = 1N4148 T1 = BC547 T2 = BC557 C2 = 33uF/25V (Timing Capacitor) Relay = SPDT, 12V/400 OhmsPCB Design

Application Note

Let's learn how the above delay ON timer circuit becomes applicable for solving the following presented issue by one of the keen followers of this blog, Mr. Nishant.Circuit Problem:

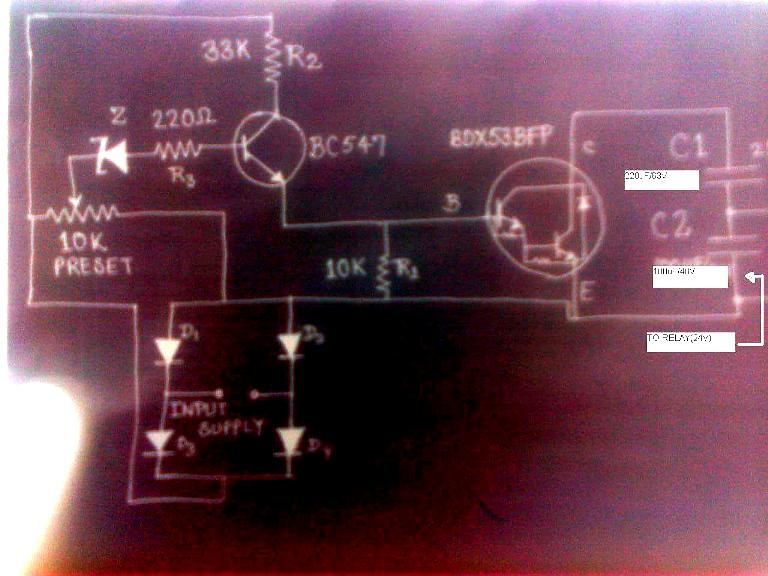

Hello Sir, I have a 1KVA automatic voltage stabilizer.It has one defect that when it is switched on, very high voltage is outputted for about 1.5s (therefore cfls and bulb got fused frequently) after that the voltage becomes OK. I have opened the stabilizer it consist of an auto-transformer,4 24V relay each relay connected to aseparatecircuit(each consisting of 10K preset,BC547,zener diode,BDX53BFP npn darlington pair transistor IC,220uF/63v capacitor,100uF/40V capacitor ,4 diodes and some resistors). These circuits are powered by a step down transformer and output of these circuit are taken across corresponding 100uF/40V capacitor and fed to corresponding relay.What to do in order to tackle the problem.please help me.Hand drawn circuit diagram is attached.

Solving the Circuit Problem

The problem in the above circuit might be due to two reasons: one of the relays is switching ON momentarily connecting the wrong contacts with the output, or one of the responsible relays is settling down with the correct voltages a little while after power switch ON. Since there are more than one relay, tracing out the fault and correcting it can be a bit tedious......the circuit of a delay ON timer explained in the above article could be actually very effective for the discussed purpose. The connections are rather simple. Using a 7812 IC, the delay timer can be powered from the existing 24V supply of the stabilizer. Next, the delay relay N/O contacts may be wired in series with the stabilizer output socket wiring. The above wiring would instantly take care of the issues as now the output would switch after some time during power witch ONs, allowing enough time for the internal relays to settle down with the correct voltages across their output contacts.Feedback from Mr. Bill

Hi Swagatam, I stumbled across your page doing research on the web to make my delay more consistent.Some back ground information first. I am a bracket drag racer and launch the car on first sight of the 3rd amber bulb as the christmas tree is coming down. I use a transbrake switch that is depressed to lock the automatic transmission in forward and reverse at the same time. This allows you to rev up the engine to build power for launch. When the button is released the transmission comes out of reverse and moves the car forward under high rpm. This is like popping the clutch on a manual transmission car, anyway my car reacts to quickly and the result is a redlight, leaving to early, and you lose the race. In dragracing your reaction time on the launch is everything and it is a game of hundreths-thousanths with the big boys, so I have put the transbrake switch on a relay and put a 1100uf cap combo across the relay to delay its release. Because of the car electronics I don't believe there is a precise voltage charging this cap every time I activate this circuit and precision is key so I bought a power stabilizer off of Ebay that takes 8-15 volts in and gives a consistent 12volts out. This turned my season around but i believe this circuit could be made to be more precise and to vary the delay time in an easier way rather than swap cap combos. Also should I run a diode in front of the relay, not currently because all that is there is the on off switch- where will the current go? I am not an electrical engineer by any means but do have some knowledge from trouble shooting high end audio for many years. Would love your thoughts- thankyou Bill KoreckyAnalyzing and Solving the Circuit

