3v, 4.5v, 6v, 9v, 12v, 24v, Automatic Battery Charger Circuit with Indicator

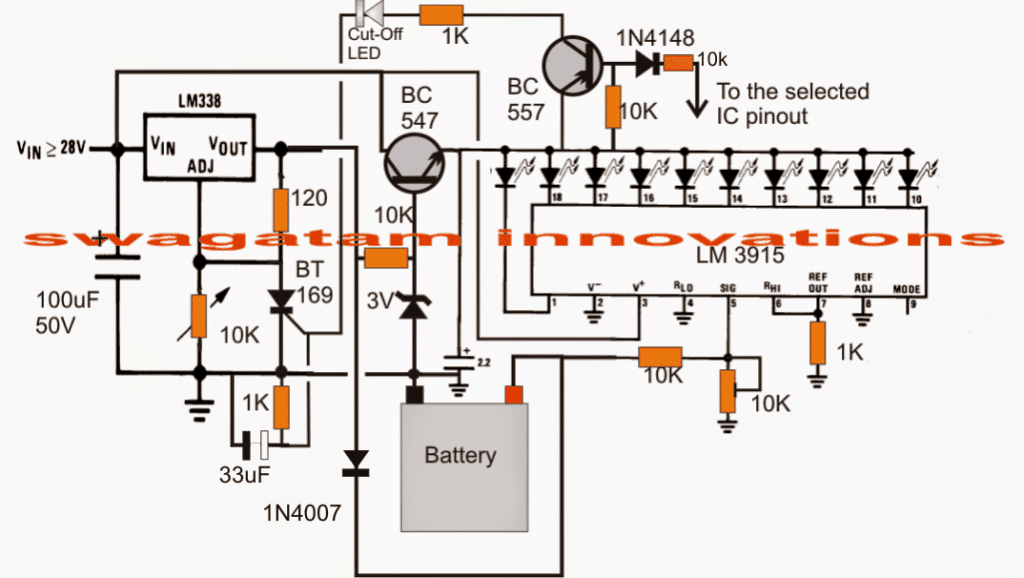

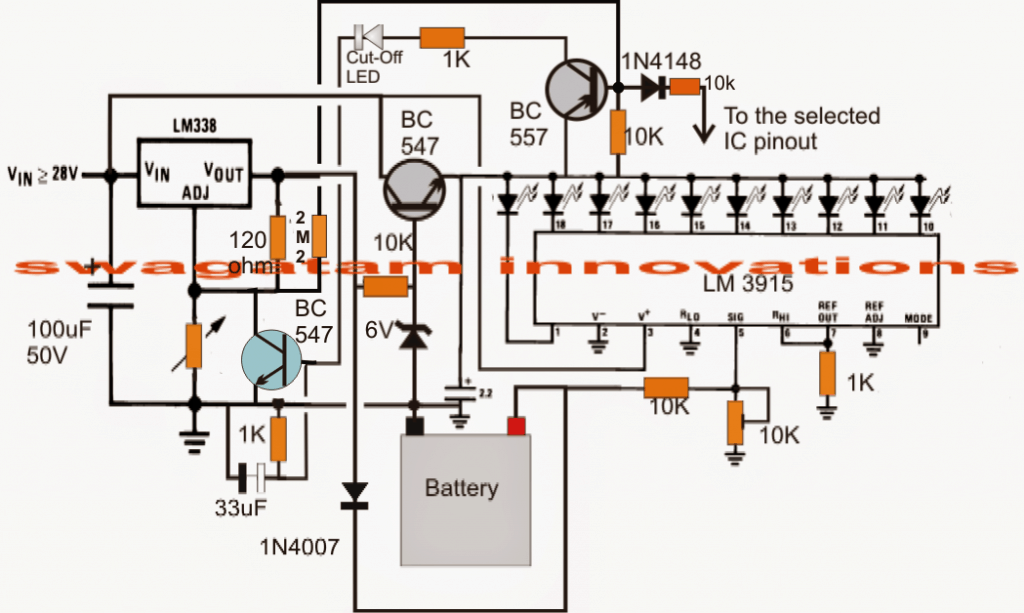

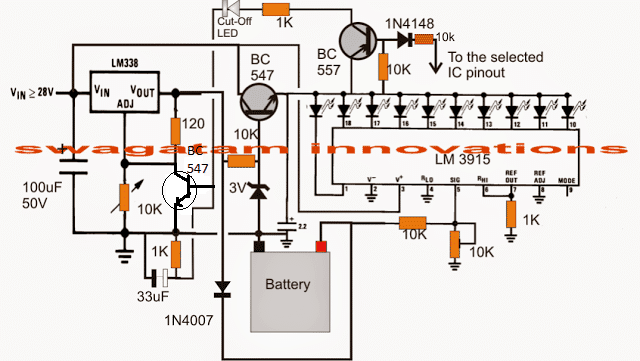

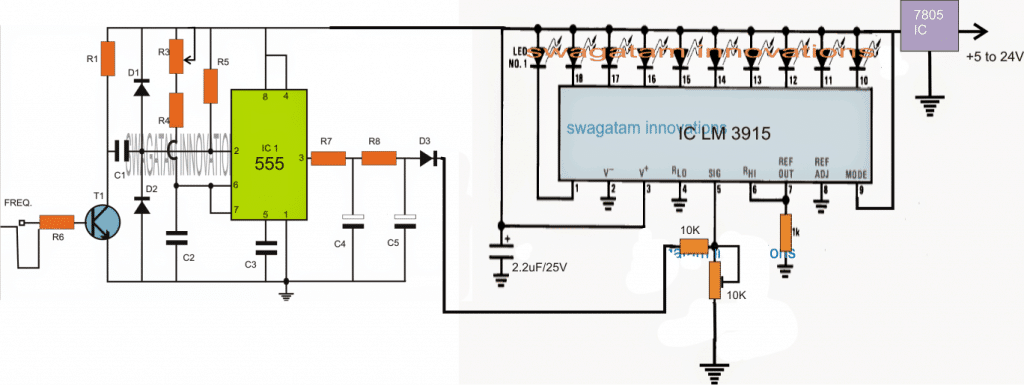

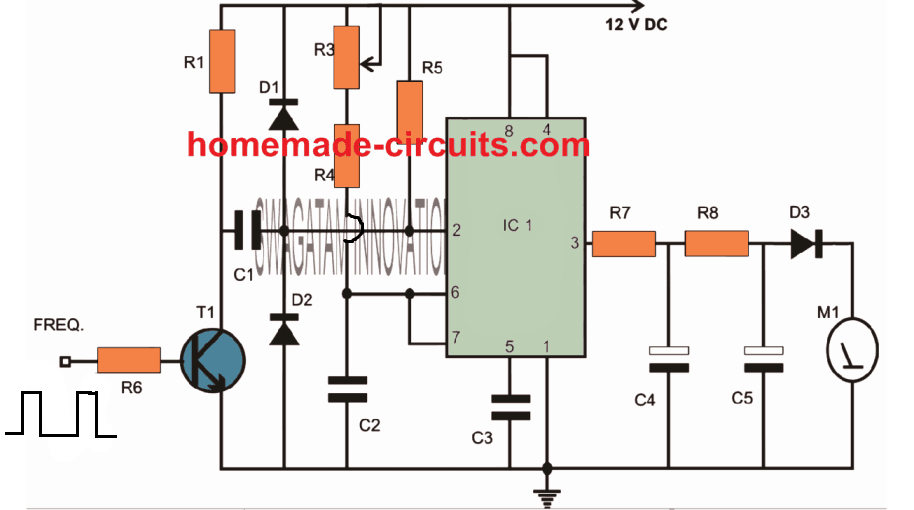

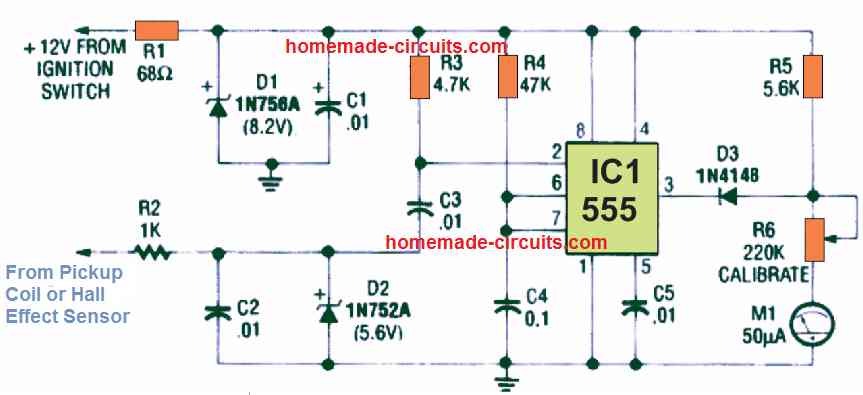

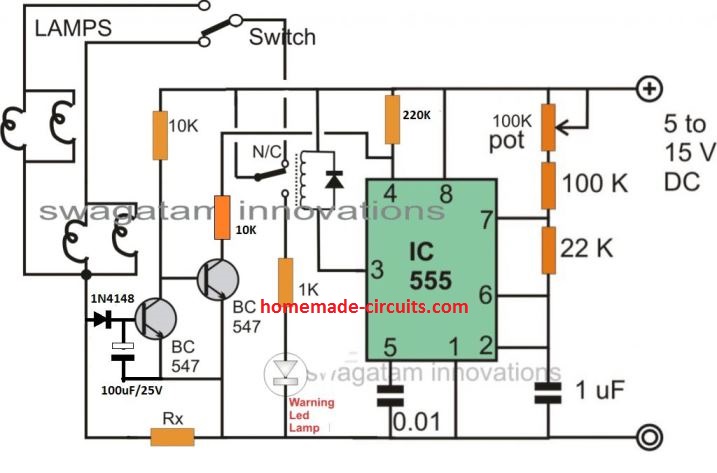

An all-in-one automatic voltage battery charger circuit is discussed in the following post; the circuit can be modified in many different ways as per individual requirements and applications. The following circuit will allow you to charge any battery right from 1.5V to 24V simply by setting up a given preset.How it Works using LM3915 IC

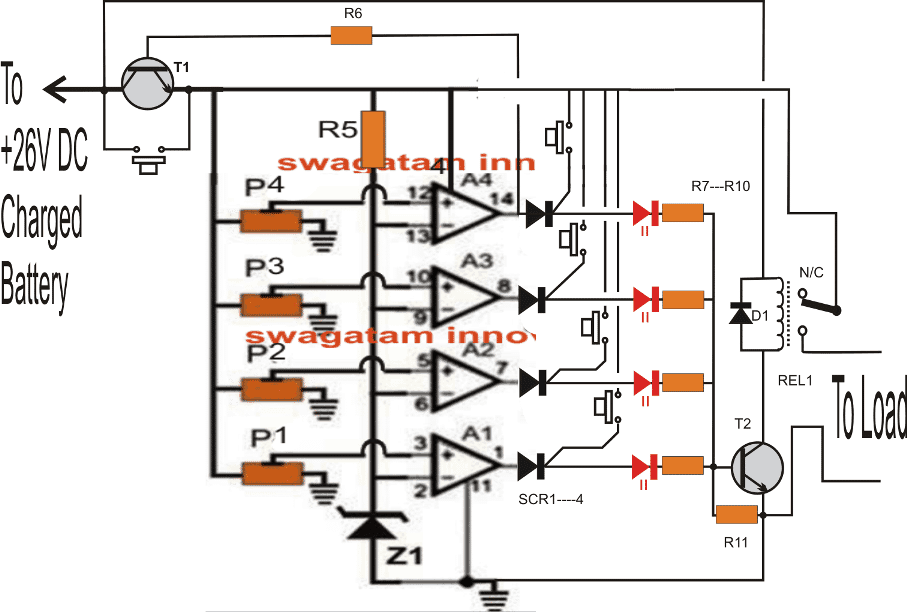

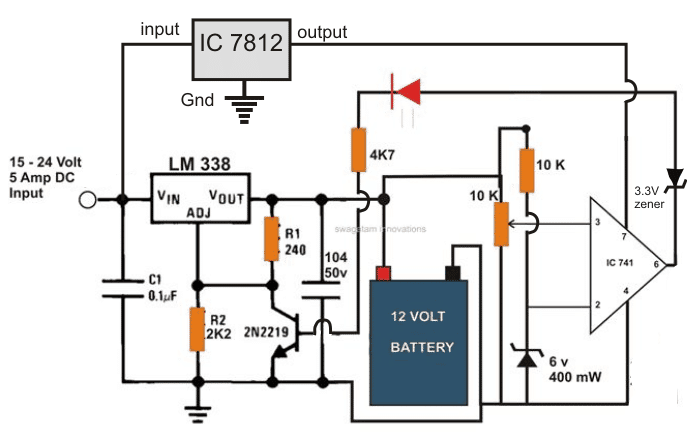

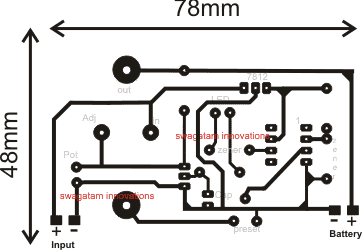

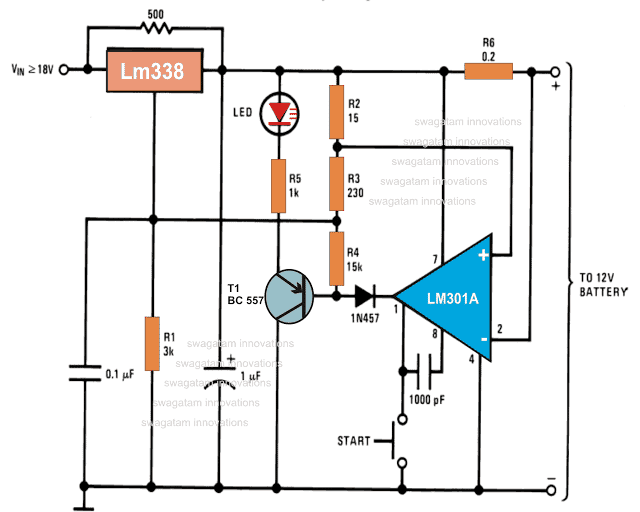

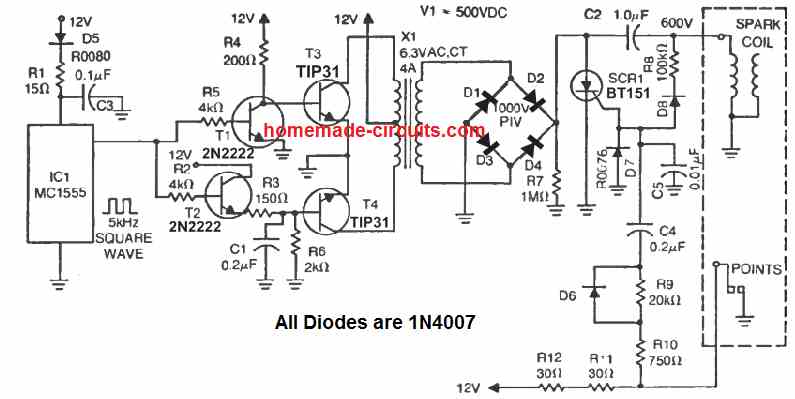

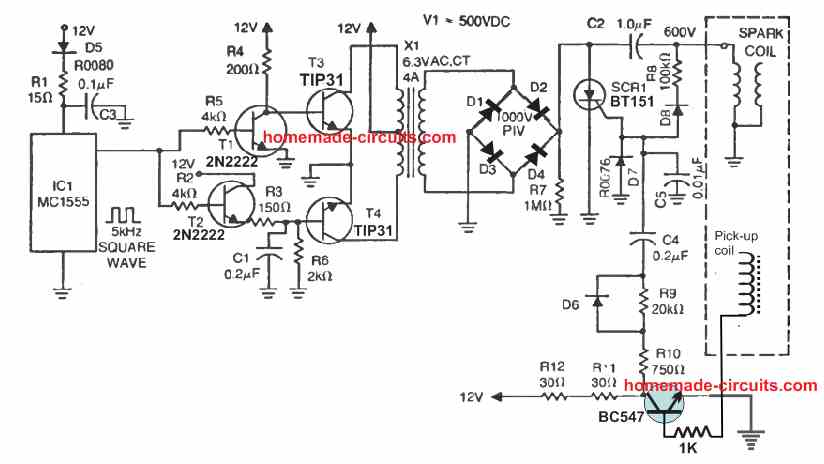

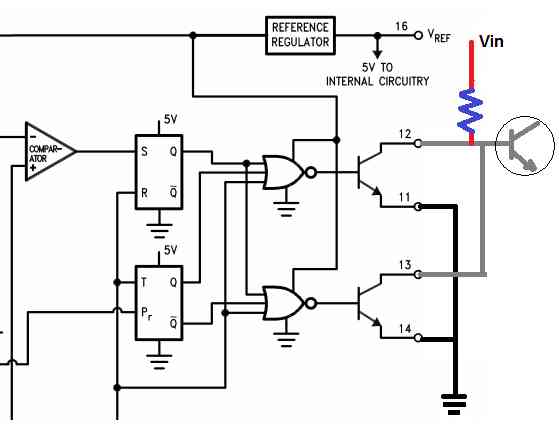

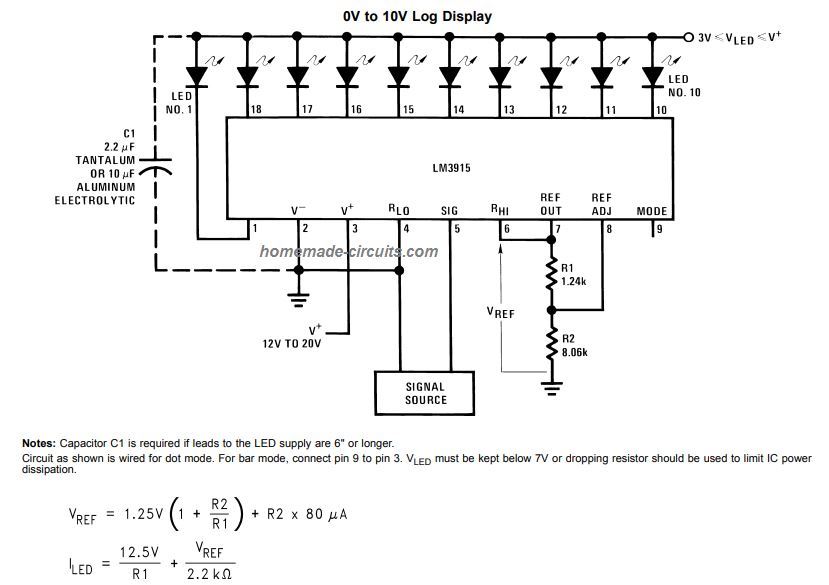

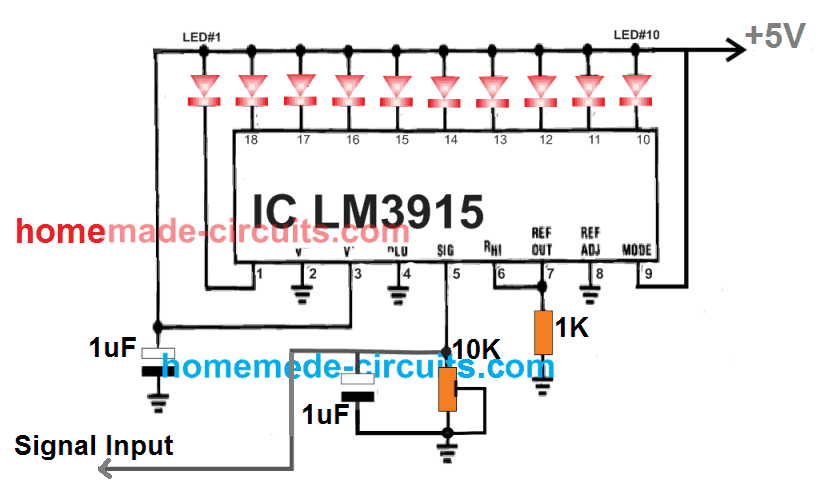

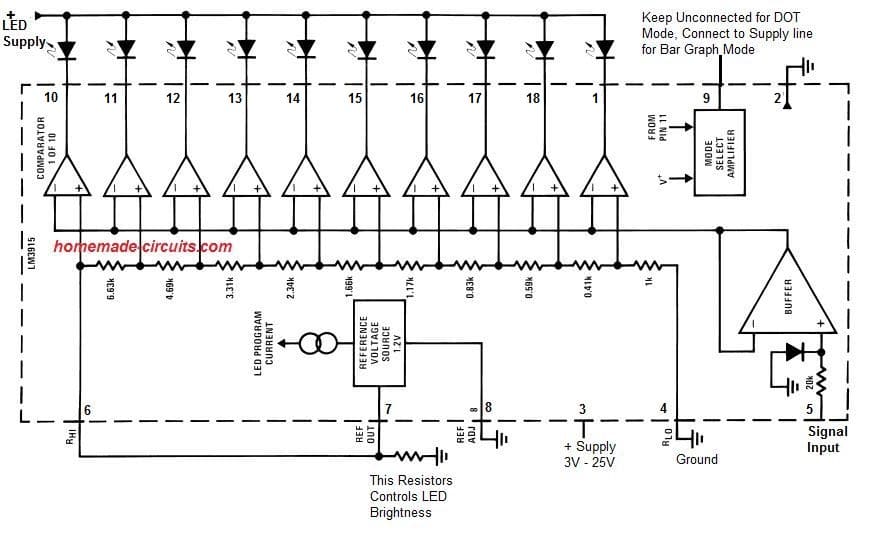

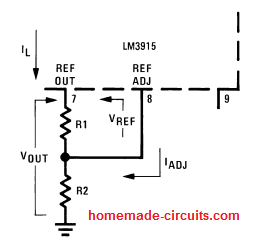

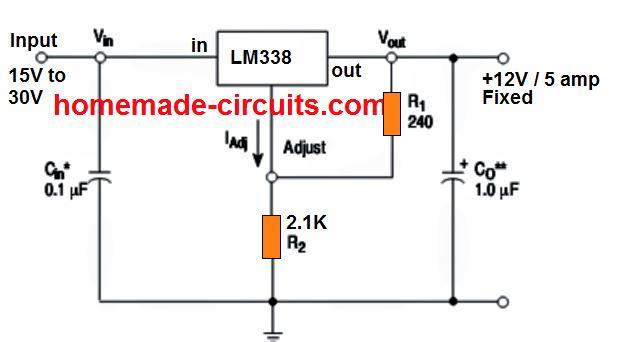

The circuit functioning may be understood with the following points: The IC LM3915 which is a Dot/Bar voltage display chip forms the main section of the circuit. The IC has ten linearly incrementing output which sequence one after the other in response to a rising potential fed at its pin#5. Thus the output sequence corresponds to the instantaneous voltage level at the "signal input" pin out of the IC. The 10K preset associated with the above IC is set as per the battery voltage which needs to be charged. After this the LEds connected at the output linearly indicate the charge level of the battery by illuminating in sequence, and finally when the last LED is lit which happens when the battery gets fully charged, the SCR is triggered shutting off the charging process permanently until the power is reset. Discover the Widest Range of Automatic Battery Charger Circuits The stage comprising the IC LM338 is a standard voltage regulator IC, the preset associated with IC is set as per the required full charge limit of the connected battery. The transistor BC547 provides a fixed 3V for the connected LEDs for controlling the IC dissipation. The transistor BC557 remains switched OFF as long as the last LED in the array which may be selected for the full charge indication is not illuminated. As soon as the last "full charge" LED switches ON, the BC557 is also switched ON triggering the SCR. The SCR instantly grounds ADJ pin of the LM338 completely disabling the IC and the output to the battery. The battery now stops receiving any voltage and thus it is inhibited from getting over charged.How to Set Up this Circuit

The circuit can be used for charging 1.5V, 3V, 6V, 9V, 12V, 15V, 18V, 21V and 24V batteries, in fact any voltage that may lie between 1 and 24V. Suppose you want to charge a 6V battery, the full charge level for this battery would be 7V. The setting of the circuit may be done in the following manner: Do not connect the battery initially and also keep the SCR gate disconnected from the BC557 network. Apply a relatively higher DC potential at the input of the IC LM338, may be a 9V or a 12V input. Adjust the 10K preset under the LM338 such that the battery terminal points receive a 7V output. Now adjust the 10K preset under the IC LM3915 such that the last LED just flickers ON at this voltage, meaning at the applied 7V. Restore the the SCR gate connection as per the circuit diagram. That's it the circuit is all set now. During the charging process each LED will correspond to 7/10 = 0.7 volts, meaning say at 5V the 7th LEd will be illuminated and with a rise of 0.7V the subsequent LED will be lit and the sequence will proceed from 7t to 8th to 9th and then finally to the 10th LEd shutting off the circuit and the charging of the battery. Alternatively if you you are interested in making the circuit respond with all batteries from 3V to 12V then you may adjust the LM3915 preset such that the last LED barely illuminates at 14.4V. Now each pinout of the IC corresponding to the relevant LED would sequence at the rate of 14.4/10 = 1.4V, therefore for a 6V battery the full charge LED pinout would be 7/1.4 = 5, meaning the 5th LED illuminated would indicate that the connected 6V battery is now fully charge. For enabling automatic cut off for the above situation you just have make sure the base of the BC557 is connected to the 5th pinout of the IC LM3915 from left to right. For a 9V battery it would 9/1.4 = 6.4th LEd, meaning when the 6th LED is fully glowing and the 7th LED is barely flickering, the 7th LEd may be selected and joined with BC557 base for acquiring the required automatic cut off.Circuit Diagram

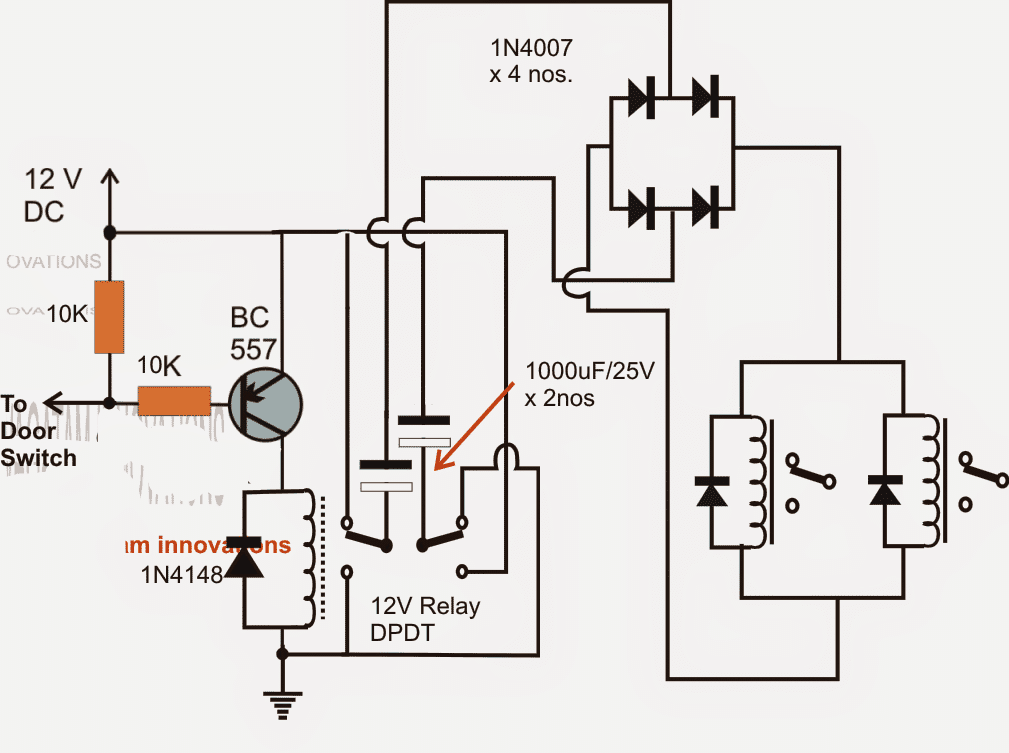

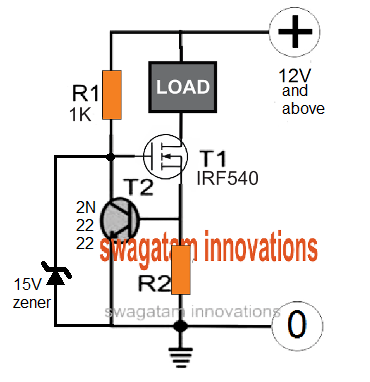

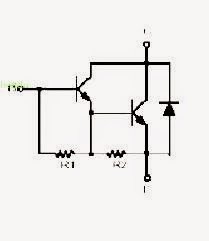

Using Transistor Latch instead of SCR

If the above circuit fails to respond with an SCR, the following circuit using a transistor latch can be employed:

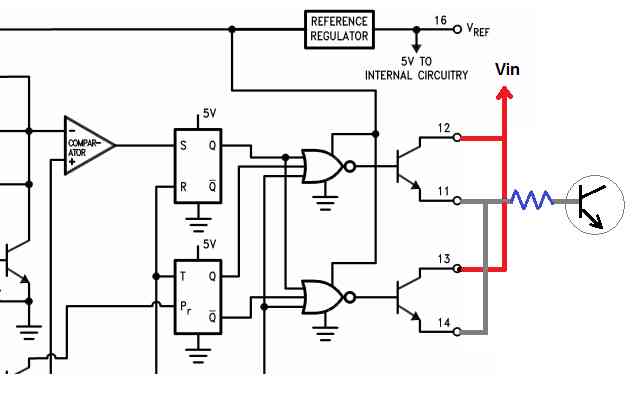

For an Automatic ON/OFF Function

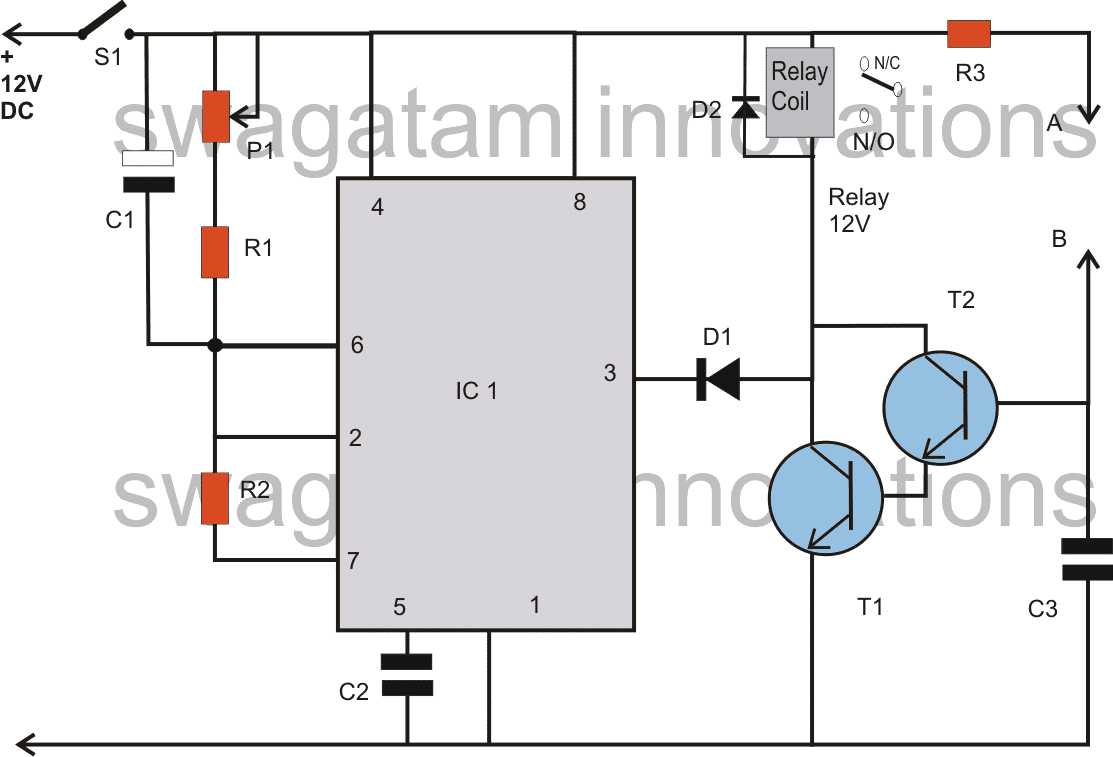

If you want the above multipurpose battery charger circuit to cut off the charger while the battery reaches the full change limit, and then quickly switch ON the charging when the battery starts dropping below the full charge limit, and continue flip flopping at this threshold level, in that case you can try modifying the design in the following manner:

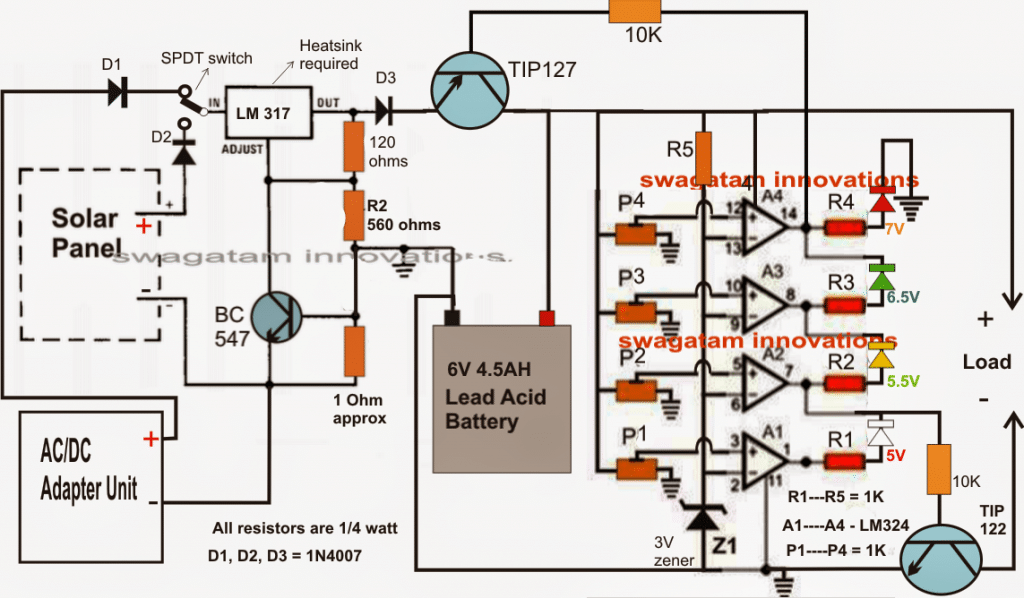

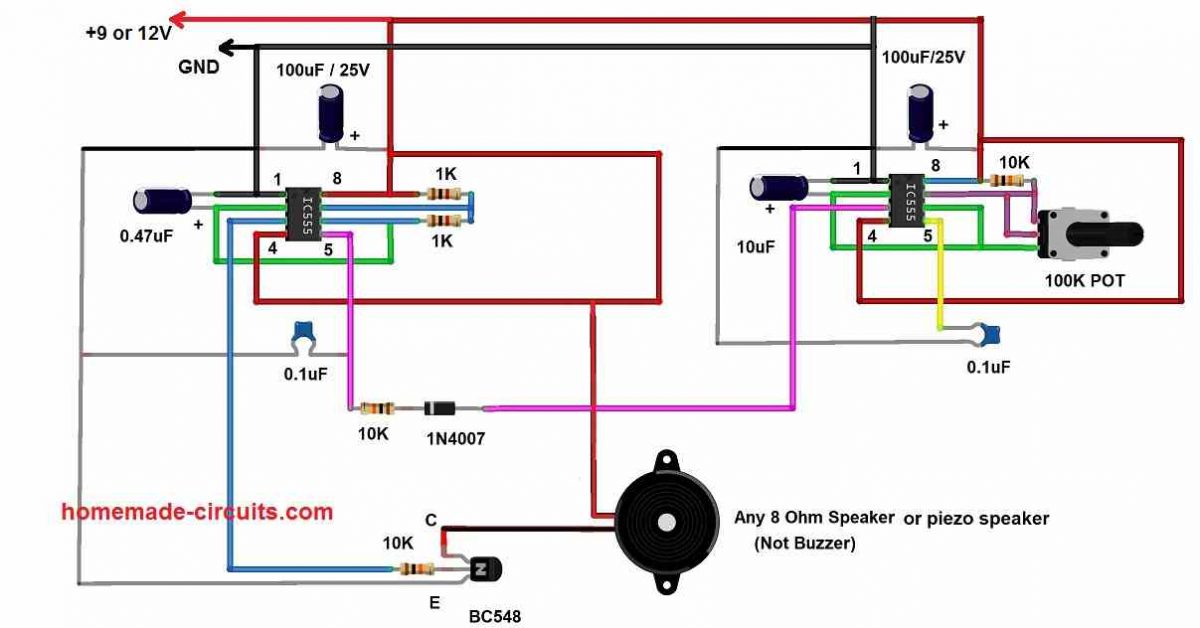

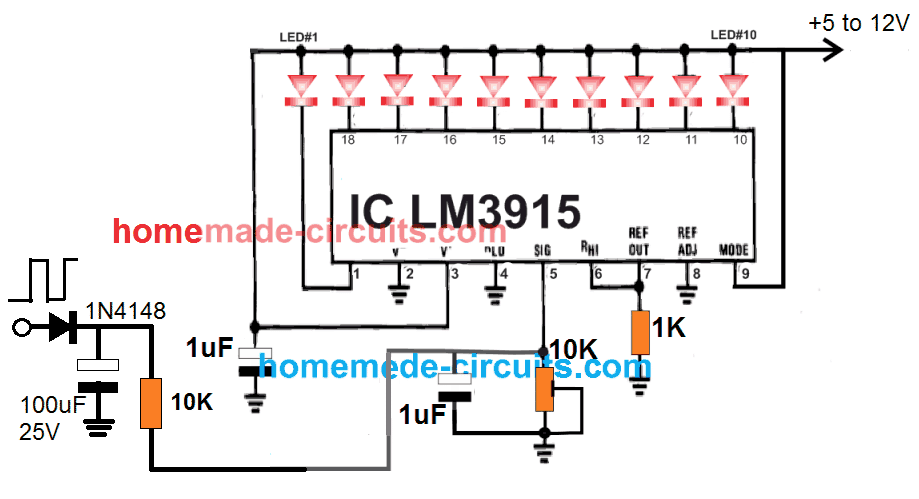

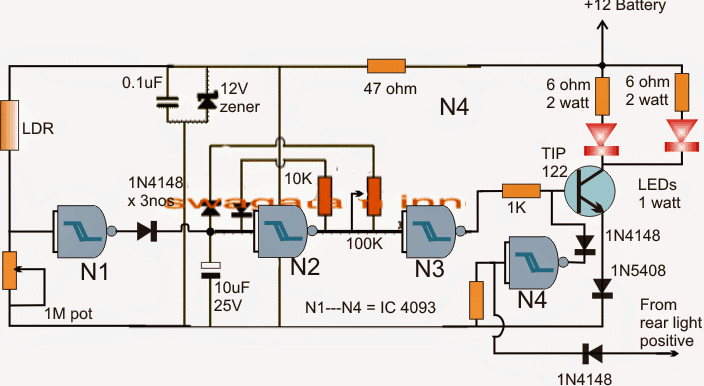

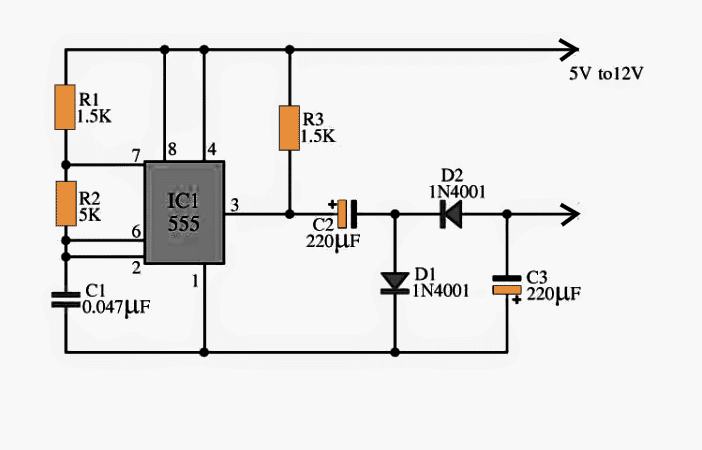

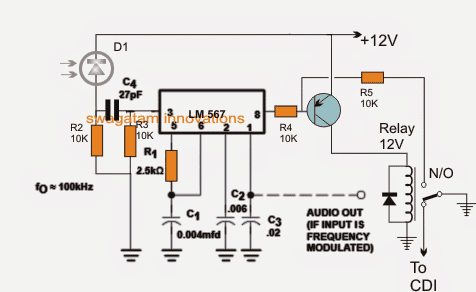

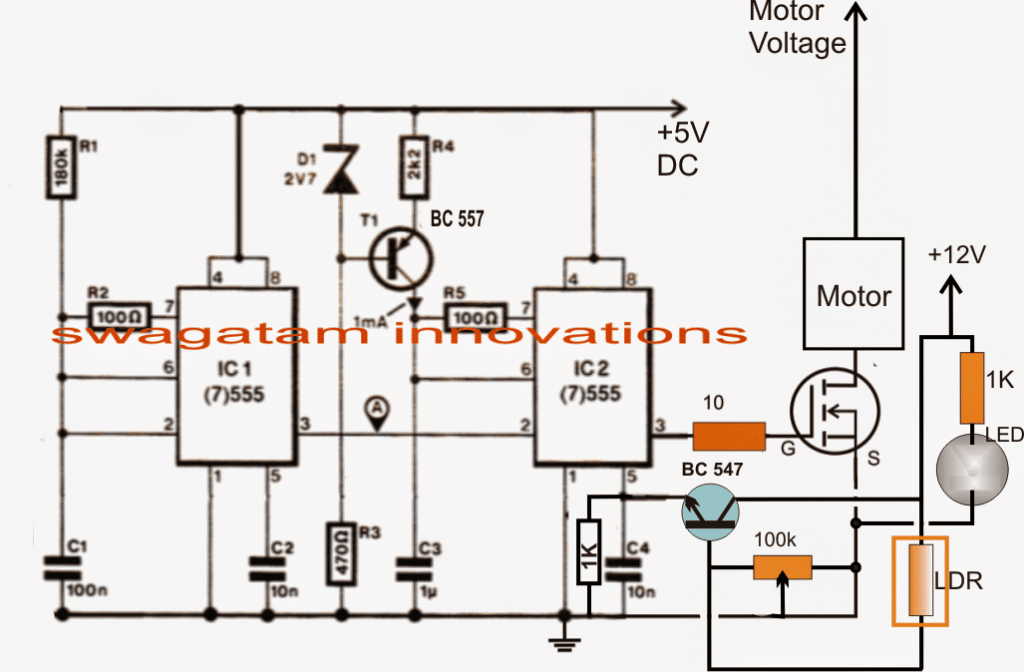

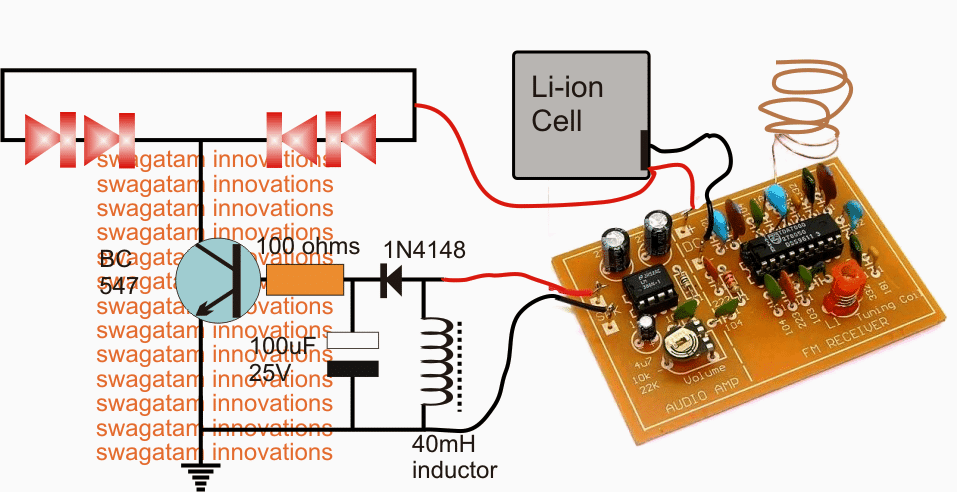

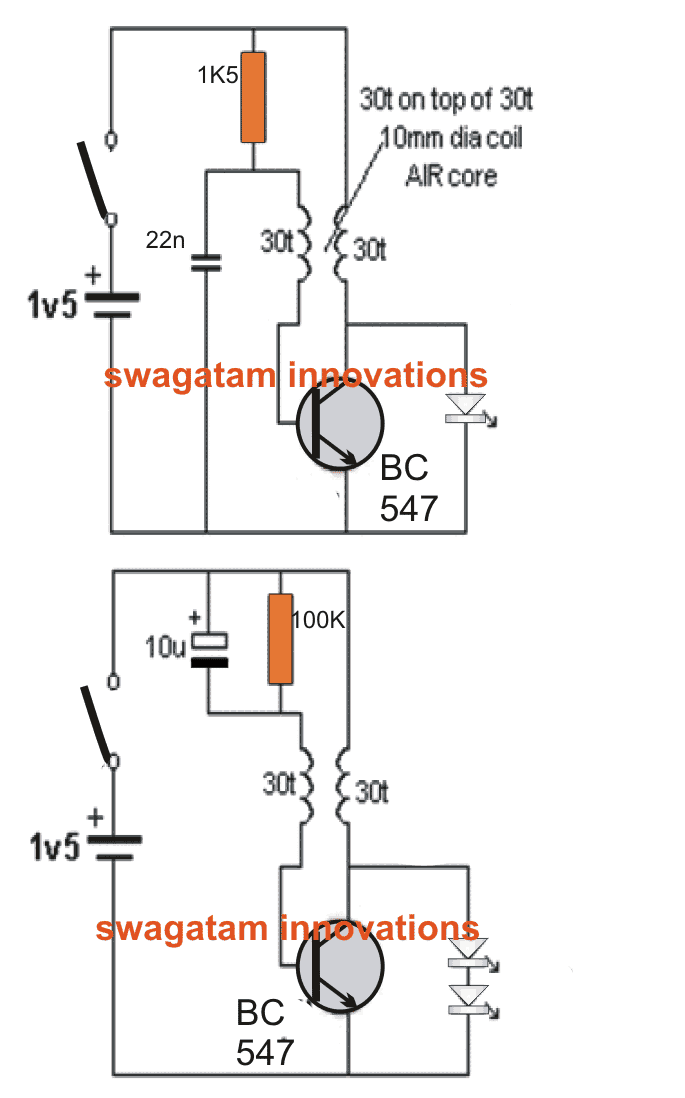

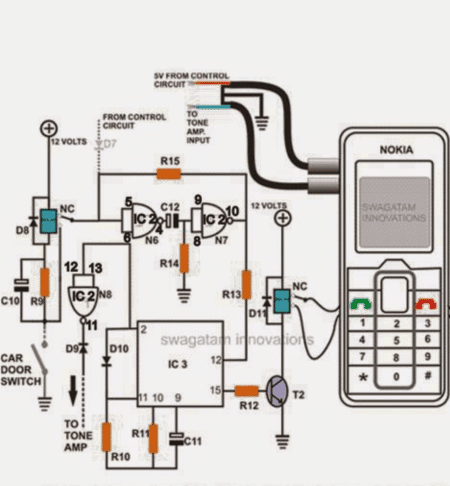

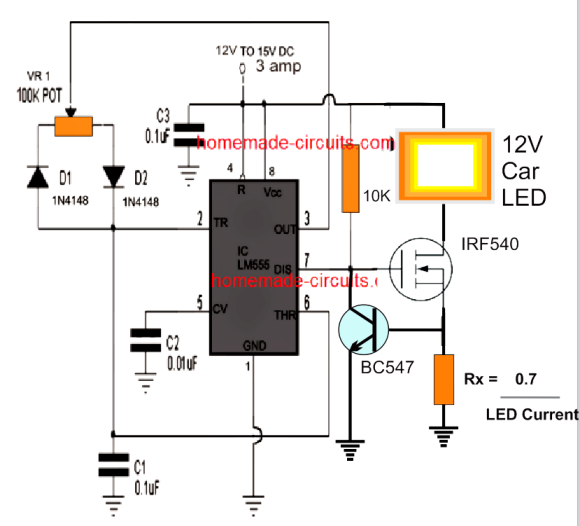

Solar Boost Charger Circuit with LED Driver Dimmer

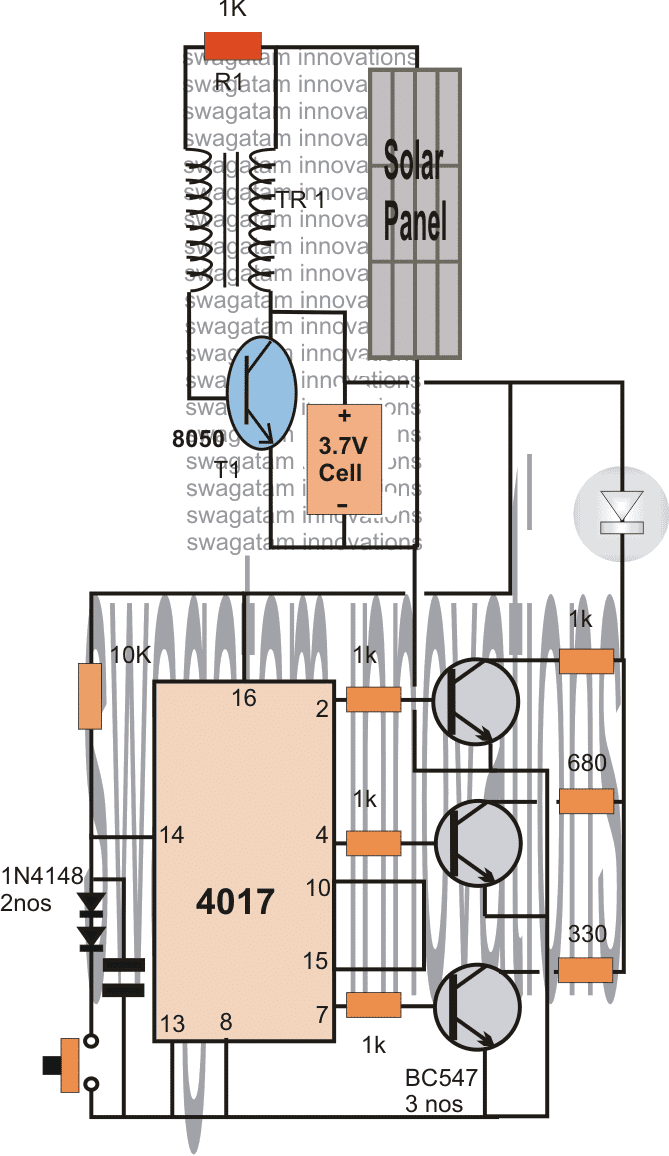

The article explains a simple solar boost charger with LED driver circuit which also includes a single push dimmable feature. The idea was requested by Mr. Ashutosh.Technical Specifications

Hi swagatam,Myself Ashutosh. I m very new to ur website, n i ll say u r superb, u r doing one of the best thing by helping hobbyists. Thank you very much. I want an LED driver cum charger circuit for our project. i know u already have thousands of request pending and at the same time u might be working on different circuits,even thoughi want to ask for it, my circuit details are as below-

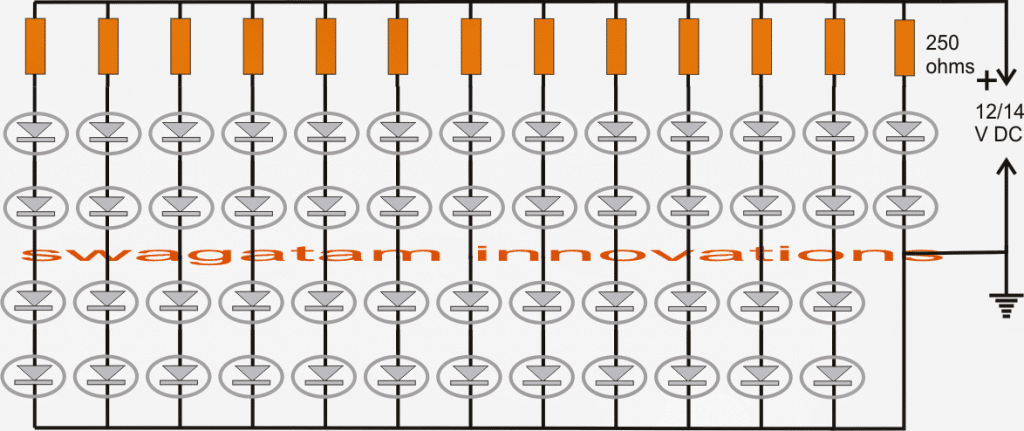

1. It's an LED lamp 2. Having 3volt (0.5watt) of solar panel for charging the battery. 3. Have to charge 3.6 volt battery from the solar panel (for this may be some boost ic is required ). 4. Regarding switching---> have one switch---> when all the connection are there the LED should be in off mode---> after 1st press it should glow in full brightness i mean 100% duty cycle----> 2nd time when i press 2nd time the switch the LEDs brightness shoulddecreasedby 40-50%---> when i press the switch 3rd time the LED should get more dimmed(say the brightness should decreased by 70-80%)----> and when i press the switch 4th time the LED should get off. 5. Circuit should be very compact(made up of very few components) and no use of microcontroller plz as, i dnt have that much idea about the microcontroller. 6. Also suggest the best LED for brightness whether it ll be an SMD LED and it's specification.

it won't be so difficult for u sir. i m bookmarking you this page for your reply, as i know from ur site, ur best thing is u used to reply almosteveryone keep doing it. A positive reply is expected from you. Thank you very much.