Hi Bill, I have attached the schematic of an adjustable delay circuit, please check it out. You can use it for the mentioned purpose. The 100K preset can used and adjusted for acquiring precise short delay periods as per your specifications. However, please note that, the supply voltage will need to be minimum 11V, for the 12V relay to operate correctly, if this is not fulfilled then the circuit might malfunction. Regards.

Simple 5 to 20 Minute Delay Timer

The following section discusses a simple 5 to 20 minute delay timer circuit for a specific industrial application. The idea was requested by Mr. Jonathan.Technical Requirements

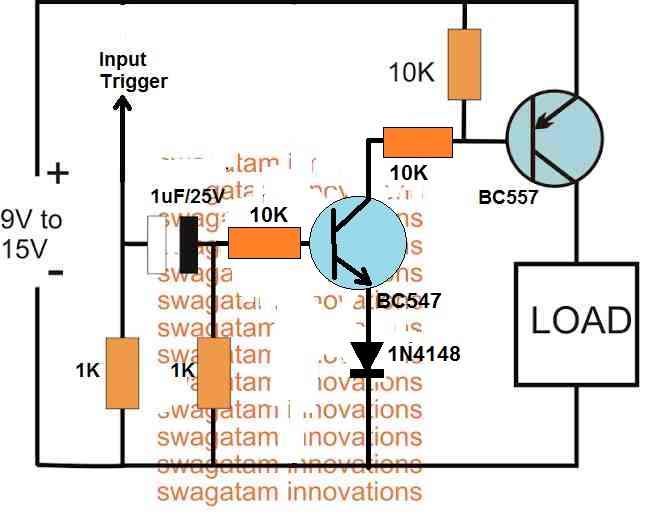

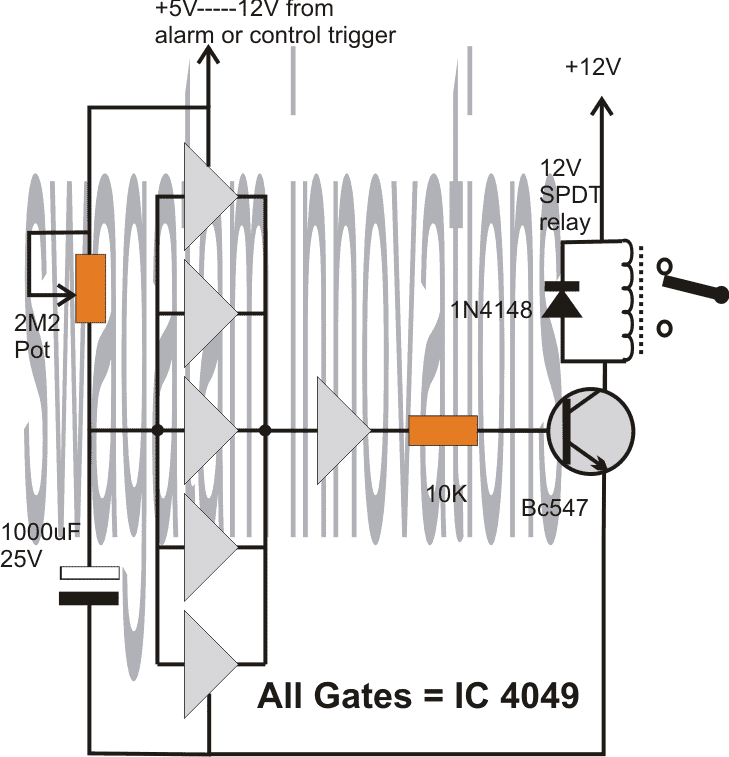

While trying to figure out a solution to my problem on google, I came across your above posting. I'm trying to figure out how to build a better Sous Vide controller. The main problem is that my water bath has a very high hysteresis, and when heating from colder temperatures will overshoot about 7 degrees from the temperature at which power is terminated. It is also very well insulated, with a gap between the inner and outer vessel which makes it act like a thermos jar, because of this it takes a very long time to decline from any excess temperature. My PID controller has an SSR control output and a relay alarm output. The alarm can be programmed as a below limit alarm with an offset from the set-point. I can use a five volt supply I already have for my circulation motor to run through the alarm relay and drive the same SSR the control output is driving. To be on the safe side and protect the PID controller I'll add a diode to both the alarm voltage and the control voltage to prevent one output from feeding back into the other. I'll then set the alarm to stay on until the temperature rises above the set-point minus 7 degrees. This will allow the PID tuning to be adjusted without having to account for the initial temperature ramp-up. Because I know that last few degrees will be achieved without any power input, I'd really like a way to delay any recognition of the control signal for about five minutes after the alarm shuts