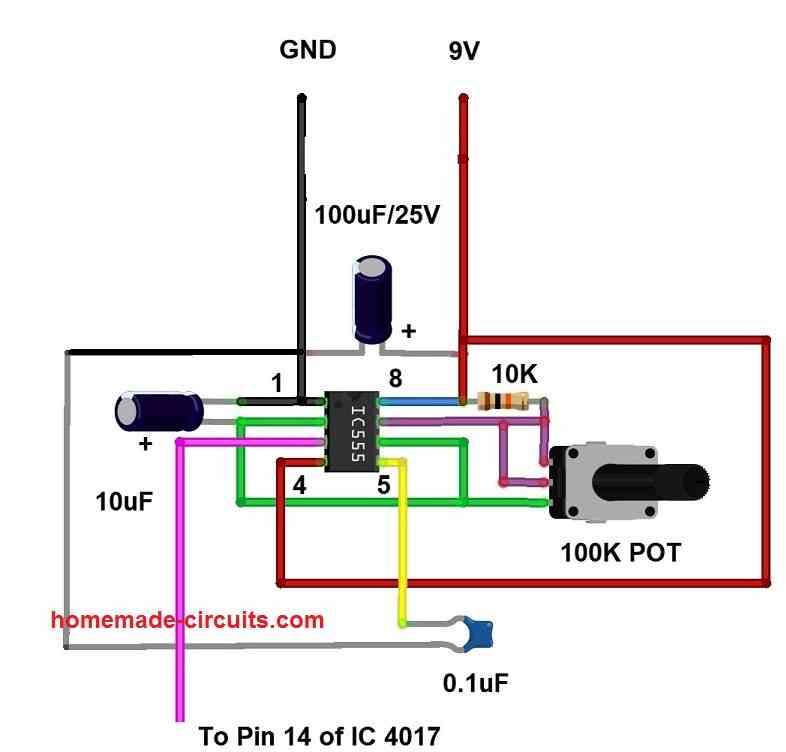

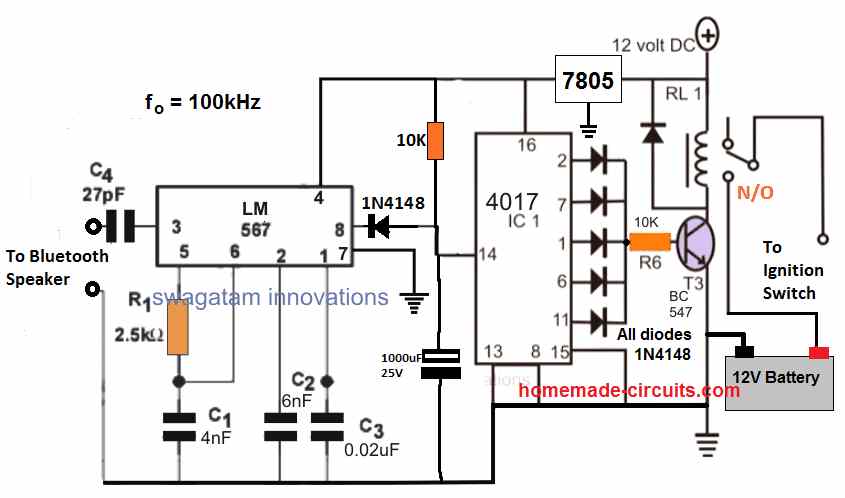

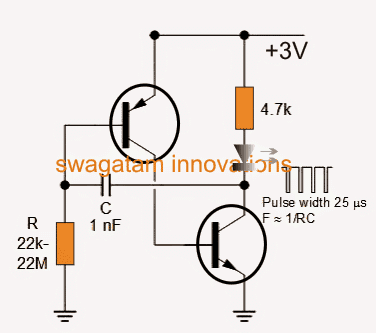

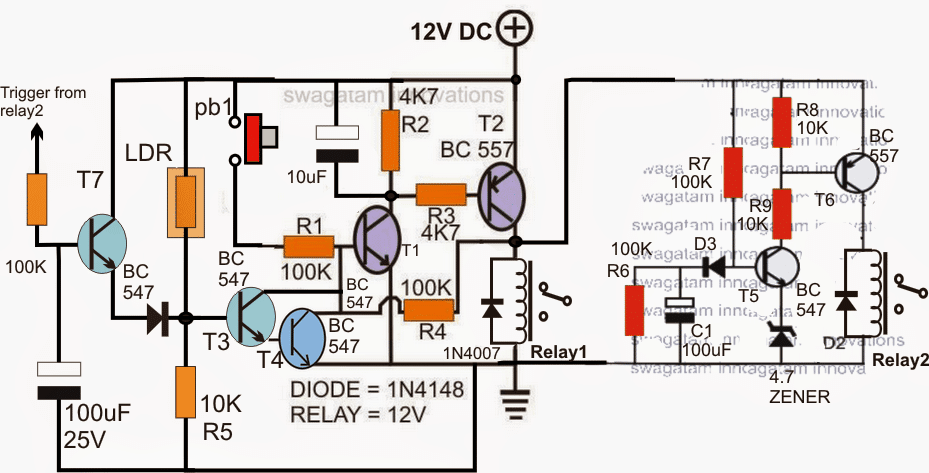

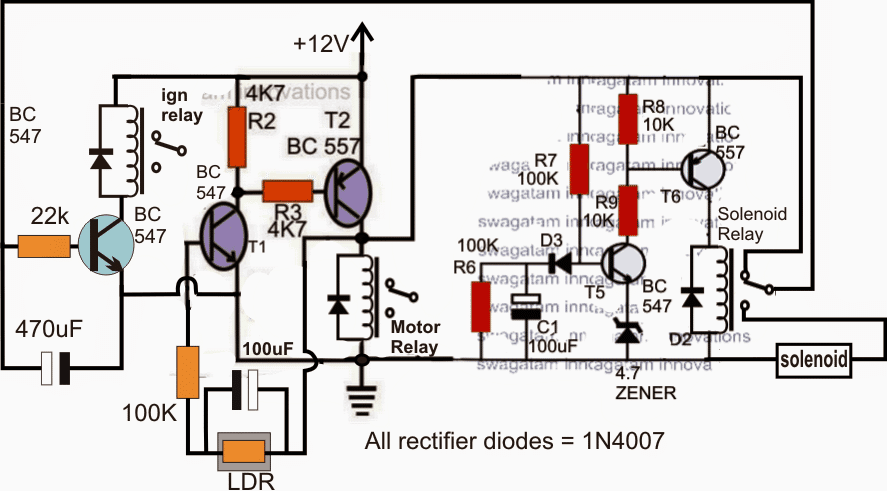

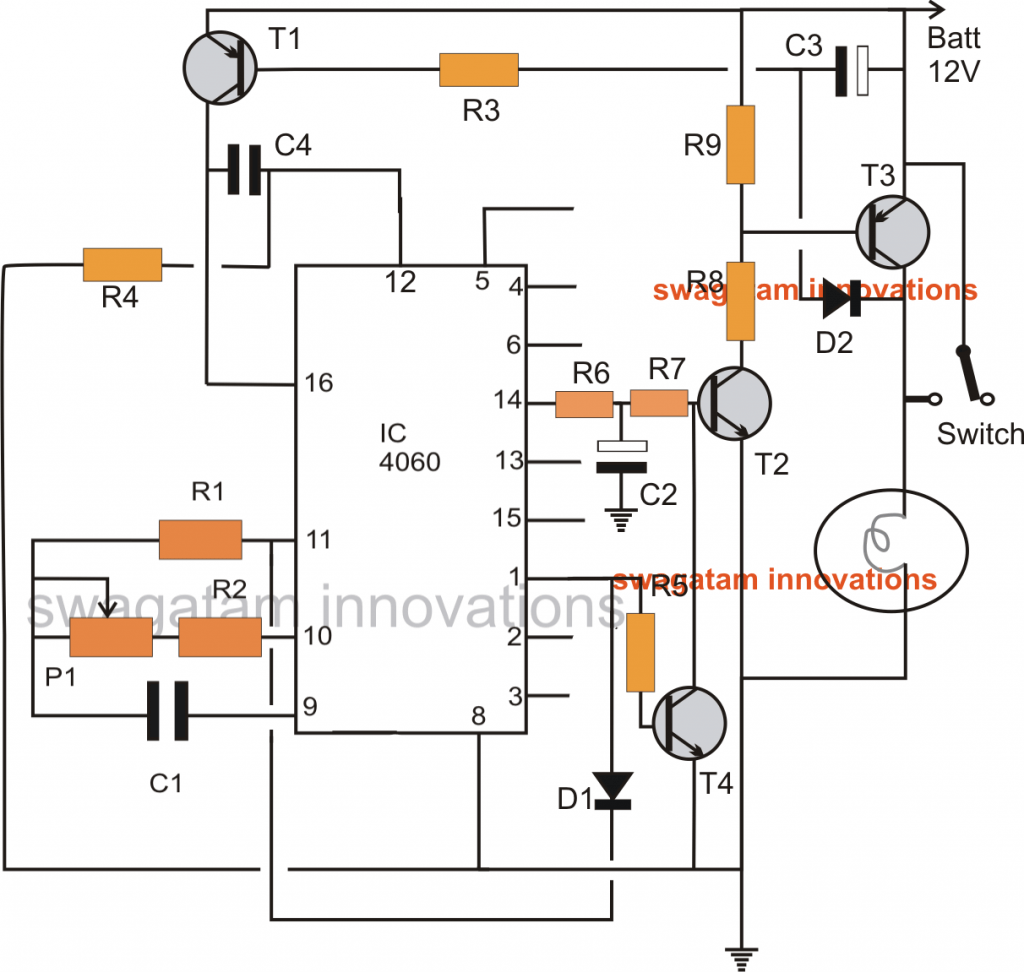

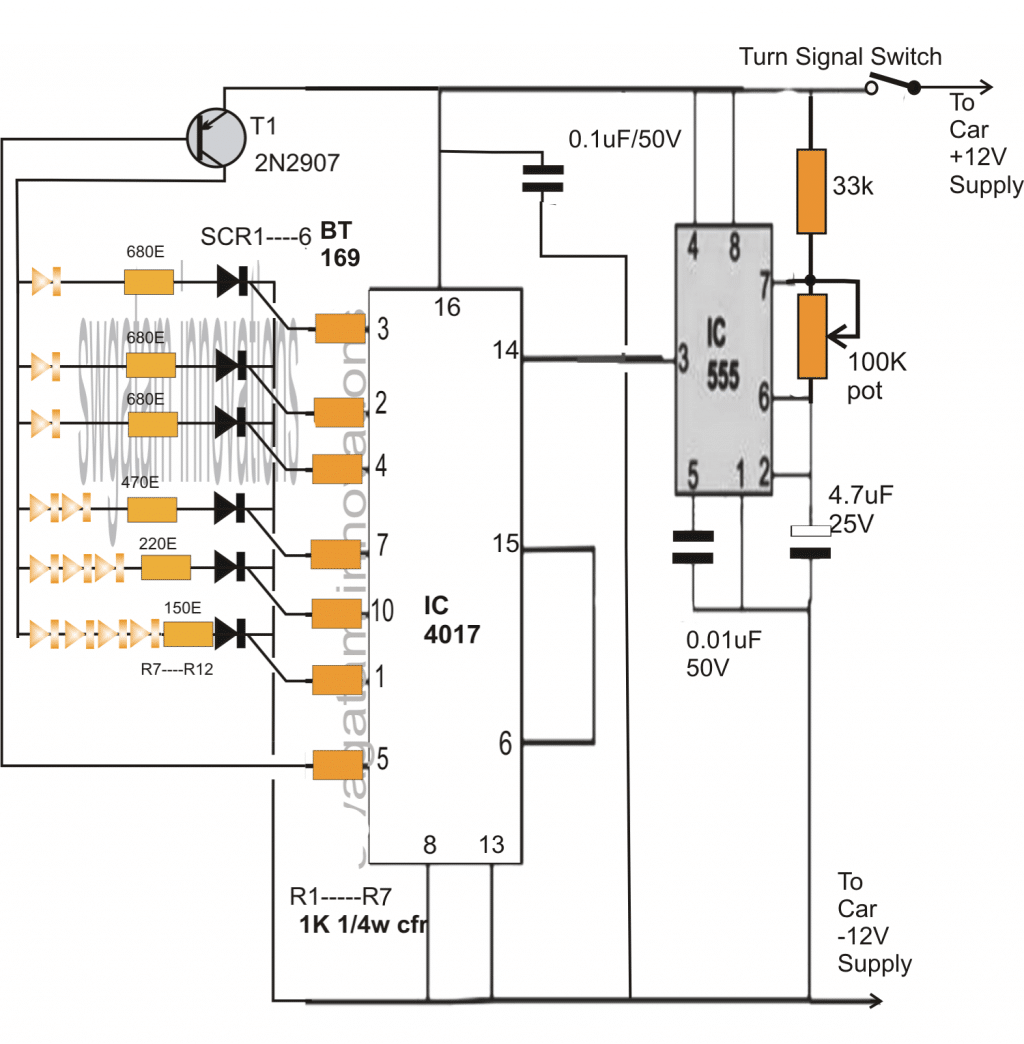

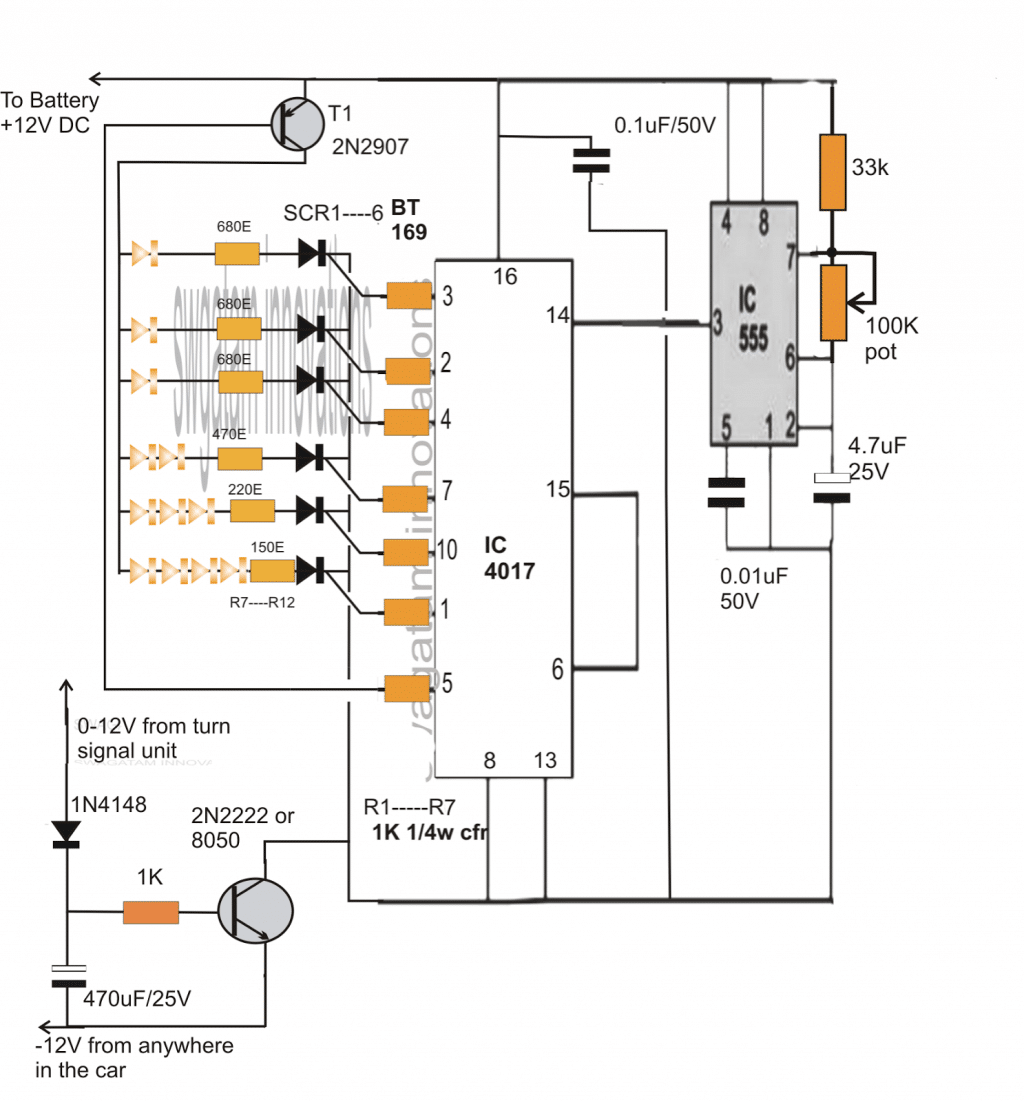

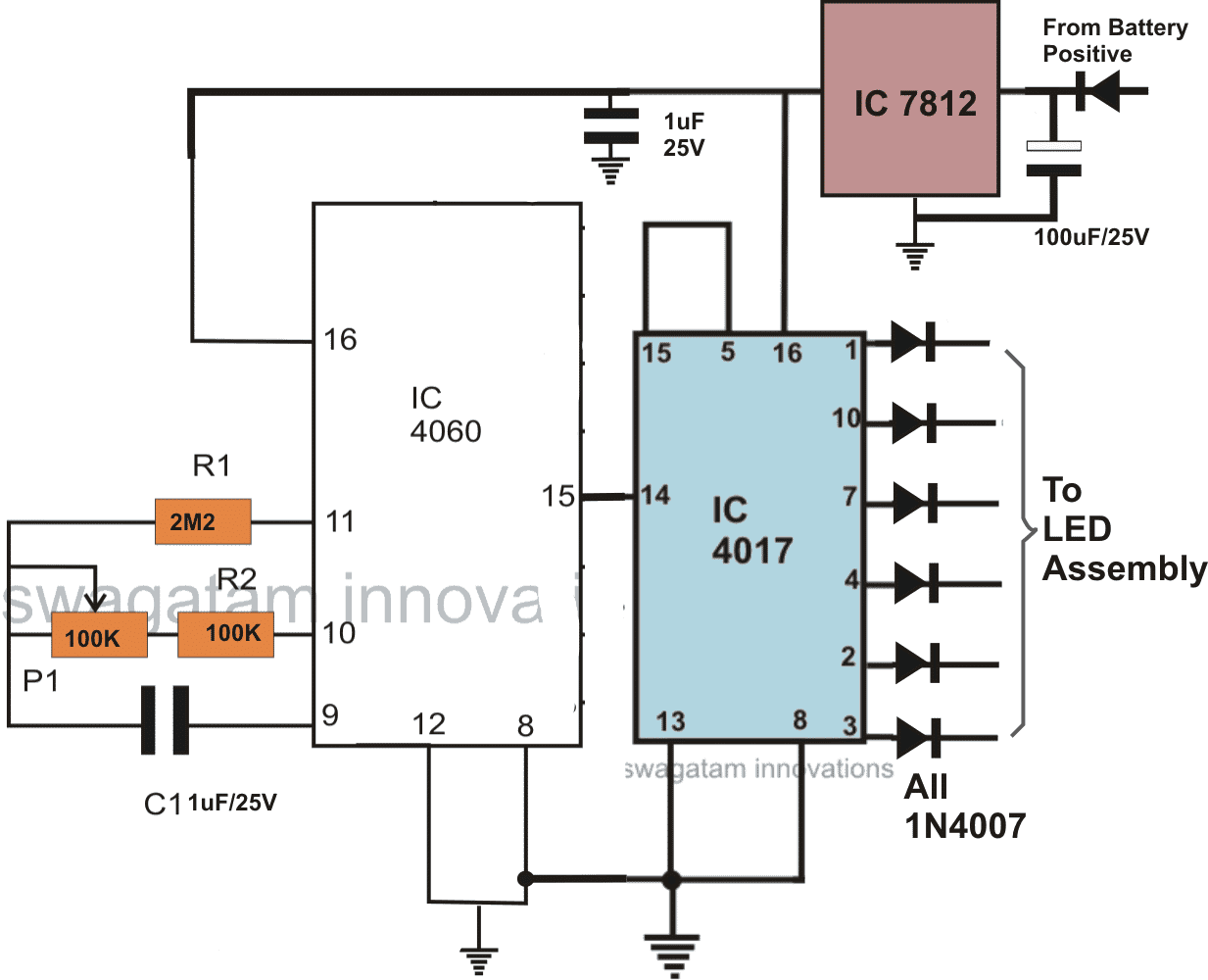

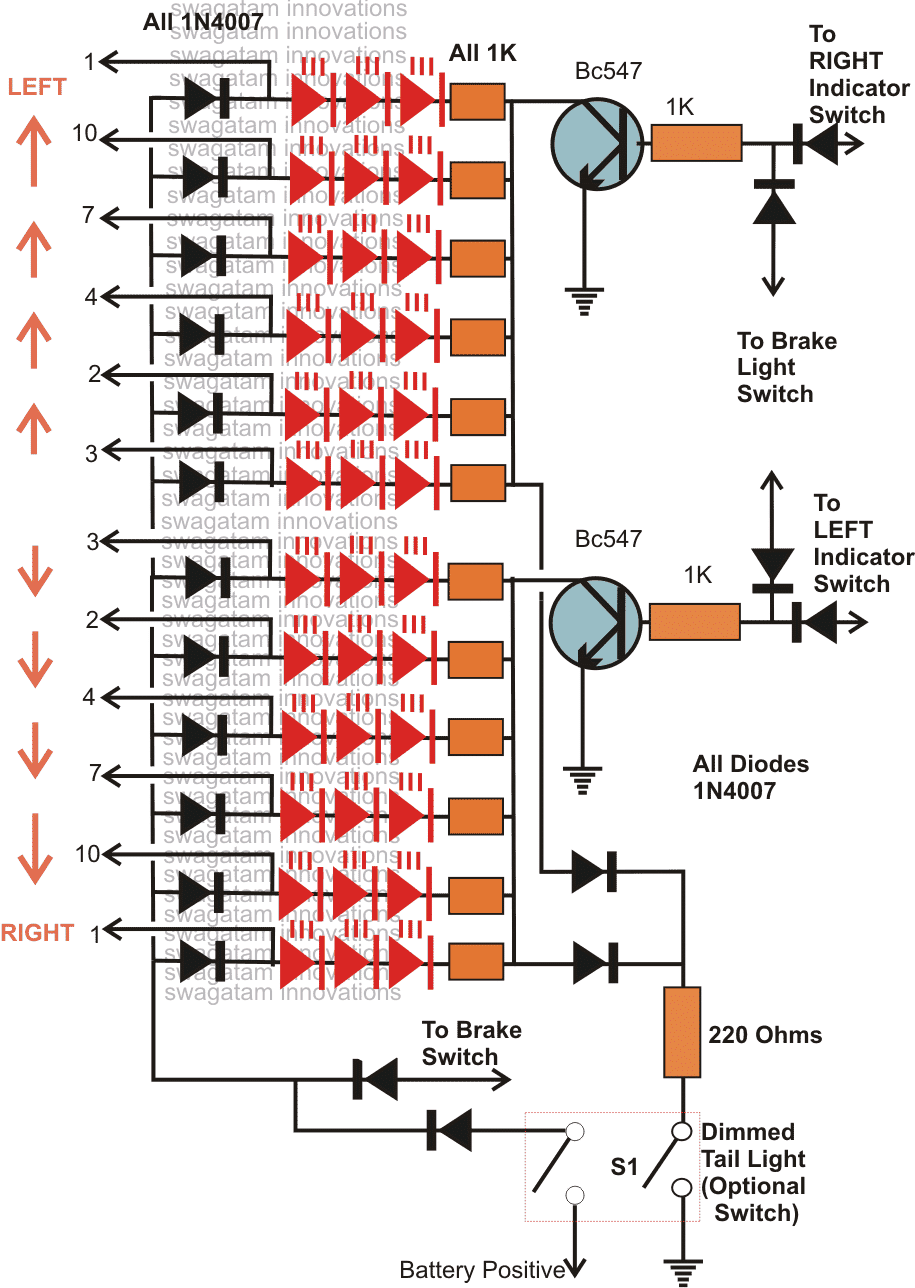

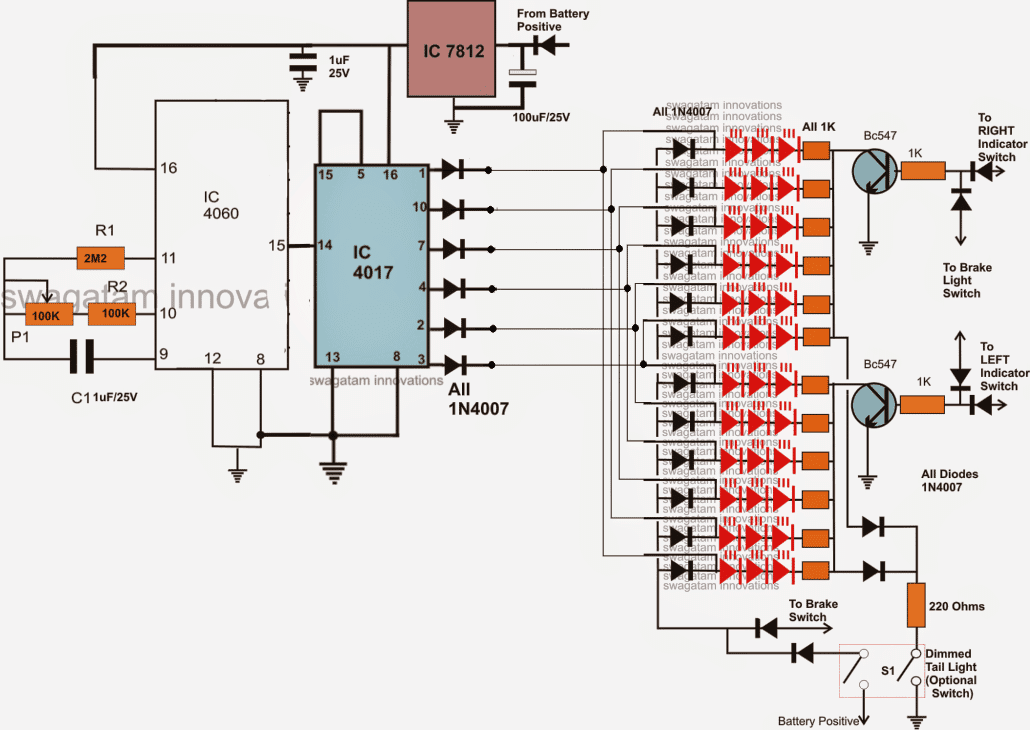

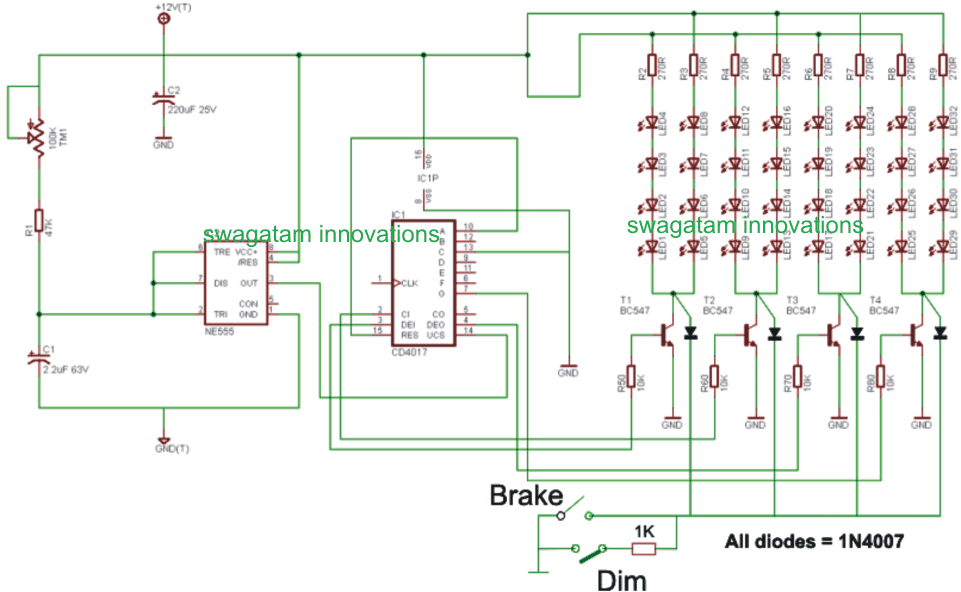

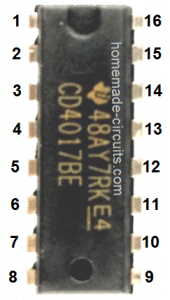

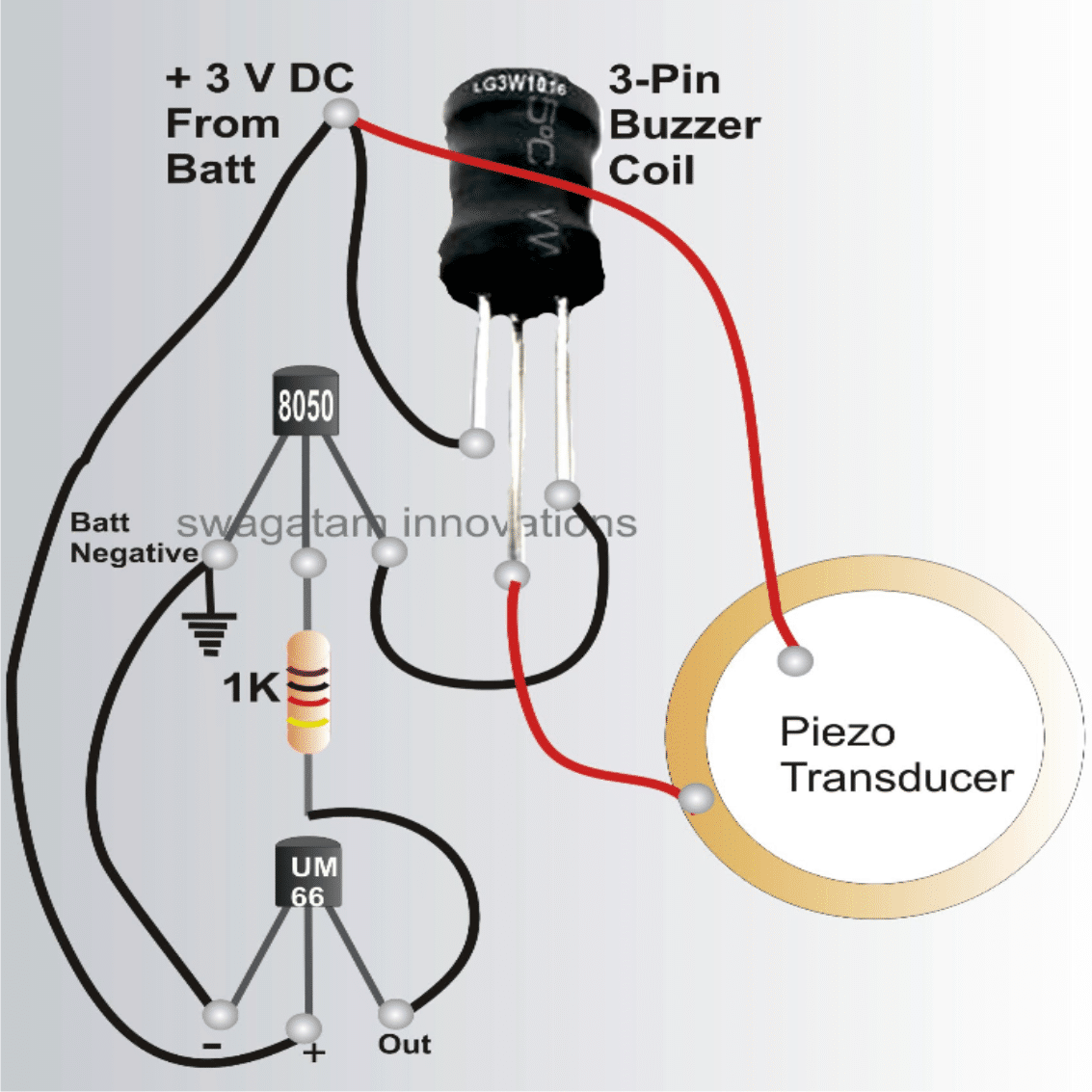

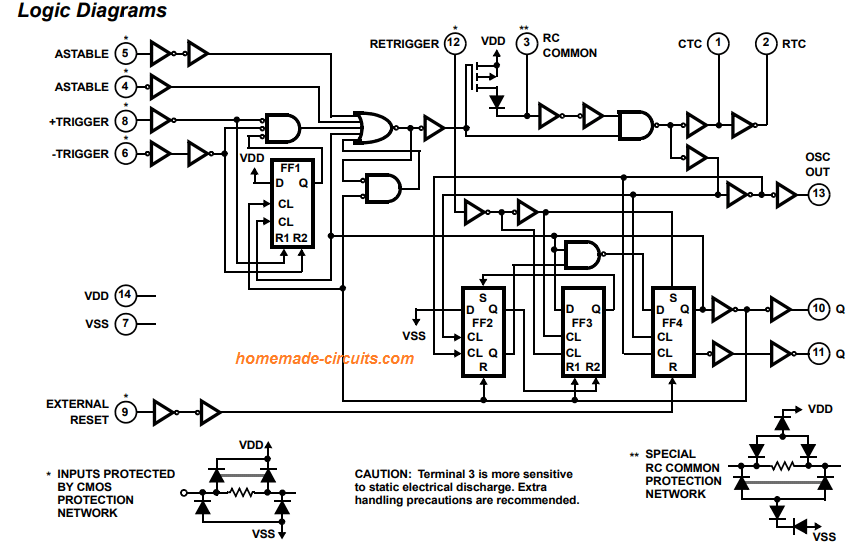

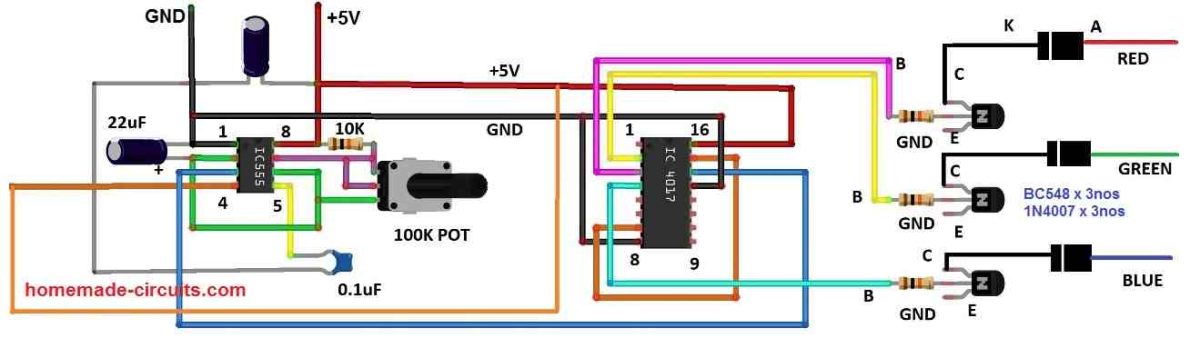

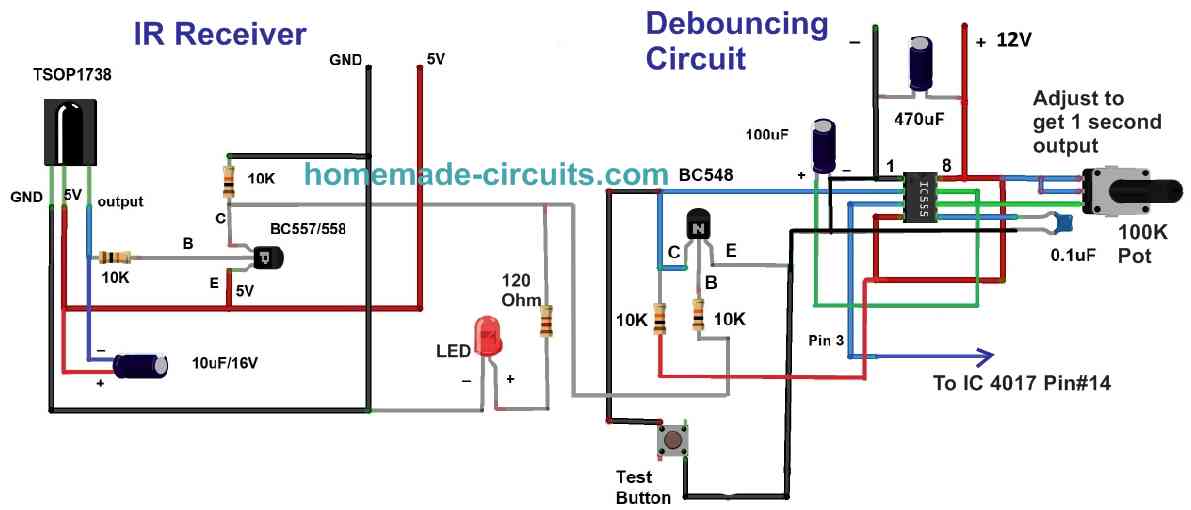

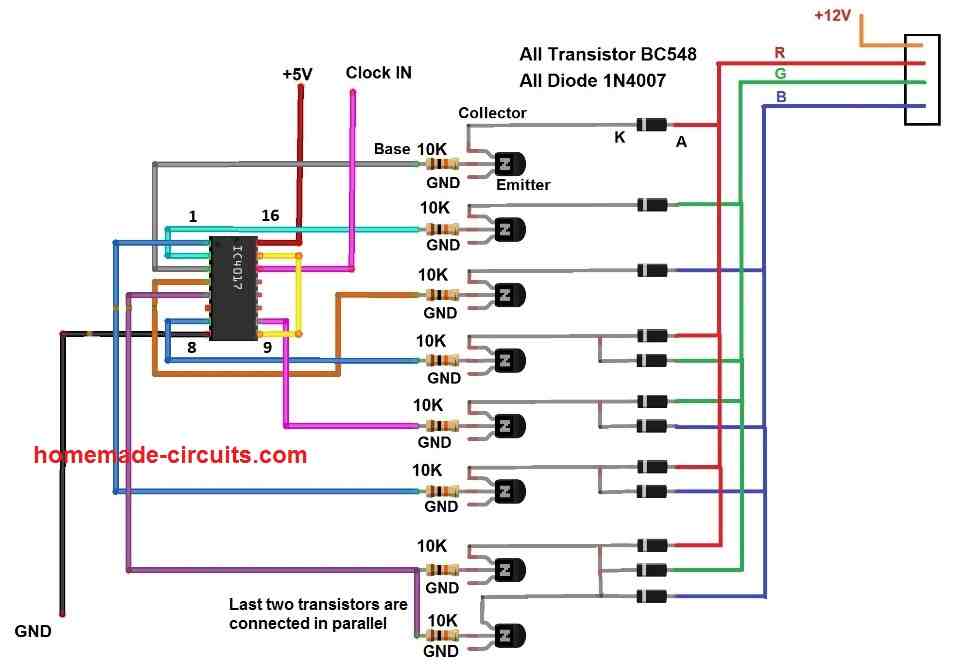

The Design

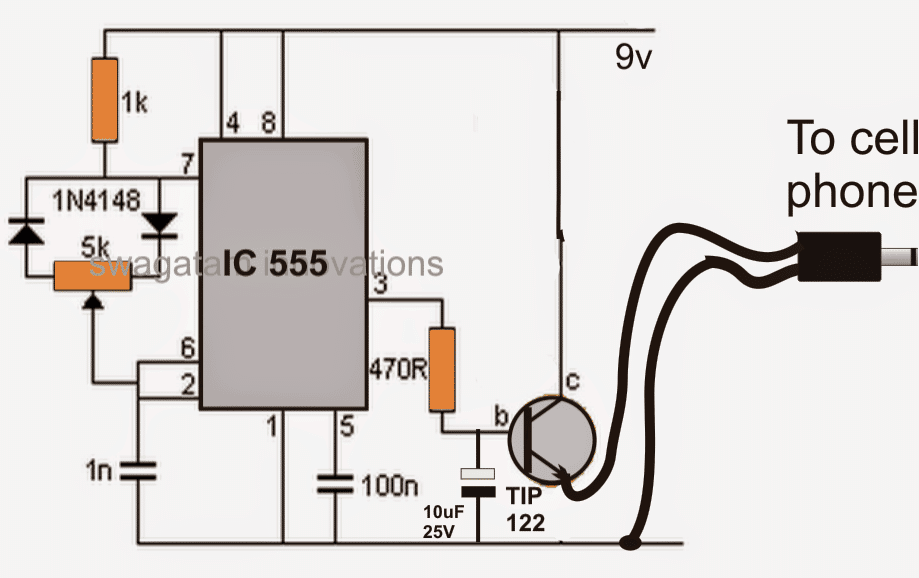

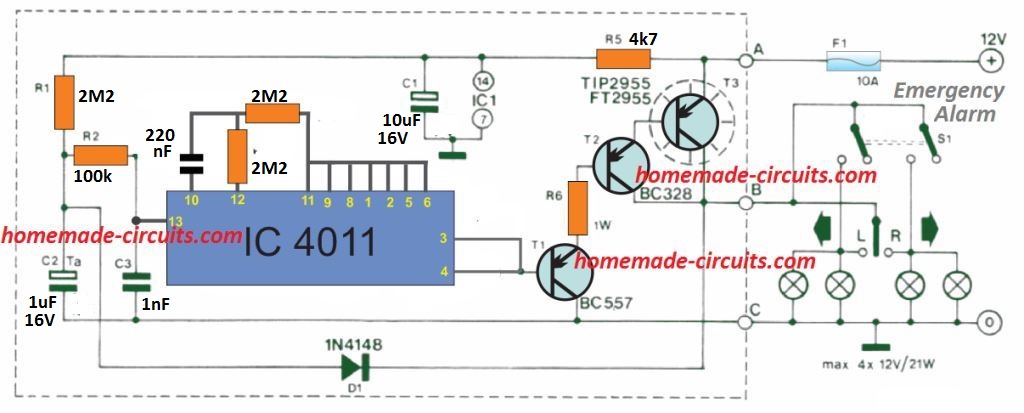

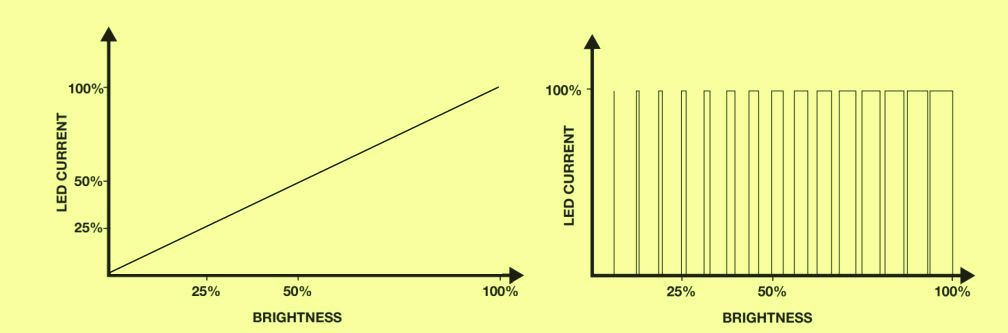

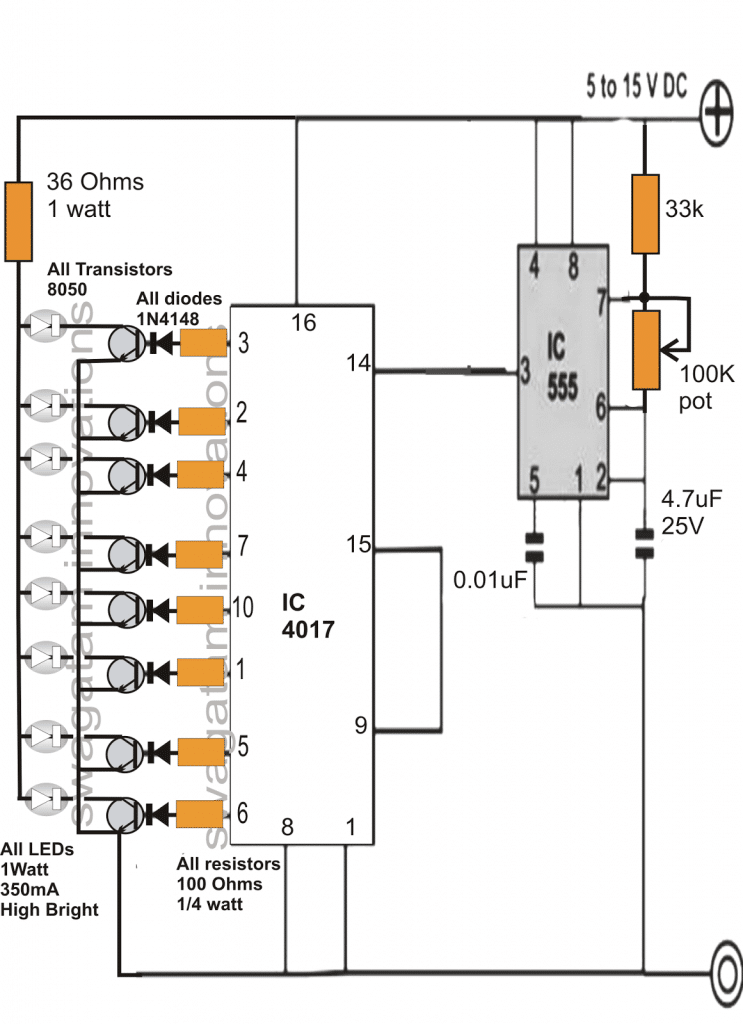

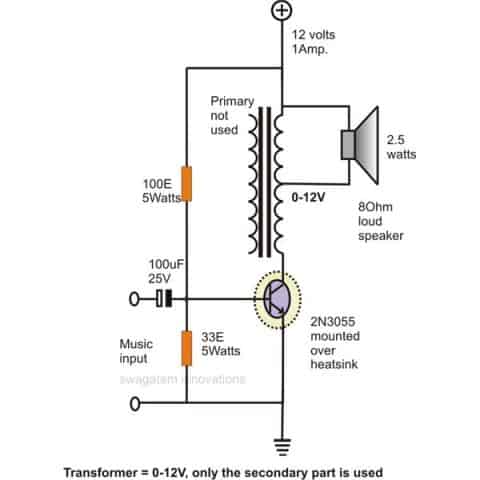

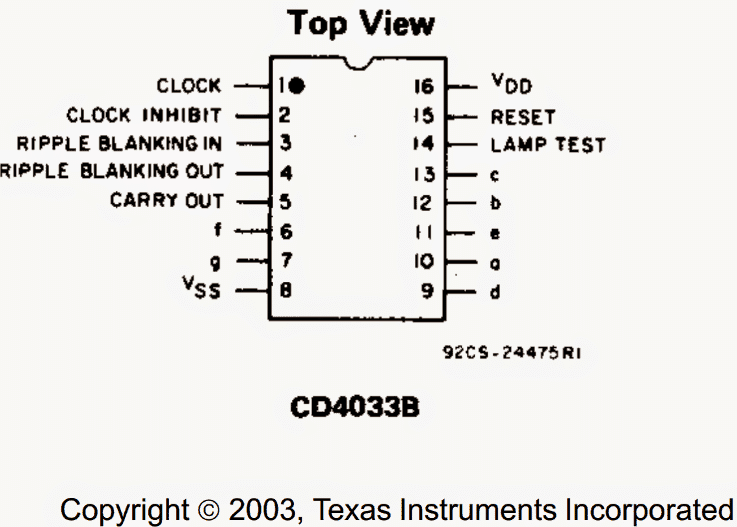

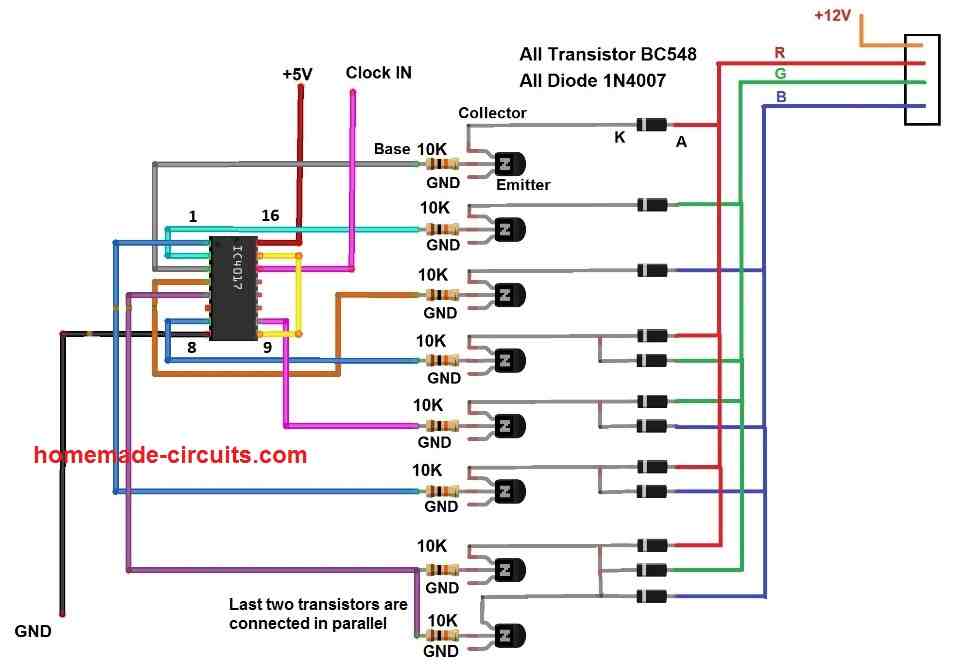

When an input is applied, the transistor instantly goes into an oscillating mode inducing a relatively stepped up voltage across the connected battery. The process starts charging the battery and depending upon the position of the IC 4017 output illuminates the connected LED with a certain intensity. The IC 4017 operates in three modes as requested above. The modes can be selected by pressing the given button momentarily. The above toggling sequences the output from the pin2 to pin7 in steps producing different glow intensities on the LED. At the first pin out pin#3 (not shown) the LED shuts down completely as it's not associated with theswitchingnetworkin anyway.

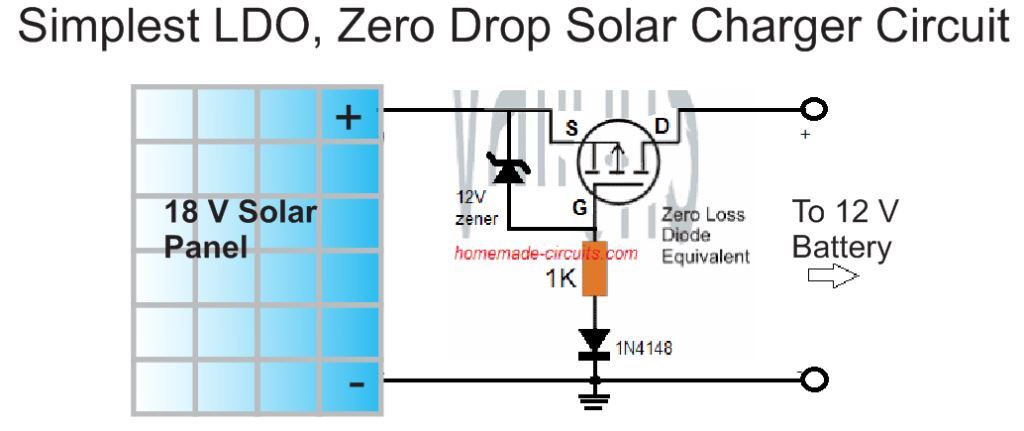

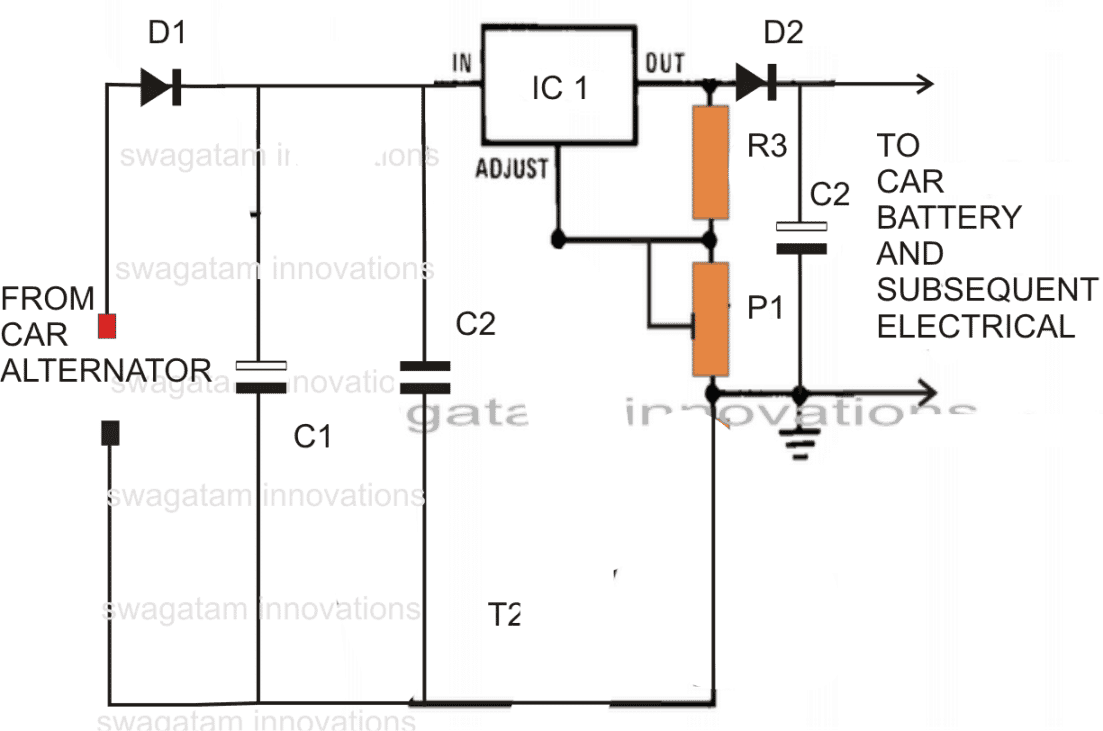

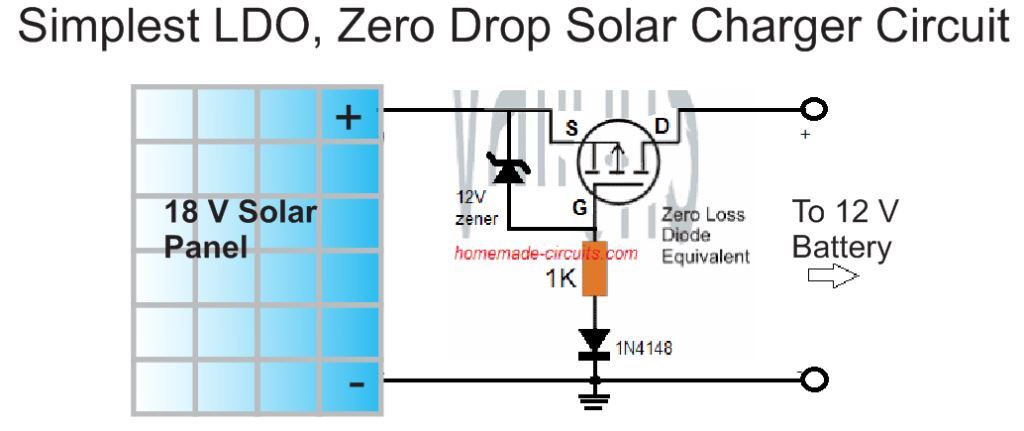

Zero Drop LDO Solar Charger Circuit

The article discusses a simple low dropout LDO, or zero drop solar charger circuit without microcontroller which can be modified in many different ways as per user preference. The circuit does not depend on microcontroller and can be built even by a layman.What is a Zero Drop Charger

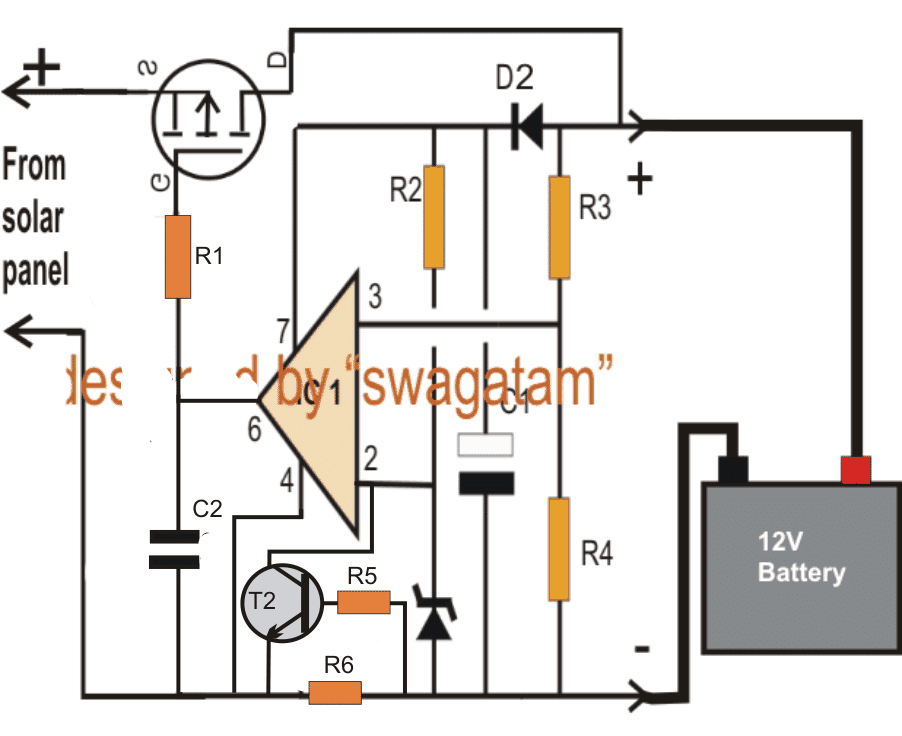

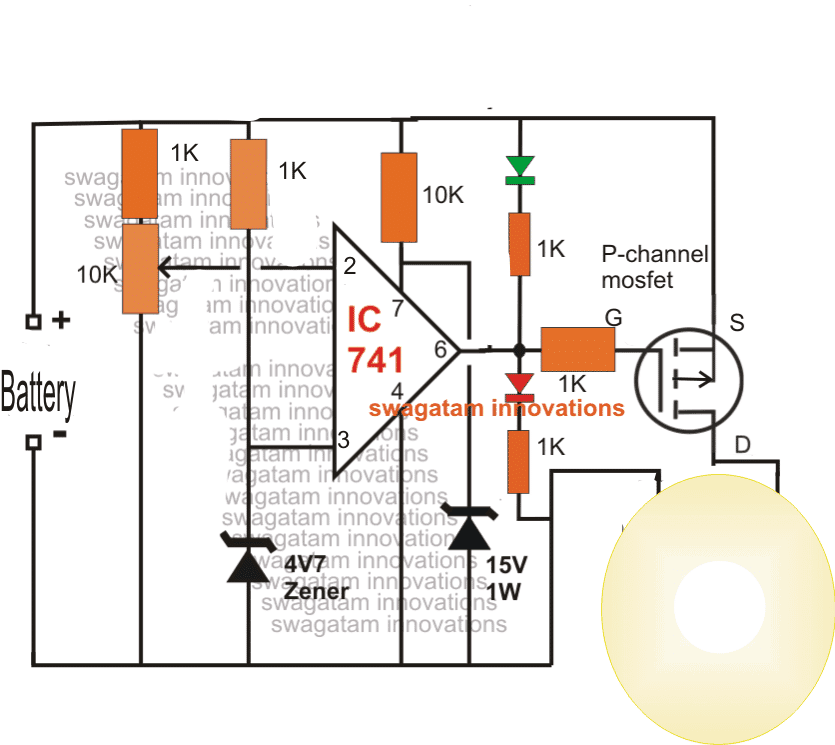

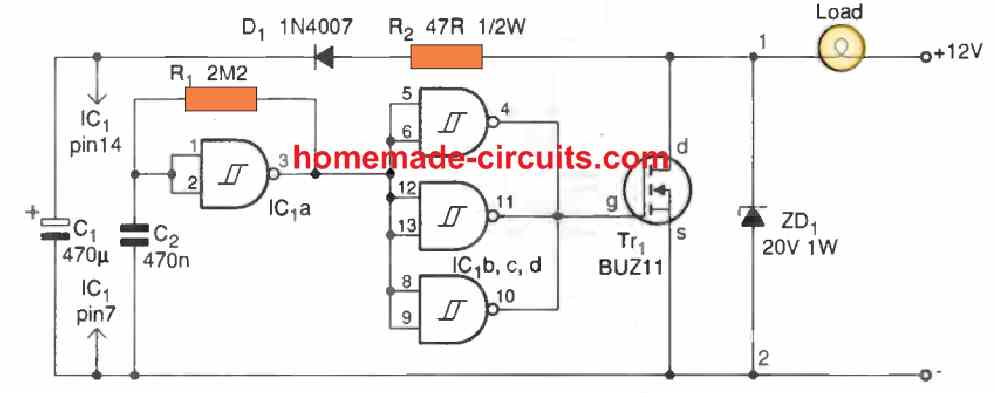

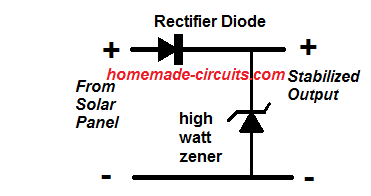

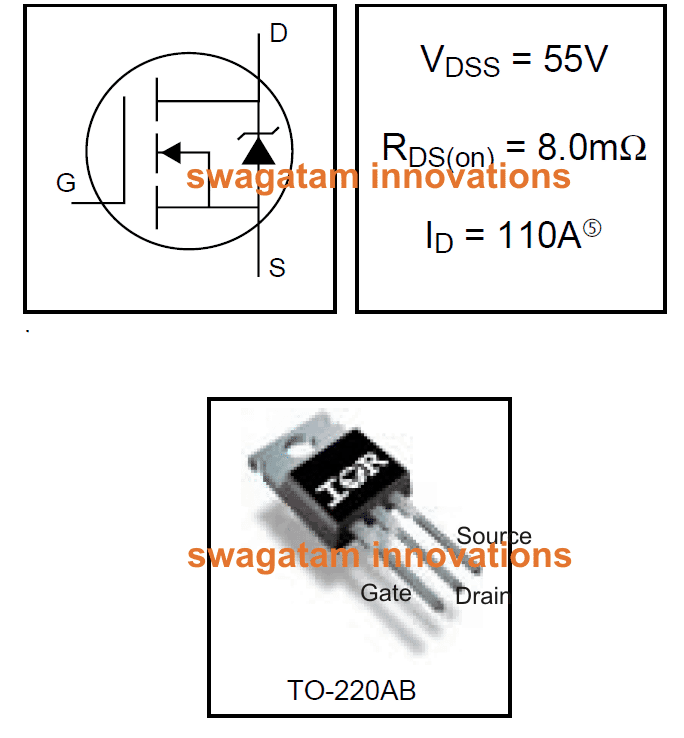

A zero drop solar charger is a device which ensures that the voltage from the solar panel reaches the battery without undergoing any drop in voltage, either due to resistance or semiconductor interference. The circuit here uses a MOSFET as a switch for ensuring minimum drop in voltage from the attached solar panel. Moreover the circuit has a distinct advantage over other forms of zero drop charger designs, it does not unnecessarily shunt the panel making sure the panel is allowed to operate at its highest efficiency zone. Let's understand how these features could be achieved through this novel circuit idea designed by me.Simplest LDO Circuit

Here's a simplest LDO solar charger example which can be built in minutes, by any interested hobbyist. These circuits can be effectively used in place of expensive Schottky diodes, for getting an equivalent zero drop transfer of solar energy to the load. A P channel MOSFET is used as a zero drop LDO switch.

The zener diode protects the MOSFET from high solar panel voltages above 20 V.

The 1N4148 protects the MOSFET from a reverse solar panel connection.

Thus, this MOSFET LDO becomes fully protected from reverse polarity conditions and also allows the battery to charge without dropping any voltage in the middle.

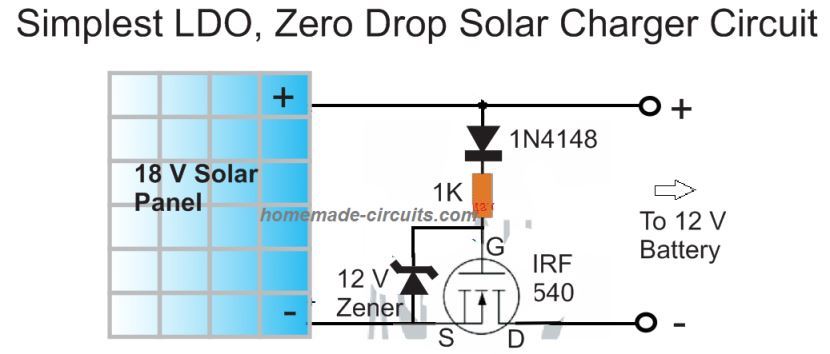

For an N-channel version you can try the following variant.

A P channel MOSFET is used as a zero drop LDO switch.

The zener diode protects the MOSFET from high solar panel voltages above 20 V.

The 1N4148 protects the MOSFET from a reverse solar panel connection.

Thus, this MOSFET LDO becomes fully protected from reverse polarity conditions and also allows the battery to charge without dropping any voltage in the middle.

For an N-channel version you can try the following variant.

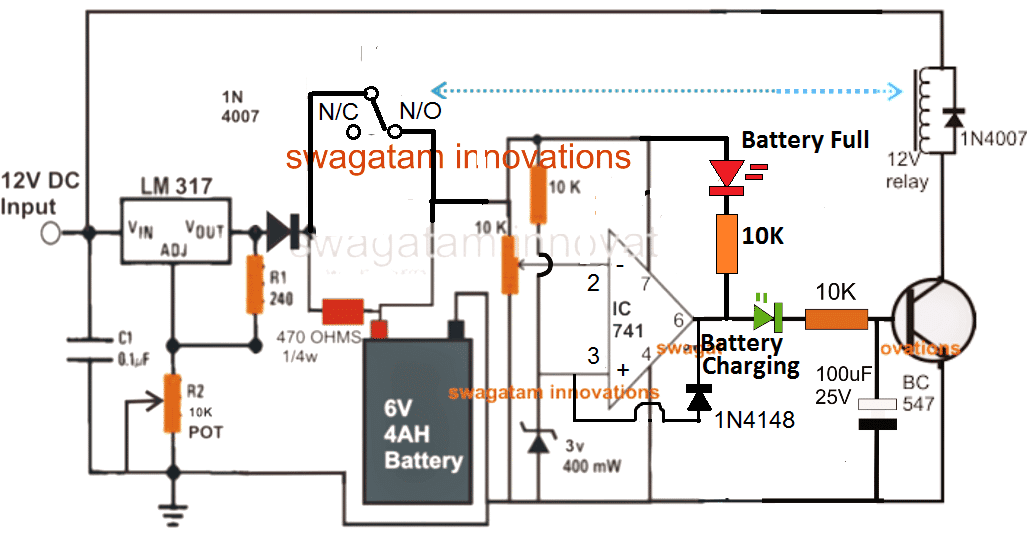

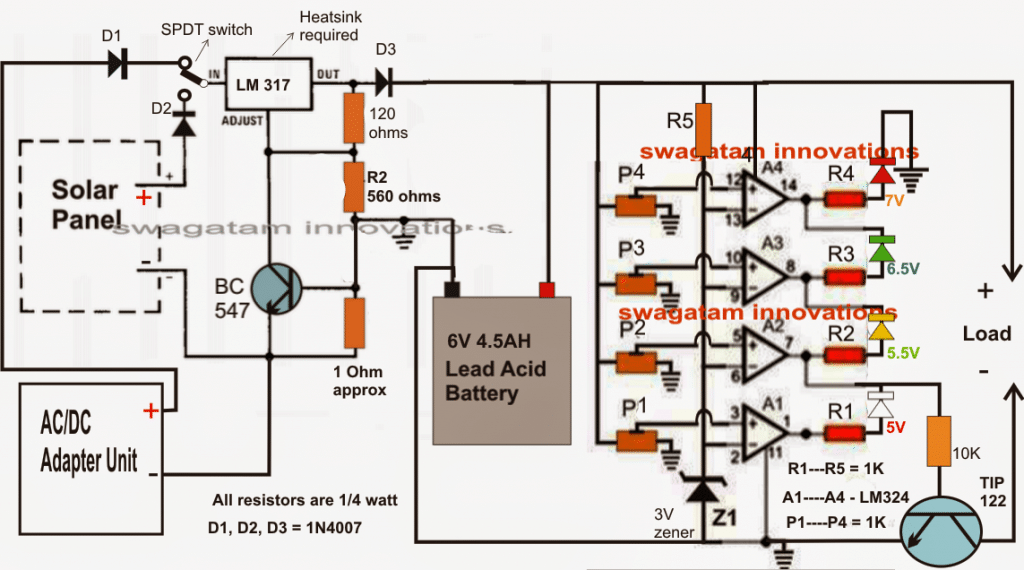

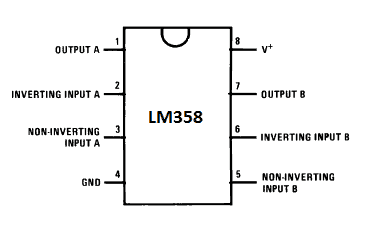

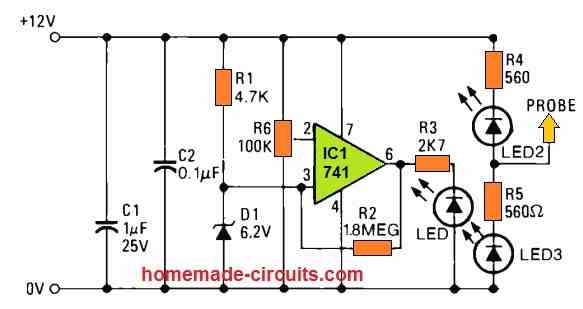

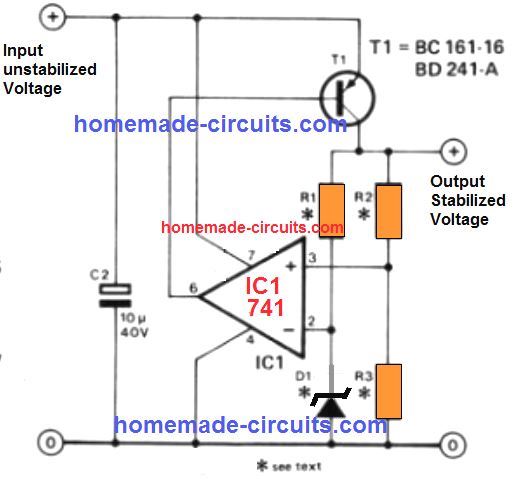

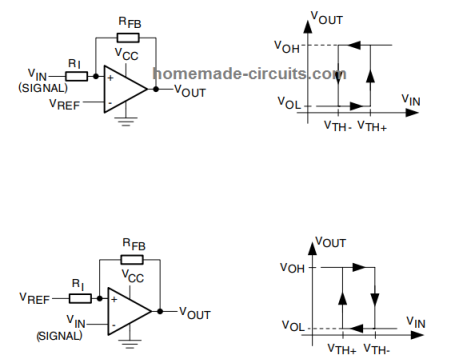

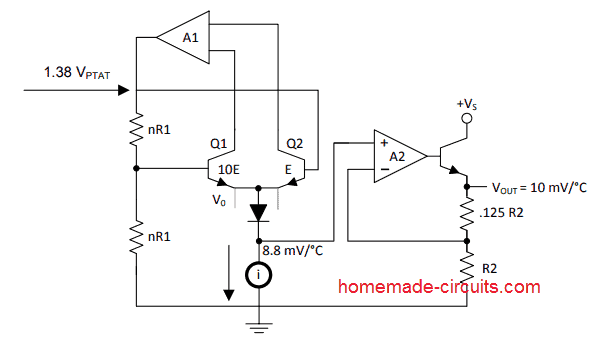

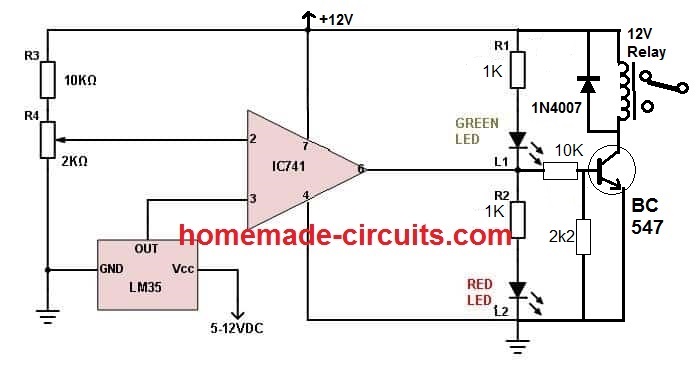

Using Op Amps

If you are interested to build a zero drop charger with automatic cut off feature, you can apply this using an op amp is wired as a comparator as shown below. In this design the non-inverting pin of the IC is positioned as the voltage sensor via a voltage divider stage made by R3 and R4. Referring to the proposed zero drop voltage regulator charger circuit diagram we see a rather straightforward configuration consisting of an opamp and a mosfet as the main active ingredients. The inverting pin is as usual rigged as the reference input using R2 and the zener diode. Assuming the battery to be charged is a 12V battery, the junction between R3 and R4 is calculated such that it produces 14.4V at a certain optimal input voltage level which may be the open circuit voltage of the connected panel. On applying the solar voltage at the shown input terminals, the mosfet initiates with the help of R1 and allows the entire voltage across its drain lead which finally reaches the R3/R4 junction. The voltage level is instantly sensed here and if in case it's higher than the set 14.4V, switches ON the opamp output to a high potential. This action instantly switches OFF the mosfet making sure no further voltage is allowed to reach its drain. However in the process the voltage now tends to fall below the 14.4V mark across the R3/R4 junction which yet again prompts the opamp output to go low and in turn switch ON the mosfet. The above switching goes on repeating rapidly which results in a constant 14.4V at the output fed to the battery terminals. The use of the mosfet ensures an almost zero drop output from the solar panel. D1/C1 are introduced for maintaining and sustaining a constant supply to the IC supply pins. Unlike shunt type regulators, here the excess voltage from the solar panel is controlled by switching OFF the panel, which ensures zero loading of the solar panel and allows it to operate at its most efficient conditions, quite like an MPPT situation. The LDO solar charger circuit without microcontroller can be easily upgraded by adding an auto cut off, and an over current limit features.Circuit Diagram

NOTE: PLEASE CONNECT THE PIN#7 OF THE IC DIRECTLY WITH THE (+)TERMINAL OF THE SOLAR PANEL OTHERWISE THE CIRCUIT WILL NOT FUNCTION.

USE LM321 IF THE SOLAR PANEL VOLTAGE IS HIGHER THAN 18 V.

Parts List

R1,R2 = 10K

R3,R4 = use an online potential divider calculator for fixing the required junction voltage

D2 = 1N4148

C1 = 10uF/50V

C2 = 0.22uF

Z1 = should be much lower than the selected battery over charge level

IC1 = 741

Mosfet = as per the battery AH and the solar voltage.

NOTE: PLEASE CONNECT THE PIN#7 OF THE IC DIRECTLY WITH THE (+)TERMINAL OF THE SOLAR PANEL OTHERWISE THE CIRCUIT WILL NOT FUNCTION.

USE LM321 IF THE SOLAR PANEL VOLTAGE IS HIGHER THAN 18 V.

Parts List

R1,R2 = 10K

R3,R4 = use an online potential divider calculator for fixing the required junction voltage

D2 = 1N4148

C1 = 10uF/50V

C2 = 0.22uF

Z1 = should be much lower than the selected battery over charge level

IC1 = 741

Mosfet = as per the battery AH and the solar voltage.

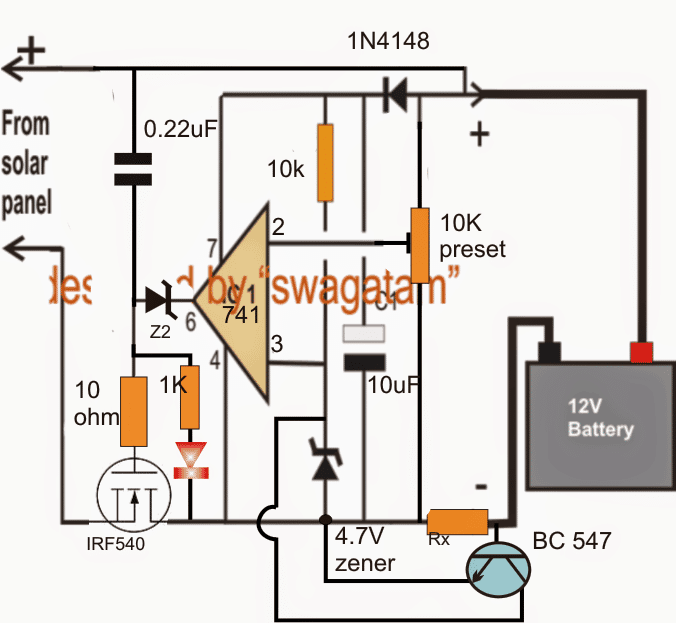

Using N-Channel MOSFET

The proposed low dropout can be also effectively implemented using an N-channel MOSFET. as indicated below: NOTE: PLEASE CONNECT THE PIN#4 OF THE IC DIRECTLY WITH THE (-)TERMINAL OF THE SOLAR PANEL, OTHERWISE THE CIRCUIT WILL CEASE TO WORK.

USE LM321 INSTEAD OF 741 IF THE PANEL OUTPUT IS HIGHER THAN 18 V.

NOTE: PLEASE CONNECT THE PIN#4 OF THE IC DIRECTLY WITH THE (-)TERMINAL OF THE SOLAR PANEL, OTHERWISE THE CIRCUIT WILL CEASE TO WORK.

USE LM321 INSTEAD OF 741 IF THE PANEL OUTPUT IS HIGHER THAN 18 V.

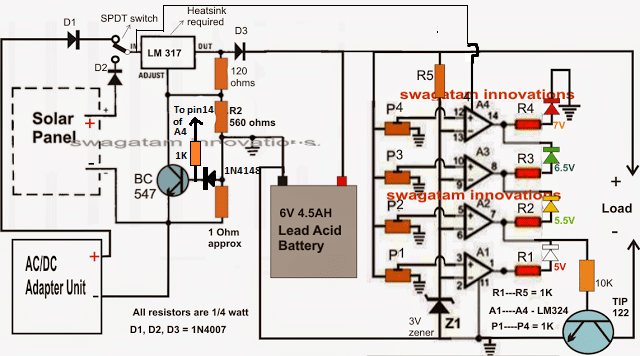

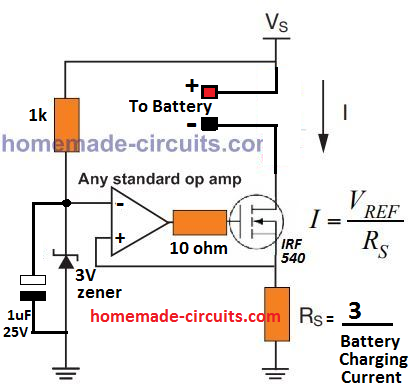

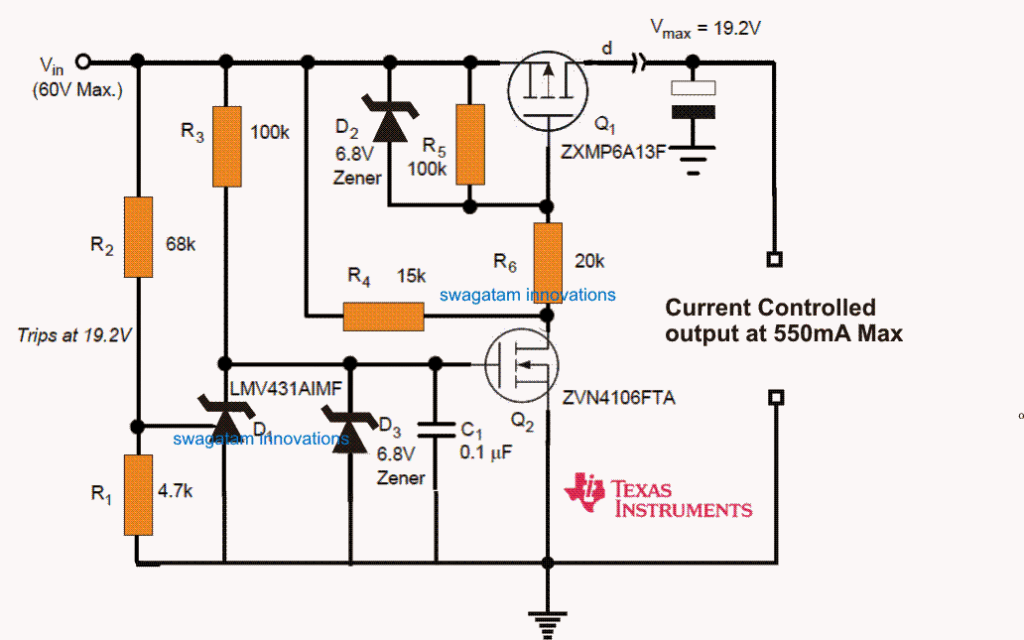

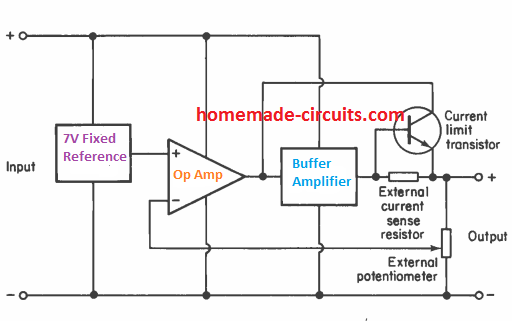

Adding a Current Control Feature

The second diagram above shows how the above the design may be upgraded with a current control feature by simply adding a BC547 transistor stage across the inverting input of the opamp. R5 can be any low value resistor such as a 100 ohm. R6 determines the maximum allowable charging current to the battery which may be set by using the formula: R(Ohms) = 0.6/I, where I is the optimal charging rate (amps) of the connected battery.Finalized Solar zero drop battery charger circuit:

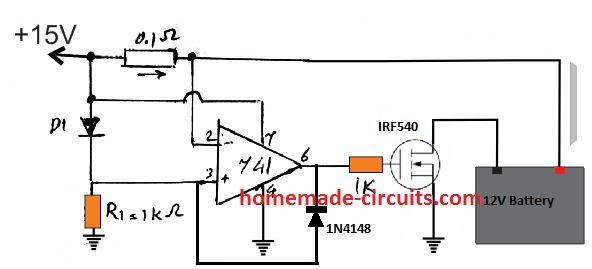

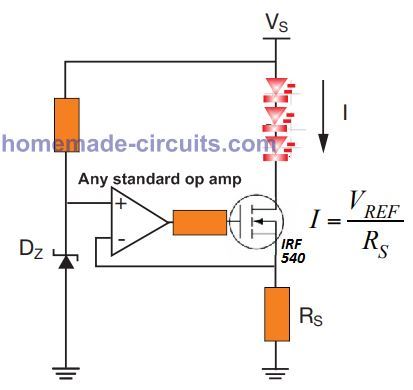

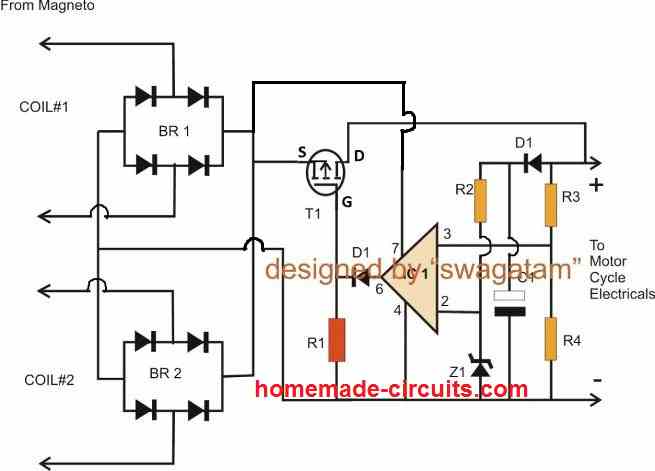

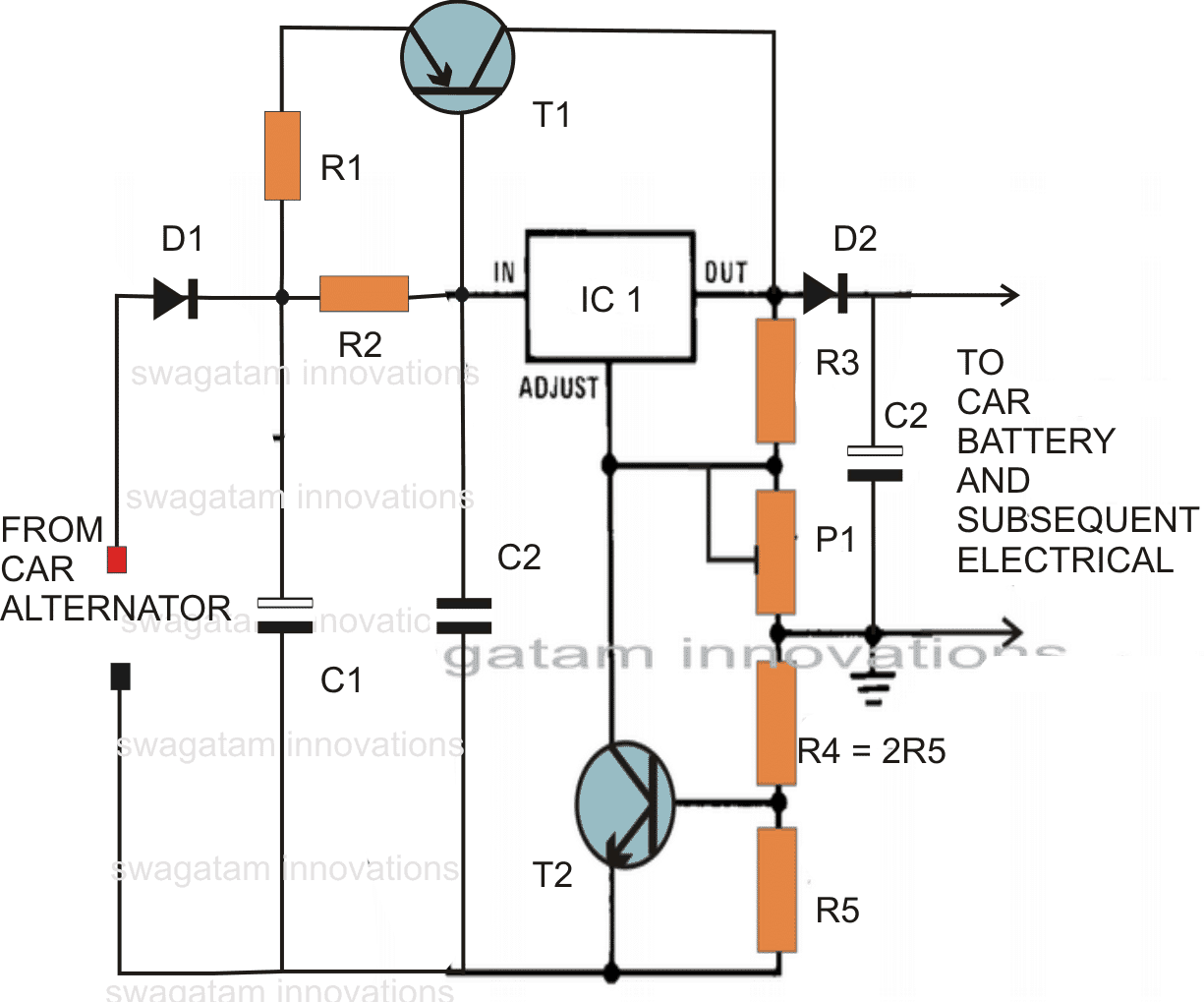

As per the suggestion of "jrp4d"the above explained designs needed some serious modifications for operating correctly. I have presented the finalized, corrected working designs for the same through the below shown diagrams: According to "jrp4d": Hi - I've been messing about with Mosfets (voltage control circuits) and I don't think either circuit will work except where the line in voltage is only a few volts large than the target battery voltage. For anything where the line in is much more than the battery the mosfet will just conduct because the control circuit can't control it. In both circuits its the same problem, with P-channel the op-amp cant drive the gate high enough to turn it off (as observed by one post) - it just passes the line voltage straight thru to the battery. In the N channel version the op-amp can't drive the gate low enough because its operating at a higher voltage than the -ve line in side. Both circuits need a driving device operating at the full line in voltage, controlled by the op-amp The suggestion above looks valid and correct. The simplest way to rectify the above problem is to connect Pin#7 of the opamp IC with the (+) of the solar panel directly. This would instantly solve the issue! Alternatively the above designs could be modified in the manner shown below for the same: Using NPN BJT or N-channel mosfet: The diode D1 can be removed once the working of the LDO is confirmed

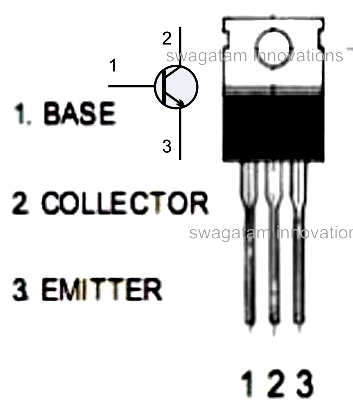

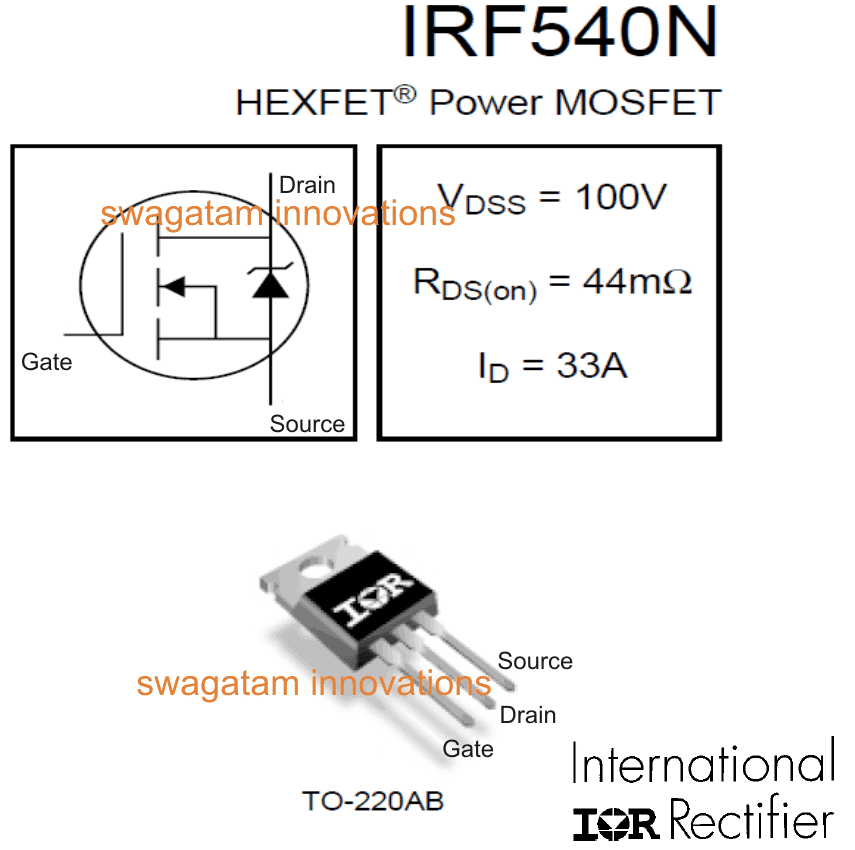

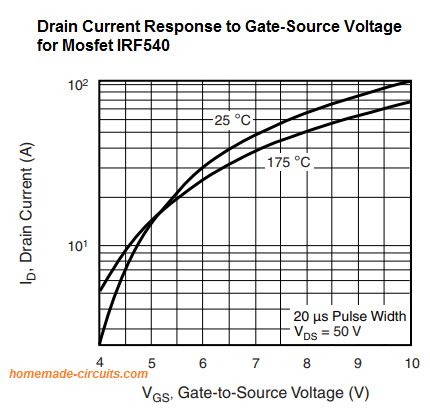

In the above figure the NPN power transistor could be a TIP142, or a IRF540 mosfet .....and please Remove D1 as it's simply not required

The diode D1 can be removed once the working of the LDO is confirmed

In the above figure the NPN power transistor could be a TIP142, or a IRF540 mosfet .....and please Remove D1 as it's simply not required

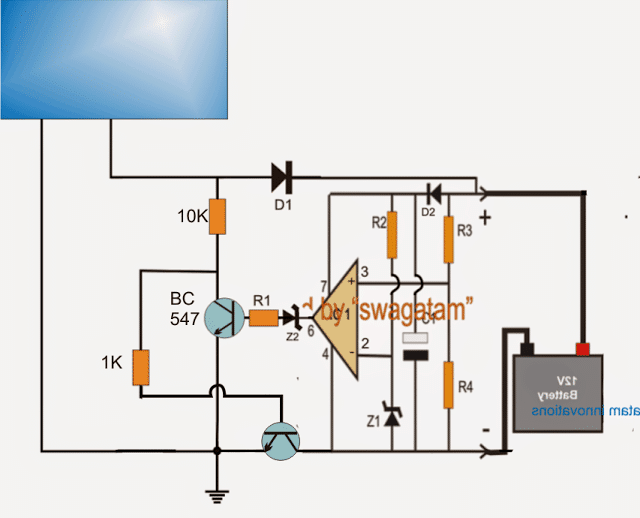

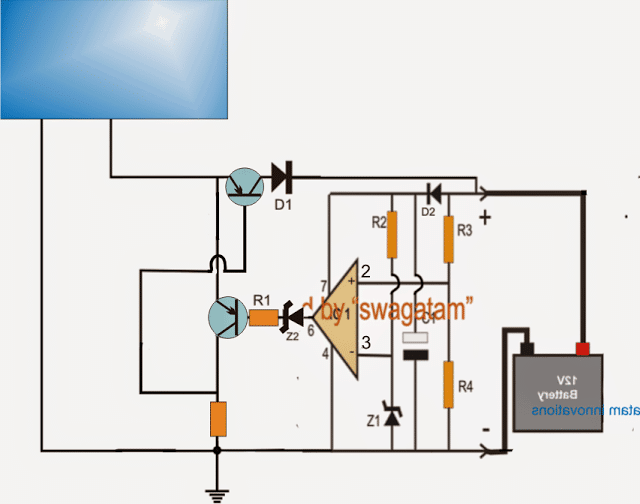

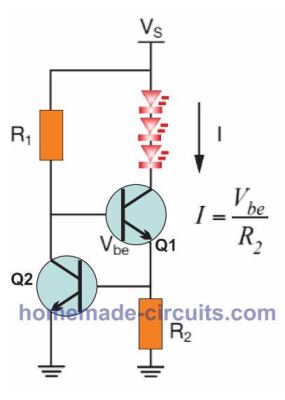

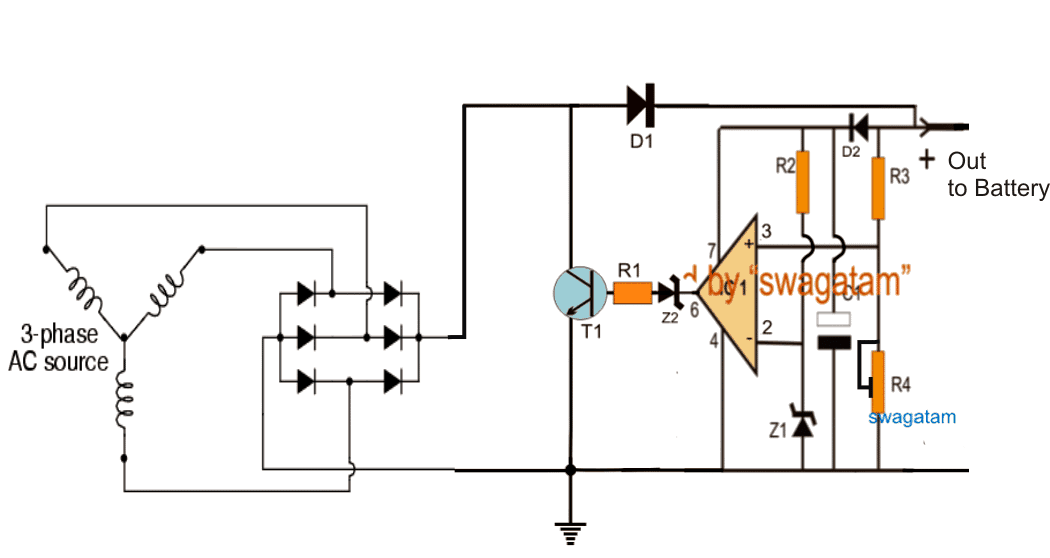

Using PNP transistor or P-mosfet

The diode D1 can be removed once the working is confirmed

In the above figure, the power transistor could be a TIP147 or a IRF9540 mosfet, the transistor associated with R1 could be a BC557 transistor......and please Remove D1 as it's simply not required.

The diode D1 can be removed once the working is confirmed

In the above figure, the power transistor could be a TIP147 or a IRF9540 mosfet, the transistor associated with R1 could be a BC557 transistor......and please Remove D1 as it's simply not required.

How to Set up the LDO solar charger circuit

It's very easy. Do not connect any supply at the mosfet side. Replace the battery with a variable power supply input and adjust it to the charging level of the battery which is supposed to be charged. Now carefully adjust the pin2 preset until the LED just shuts off....flick the preset to and fro and check the LED response it should also blink ON/OFF correspondingly, finally adjust the preset to a point where the LeD just shuts off completely....seal the preset. Your zero drop solar charger is ready, and set. You can confirm the above by applying a much higher input voltage at the mosfet side, you'll find the battery side output producing the perfectly regulated voltage level that was previously set by you.Convert SMPS into a Solar Charger

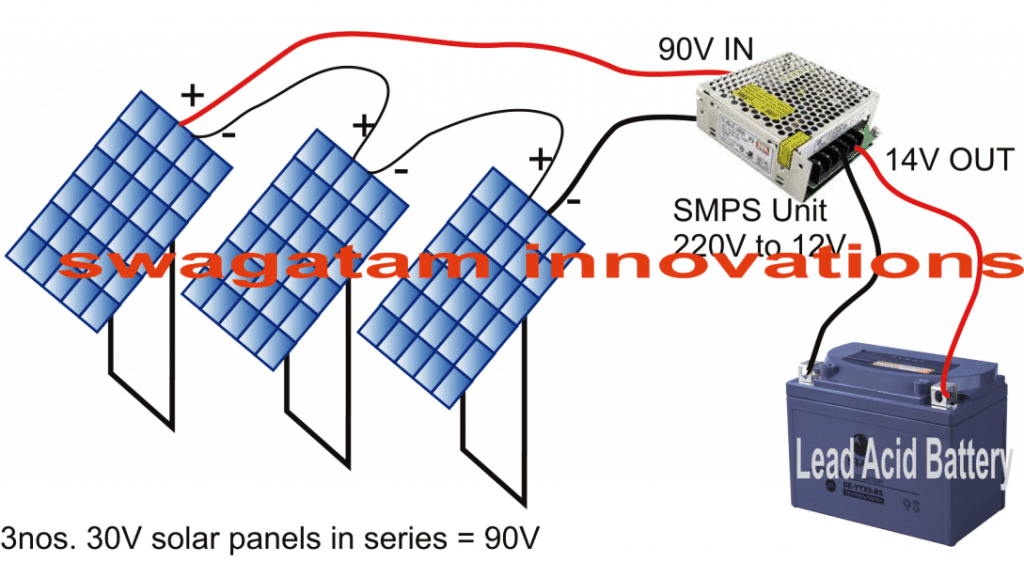

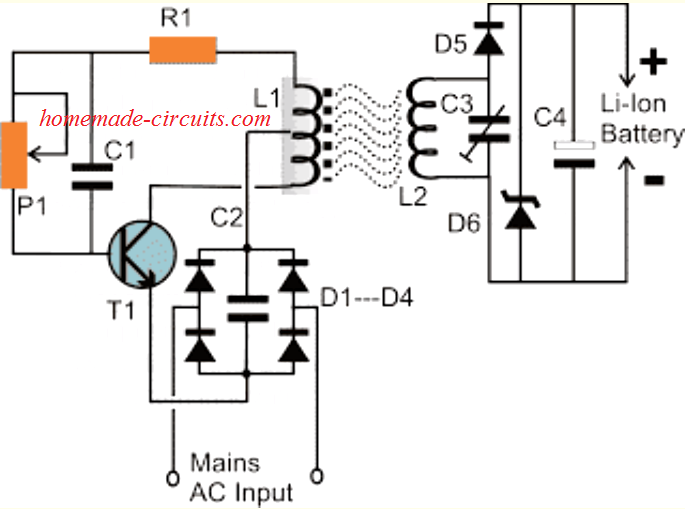

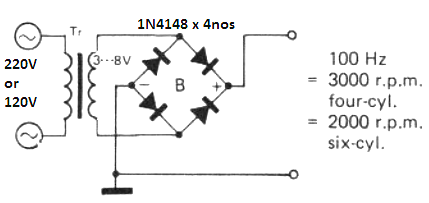

The post explains how to convert smps into a solar charger circuit. The method will result in an extremely efficient and fast solar charging of the connected battery.SMPS Solar Chargers

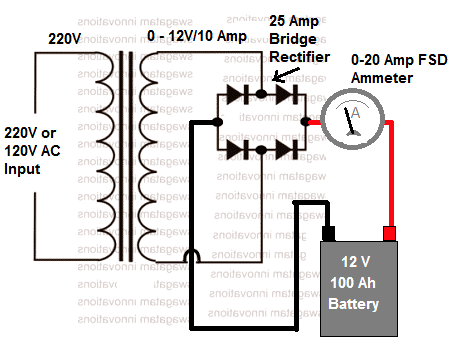

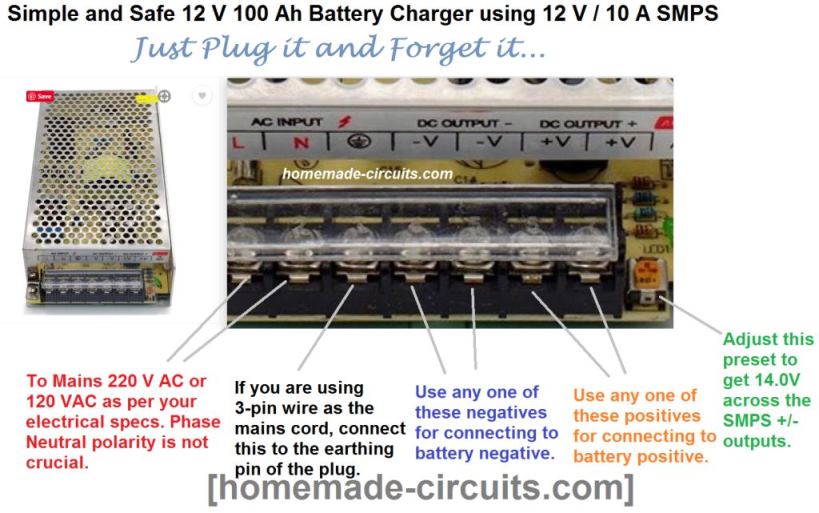

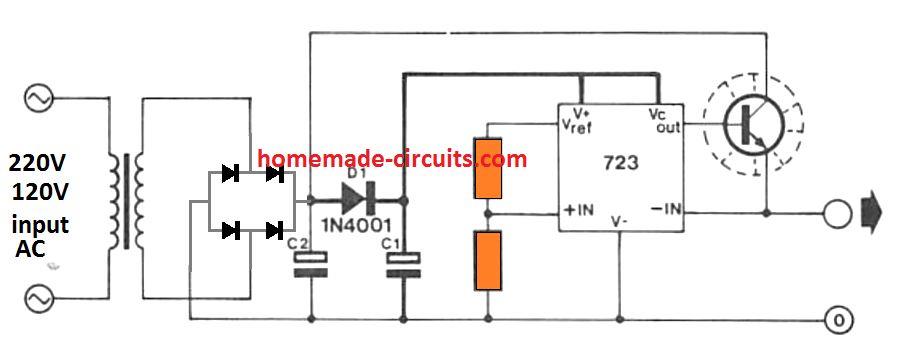

SMPSs have become very common nowadays and we find them being used in the form of AC to DC adapters wherever needed. The best example is our cell phone chargers which are actually compact SMPS 5V chargers. Solar charger devices are also becoming popular nowadays and folks are constantly in look out for options in the form of solar chargers having the most efficient charging response. Solar panels or PV devices are normally utilized for charging lead acid batteries which tends to take relatively long hours for getting fully charged, besides when the sunlight conditions are bad things start getting even more sluggish. For tackling the above condition or rather for enabling quicker charging from solar panels, special MPPT based soar chargers have been developed which effectively monitor the solar panel maximum power point levels and generate the most efficient charging conditions for the connected battery. In this article although we won't be discussing an ideal MPPT, yet the discussed method will give you an opportunity to acquire the most efficient way of charging your battery through a solar panel. As proposed in one of my previous articles discussing understanding solar mppt solar chargers, a switch mode based power supply (SMPS) is probably the best option for making it work as a solar charger circuit, so here we will learn how to make an smps based solar charger circuit at home. Making an SMPS can be quite complex and might require considerable amount of time and knowledge for the implementations, so here rather we will focus on how to convert a ready made smps into an effective solar charger circuit quickly. For this you will require the following materials, assuming the battery to be charged is 12V rated: A ready-made 120V or 220V to 12V SMPS unit having current rating equal to 1/5th of the battery AH which is to be charged. A few Solar Panels whose total open circuit voltage equals around 100V. Connecting wires.Converting SMPS into a Solar Charger Circuit.

As we all know a normal mains SMPS are mostly rated with minimum of 85V to 100V input in order to provide the specified output DC, let's assume it to be 12V, meaning for acquiring 12V it must be supplied with a minimum of 100V at the input. Keeping the above issue in mind, we must select a solar panel which may be able to produce approximately 100V for making the procured SMPS work. Since PV panels with such high voltage might not be available, we may opt for many low voltage solar panels connected in series for generating the above voltage. For instance you can go for 3nos. of 30V solar panels and connect them in series to get 90V from it, which might just do the job. The above input supplied to the procured SMPS would generate the required 12V which may be directly attached to the battery for charging it efficiently. However a 12V supply might not charge a 12V battery we need at least 14V for it, so that's not a big issue, the required voltage can be easily tweaked and set by adjusting the output voltage of the SMPS manually, the procedures can be learned in this article which explains how to modify an SMPS circuit. That's it, you have just now converted a ready made SMPS unit into an efficient solar charger circuit that might generate results equivalent to MPPT charger circuits for you.

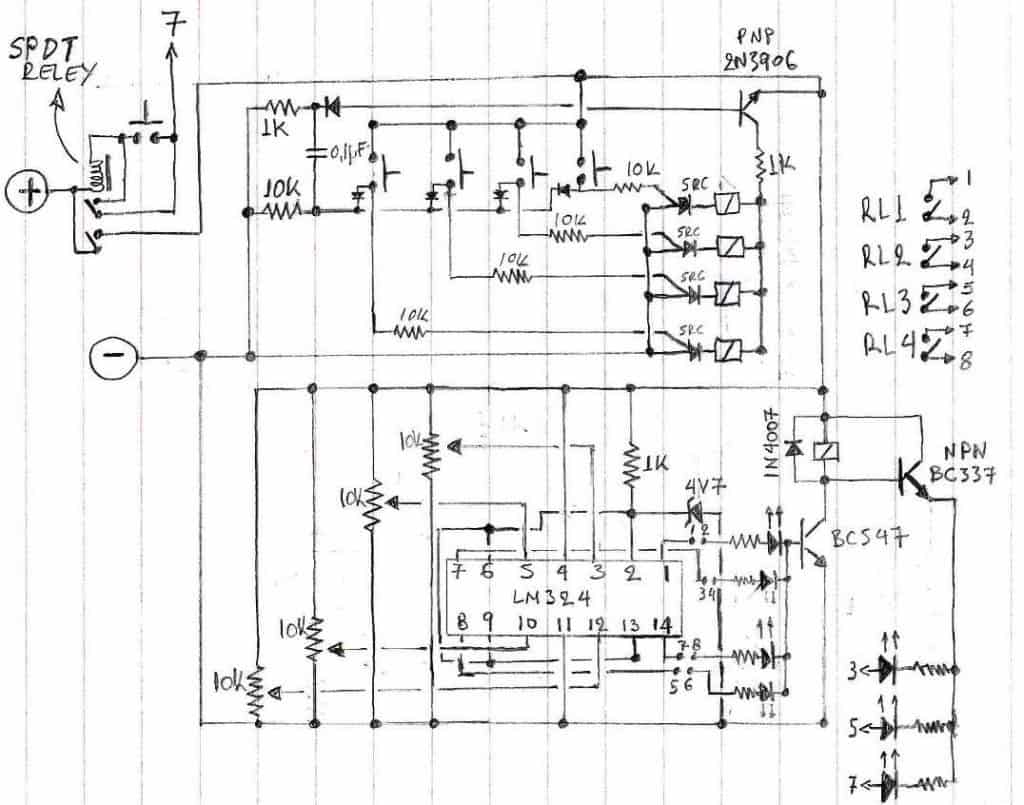

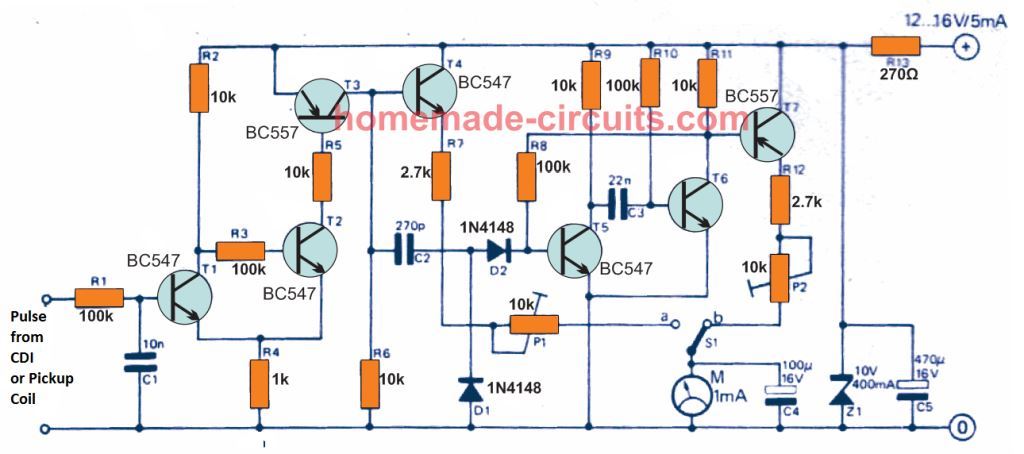

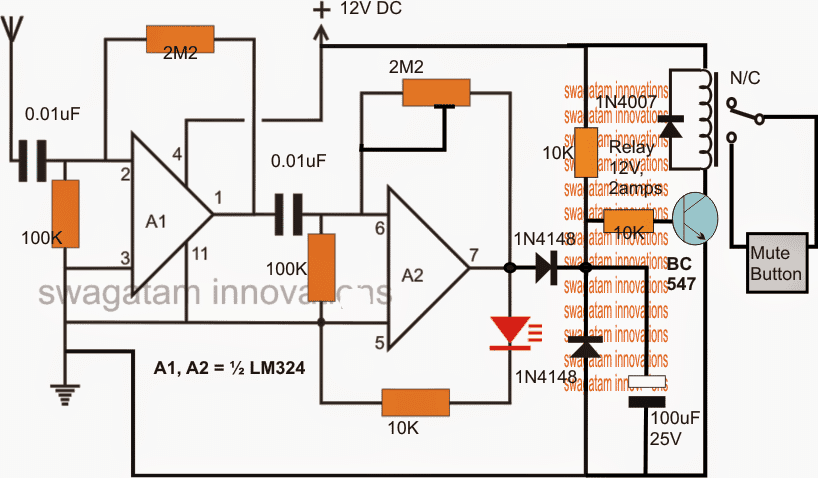

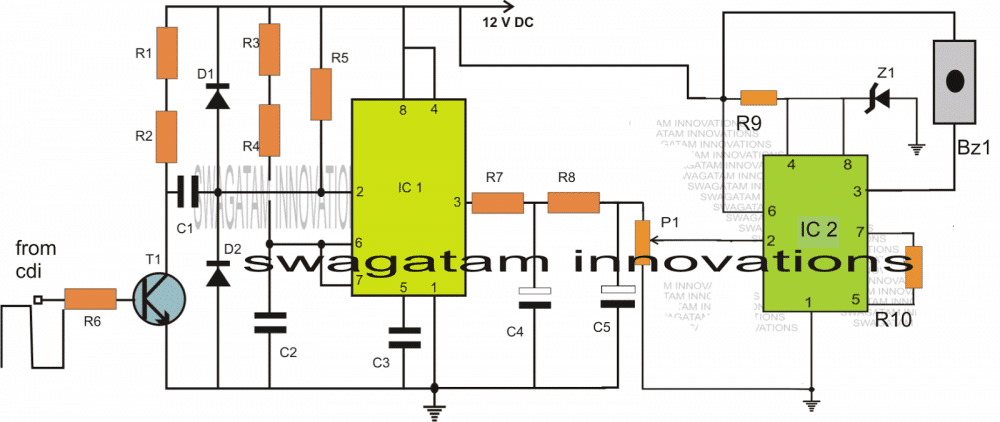

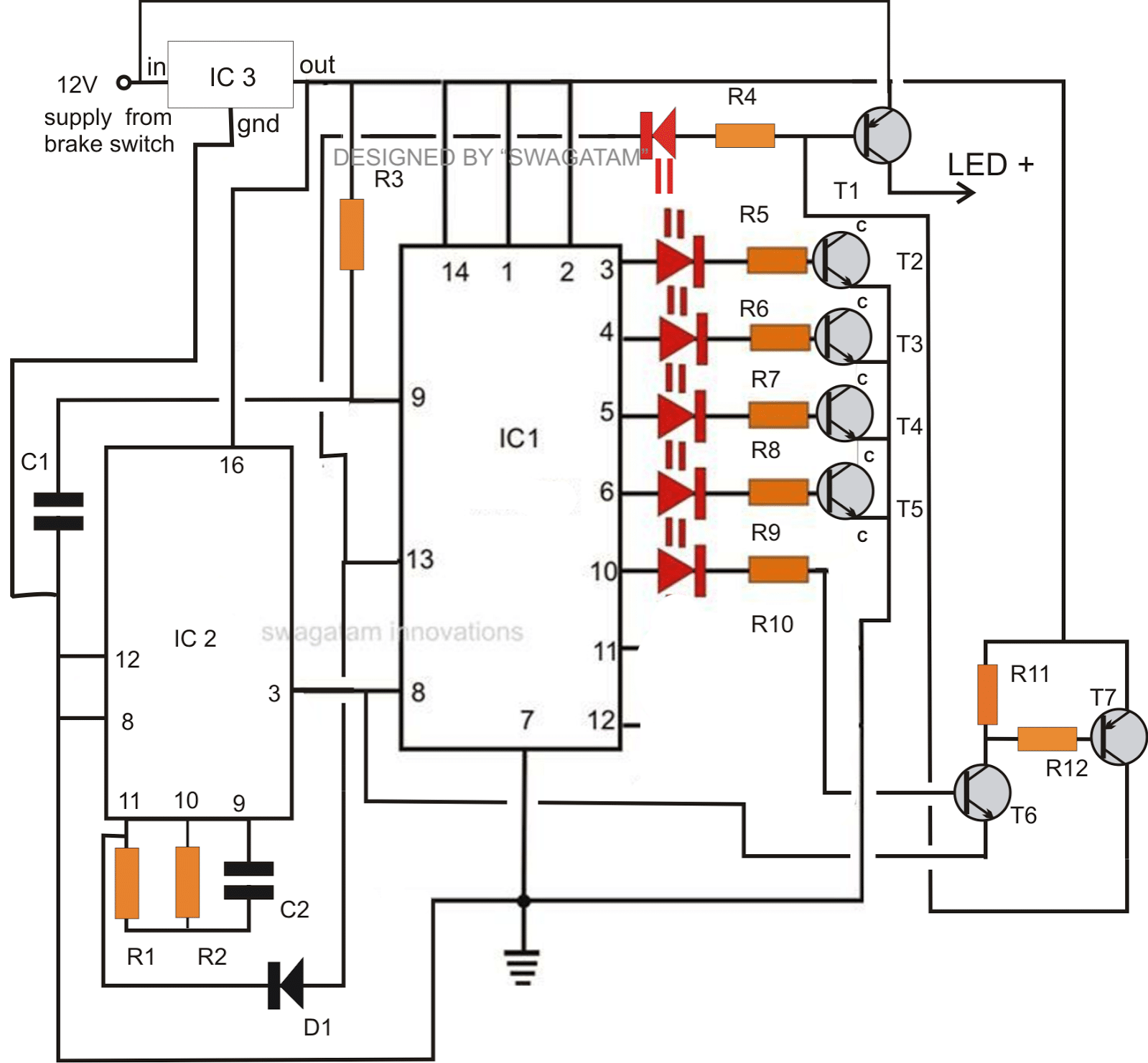

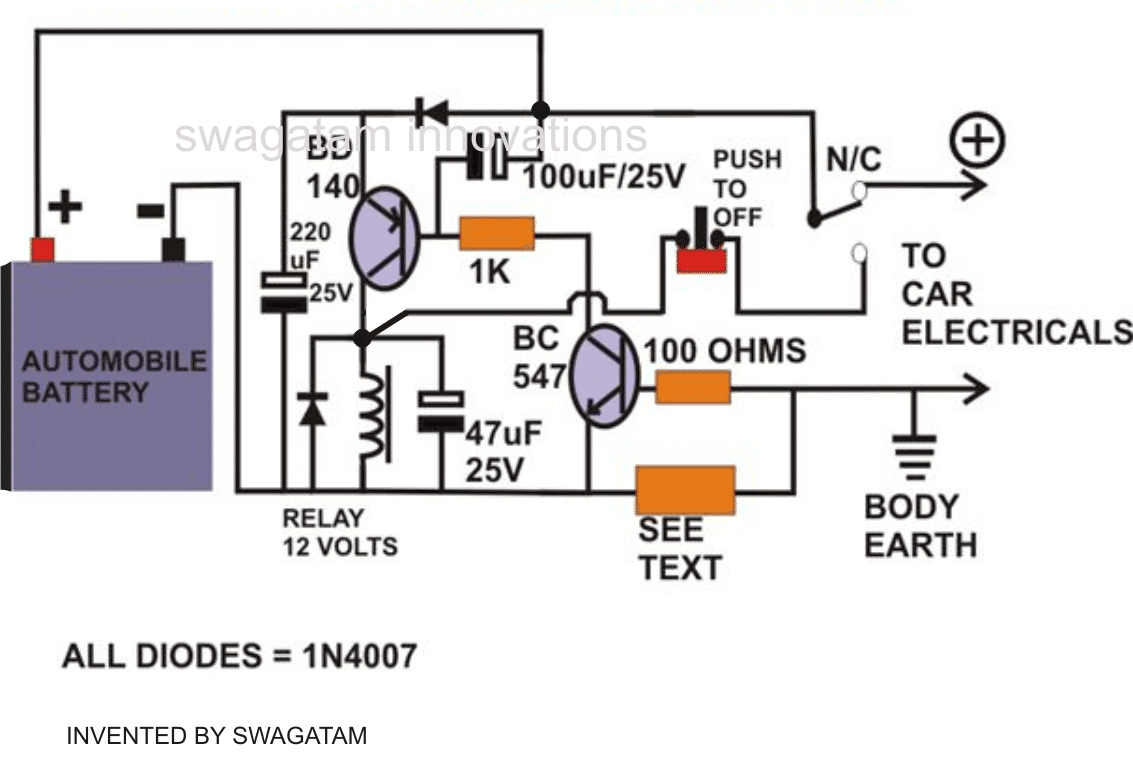

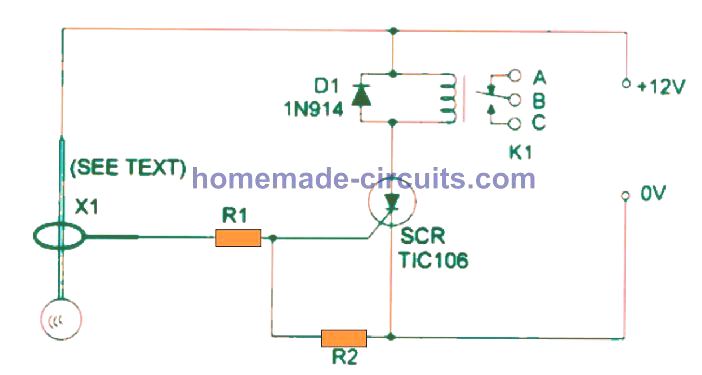

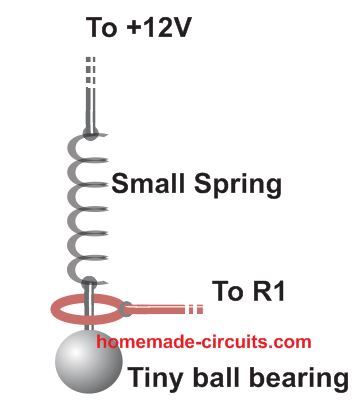

Selectable 4 Step Low Voltage Battery Cut off Circuit

The post explains a circuitconfigurationwhich facilitates a multi-step low voltage selection and cut-off for the battery being used and monitored. The circuit was proposed by Mr. Pete.Technical Specifications

Dear Swagatam,Your assistance during the past few days has been incredible, thanks to which I think I have managed to get close to this 4 step low battery cut off circuit I need.

Having combined yourinfo, a selector circuit I found in a different source and by adding my own ideas I came up with the following circuit:

I know there are issues which with my knowledge I cannot solve, but I think I am close (I will list these issues at the end of this post).

My knowledge is limited (I am neither an expert nor a novice in electronics), so I would like to hear your opinion and recommendations.

To my understanding, what I expect it to do is as follows:

LM324 will monitor the voltage and turn off the relay at the bottom of four scales: 18.5-20V, 20-22V, 22-24V, 24-28V adjusted by the various 10K presets.

The circuit starts (battery full) with the relay armed (load connected) and the 24-28V LED on (left hand side set of LEDs). The selector circuit (top part) assures that only the selected OPAMP arms the relay although all of the OPAMP outputs will be high at the same time (this I need for a later function, see end of next paragraph).

During discharge, when 24V is reached the equivalent output (1) will go low and the relay will disarm, disconnecting the load. At the same time BC337 (NPN) will conduct and light up the three right hand side LEDs, to indicate scale options that are available.

Once a button on the selector is pressed for a lower scale (i.e 22-24V), the relay at the lower circuit will arm by the second OPAMP (output 7) and the load will be connected. Same goes for the equivalent left hand side LED. The same applies for the 20-22V scale, but only 2 LEDs will light from the right hand side set).

Now, if the last scale (18-20V) is selected, when 18V is reached the 4th OPAMP of the LM324 will disconnect the load once again but at the same time the SPDT relay at the top left of my picture which is connected as a latching relay will disarm and take power completely off of the circuit to minimize consumption as the battery will be very deeply discharged now. In order to start the system again, manual reset will be required via the push button near the latching relay, once the battery is charged again.

The purpose of this circuit is for a solar system used to power an emergency communications station. This is the reason it cannot be set in a completely automatic way. Although deep discharging of the batteries is not recommended, in such stations the operator will have to judge whether he must deep discharge the battery or not, in case the type of emergency makes it inevitable. Under normal situations, the power will cut off at 24V automatically protecting the batteries, but it is important that the operator will have the option to continue drowning the batteries if necessary.

So here are my circuit issues: 1. I have a fear that in the way the circuit works, the outputs go high, not low when thresholds are met. If it is so the circuit will not operate in the intended way, especially the latch relay function.

2. I have a feeling that there will be a lot of small and big flaws in my additions to the design. I am confident in building it when it is all designed, but designing of circuits is a skill I only have to certain extend.

3. I wonder if I can substitute the relays of the top part of the circuit with some kind of low power MOSFET. If so, please give me a clue as to how to connect them.

4. I am also thinking that the disconnection of the load will cause the system to do some chasing effect, so I wonder if some small hysteresis can be added.

Please get back to me with you thoughts; I believe this can be a useful 4 step low battery cut off circuit if ever completed for many people (maybe by adjusting the thresholds to higher values, not everybody needs to drain their batteries so much).

My gratitude once again for the tones of information you have helped me to collect during the past week.