off, as it will still be calling for heat. This is the part I've yet to figure out the circuitry for. I*m thinking of a normally closed relay in series with the control output, which is held open by the alarm signal. When the alarm signal is terminated, I need a delay on the order of five minutes before the relay returns to its &off* normally closed state. I would appreciate help with the delayed off portion of the relay circuit. I like the simplicity of the initial designs on the page, but I get the impression they wouldn*t handle anywhere near five minutes. Thank you, Jonathan LundquistThe Circuit Design

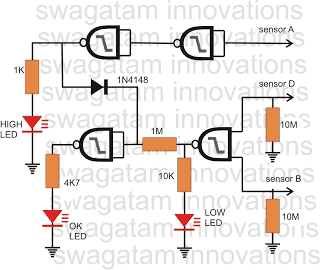

The following circuit design of a simple 5 to 20 minute delay timer circuit can be suitably applied for the above specified application. The circuit employs the IC4049 for the required NOT gates which are configured as voltage comparators. The 5 gates in parallel form the sensing section and provides the required time delay trigger to the subsequent buffer and the relay driver stages. The control input is acquired from the alarm output as indicated in the above description. This input becomes the switching voltage for the proposed timer circuit. On receiving this trigger, the input of the 5 NOT gates are initially held at logic zero because the capacitor grounds the initial trigger via the 2m2 pot. Depending upon the 2m2 setting, the capacitor starts charging up and the moment the voltage across the capacitor reaches a recognizable value, the NOT gates revert their output to logic low, which is translated as a logic high at the output of the right single NOT gate. This instantly triggers the connected transistor and the relay for the required delay output across the relay contacts. The 2M2 pot may be adjusted for determining the required delays.Circuit Diagram

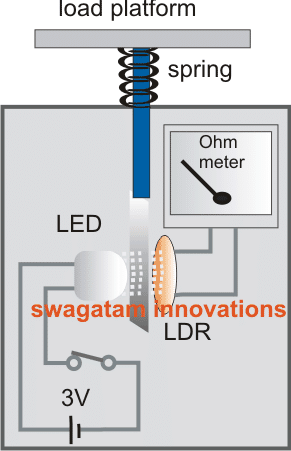

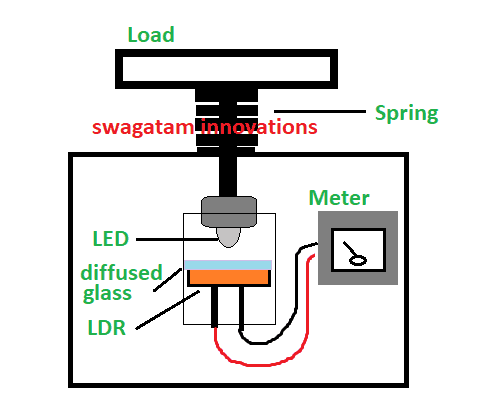

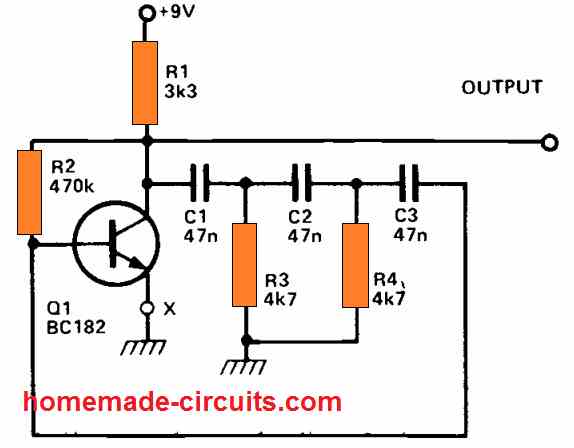

Simple LDR Motion Detector Alarm Circuit

Here we learn how to build a simple LDR based motion detector sensor circuit using ordinary parts such as LDRs and opamps, reasonably accurately.What are Motion Detectors