Regards, Pete SimplifiedDiagram for the above Circuit Issue [Solved]

Parts List

All resistors can be 10K 1/4 watt All presets = 10K T1, T2 = BC547 Relay = 24V/SPDT Scr = BT169 IC = LM324 D1 = 1N4007 Z1 = 6V/400mWCalculating Solar Panel, Inverter, Battery Charger

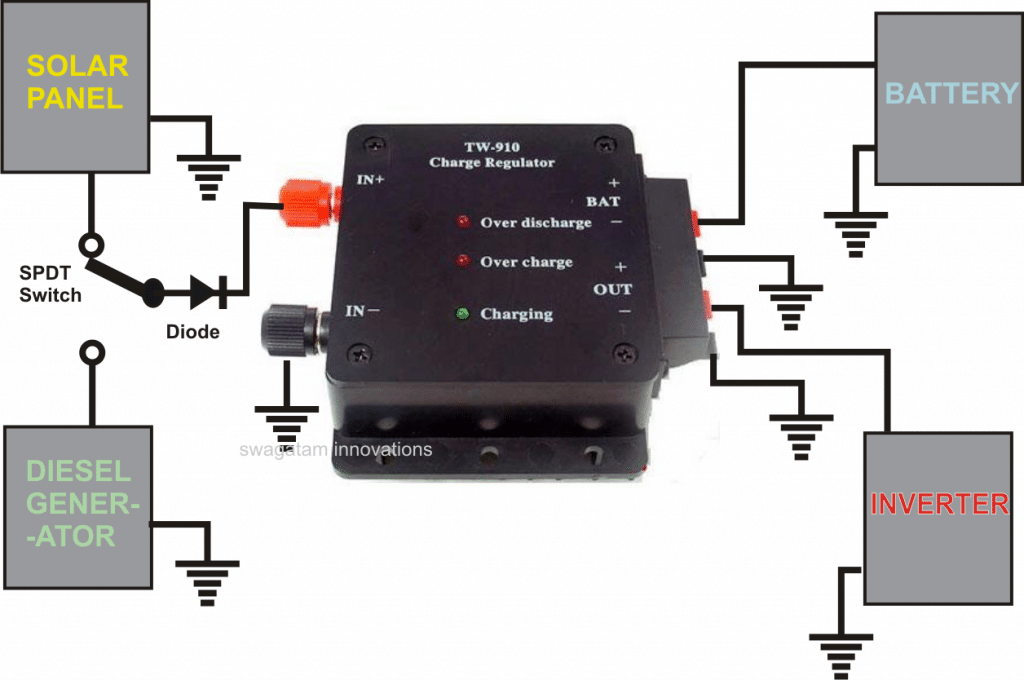

The following post explains through calculations how to select and interface the solar panel, inverter and charger controller combinations correctly, for acquiring the most optimal results from the set up.

Calculating Solar Panel, Inverter and Battery Charger Specifications

For the sake of convenience, let's believe you possess a a 100 watt appliance or load that you would like to operate, free of charge through solar power, for around ten hours every night. In order to exactly determine the dimensions of the solar panel, batteries, charge controller and inverter the following mentioned parameters will need to be strictly calculated and configured.Estimating Load Wattage

1) First you will need to estimate how much watts of electricity you may require for the specified load. Let's say you have a 100 watt load that needs to be operated for approximately 10 hours, in that case the total power required could be estimated simply by multiplying the load with hours, as given under 100 Watts x 10 hours = 1,000 Watt hours. This becomes the absolute power necessary from the panel.Determining Approximate Solar Panel Dimension

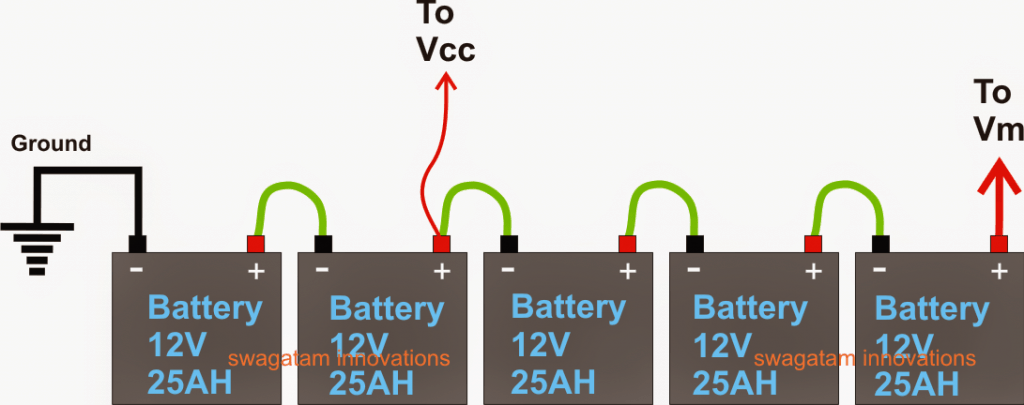

2) Next, we need to determine the approximate dimensions of the solar panel for satisfying the above estimated load requirement. If we assume a roughly ten hour daily optimal sunshine, the specifications for the solar panel could be simply and quickly calculated as explained in the following expression: 1,000 Watt hours / 10 hours sunlight = 100 Watt solar panel. However, you may notice that mostly during the summer seasons you may normally get around 10 hours of reasonable amount of sunshine, but the winter season may produce roughly around 4-5 hours of effective sunshine. Contemplating the above scenario, you too might agree and recommend considering the worst possible sunshine hour into calculation so that even on the weakest of sunshines your load keeps running optimally. Therefore taking into account the 4 to 5 hours sunshine per day consideration, we calculate the true power for the solar panel which would enable your load to keep running throughout the year . 1,000 Watt hours / 5 hours sunlight = 200 Watt solar panel.Calculating Battery Ah

3) Once you have calculated the solar panel as per the above calculations, it's time to calculate the AH rating for the batteries that might be required for operating the specified load under all conditions. If the selected battery is rated at 12V, in that case: Dividing 1,000 Watt hours by 12 Volts = 83 Amp Hours of reserve battery power. Let's upgrade this value a little more with a 20% added tolerance, which finally gives a rounded up figure of around 100 AH. Hence, a 100AH 12V battery is what you may finally require for the inverter.Evaluating Charger Controller Specifications

4) Now, to figure out how big your solar charge controller would need to be for the above calculated parameters, you might need to take your solar panel current or the Amperage specs into consideration, which may be simply gotten by dividing the panel's wattage rating with its voltage rating (Ohms law remember?) 100 / 12 = 8.3 Amps. We have so far applied a "plus tolerance" to all the previous parameters, so let's show some generosity to the Amp spec of the panel also, and instead of sticking to the 8.3 amps limit, you might be happy raising the level to around 10 Amps? That looks good, right?Assessing Inverter Specifications

5) Finally we boil down to the inverter specifications, and determine the reasonably exact capacity that would keep the unit compatible with the above discussed results, and keep the load running without issues, whenever required. Well, calculating the inverter specs doesn't look difficult at this point of the discussion. Since we already know the maximum load wattage which is 100 Watts, implies that we simply choose an inverter which might be capable of handling a 100 watt comfortably. That implies, we simply need to get an inverter rated at 100 watts,.... OK, you may be thinking of adding some tolerance to this candidate also, not an issue, instead of 100 watts you can opt for a 125 watt inverter, allowing all the gadgets to happily "shake-hands" and your house powered round the clock forever, free of cost.Low Battery Indicator Circuit Using Two Transistors Only

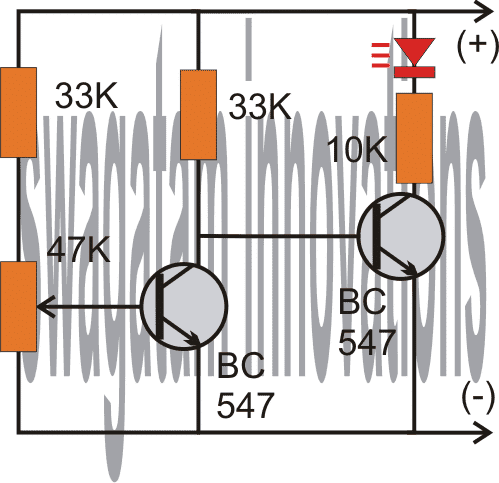

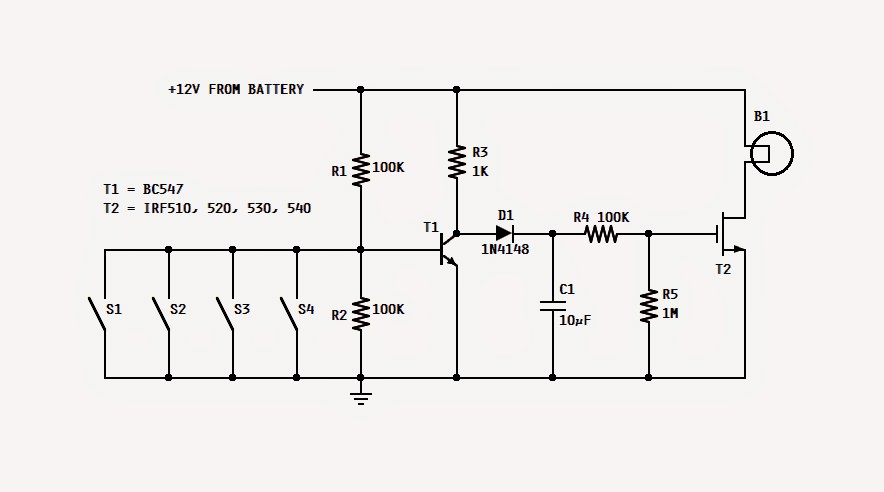

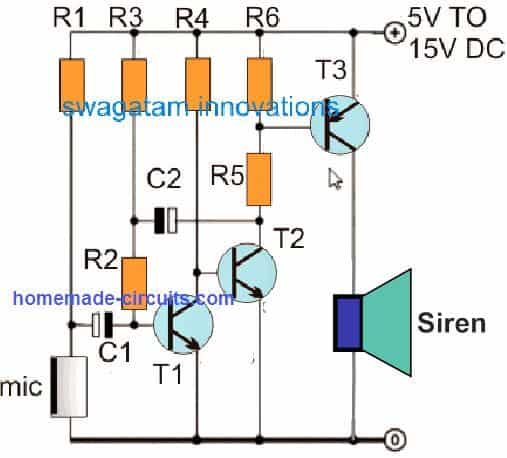

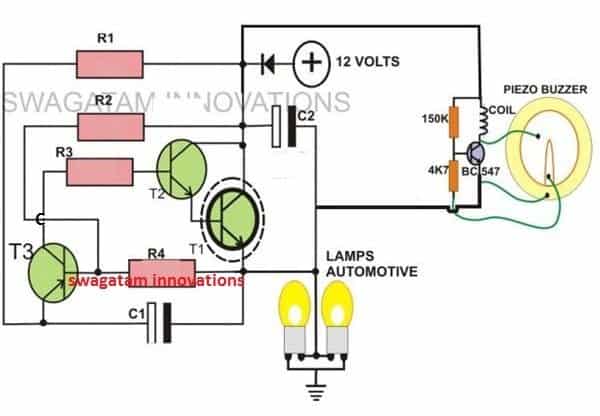

The following post describes a simple low battery indicator circuit by using just two inexpensive NPN transistors. The main feature of this circuit is its very low stand by current consumption.The Circuit Concept

We have so far seen how to make a low battery indicator circuits using a 741 IC and a 555 IC, which are no doubt outstanding with their abilities of detecting and indicating low battery voltage thresholds. However the following post relates yet another similar circuitwhich is much cheaper and employs just a couple of NPN transistors for producing the required low battery indications.Advantage of Transistor over IC

The main advantage of the proposed two transistor low battery indicator circuit is its very low current consumption compared to the IC counterparts which consume relatively higher currents. A IC 555 would consume around 5mA, a IC741 around 3 mA, while the present circuit would just consume around 1.5mA current. Thus the present circuit becomes more efficient especially in cases where stand by current consumption tend to become an issue, example suppose in units which depend on low current battery supplies such as a 9V PP3 battery.Circuit can Operate at 1.5V

Another advantage of this circuit is it's ability to work even at voltages around 1.5V which gives it a clear edge over the IC based circuits. As shown in the following circuit diagram, the two transistors are configured as voltage sensor and inverter. The first transistor on the left senses the threshold voltage level as per the setting of the 47K preset. As long as this transistor conducts, the second transistor on the right is held switched OFF, which also keeps the LED switched OFF. As soon as the battery voltage falls below the set threshold level, the left transistor is no longer able to conduct. This situation instantly triggers the right hand side transistor, switching ON the LED. The LED switches ON and provides the required indications of a low battery warning.Circuit Diagram

Video Demonstration:

The above circuit was successfully built and installed by Mr.

Allan in his paranormal depletion detector unit.

The following video presents the implementation results:

Video Demonstration:

The above circuit was successfully built and installed by Mr.

Allan in his paranormal depletion detector unit.

The following video presents the implementation results:

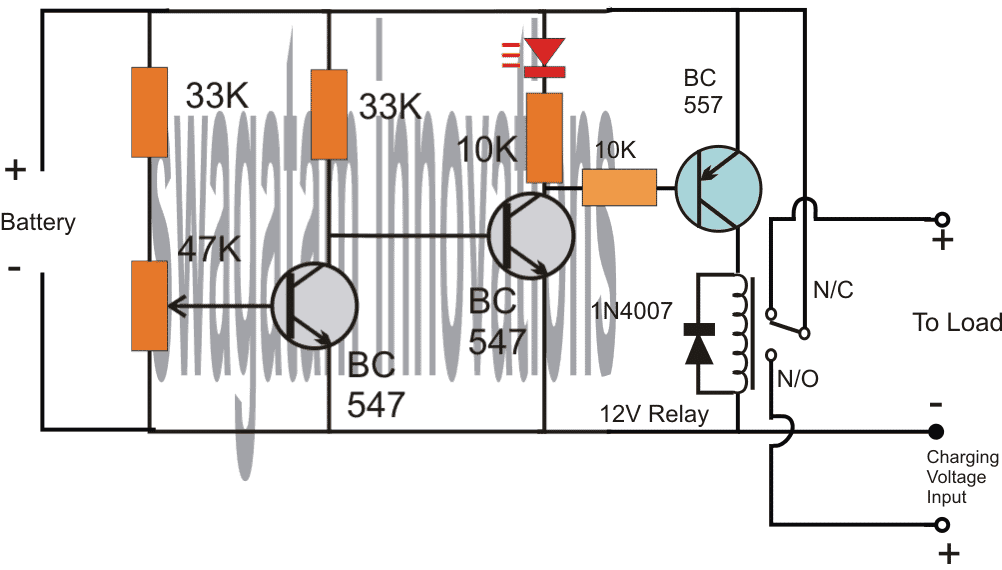

Upgrading the above Transistorized Low Battery circuit into a Low Battery Cut-off Circuit

Referring to the above diagram, the low battery indicator is formed by the two NPN transistors, while the additional BC557 and the relay are used for cutting OFF the battery from the load when it reaches the lower threshold, in this state the relay connects the battery to the available charging input.

However when the battery is in its normal state the relay connects the battery with the load and allows the load to operate through battery power.

Referring to the above diagram, the low battery indicator is formed by the two NPN transistors, while the additional BC557 and the relay are used for cutting OFF the battery from the load when it reaches the lower threshold, in this state the relay connects the battery to the available charging input.

However when the battery is in its normal state the relay connects the battery with the load and allows the load to operate through battery power.

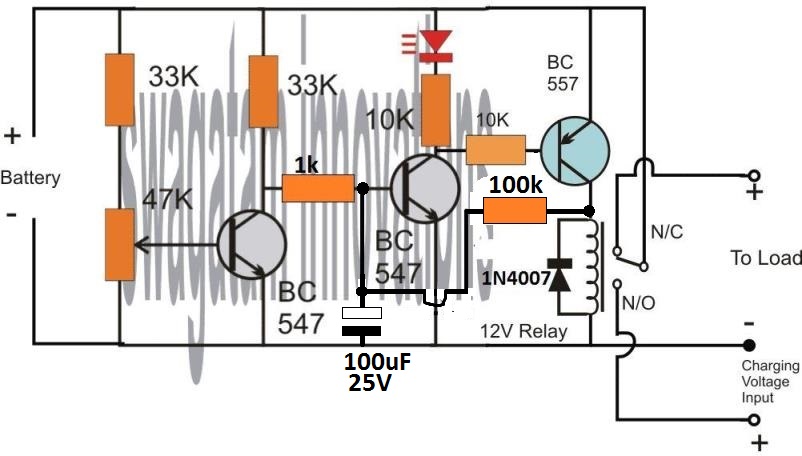

Adding Hysteresis

One drawback of the above design could be the chattering of the relay at the threshold voltage levels, due to the battery voltage dropping immediately during the relay changeover process. This can be prevented by adding a 100uF at the base of the middle BC547. However, this still wouldn't stop the relay from constantly switching ON/OFF at the low battery changeover threshold. In order to rectify this, a hysteresis effect will need to be introduced which can be accomplished through a feedback resistor between the collector of the BC557 and the middle BC547 transistor. The modified design for implementing the above condition can be seen in the following diagram: The two resistors, one at the base of BC547 and the other at the collector of BC557 decide the other threshold of the relay changeover, meaning the full charge cut off threshold of the battery.

Here, the values are arbitrarily selected, for accurate results these values will need to be optimized with some trial and error.

The two resistors, one at the base of BC547 and the other at the collector of BC557 decide the other threshold of the relay changeover, meaning the full charge cut off threshold of the battery.

Here, the values are arbitrarily selected, for accurate results these values will need to be optimized with some trial and error.

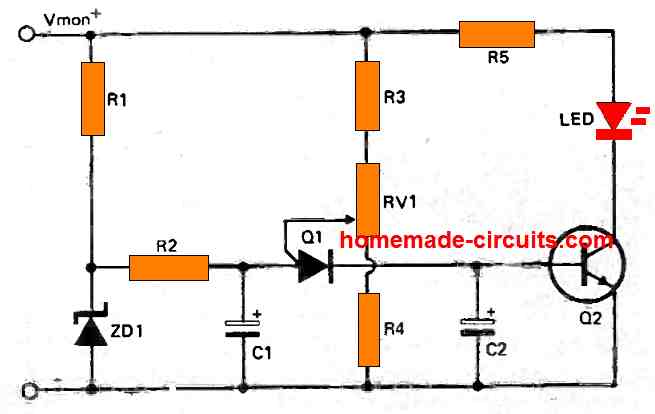

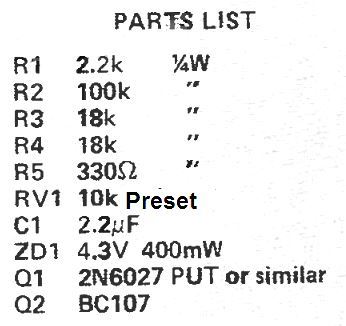

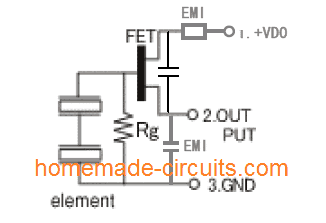

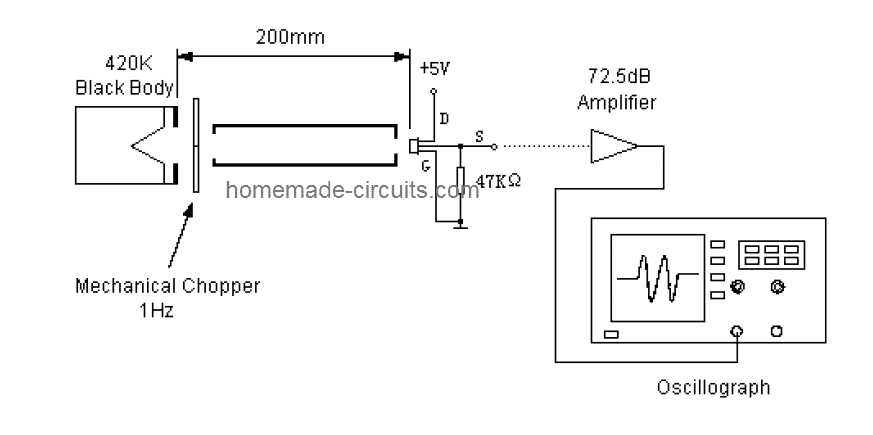

Low Battery Indicator using a PUT

This low battery indicator circuit is used with a programmable unijunction transistor (PUT), since the threshold characteristics of the UJT could be effectively defined, and can be designed to flash a connected LED indicator. The PUT (Q1) is configured like a relaxation oscillator circuit. As the supply voltage which is being monitored (Vmon) starts dropping, the gate voltage of the PUT (Vg) also begins dropping, while its anode voltage (Va) basically stays constant. The PUT begins oscillating only as soon as the gate voltage drops below Va by 0.6 volts.

As Vmon comes down further, Vg also drops accordingly and this situation triggers ON the PUT.

Therefore, the period of the cycle becomes lesser and this causes an increase in the frequency of flashing indicating that the battery has become too low and needs to be changed.

The PUT begins oscillating only as soon as the gate voltage drops below Va by 0.6 volts.

As Vmon comes down further, Vg also drops accordingly and this situation triggers ON the PUT.

Therefore, the period of the cycle becomes lesser and this causes an increase in the frequency of flashing indicating that the battery has become too low and needs to be changed.

Parts List

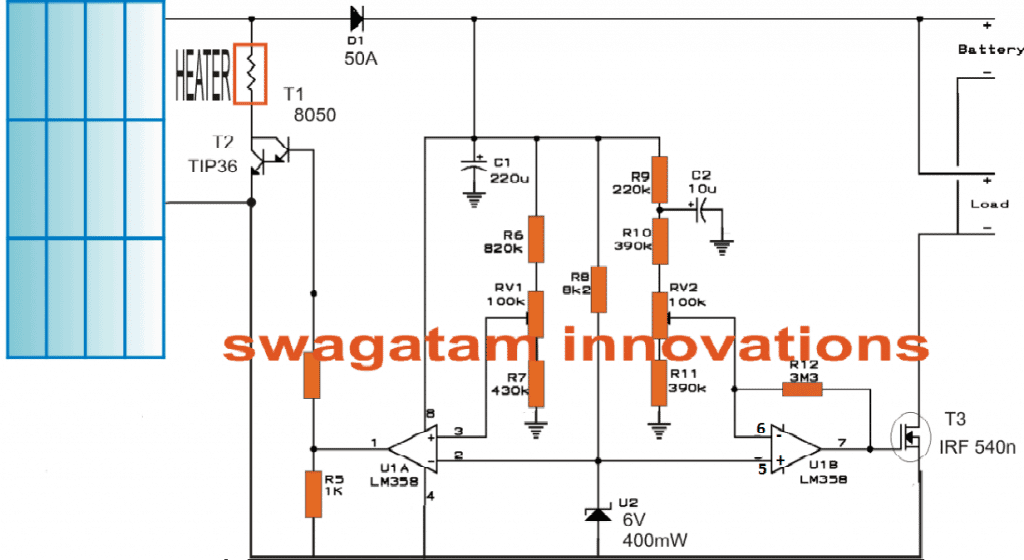

How to Recharge Dead Batteries

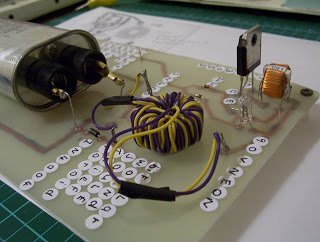

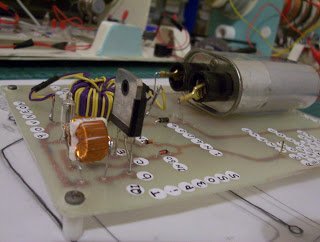

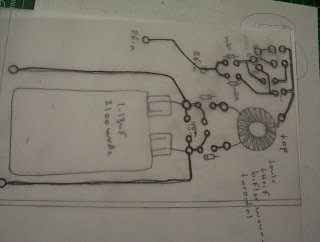

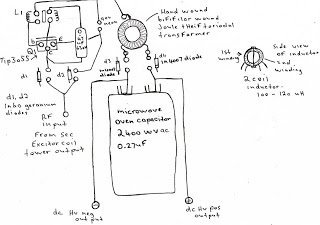

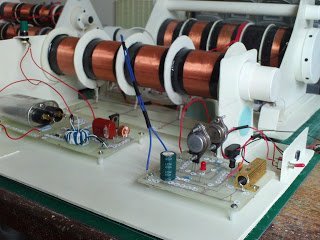

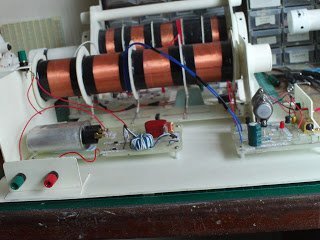

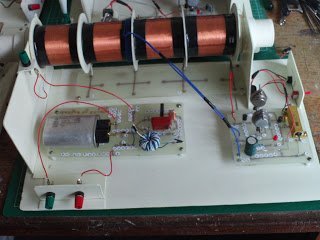

In this post we learn how to recharge and use bad, defective discarded batteries using an innovative battery charging process invented by John Bedini. Lead acid batteries can sometimes be a problem to get rid of. They can also be high priced to upgrade. In case discarded in the wrong way, they have a tendency to finish up in the land fill up or even rotting of in your junkyard.Contribution of John Bedini

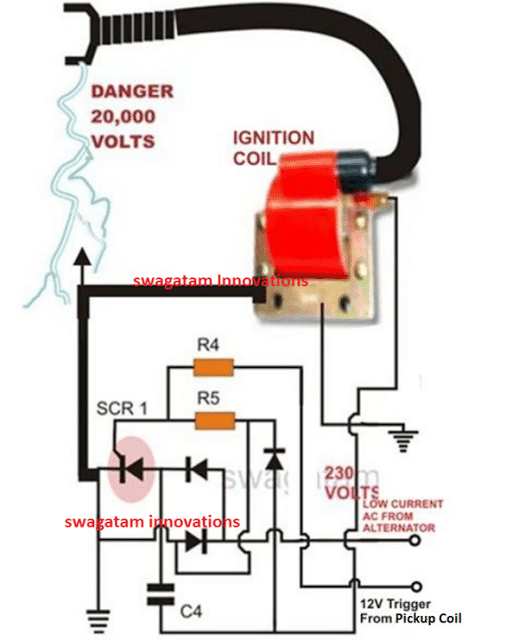

John Bedini has presented a bequest to the world which can bring back and enrich the used, abandoned, sulfated batteries. In case your battery is sulfated from typical utilization, it may commonly be recovered using this discovery. Batteries which have material impairment or have warped plates are worthless. The Bedini SSG (Simplified School Girl) generator can separate the sulfation on the battery plates and energize the batteries. On many occasions, the battery will in fact acquire further voltage, workable power compared to the time it had been purchased. By means of routine utilization, a battery would probably gradually drop its potential to hold electricity. This can be witnessed by the necessity to charge the battery far sooner every time. Typical battery chargers often give rise to this consequence due to heating effect of the battery. Because the plates get hot by way of charging, these are steadily weakened. A battery may have less electrical power every time it is utilized. With the Bedini charger, that is not the situation. I have reconditioned batteries which were found resting around in a trash. A couple of such batteries that possessed a charge of below 2 volts each presently are running my electric boat generator. These types of batteries were not consuming a charge with regular chargers. After a while and many rounds with the Bedini charger, the batteries have become superior to brand new.How Bedini SSG Function

This electric motor would not self start. You need to provide it with a little bit force to pick it up going, however once it begins rotating it is going to turn up by itself and self adjust its very own acceleration and speed depending on the dimensions and charge condition of the batteries getting charged. Since a magnet moves down the coil, a tiny electric current is stimulated into the main coil. This activates the transistor to switch on, enabling electricity from the operated battery to stream by way of the supplementary coil. The magnetic field generated in the secondary coil provides the cycle a tiny lift up on its path past the coil. As the magnetic field sets off the coil, the transistor is turned back off. This leads to the magnetic field in the supplementary coil to drop (back emf). During this period, the vibrant electric power makes its way into the process which is emptied via a diode into the batteries to be charged. This method could be demonstrated to generate additional energy on the recharging aspect compared to the need to steer the motor. In the method presented, the input current amounts between 150-200 mA.

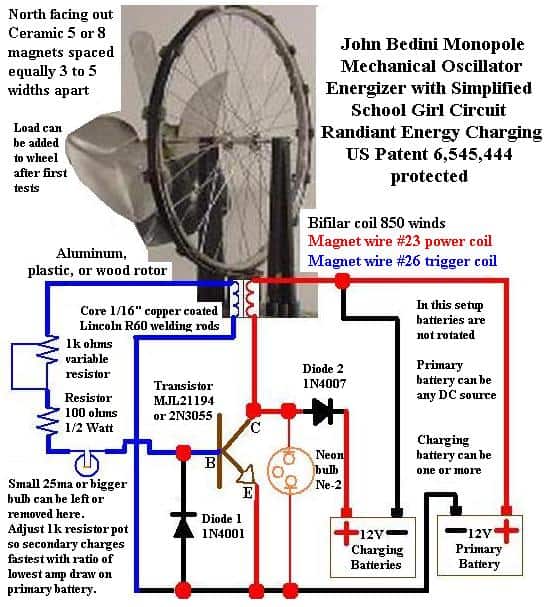

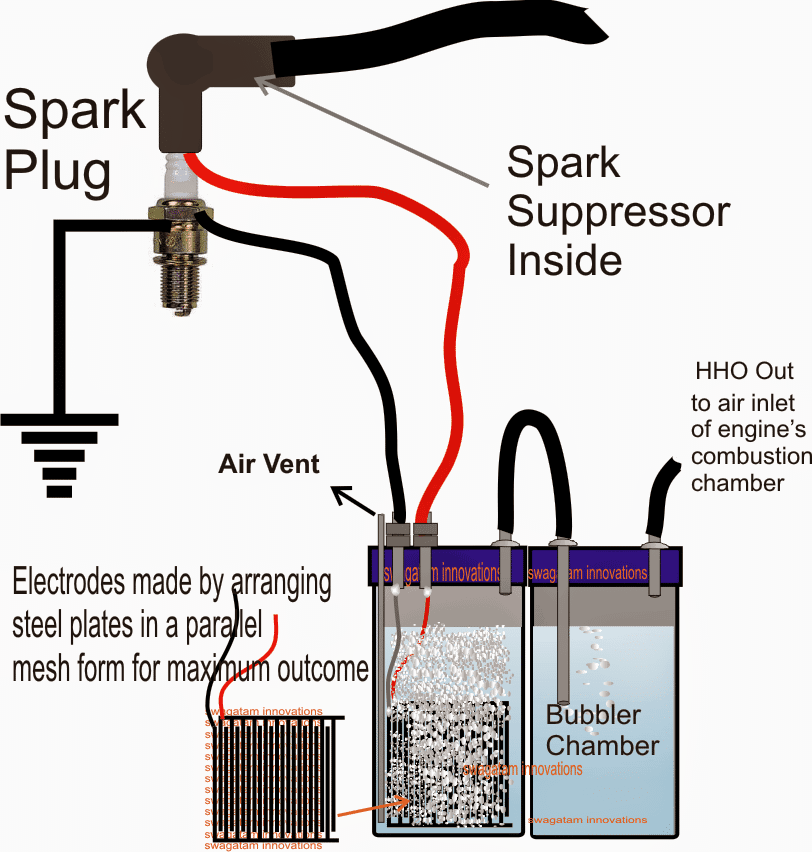

Solar Water Heater Circuit with Battery Charger

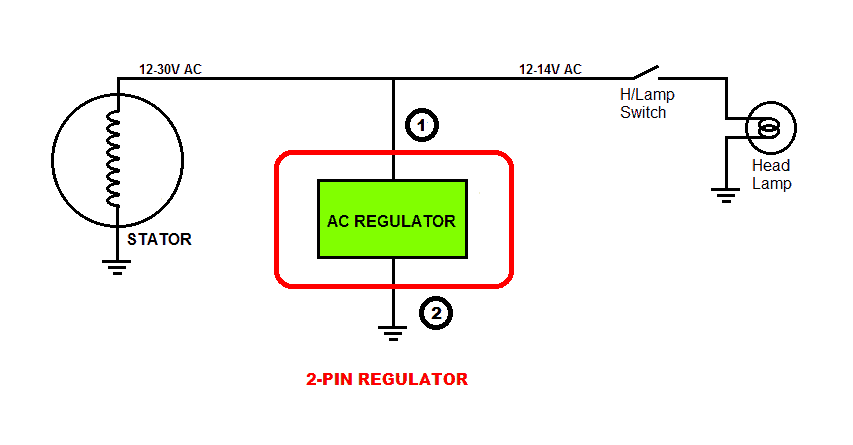

The proposed solar water heater with battery charger controller circuit explains a simple method of utilizing the excess solar energy from a solar panel for heating water in water tanks orswimmingpools or poultry egg chambers. Normally the circuit also functions like an automatic solar battery charger, and simultaneously powers domestic electrical appliances.Understanding Solar Charging

Solar energy is abundantly available across the globe and it's free to use. It's all about laying down a solar energy collector or simply a solar PV panel, and harness the available resource. In this blog and in many other sites you might have come across various efficient solar battery charger circuits. However these circuits generally speak about using the solar panel for acquiring electrical energy. While functioning, the involved regulators/chargers stabilize the solar voltage suchthat the output voltagebecomes suitable for the connected battery which is normally a 12V lead acid battery. Since normally a solar panel is designed for generating voltages in excess of 12V, that is around 20 to 30 volts, the process of stabilization completely neglects the excess voltage which is either shunted to ground or cancelled out through electronic circuitry. In the present article we learn a simple method of converting excess solar energy to heat even while charging a battery, and operating household appliances safely together. The circuit functioning may be understood withthefollowing points:Using Excess Unused Solar Power for Heating Water

In the given solar water heater with battery charger controller circuit diagram, let's assume at peak sunshine the attached solar panel is capable of generating around 24V. In the diagram we can see a couple of opamps positioned in between the solar input and the battery charging outlet. The opamp at the left is basically set for allowing the specified charging voltage to its right hand side stages. For a 12V battery this voltage would be around 14.4V. RV1 is therefore adjusted such that the output of the opamp becomes high in case the input voltage exceeds the 14.4V mark. The opamp at the right is designated as the over charge cut off stage which is responsible for monitoring the charging voltage of the battery, and cut it off when the upper threshold is reached. This happens when the non inverting input of U1B senses the higher threshold and shuts off the positive bias to the mosfet which in turn cuts off power to the connected battery. However the load which is essentially an inverter stays operative, as now it starts deriving the power from the charged battery. In the course, if the voltage drops even by a few voltages, U1B reverts its output to logic high and the battery once again begins getting charged while simultaneously allowing the connected appliances to remain operative via the common panel voltage. Meanwhile as discussed in the previous lines, U1A monitors the panel voltage and just like U1B when it instantaneously senses the panel voltage exceeding the 14.4 mark, it switches its output to logic high so that the connected transistors are instantly switched ON. A DC heater coil can be seen attached across the collector and positive of the transistor. When the transistor conducts, the coil is shunted across the direct panel voltage, and therefore it instantly begins getting hot. The low resistance of the coil pulls lot of current from the panel which forces the voltage to drop below the set 14.4 level for U1A. The moment this tends to happen, U1A reverts the situation and cuts off the supply to the transistors and the process rapidly fluctuates, such that the voltage fed to the battery stays within the 14.4V mark and in the process the heater coil manages to stay active so that its heat becomes applicable for any preferred purpose.

Diagram for the solar water heater with battery charger controller circuit

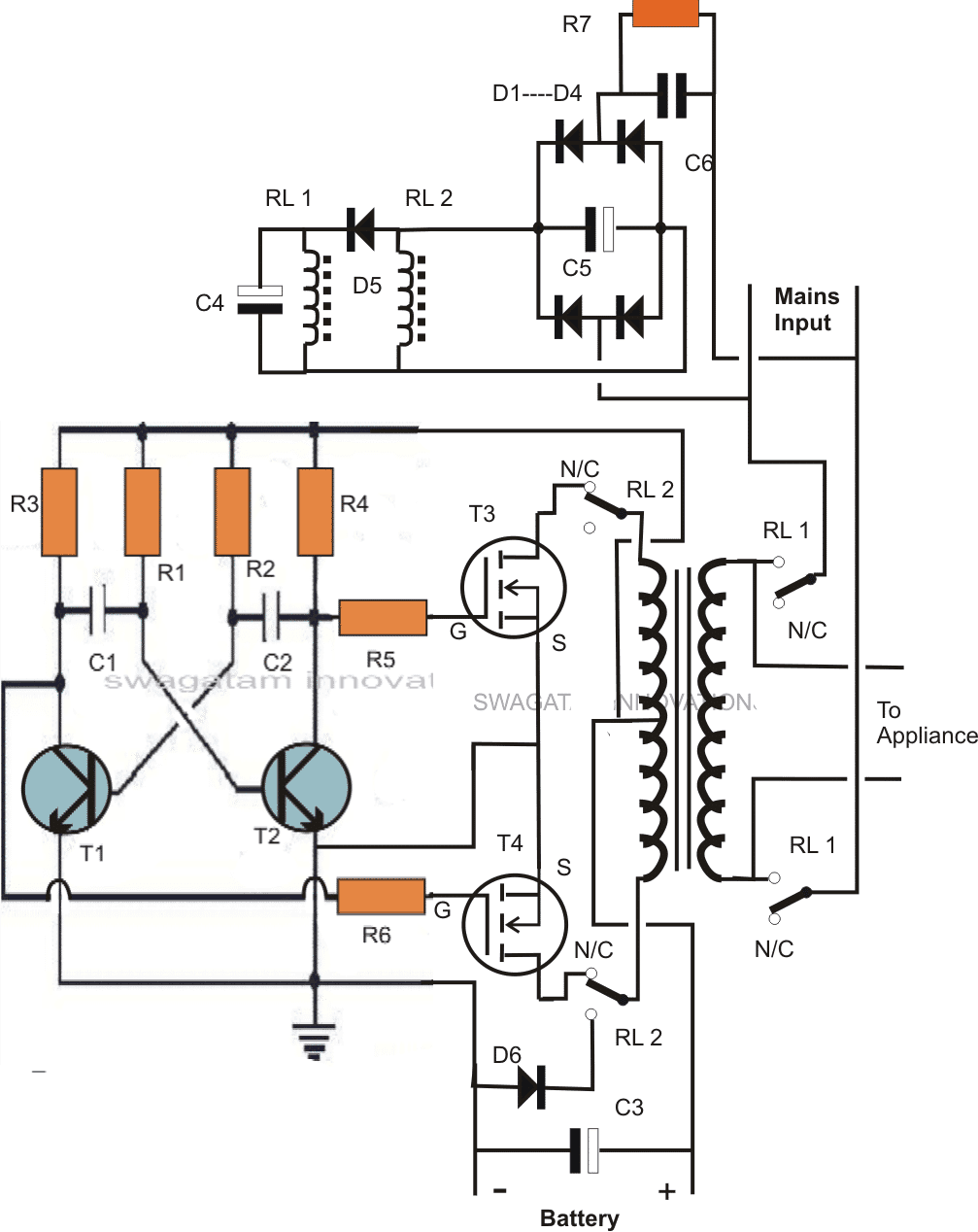

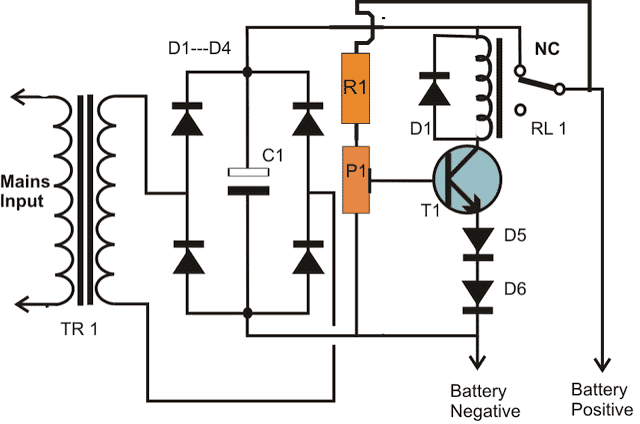

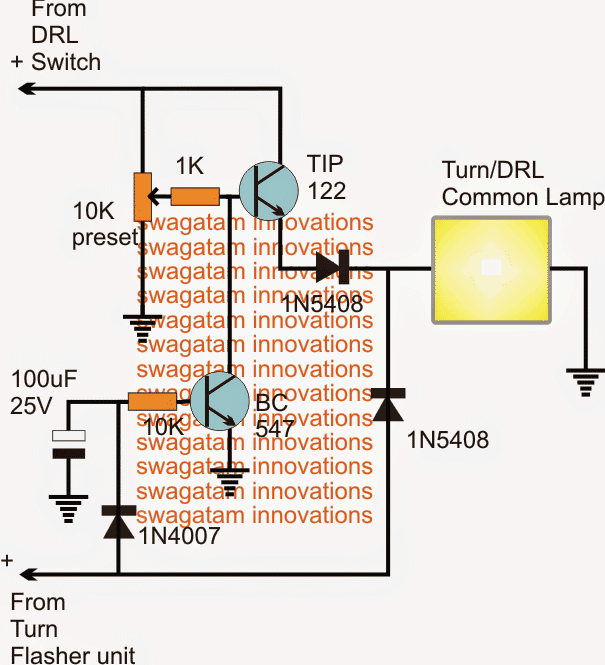

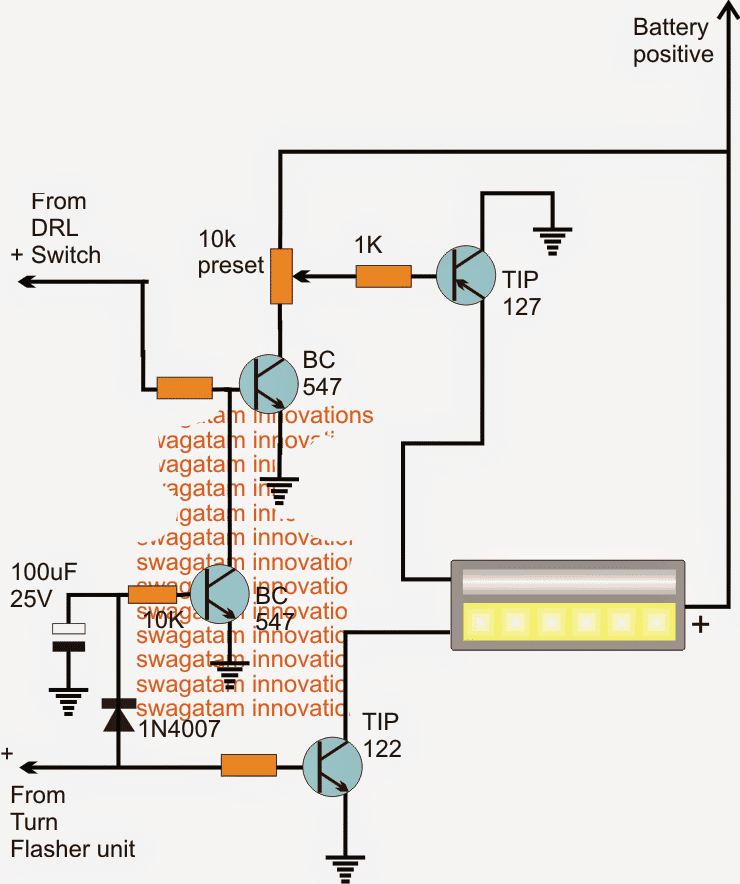

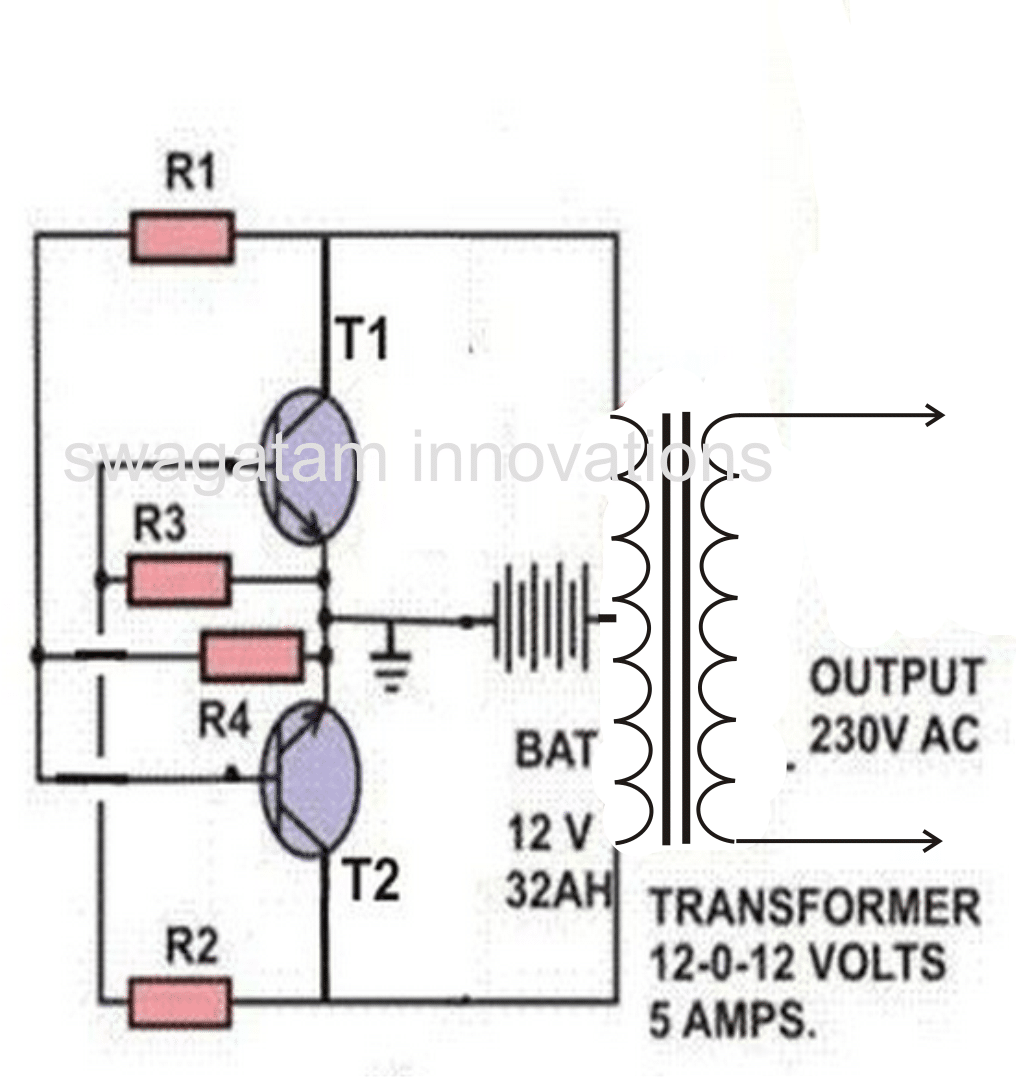

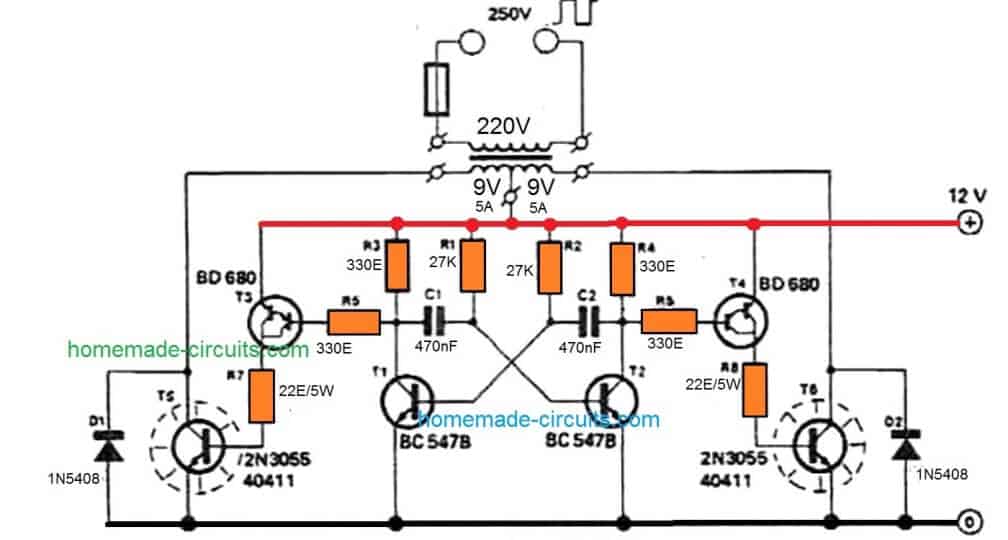

Single Transformer Inverter/Charger Circuit

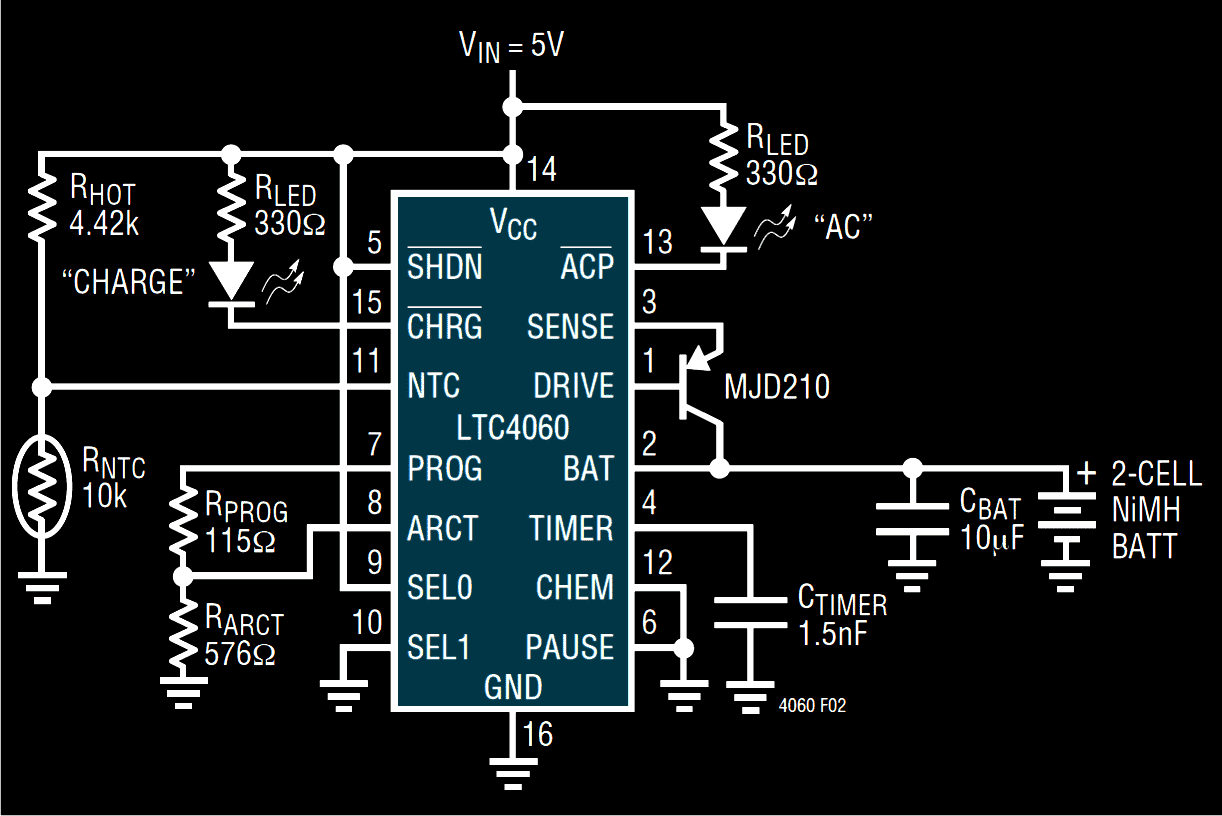

The post explains how to build an innovative inverter circuit with a single transformer that works both as an inverter and a battery charger transformer, Let's learn the details from the following discussion.The Circuit Objective

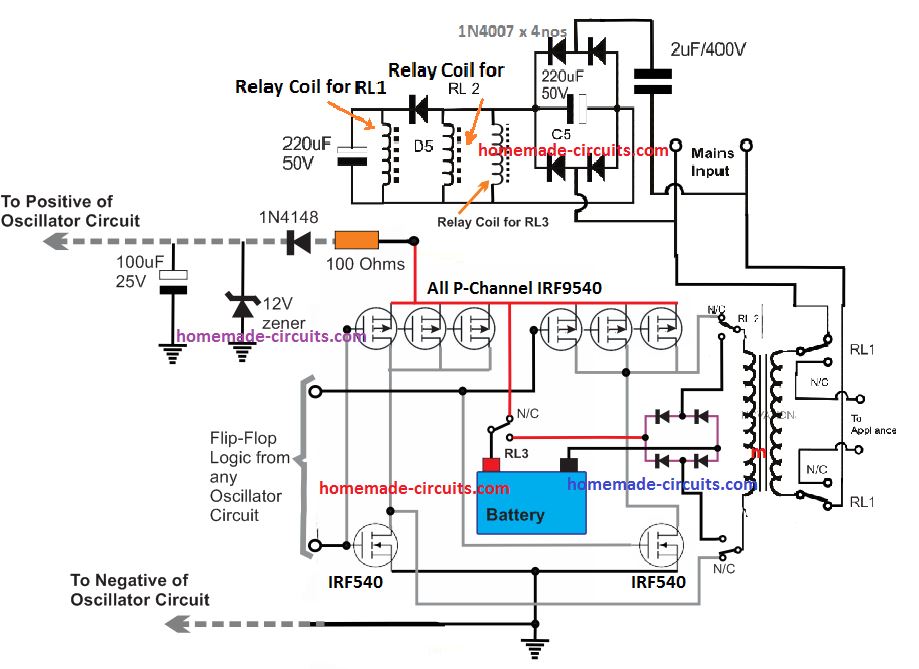

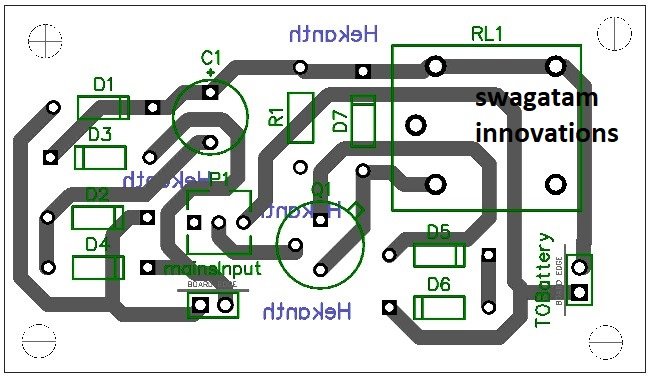

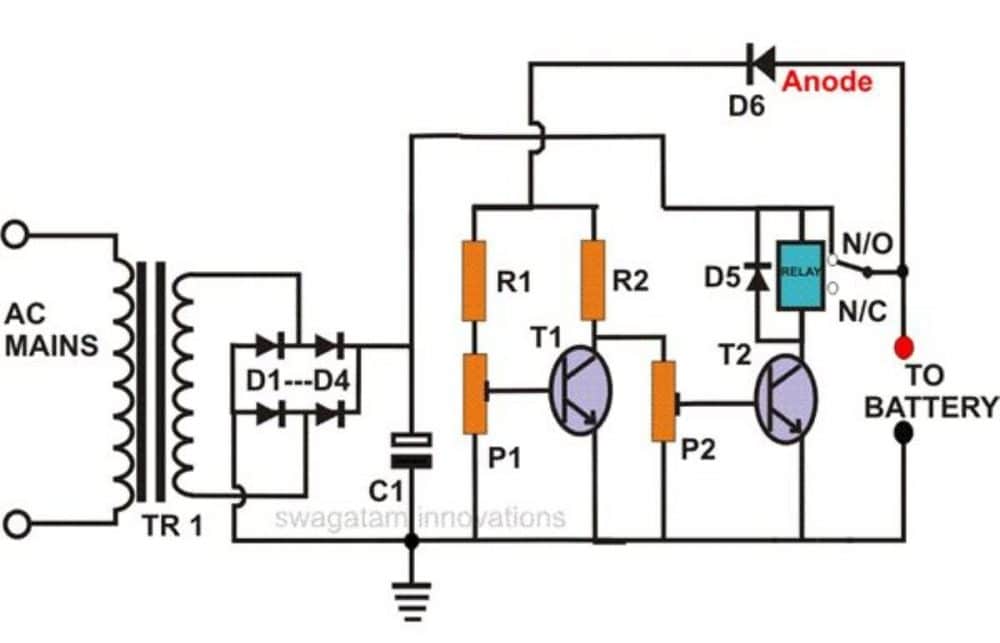

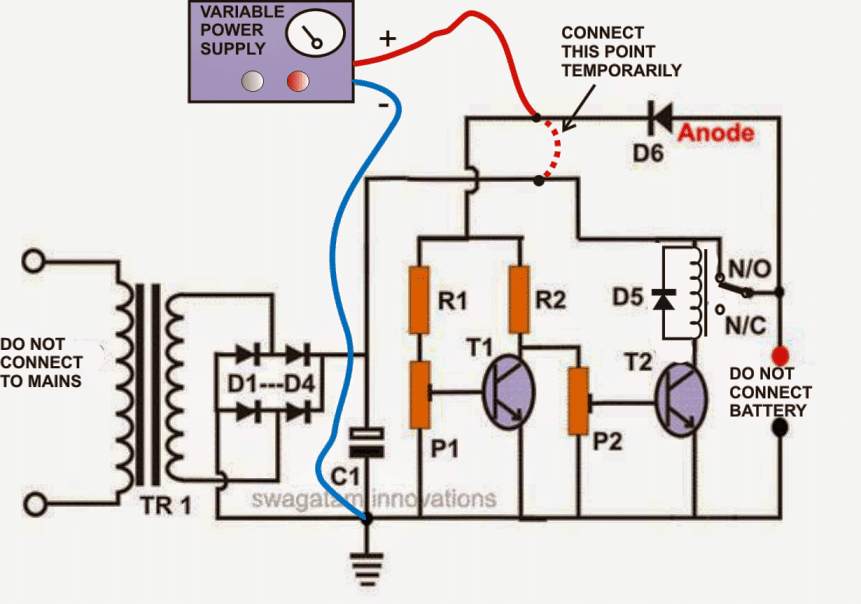

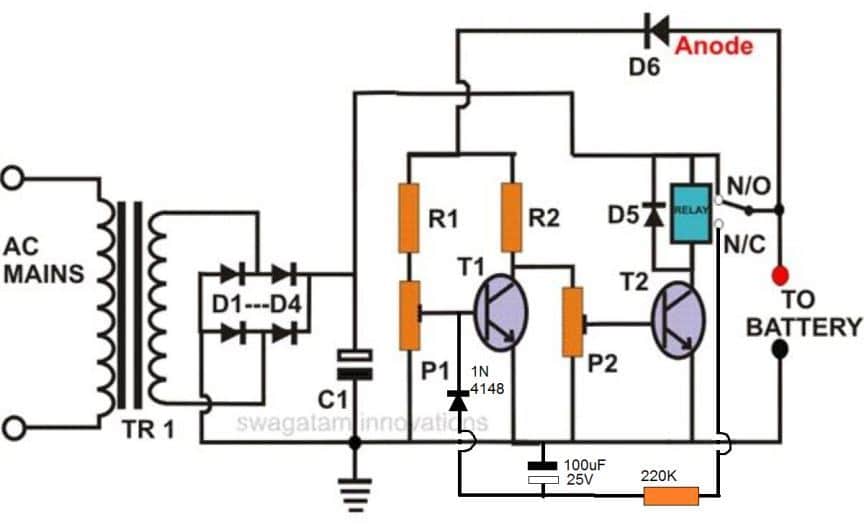

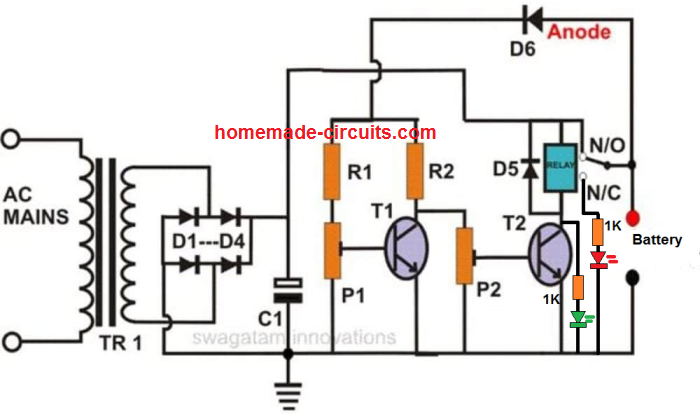

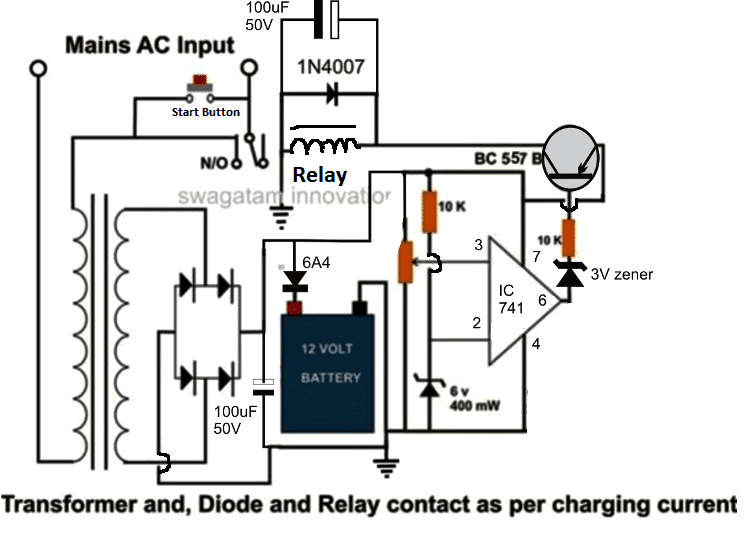

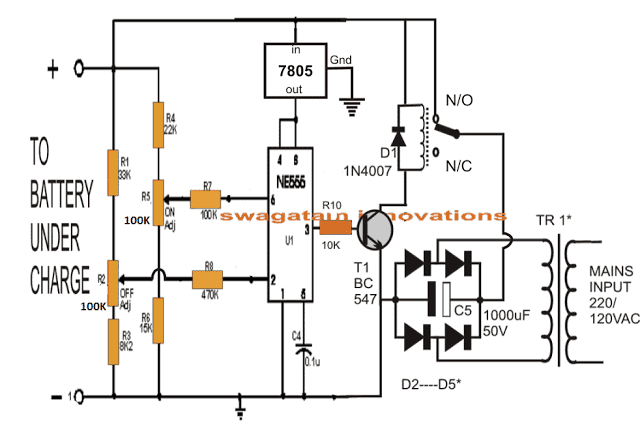

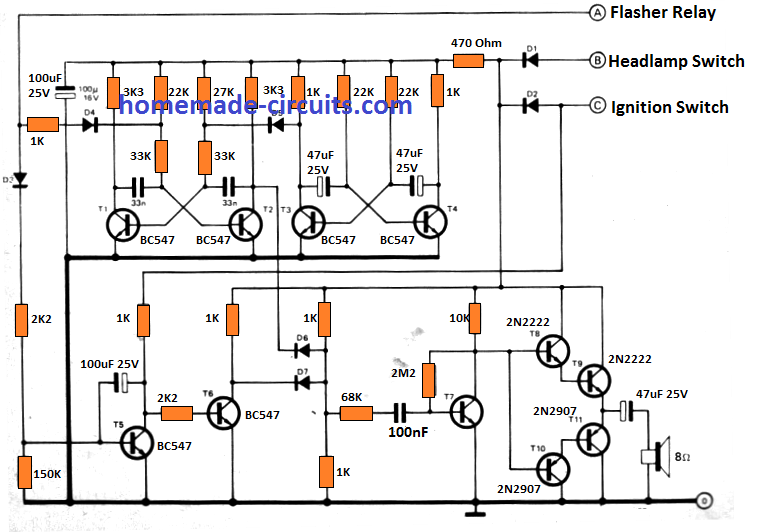

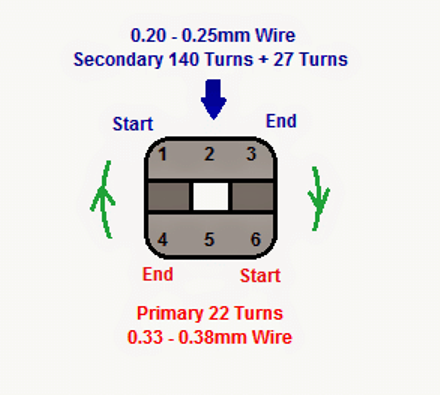

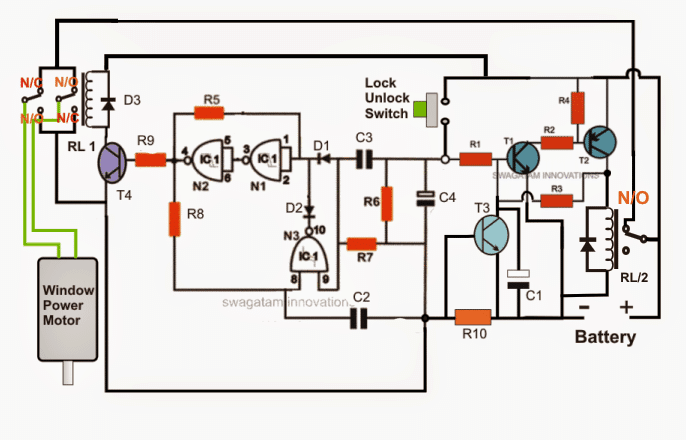

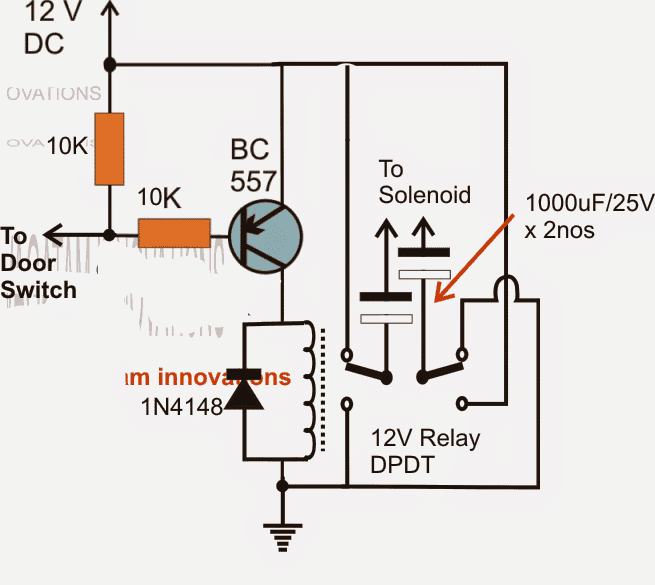

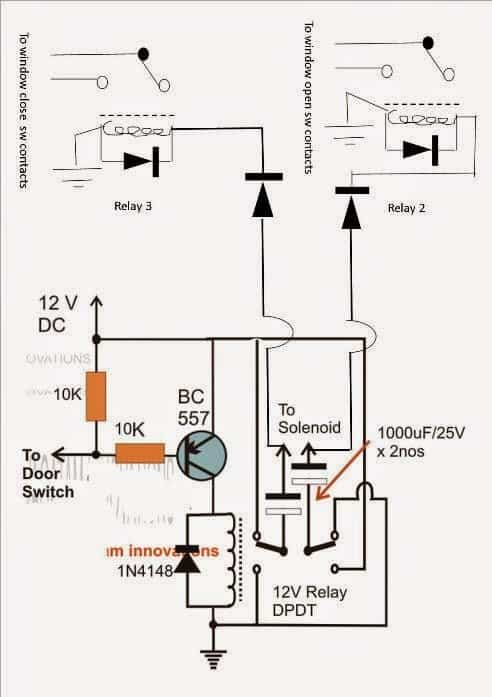

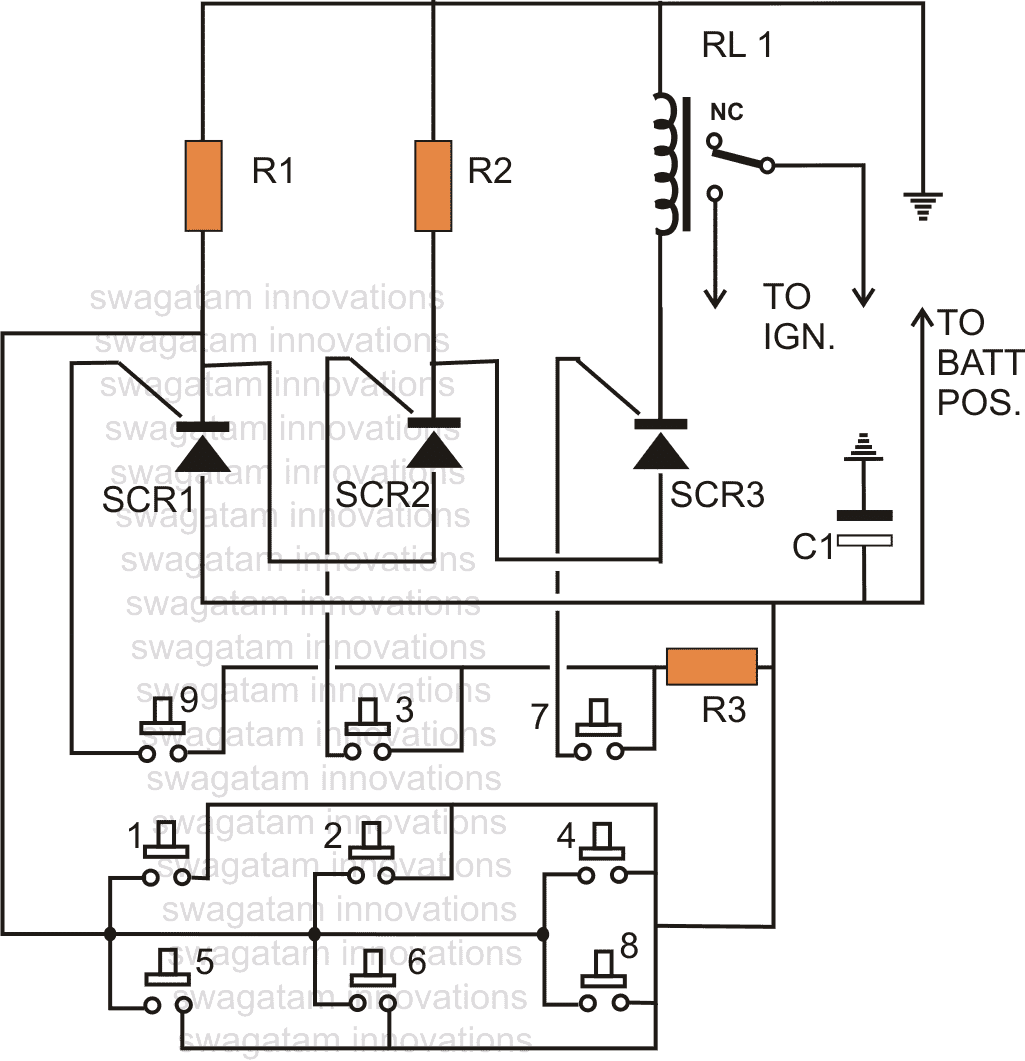

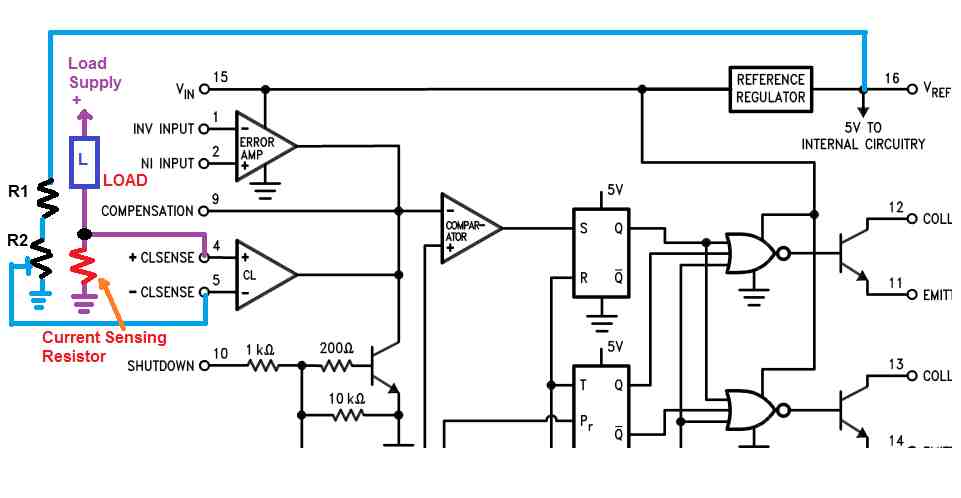

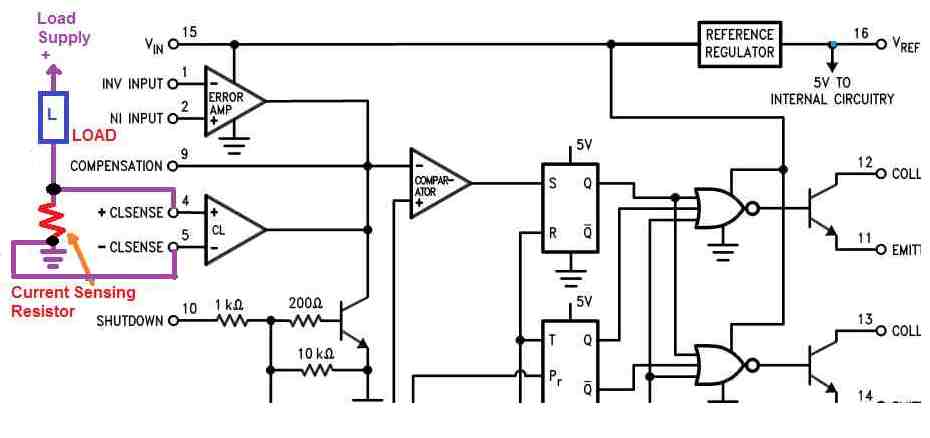

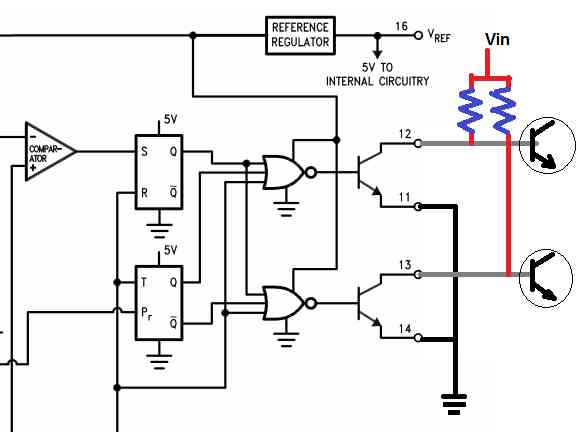

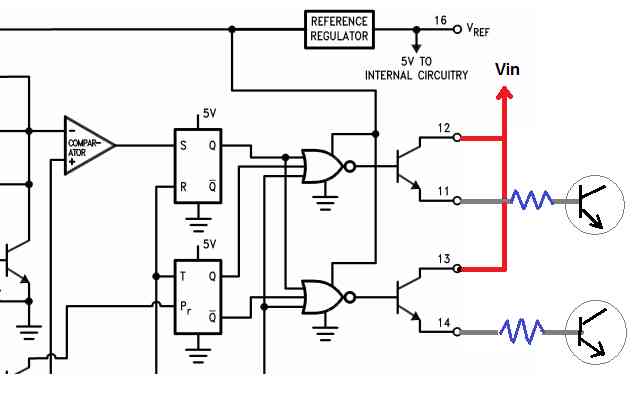

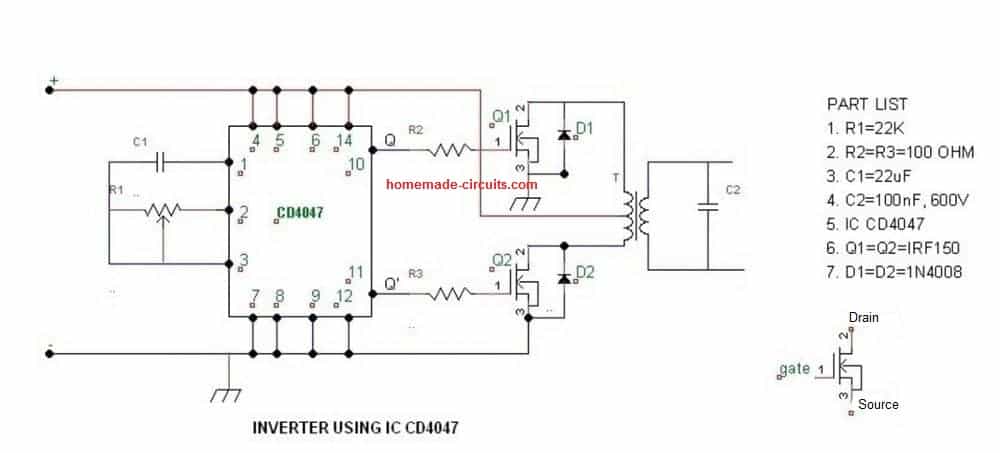

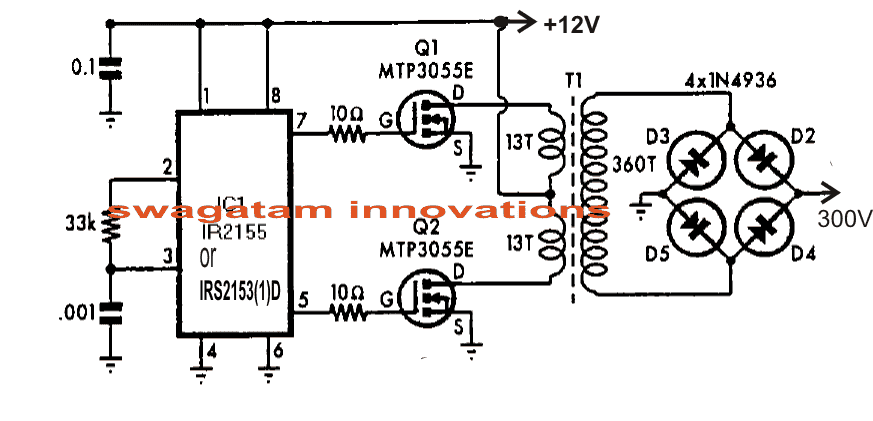

Though you may find many inverters having an integral battery charger, the section will mostly employ a separate transformer for implementing it. The following article describes a unique design which utilizes the inverter transformer for power inverting as well as for charging the battery. The circuit diagram below shows a design where a single power transformer is used for inverting purpose as well as for charging the battery when mains is present. The good thing about the circuit is that the transformer doesn't employ separate winding for this, rather works with the same input winding and reverts DC to the battery with the help of a few DPDT relays. The circuit can be understood with the following points:How the Circuit Functions

The inverter section can be easiy recognized in the diagram, R1 to R6, including the T1 and T2 forms a general astable multivibrator circuit for producing the required 50 or 60 Hz pulses. These pulses drive the mosfets alternately which in turn saturate the transformer by switching the battery voltage in it. Thesecondary ofthe transformer generates the corresponding magnitude of AC which is finally used for operating the connected appliances. The above configuration suggests an normal or ordinary inverter operation. By adding a couple of DPDT relays in the above discussed operation, we can force the circuit to charge the battery in the prsence of an AC mains source. The coils of the two relays are powered through a capacitive low current compact power supply, involving C6, C5, D1----D5. The above circuit is connected to a mains AC source, this source is also connected to RL1 poles. The second relay RL2 is wired up with input winding of the transformer. In the absence of mains AC, the position of the relay contacts are in the N/C as shown in the figure. In this position the mosfets get linked with the transformer input winding, and the battery with the circuit so that the inverter starts oscillating and the output appliances gets the AC power from the battery. In the presence of mains AC the relay coils instantly get the required DC power and the contacts activate. RL1 activates andconnectsthe mains input to the transformer, theappliancesalso get connected with the mains AC in the process. Also due to the action of RL2 the mosfets get disconnected from the transformer, while the the lower tap connects with D6. Since the center is already connected to battery positive, the inclusion of D6 provides a half wave rectified voltage to the battery, which is effectively filtered by C3 so that the battery is able to get the required sufficient charging voltage. The above charging process continues until mains is present, so itshouldbe monitored manually. When mains fails, the action reverts into inverting mode without interrupting the applianceoperations andby using a single transformer for both the operations. C4 makes sure that RL1 always activates a shade later than RL2 for safetyreasons. CAUTION: THIS CIRCUIT IS DEFINITELY NOT RECOMMENDED FOR THE NEW HOBBYISTS, IT'S SUITABLE ONLY FOR THE EXPERTS.

IF YOU ARE A NOVICE AND INTERESTED TO TRY THIS....

BUILD IT AT YOUR OWN RISK.

CAUTION: THIS CIRCUIT IS DEFINITELY NOT RECOMMENDED FOR THE NEW HOBBYISTS, IT'S SUITABLE ONLY FOR THE EXPERTS.

IF YOU ARE A NOVICE AND INTERESTED TO TRY THIS....

BUILD IT AT YOUR OWN RISK.

Parts List

R1, R2 = 27K, R3, R4, R5, R6 = 470 Ohms, C1,C2 = 0.47uF/100V metallized T1, T2 = BC547, T3, T4 = any 30V, 10amp mosfet, N-channel. C3 = 47000uF/25V C4 = 220uF/25v C5 = 47uF/100v C6 = 105/400V R7 = 1M D1---D5 = 1N4007 D6 = 1N5402 RL1, RL2 = DPDT, 400 OHMS, 12V, 7 AMPS/220V Transformer = 12-0-12V, current as per requirement. For only inverter design please refer to this ARTICLEUsing a 2-Wire Transformer

If you do not want to use a center tap transformer for the inverter, then you can use the following P-channel and N-channel MOSFET H-bridge inverter module for getting an identical single transformer inverter/charger results:

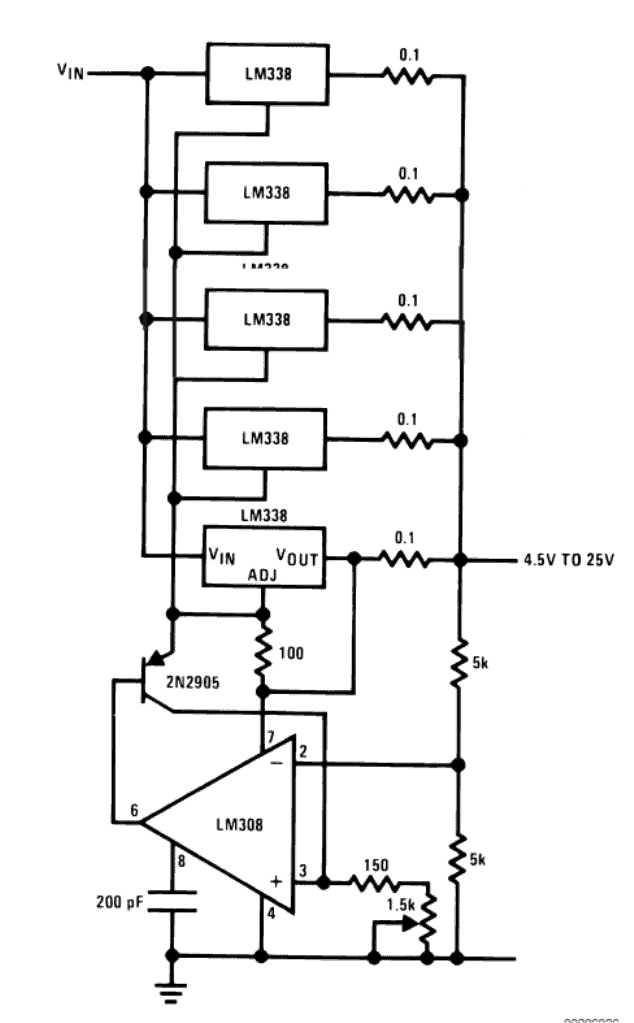

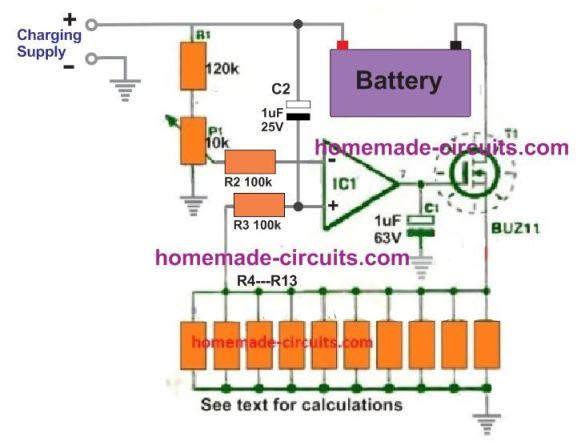

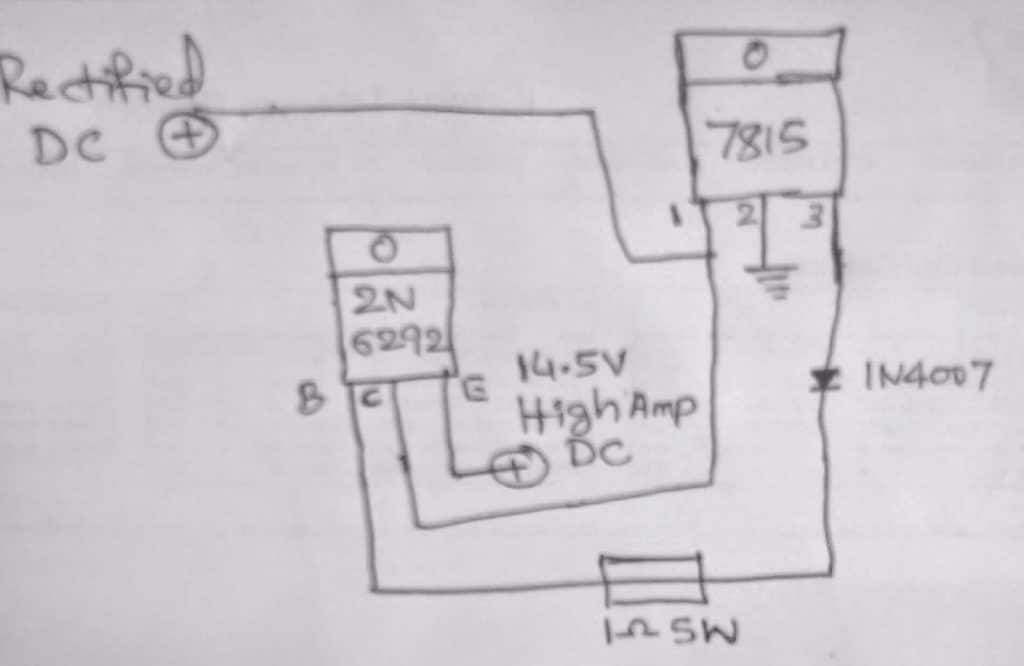

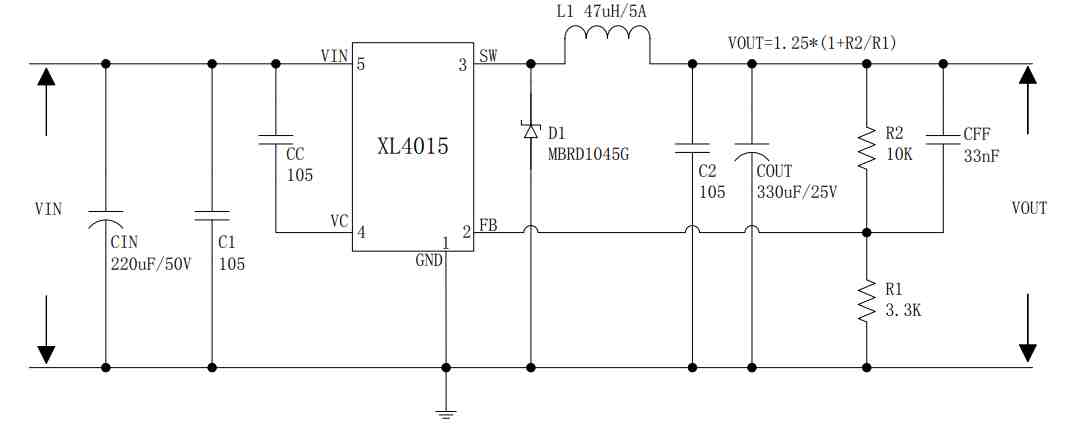

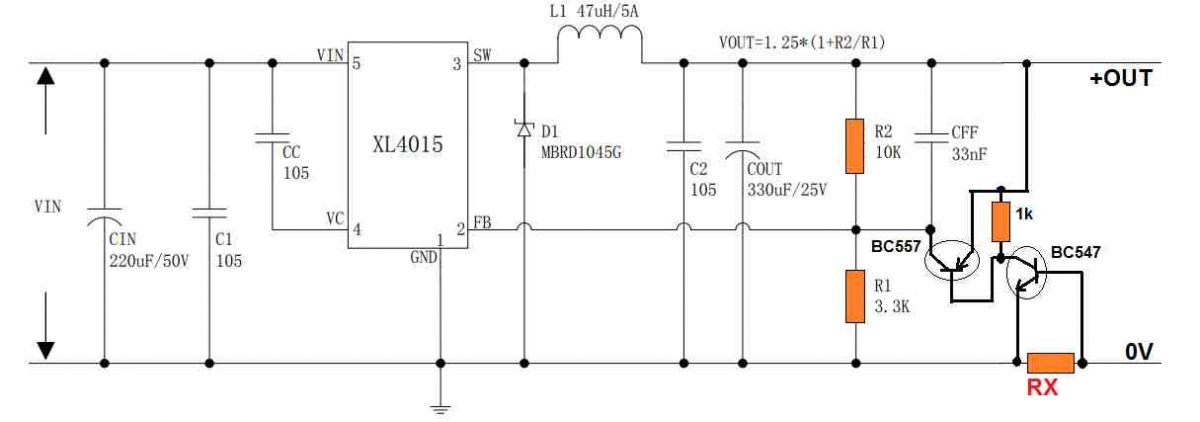

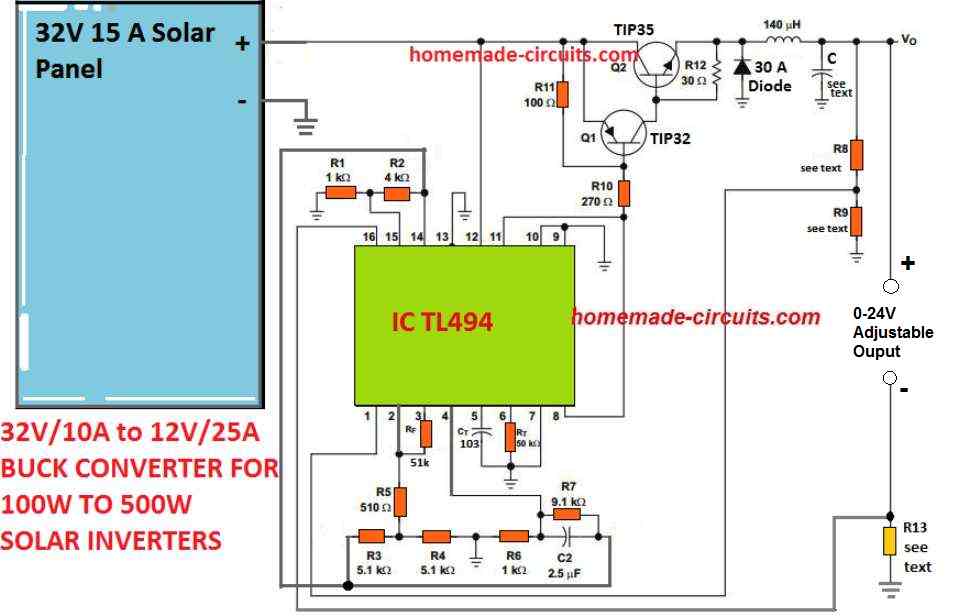

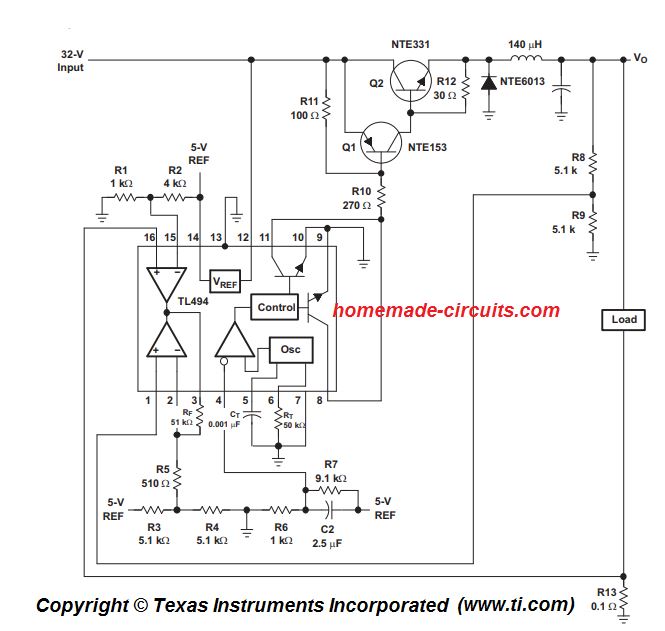

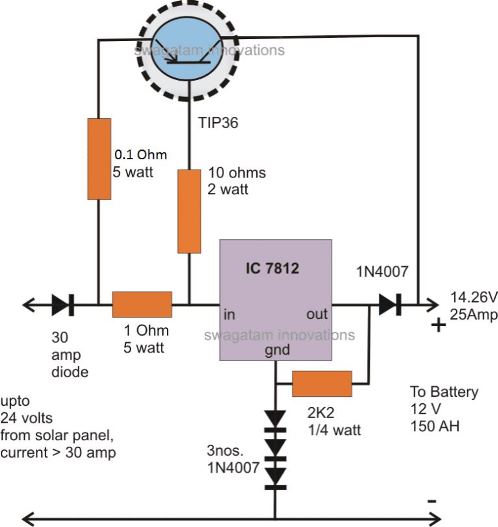

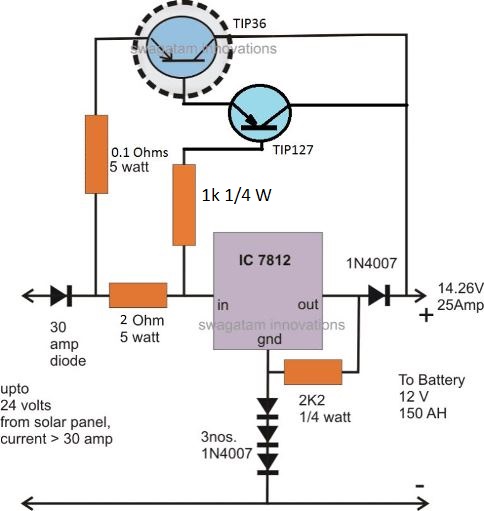

High Current Solar Battery Charger Circuit 每 25 Amps

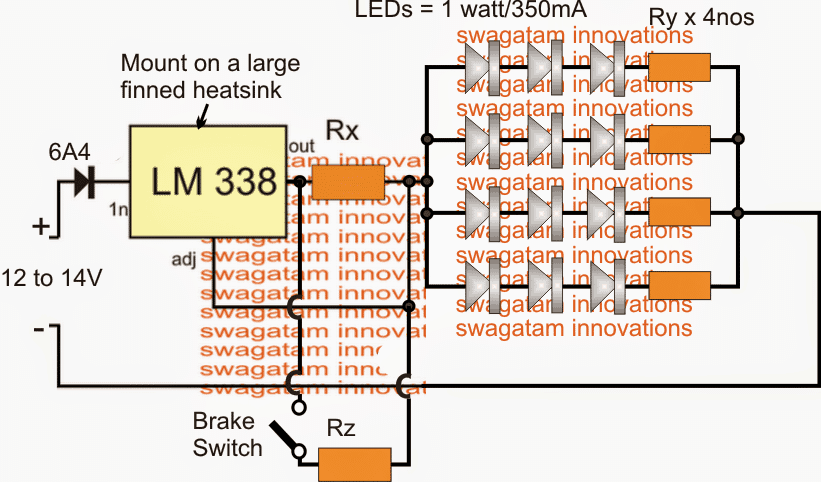

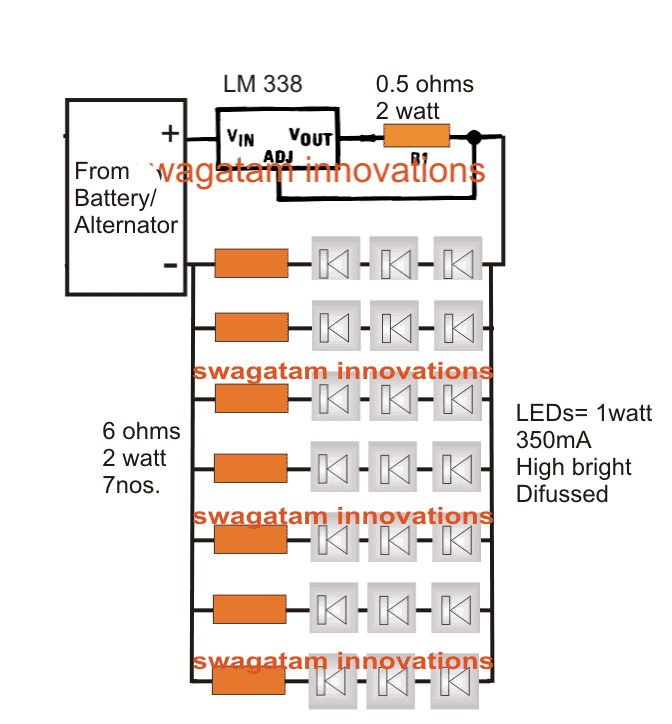

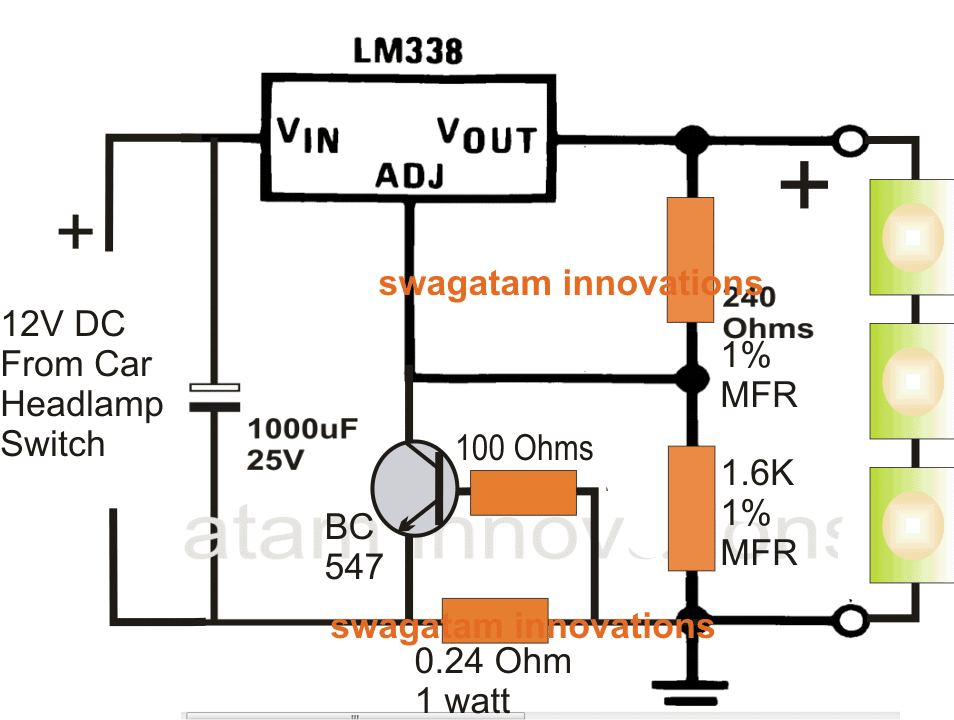

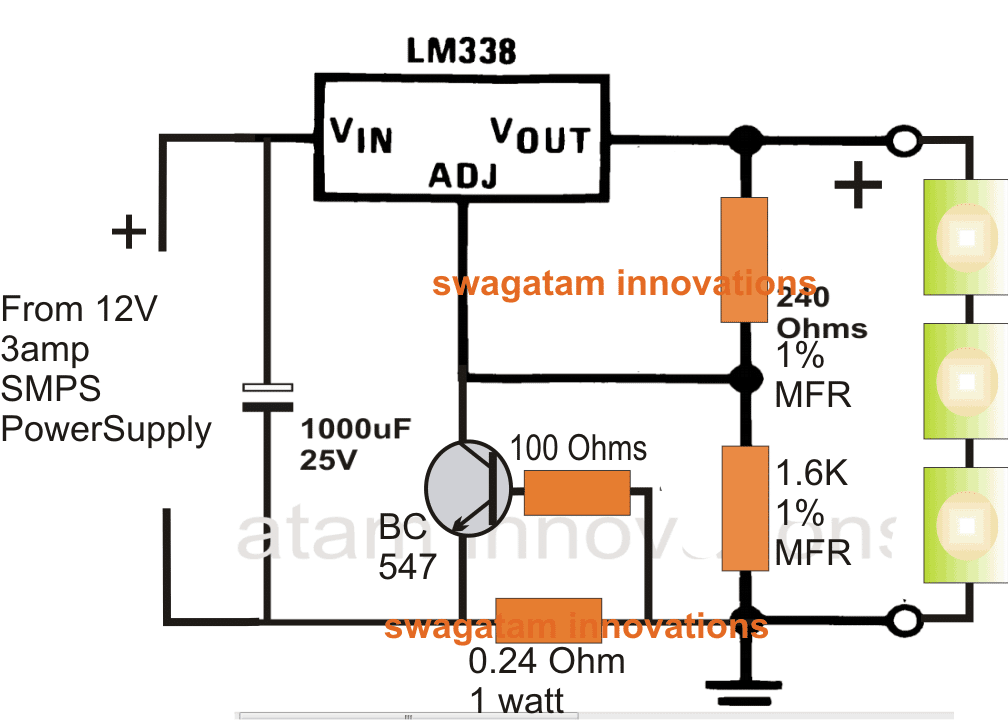

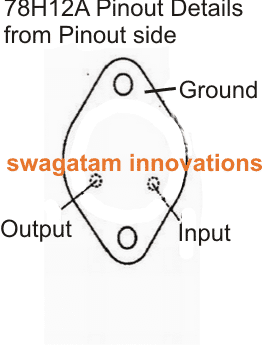

This circuit is capable of providing as high as 25 Amps of current at any specified voltage between 1.25 V to 30V as per the adjustment of the given pot. The current is constant irrespective of the voltage settings. The circuit can be used for charging batteries in range of 50 to 200 AH.How it Works

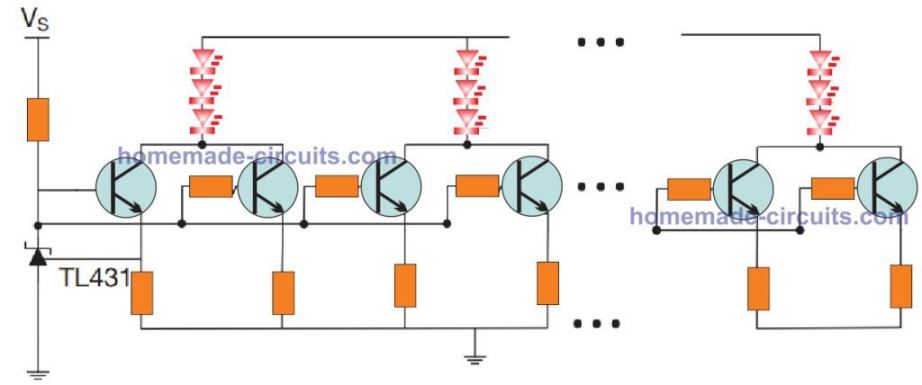

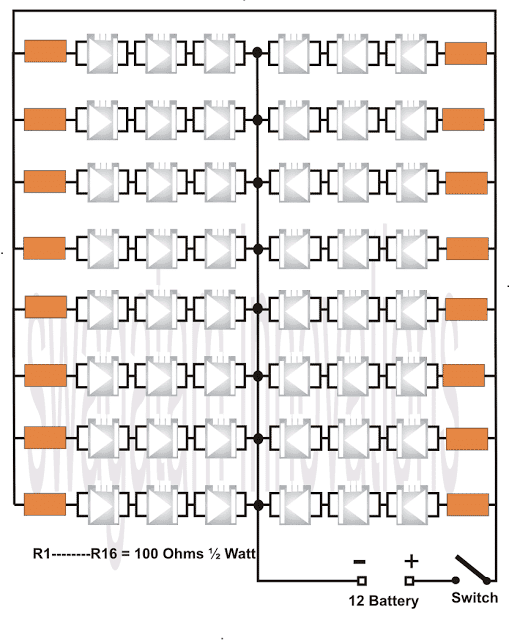

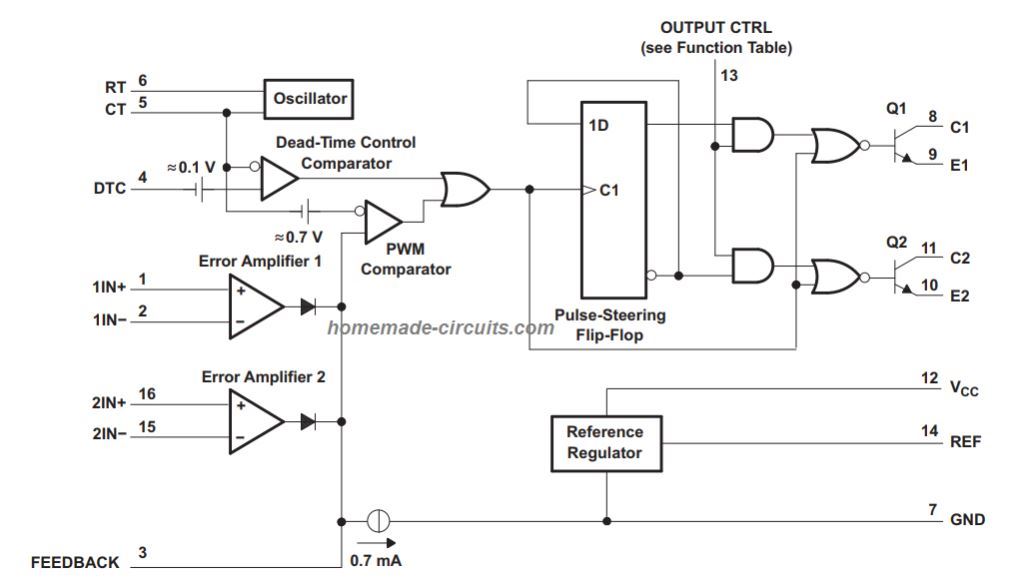

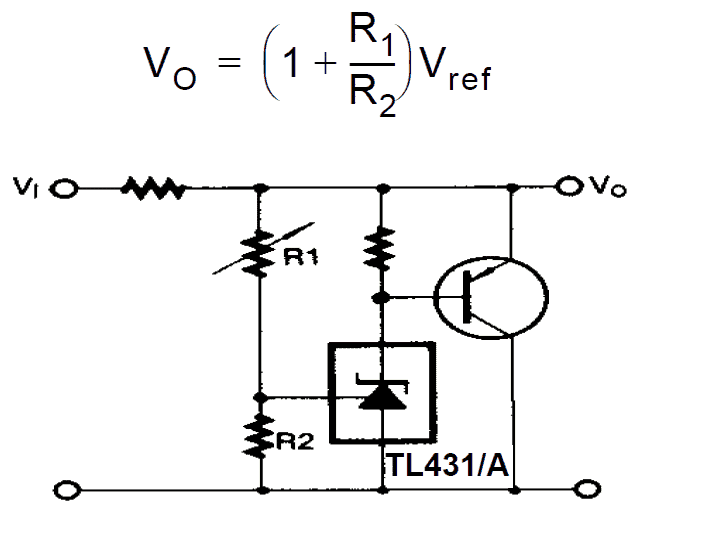

The figure below shows a straightforward design of a simple high current solar battery charger power supply circuit which would generate a constant 25 amps of current from any source which is able to generate currents in excess of 25 amps and at 32 volts maximum. We know that the IC LM338 is specified with a maximum of 5 amp current, the IC restricts anything above this limit. By connecting 5 of these ICs in parallel it thus becomes possible to generate a current output of about 25 amps. The great thing about using these ICs is that, these devices are internally protected from thermal runaway situations and short circuit or overload conditions. It means the present circuit automatically becomes safe from such adverse parameters and thus becomes completely indestructible given the input is not exceeded above 32 volts. However the ICs cannot be directly connected in parallel, because that would cause a difference in the voltages at the output from each of the ICs which in turn would cause an imbalance between the IC dissipation, this wouldn't be good for the overall functioning of the circuit. Therefore the additional components in the form of the opamp and the transistor have been included in the circuit which controls and maintains a constant voltage output from all the ICs keeping the situation well under control.

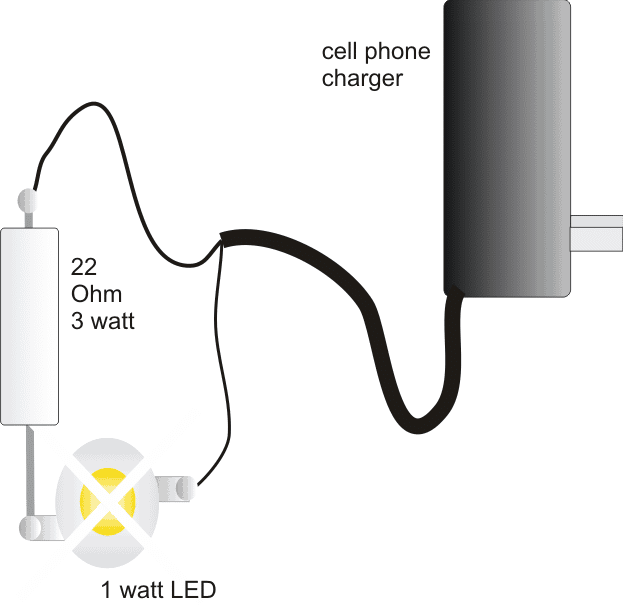

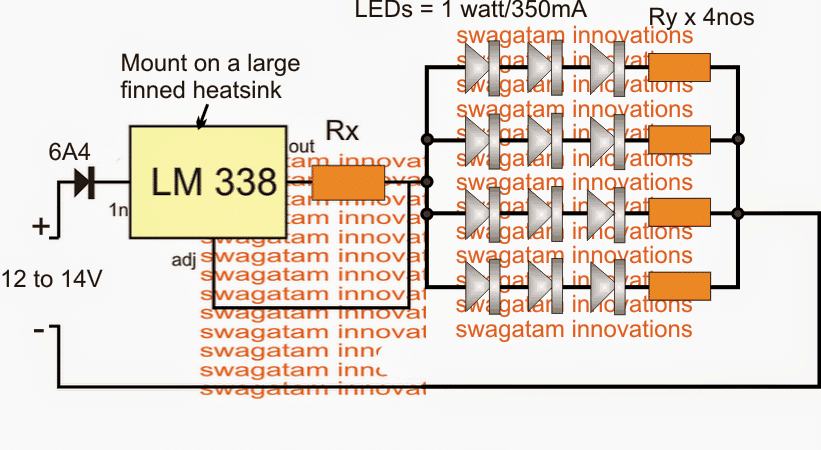

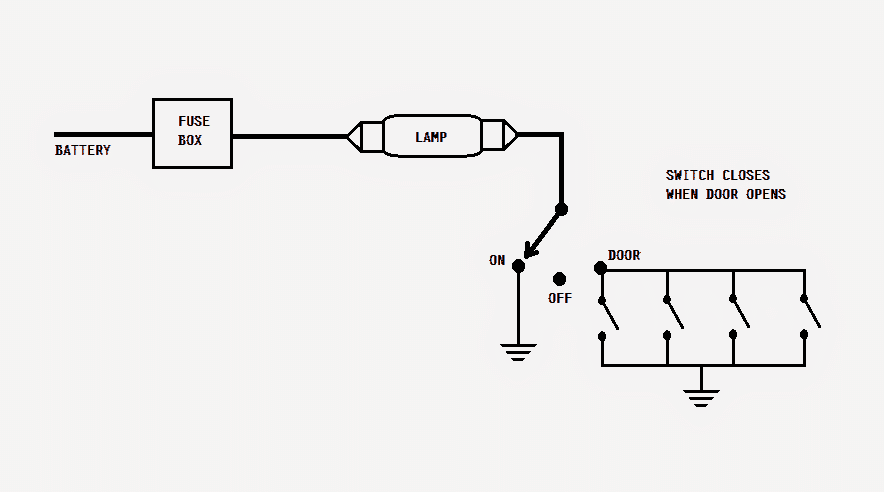

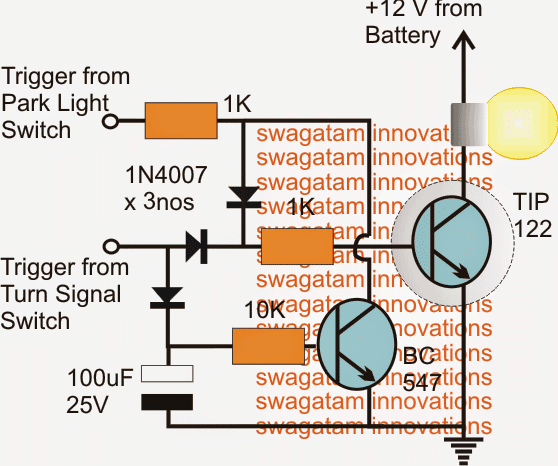

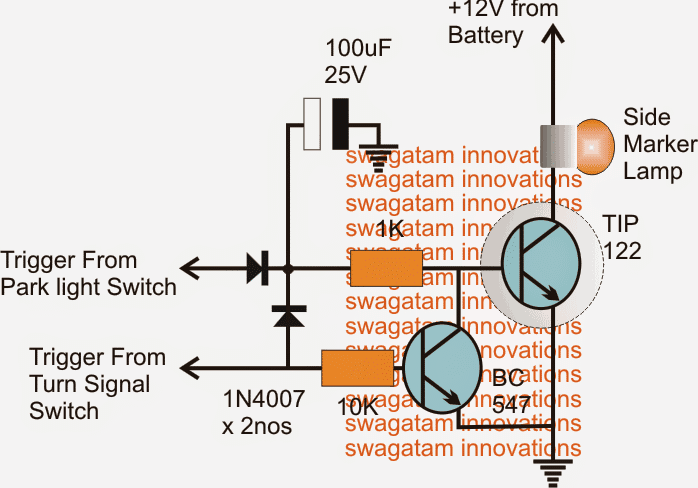

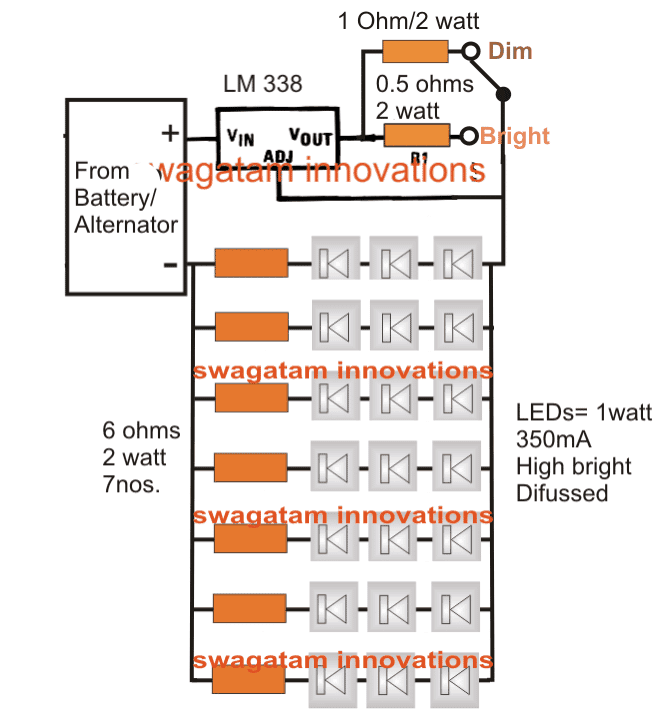

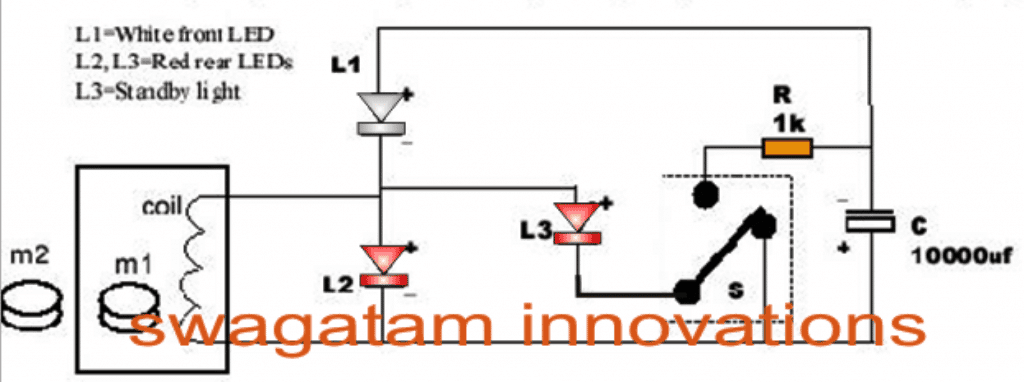

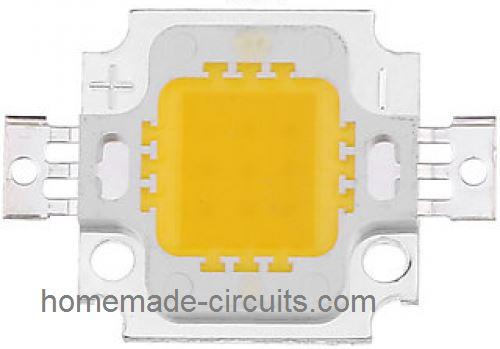

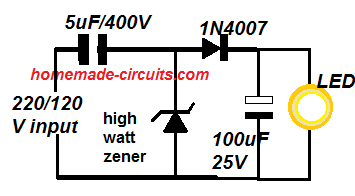

How to Illuminate 1 Watt LEDs with Cell Phone Charger

Nowadays probably all of us have a spare cell phone charger lying idle in our cupboards or table drawers......so wouldn't it be a great idea if we could employitlike a super bright 1 watt LED driver and illuminate our room with white cool moon light.Circuit Concept

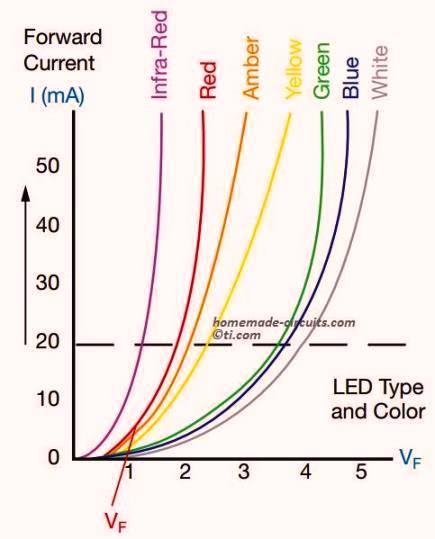

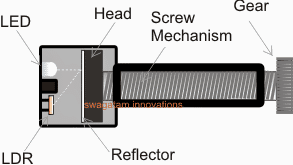

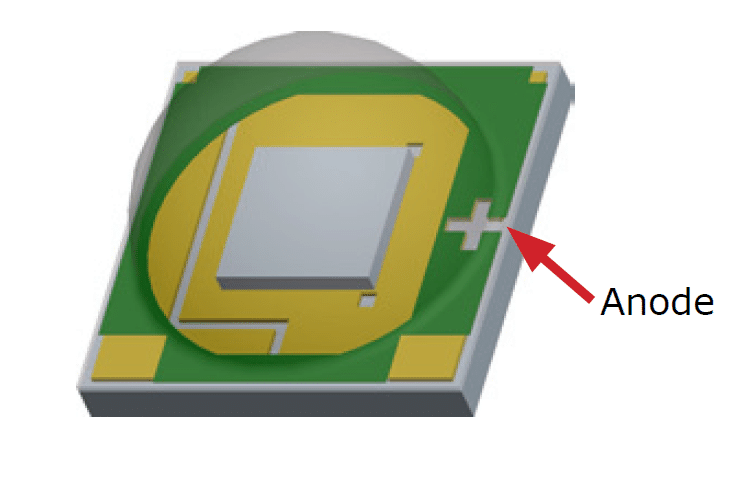

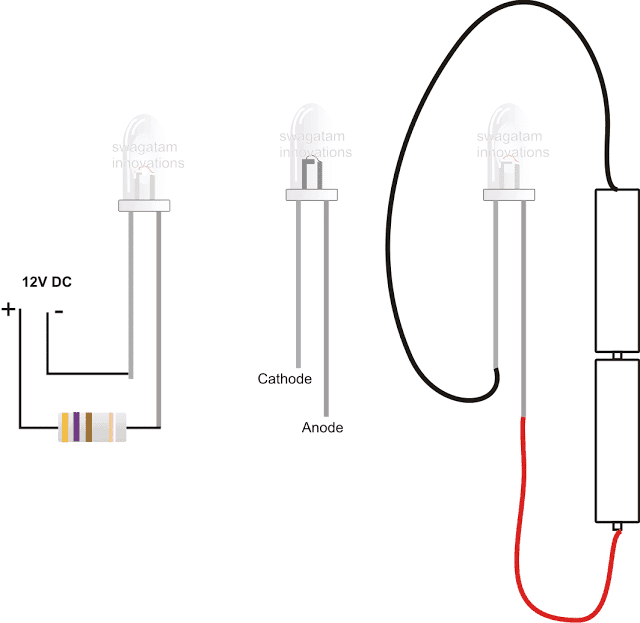

As we all know that a 1 watt LED consumes about 350 mA of current and is capable of generating intense blinding white point lights. If this little high bright light source is enclosed within a reflector cabinet consisting of mirror finish lens, the light from it can be enhanced to great levels. However a 1 watt type of LED would require a suitable constant voltage power supply for illuminating safely with thespecifiedoutputs. Though there are a number of suitable drivers which are available in the market, a cell phone charger can be ideally used for this purpose. If we look at the diagram given below, we see that the whole thing can be configured using just a single current limiting resistor. Let's learn regarding the involved making procedures with the following points:

You would require a standard cell phone charger.

A 1 watt LED/350 mA white.

A 22 Ohm 3 watt resistor,

An aluminum heatsink, as specified in the given text.

Small piece of general purpose PCB, about 1 by 1 inch.

Let's learn regarding the involved making procedures with the following points:

You would require a standard cell phone charger.

A 1 watt LED/350 mA white.

A 22 Ohm 3 watt resistor,

An aluminum heatsink, as specified in the given text.

Small piece of general purpose PCB, about 1 by 1 inch.

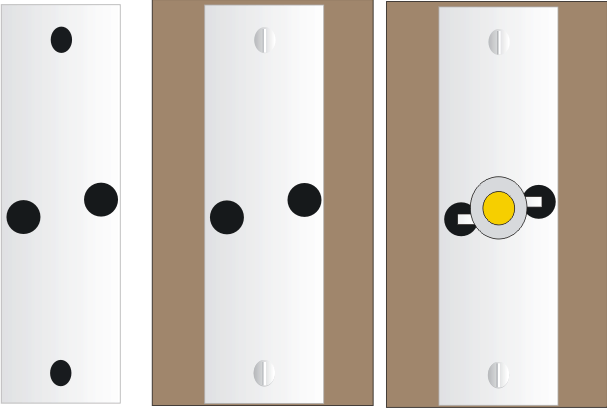

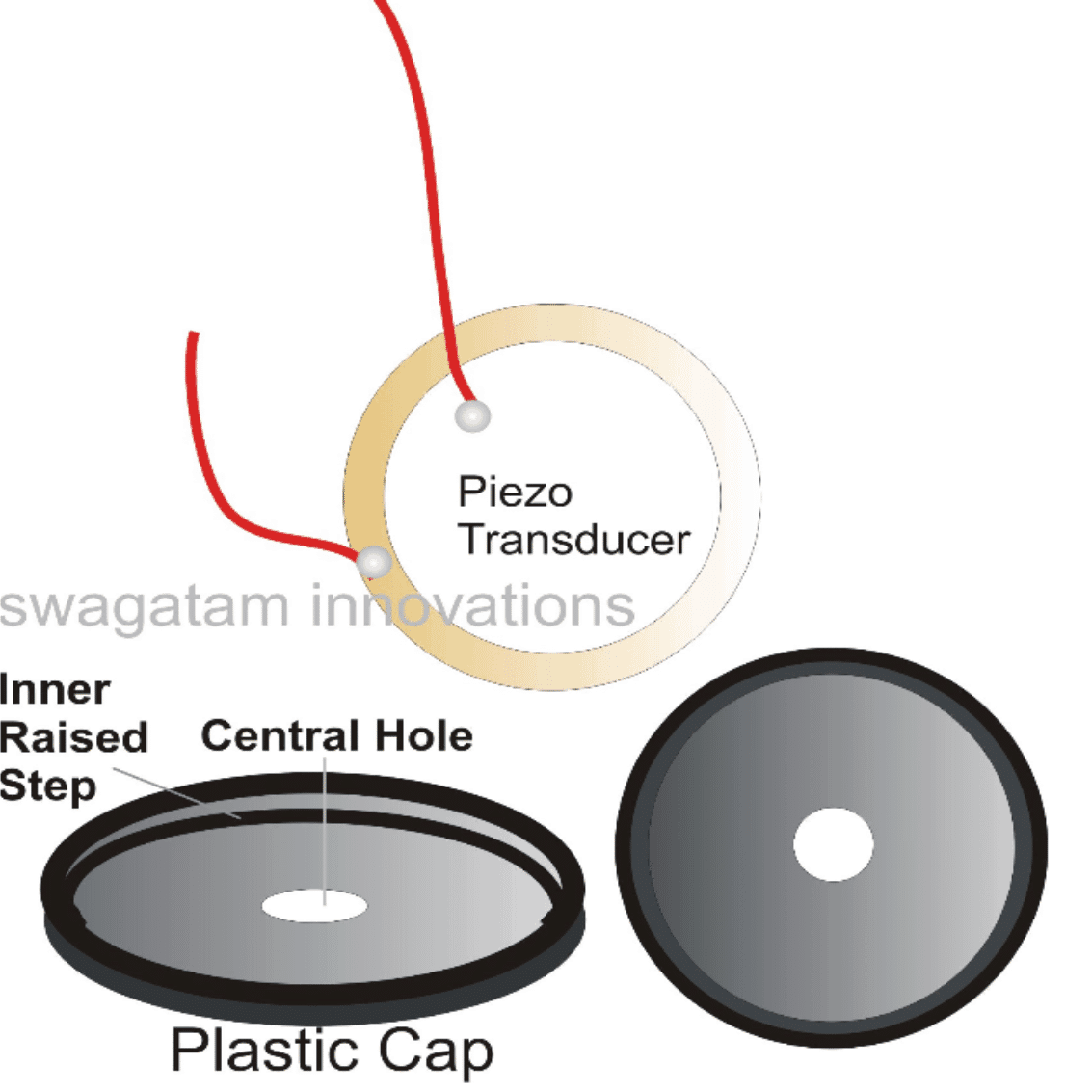

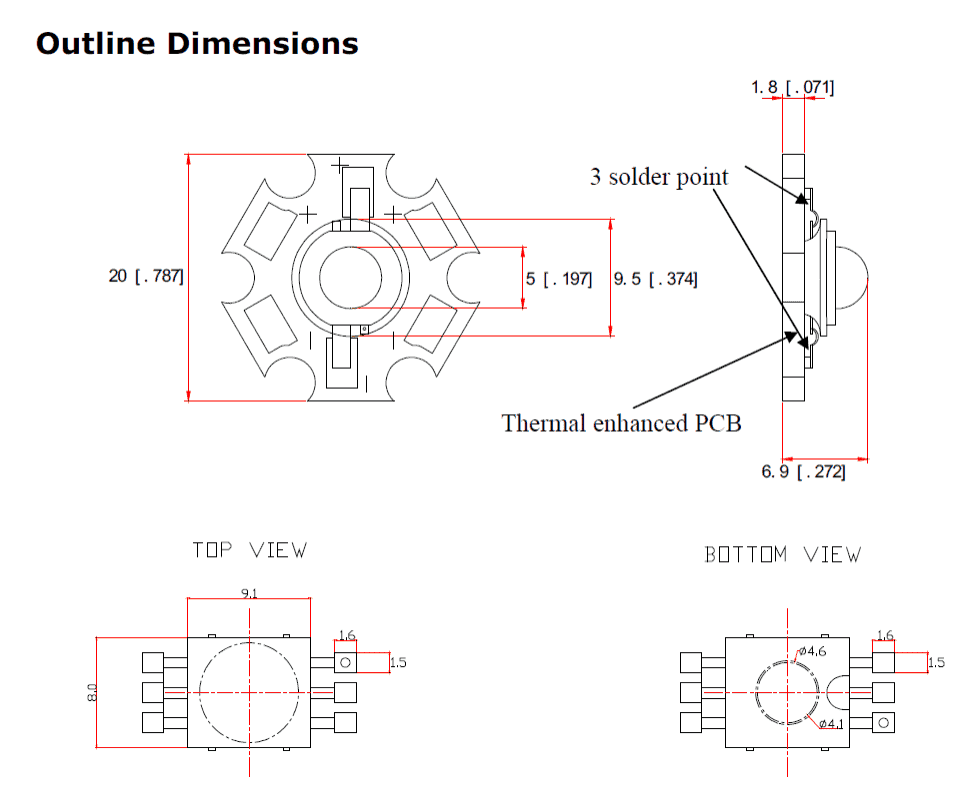

Construction Procedure:

Since the LED would be generating considerable amount heat, a neatly fabricated aluminum heatsink would be required to be integrated with it so that the life and theefficiencyof the device is maintained for many many years. Please see the below given diagram to know thebasicheatsink design, the holes must be drilled just as soecified in the diagram and the LED leads should not touch the heatsink while it ispassedthrough the holes and soldered over the underside PCB pads. A small 1 mm square piece of aluminum cut into 1/2 by 1/2 inch would just suffice.

Drill the holes into the above metal, as shown in the below given diagram and fix the heatsink over the PCB using small 1/8 x1/4 screw nuts.

A small 1 mm square piece of aluminum cut into 1/2 by 1/2 inch would just suffice.

Drill the holes into the above metal, as shown in the below given diagram and fix the heatsink over the PCB using small 1/8 x1/4 screw nuts.

Next fix the LED over the heatsink in between the two center holes, and solder it leads with supporting copper wires such that it becomes locked with the underneath PCB pads.

Be careful not to short the leads with the heatsink metal.

Connect the 22 Ohm resistor with one of the leads of the LED, preferably with the positive lead.

Finally, connect the cell phone charger wires to the resistor end and the other free LED end.

Make sure the polarity is correct while connecting the wires t the LED, identify them using a digital multimeter before doing the connections.

Your cell phone charger powered 1 watt LED lamp is ready,placeit neatly over some corner of the room, plug it in and experience the awesome illumination, dazzling the entirepremise.

Optionally the unit canbefixed inside a halogen lamp reflector for enhancing the light intensity many folds.

Next fix the LED over the heatsink in between the two center holes, and solder it leads with supporting copper wires such that it becomes locked with the underneath PCB pads.

Be careful not to short the leads with the heatsink metal.

Connect the 22 Ohm resistor with one of the leads of the LED, preferably with the positive lead.

Finally, connect the cell phone charger wires to the resistor end and the other free LED end.

Make sure the polarity is correct while connecting the wires t the LED, identify them using a digital multimeter before doing the connections.

Your cell phone charger powered 1 watt LED lamp is ready,placeit neatly over some corner of the room, plug it in and experience the awesome illumination, dazzling the entirepremise.

Optionally the unit canbefixed inside a halogen lamp reflector for enhancing the light intensity many folds.

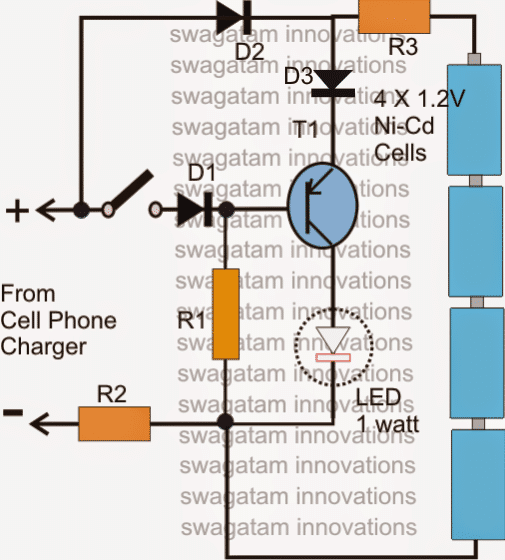

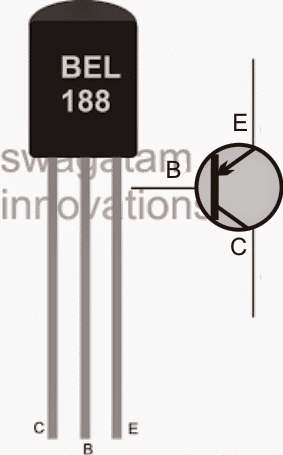

Making a 1 watt LED automatic emergency light circuit

As suggested by Mr.Amit (see comment) the above concept can be very simply converted into a nice little emergency light circuit, let's see how it is done: Referring to the figure below, assuming the voltage from the mains operated charger input to be present, and the switch in the closed position, T1 is held reverse biased so that it isunableto conduct and the LED remains switched OFF. At this position the batteries are trickle charged through R2, R3 and D2. In case the mains fails, T1 instantly conducts and switches ON the LEDautomaticallyand vice versa. Now suppose during the presence of mains the switch is turned of, T1 instantly switches ON, however now the LED lights up through the charger voltage (mains) while the batteries still continue to get trickle charged without getting drained through the LED.