Motion detector or sensor alarm is a device which detects the presence of a motion or movement within a certain fixed range and raises an alarm on doing so. You might find many electronic circuits related to motion sensing but most of them incorporate shadow detection through a single LDR, which does not work very effectively. Because a shadow might not always be very sharp enough and at times the circuit may just fail to interpret it. The present motion detector/sensor circuit is also based on similar principles but it detects a motion by differentiating the light level using two LDRs, this makes the system more sensitive and works irrespective of the shadow intensity.Circuit Operation

The circuit diagram shows a simple configuration consisting of a couple of opamps from the IC LM324. The two opamps are arranged in a differential mode and as comparators. Both the comparators consists of their own discrete light sensing components in the form of LDRs. The presets provided with the opamps decide at what point the outputs of the both the opamps remain on the same level, that is at zero potential. Also the above condition is met when the light level over both the LDRs are approximately at the same levels. However the moment the light level (or the shade level) on the LDRs differ even slightly, the comparators instantly detects this and one of the relevant opamp outputs goes high. The transistor at the output immediately triggers and activates the relay and the connected alarm mechanism. The LDRs must be positioned at least a feet apart for proper optimization of the detection level. Also the LDRs and the nit itself must be positioned in such a way that the ambient light directly become incident over the sensors.

How to Set Up the Circuit.

You will require a lot of dexterity for setting up the circuit accurately. It may be done as follows: Let a constant source of light fall on the LDRs with uniform intensity. Now without letting any of your body part disturbing the light source, gently and skilfully adjust the two presets such that both the LEDs just shut off. That's it, your circuit is now all set and ready to detect even the slightest of motions across any of the LDRs. However it must be ensured that the light source intensities on the LDRs does not change, or else the set up could get rattled.Simple Programmable Timer Circuit

This programmable timer can be used for switching a load ON and OFF with two sets of time delays, which are programmable from 2 seconds to 24 hours independently. The delay timings are adjustable according to the users personal specs. The ON time delay and the OFF time delay are independently settable and this facility becomes the most important feature of a programmable timer circuit.Using Versatile IC 4060

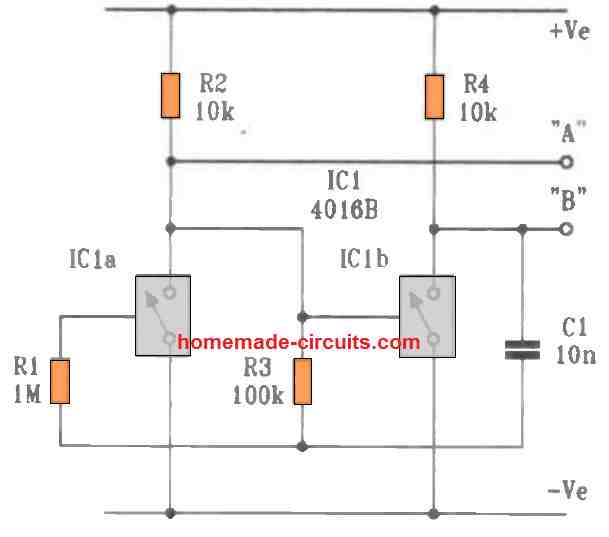

In this page we will discuss a very simple yet reasonably useful timer circuit diagram whose ON time and OFF time settings are independently adjustable through ordinary pots. The idea becomes so easily configurable due to the versatile IC 4060 which require minimal number of component for getting the unit running. Looking at the CIRCUIT DIAGRAM below we can see that two inexpensive IC 4060 have been wired up as two independent timer modes. However though the timing settings are independent for the two sections, these are coupled with other such that their initialization become very much interconnected. Basically both the configurations are similar and have been rigged in the standard counting modes of the IC 4060 devices. You may also want to make this Arduino based programmable timer circuitHow the Circuit Functions

The output of the upper IC is coupled to the reset input of the lower IC via a transistor in such a way that once the upper IC's output goes high, it triggers the lower timer into operation. The lower IC then starts counting and when its output goes high, it halts the upper ICs counting and resets it to its original state and the process is initiated back from the start. It simply means that as long as the upper ICs timing does not lapse the lower IC remains idle, however once the upper ICs timing lapses and its output becomes high, it switches the output load as well as the lower ICs operation. The pot associated with the upper IC can be used for determining after how long the load will be switched ON, while the pot associated with the lower IC is used for determining how long the load remains in the switched ON position or simply after what time it should be switched OFF. Update: The LED positions have been changed in the following updated designs, because the earlier LED positions were conflicting with the relay operations, and therefore the positions have been relocated for ensuring foolproof operations.Circuit Diagram of a Versatile Programmable Timer

PCB Layout

Video showing the proposed 2-stage programmable timer circuit with LEDs

Video showing the proposed 2-stage programmable timer circuit with LEDs

Using a Start Push-Button

The above design could be upgraded with a push-button to facilitate a push button start. This further ensures that the timer shuts off completely in case a power failure occurs while the circuit is operational, which in turn ensures that crucial loads like heater, or geyser are completely turned OFF during such situations.

Calculating RCTiming Components

It can be done through a formula, but the manual way is much simpler and accurate. It can be done as explained below: Connect any arbitrarily selected resistor above 100K in place of P1/R2 in the upper circuit. Switch ON and carefully note down after how much time pin#3 of upper IC 4060 becomes HIGH. This will be your "sample delay". Once this is noted, the other desired time delays could be calculated using the following simple cross multiplication: Sample Delay / Desired Delay = Selected Resistor / Unknown Resistor For example if you find the pin3 becoming high after 300 seconds, this becomes your sample delay value. Now, we have the sample delay and the resistor value responsible for this delay. Therefore if we assume the desired delay to be 1 hour or 3600 seconds, we can calculate it by substituting the values in the previous equation: Sample Delay / Desired Delay = Selected Resistor / Unknown Resistor 300 / 3600 = 100 / x (unknown resistor) 300x = 360000 x = 1200 k or 1.2 Meg This shows that 1.2 Meg in place of the P1/R2 will produce the required delay of 1 hour at pin3 of a IC 4060 Please note that the above calculation is only an example and the values do not indicate the actual results.Customizing the Above Concept

This circuit of a flexible programmable timer circuit explained in this article was designed by me in response to a request by Mr.Amit. Let's know more about the request and the circuit details. "I need a circuit for my auquarium where it should do the followingit should switch off the lights at 10:00 pm and start at 7:00 am daily + switch off the light at 12:00 pm daily and switch up at 6:00 pm back.

this will help to make my fishes live longer.

Thanks in advance.

Amit desai"

The Design

So here's the circuit that I came up with. As the name suggest, the timer is pretty flexible and may be adjusted to produce any desired time periods, according to the above requested format. The circuit consists of four identical stages, made up of the IC 4060 timer configuration. Te timer sequence begins from the IC at the top left corner. When power is switched ON this IC starts counting. Depending upon the setting of its pot, the IC triggers after a certain period og time interval. This switches ON the relay and the driver transistor BC547 which consequently switches OFF the connected lamp. The stage gets latched with the help of the diode connected across its pin 3 and pin 11. The above triggering also switches another BC547 transistor which connects the reset pin of the next IC 4060 to ground which initiates this stage also. After a predetermined time, this IC also triggers its output at pin3 and gets latched by the corresponding diode, however this actionsends a feedback signal to the relay driver transistor, instantly switching it off and restoring power back to the lamp so that it lights up again. Just as the above actions, the sequence further proceeds and switches ON the third IC 4060 in the line which counts the set time interval and pulls the relay back to OFFpositionvia the diode connected to the collector of its bc547 transistor, such that the lamp again gets switched OFF. Assoonas the above triggering happens the last section at the bottom right corner switches into action and counts as per the setting of the respective pot, until the ICs output becomes high, this high reset the the first IC and switches ON the lamp once again so thattheprocess may berestartthe cycle all over again. The pots may be increased to 3m3 for generating higher time interval periods, so is true with the respective capacitors.Circuit Diagram

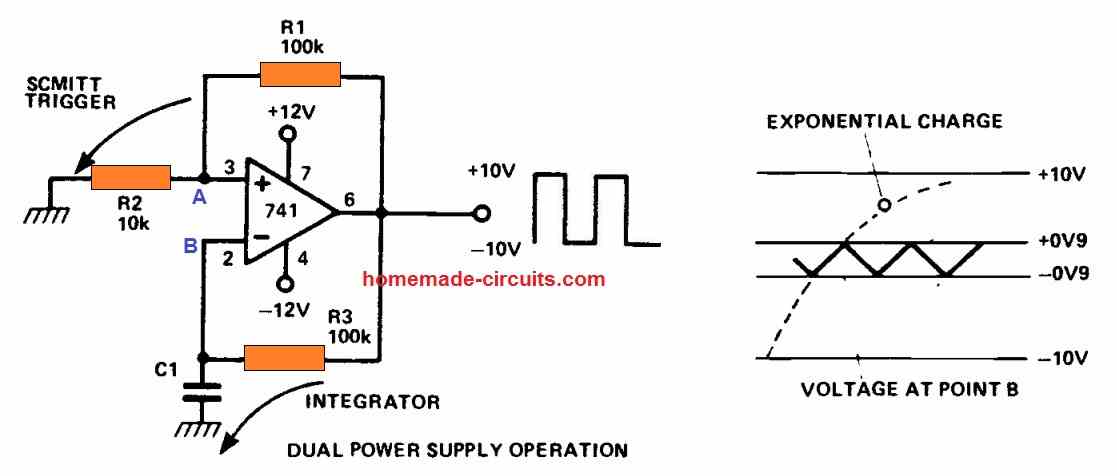

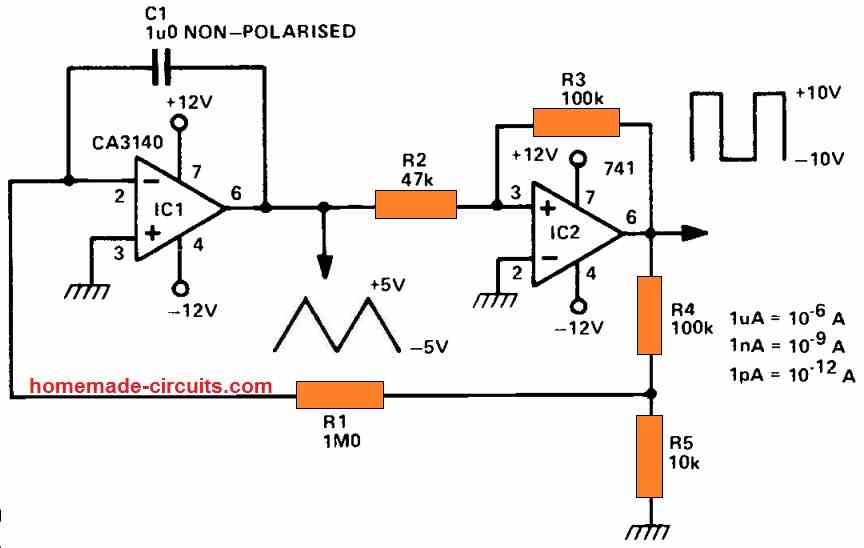

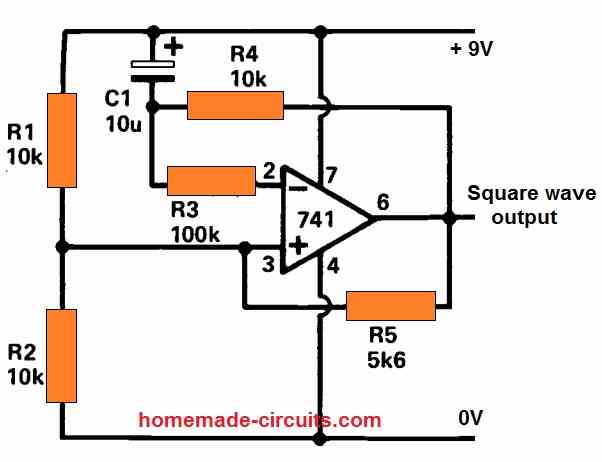

How to Adjust and Set Up