Parts List

R1= 100 Ohms, 1/2 watt R2 = 47 Ohms, 1/2 watt R3 = 22 Ohms, 1/2 watt D1,D2,D3 = 1N4007 T1 = 8550 or 187, 2N2907 LED = 1 watt, 350 mA, high bright Battery = 4 nos. Ni-Cd, AAA

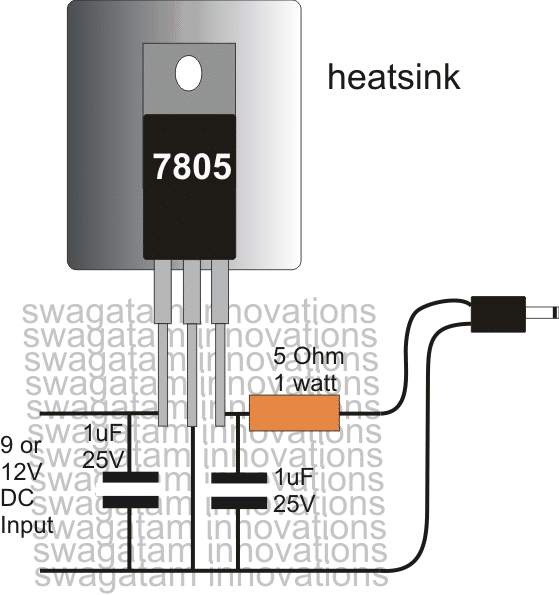

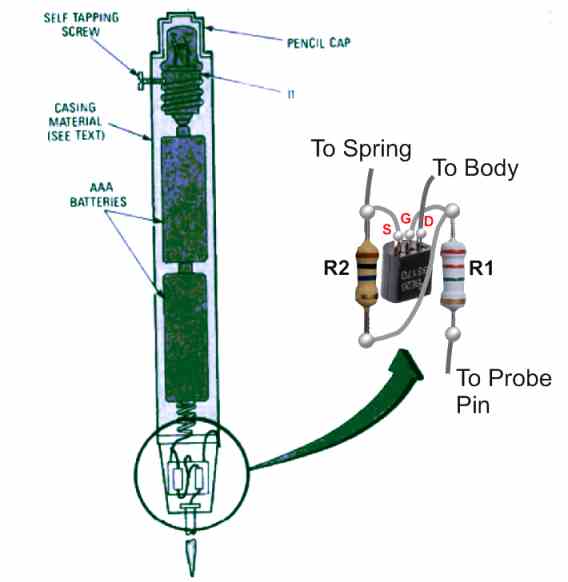

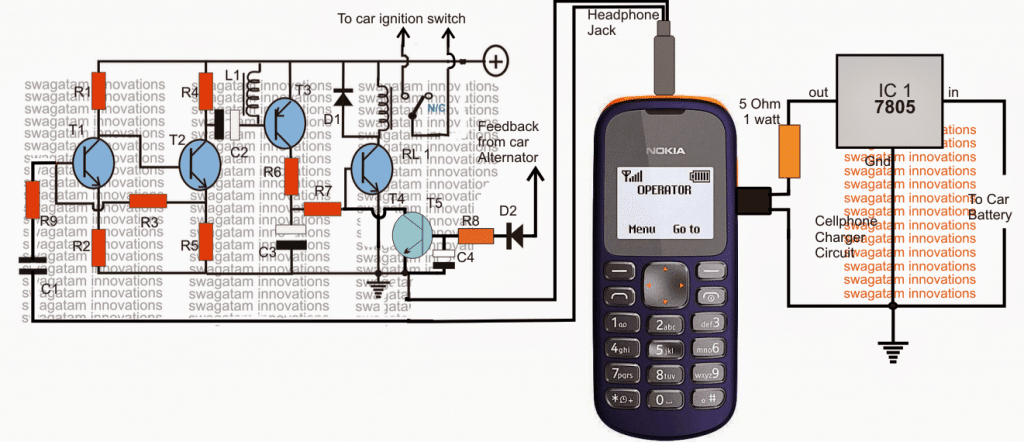

Cell Phone Emergency Charger Pack using Ni-Cd Batteries

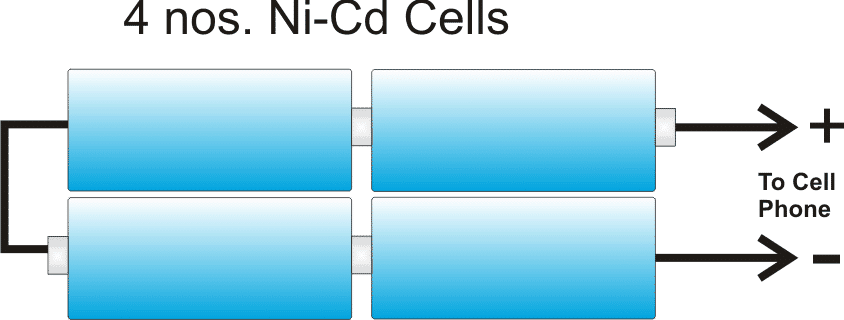

In this post we discuss the construction of a simple emergency charger pack using Nicket Cadmium (Ni-Cd) batteries for your cellphones and smart phones for emergency charging of your cellphone, so that next time you are never stuck on a highway with a full discharged dead cellphone battery.Circuit Concept

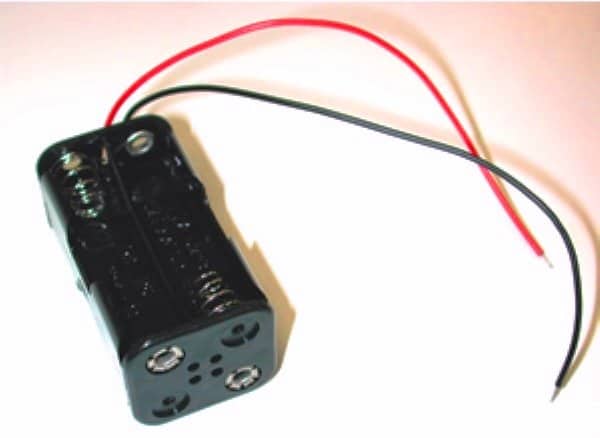

It often happens, our cell phone goes into a low battery condition right in the middle of animportantconversation, and even worse it happens while we are travelling or situated in some remoteoutdoorlocation where there's no charging facility available. No matter what, this little pack will give your cell phone an immediate refillevery timeit tends to get flatoutdoors. We all know that at 3.7 V DC, a cell phone battery isconsideredto be fully charged. For charging it at the above level a charging source needs to provide around 4 to 5 volts to the discharged cell phone battery. Since here we are discussing an energy transfer from one battery to the other or rather from some power source to the cell phone, we need to have some sort of chargeable battery pack which wouldgeneratethe required 4 volts and which could be used anytime for charging a flat cell phone simply by integrating the two together. The above emergency battery pack can be very easily made by putting four Ni-Cd cells in series. Let's learn how to do it.Materials you will Require

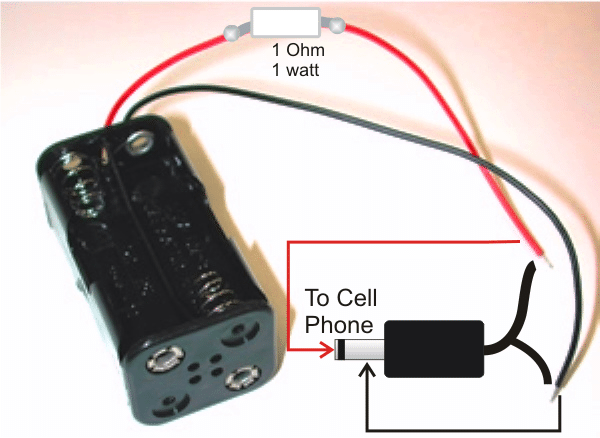

It's not difficult, you would require four 1.2V Ni-Cd AAA penlight cells, a four cell holder assembly and a 1 Ohm 1 watt resistor.

How to Build the Cellphone Battery Bank

The above holder would generate a voltage of about 4.8V at its wire terminals with four AAA 1.2 Ni-Cd attached to within the given slots correctly. The 1 Ohm resistor can be connected at the center of the red wire by cutting the red wire at the center and bridging the resistor terminals such that it comes in series with the red wire. The resistor should covered under a plastic tubing or sleeving. The red and the black wires of above assembly should be terminated with a suitable cell phone charger-pin so that it can be easily inserted into the cell phone charging socket whenever required.

The red and the black wires of above assembly should be terminated with a suitable cell phone charger-pin so that it can be easily inserted into the cell phone charging socket whenever required.

Now let's learn how we can charge the above emergency battery pack at home.

Ni-Cd cells can be charged safely for about 10 to 14 hours using a constant voltage charger at C/10 rate.

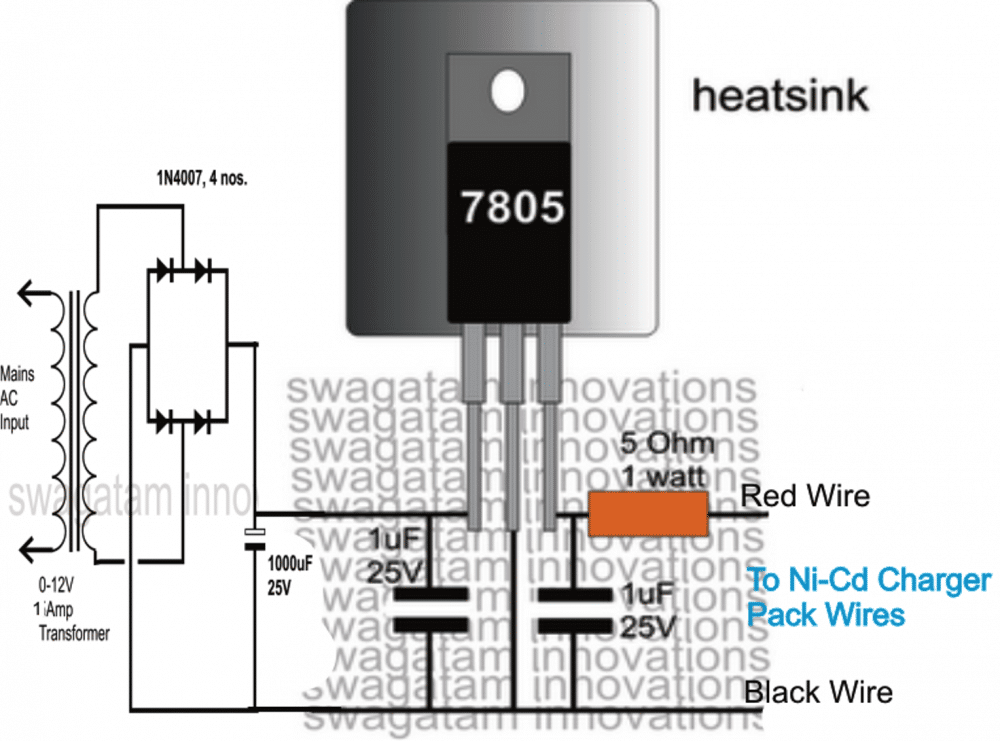

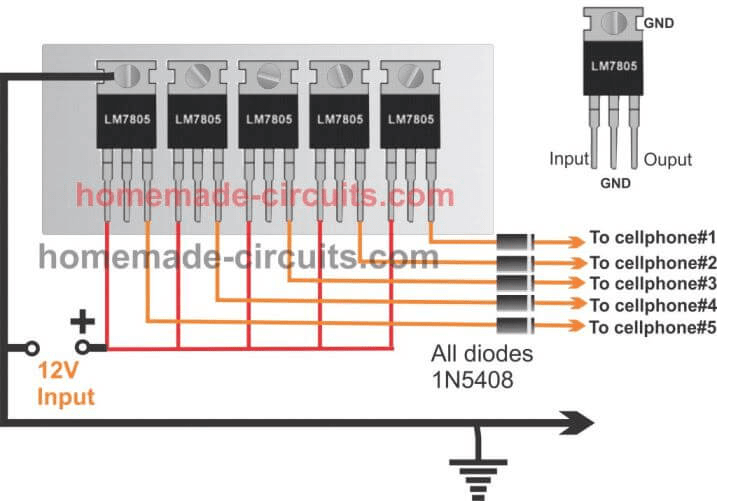

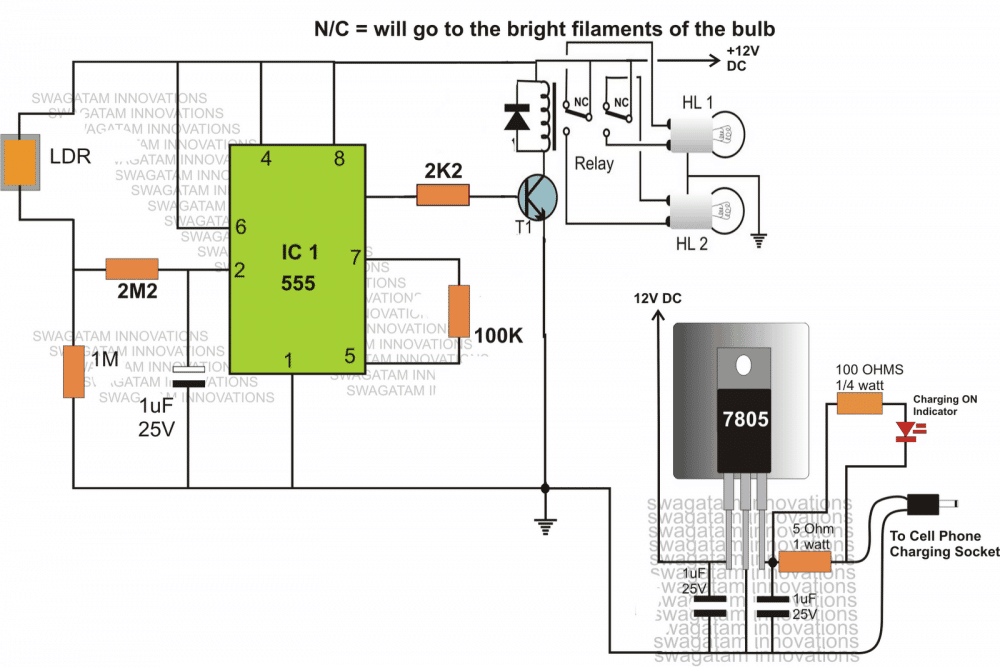

The very useful 7805 voltage regulator IC can be used here for charging the Ni-Cd battery pack.

The following diagramshowsa very simple Ni-Cd charger circuit which can be used for charging the above battery pack so that it remains in a standby position and can be taken outdoors in the form of anemergencycell phone charger unit.

Now let's learn how we can charge the above emergency battery pack at home.

Ni-Cd cells can be charged safely for about 10 to 14 hours using a constant voltage charger at C/10 rate.

The very useful 7805 voltage regulator IC can be used here for charging the Ni-Cd battery pack.

The following diagramshowsa very simple Ni-Cd charger circuit which can be used for charging the above battery pack so that it remains in a standby position and can be taken outdoors in the form of anemergencycell phone charger unit.

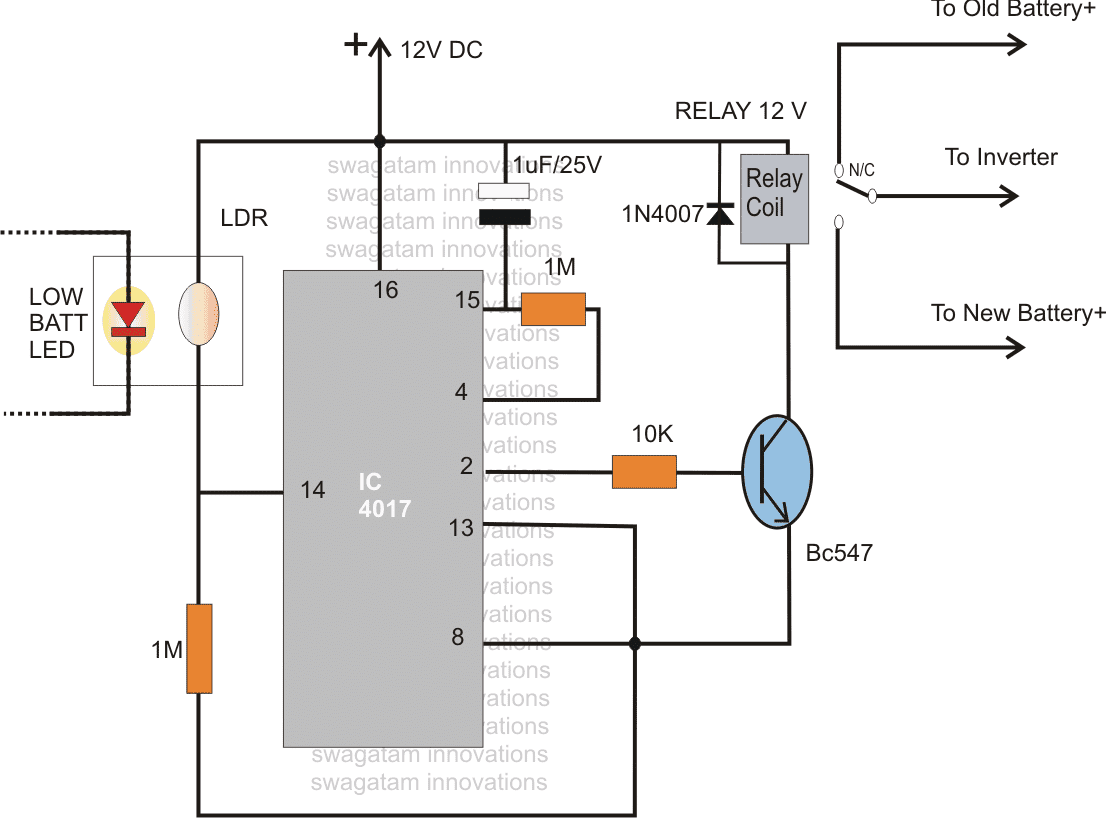

How to Switch Two Batteries Manually using Opto Coupler

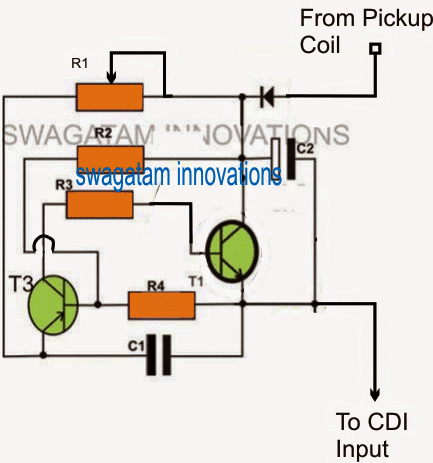

Thefollowing article explaining a dual battery changeover relay circuit was requested by Mr.Raja so that it could become possible to switch between his old and new inverter batteriesautomatically,eliminating manualinterventions. Let's read it in details. "Ibought a new 12v 110 Ah lead acid battery for the dc home lighting system. I had another 12v 110ah battery which is about 8year old. ( which is connected earlier in the same lighting system in my house itself) . But the old one has approximately 25ah capacity as i calculated. But it is not sufficient to glow light for about 5 hours of night.(i.e. From 6pm to 11pm) So i want to use old and new Battery. But i can't join them in parallel, as old one may takes charge from new battery, which decrease the life of new one (as i think) Therefore at present i am using a'Two-way' switch to switch on and off between old and new battery. Whenever lighting system controller shows red light, i.e. At about 11.5v, i manually operate the two way switch to switch on the new battery. Now , please give me the circuit to switch on and off between two batteries in such a way that, initially lighting system operates with old bty and as the voltage of old bty decreases (below 11.5v) then only switch on to new one.. Thanking you"The Design

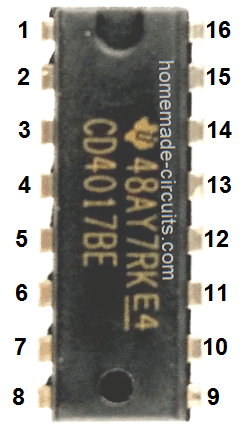

The designed idea of the proposed dual battery changeover circuit or rather old to new batterychangeovercircuit may be understood with the followingpoints: Referringto the circuit diagram we see a IC 4017 which functions as a sequence toggler or switcher. The IC will shift its output from pin#3 to pin#2 and then to pin#4 inresponseto every positive pulse at its input pin#14. pin#4 of the IC has been connected to the reset pin#15 of the IC, means the moment the logic sequence reaches pin#4, thesequence getsreset back to pin#3 so that the cycle can repeat. Here the input pulse is derived from the low battery warning indicator from the existing inverter system. The LED light from the low battery warning has been integrated to an LDR using a light proof tubing. Initially when the power is switched ON, the 1uF capacitor resets the IC so that the logic sequence initiates from pin#3. The relay at this pointremainsconnected with its N/C pole connecting the old battery positive with the inverter. The inverterstartsoperating, draining the old battery On reaching the lowbatterythreshold, the inverter low battery LED illuminates which instantly lowers the enclosed LDR resistance supplying a positive pulse to the pin#14 of the IC. The IC responds shifting the logic sequence from pin#3 to pin#2. Since pin#2 of the IC is connected to the relay driver transistor, the relay immediately activates, switching the new battery into action through its N/O contacts. The new battery being fully charged toggles OFF the low battery indicator light, the IC goes into a standby position holding the situation intact.... until, the new battery also reaches a low-battery condition switching ON the LED and resetting the IC into its initial position. The cycle then repeats producing the required automatic dual battery changeover actions.

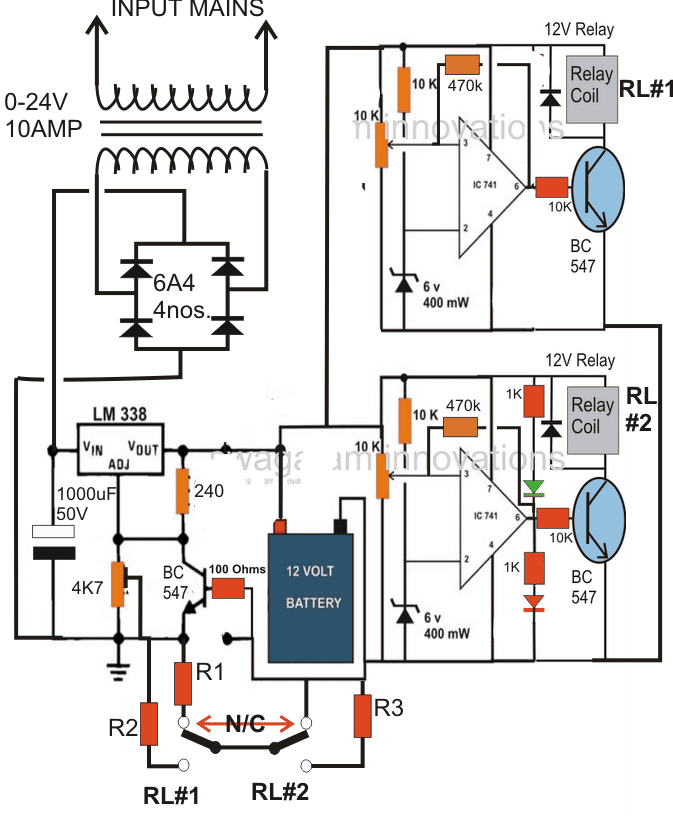

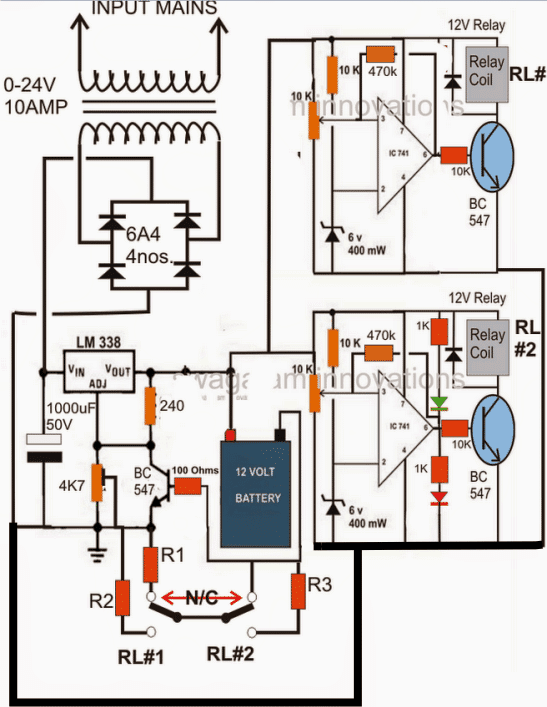

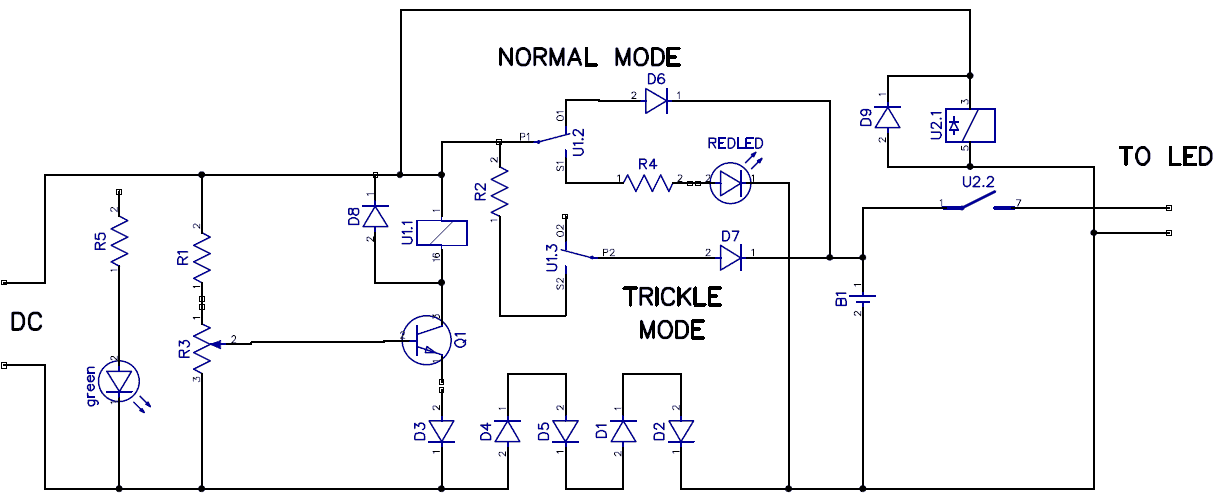

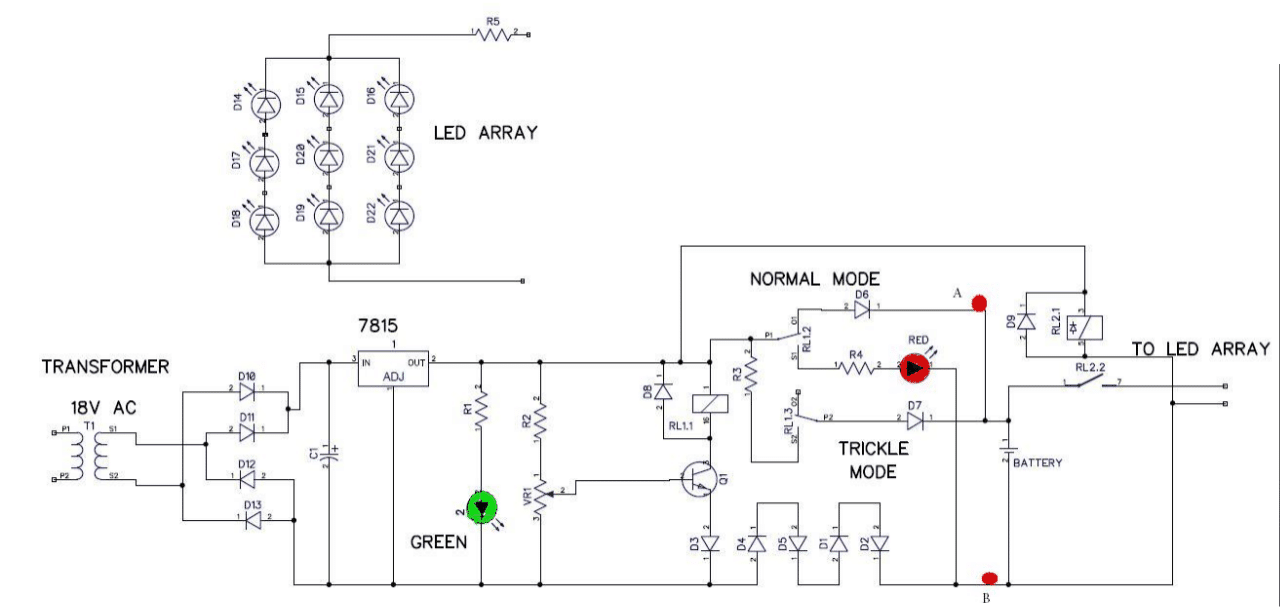

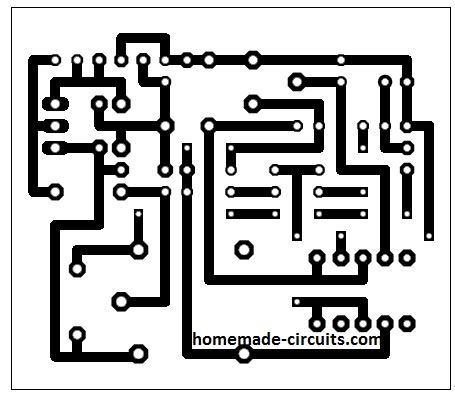

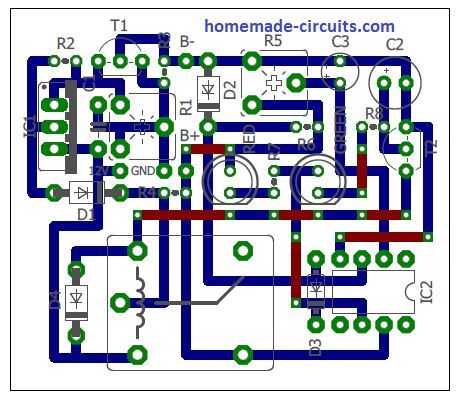

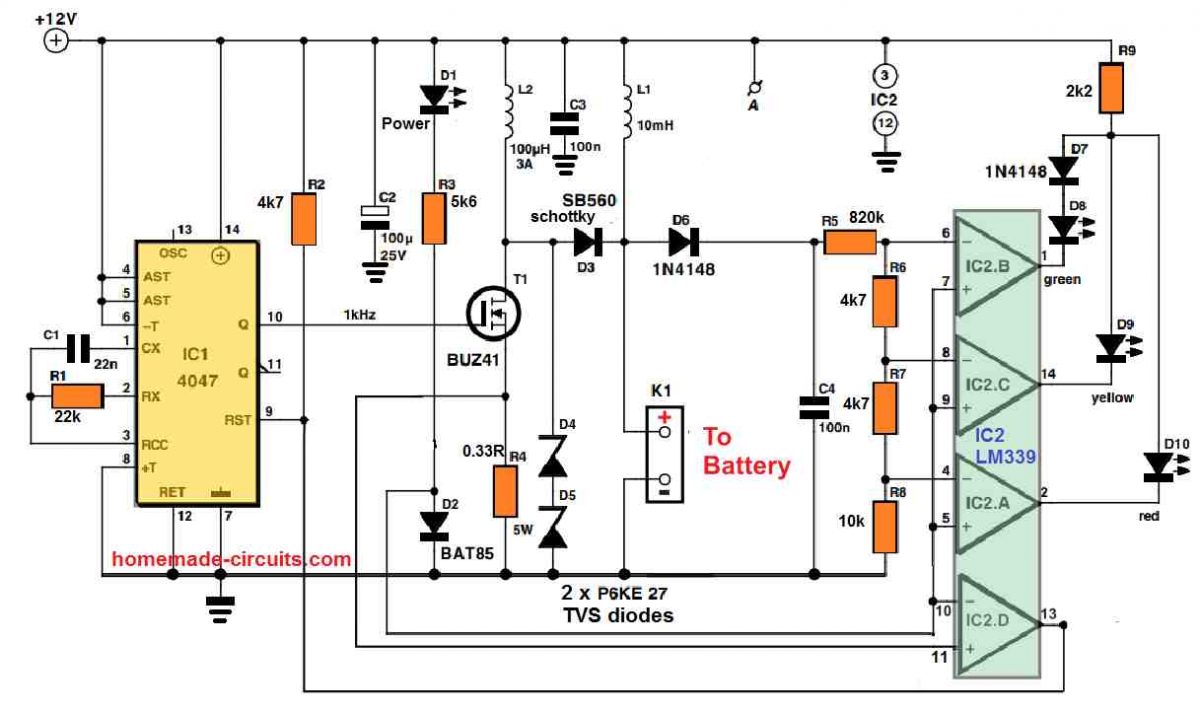

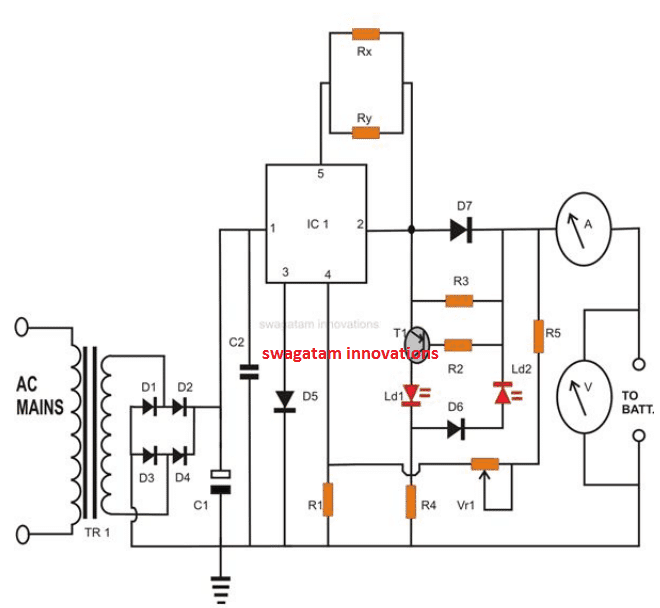

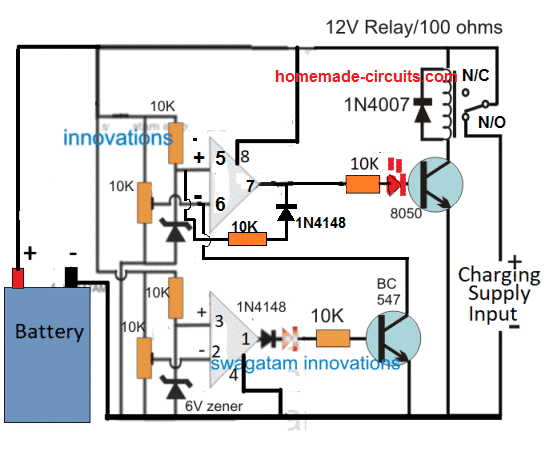

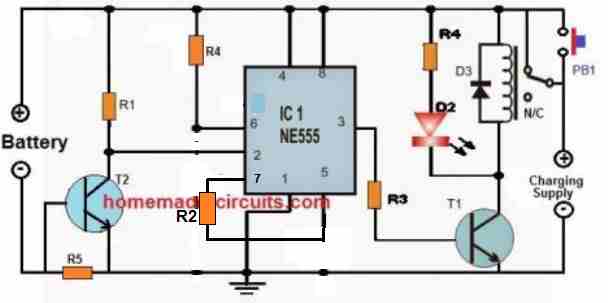

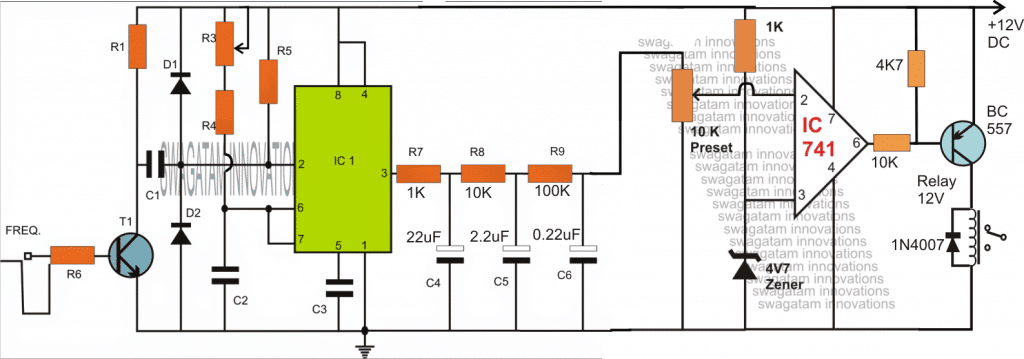

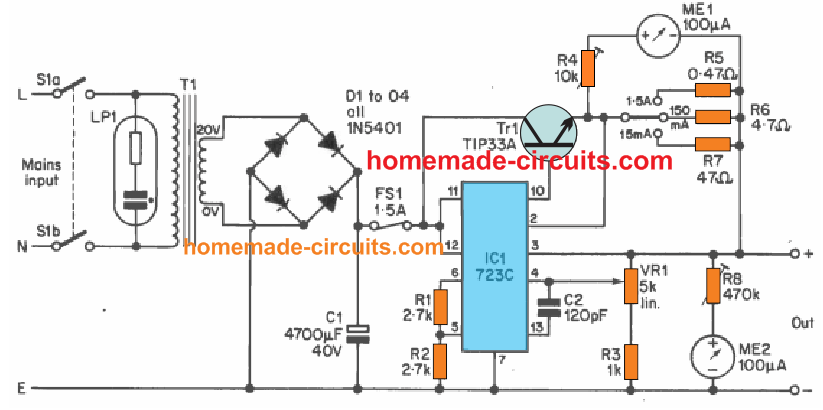

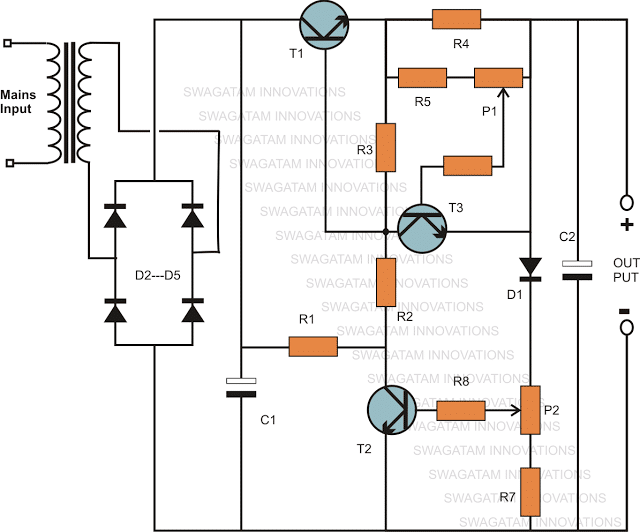

3 Step Automatic Battery Charger/Controller Circuit

Generallyit is noticed that while charging batteries people hardly pay any special attentiontowardthe procedures. For them charging a battery is simply connecting any DC supply with matching voltage with the battery terminals.How to Correctly Charge a Lead Acid Battery

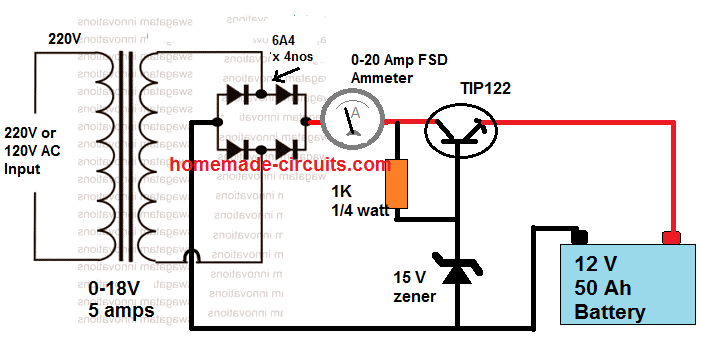

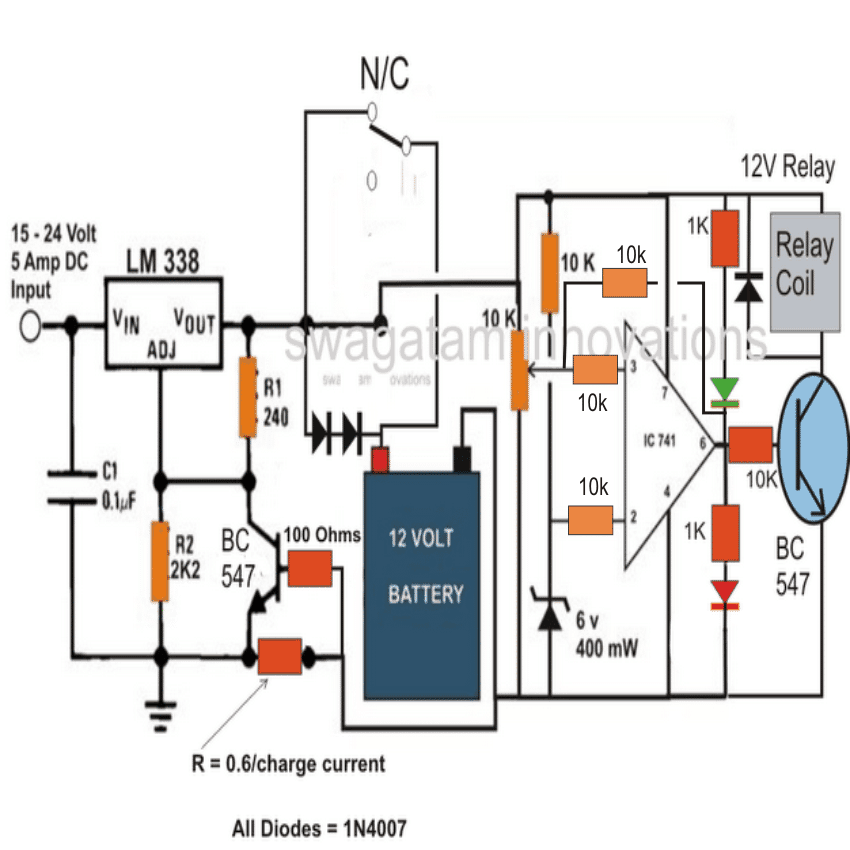

I have seen motor garage mechanics charge all types of batteries with the same power supply source irrespective of the AH rating associated with the particular batteries. That's gravely wrong! That's like giving the batteries a slow "death". Lead Acid batteries to a very extent are rugged and are capable of taking on the crude charging methods, however it's alwaysrecommendedto charge even the LA batteries with a lot care. This "care" will not only increase thelongevitybut will also enhance theefficiencyof the unit. Ideally all batteries should be charged in a step wise manner, meaning the current should be reduced in steps as the voltage nears the "full charge" value. For a typical Lead Acid battery or an SMF/VRL battery the above approach can be considered very healthy and a reliable method. In this post we are discussing one such automatic step battery charger circuit which can be effectively used for charging most of the rechargeable types of batteries.How the Circuit Functions

Referring to the circuit diagram below, two 741 ICs are configured as comparaters. The presets at pin#2 of each stage is adjusted such that the output goes high after specific voltage levels are identified, or in other words theoutputsof the respective ICs are made to go high in sequence after predetermined charge levels areaccomplisheddiscretely over the connectedbattery. The IC associated with RL1 is the one which conducts first, after say the battery voltage reaches around 13.5V, until this point the battery is charged with the maximum specified current (determined by the value of R1). Once the charge reaches the above value, RL#1 operates, disconnect R1 and connects R2 in line with the circuit. R2 is selected higher than R1 and is appropriately calculated to provide a reduced charging current to the battery. Once the battery terminals reaches the maximum specified charging voltage say at 14.3V, Opamp supporting RL#2 triggers the relay. RL#2 instantly connects R3 in series with R2bringingdown the current to a trickle charge level. Resistors R1, R2, and R3 along with the transistor and the IC LM338 forms a current regulator stage, where the value of theresistorsdetermines the maximum allowable current limit to the battery, or the output of the IC LM338. At this point the battery may be leftunattendedfor many hours, yet the charge level remains perfectly safe,intact and in a topped up condition. The above 3 step charging process ensures a veryefficientway of charging resulting in almost a 98% chargeaccumulationwith the connected battery. The circuit has been designed by "Swagatam" R1 = 0.6/ half battery AH

R2 = 0.6/one fifth of battery AH

R3 = 0.6/one 50th of battery AH.

A closer inspection of the above diagram reveals that during the period when the relay contacts are about to release or move from the N/C position might cause a momentary diconnection of the ground to the circuit which in turn migh result in a ringing effect on the relay operation.

The remedy is to connect the ground of the circuit directly with the bridge rectifier ground and keep the ground from the R1/R2/R3 resistors attached solely with the battery negative.

The corrected diagram may be witnessed below:

R1 = 0.6/ half battery AH

R2 = 0.6/one fifth of battery AH

R3 = 0.6/one 50th of battery AH.

A closer inspection of the above diagram reveals that during the period when the relay contacts are about to release or move from the N/C position might cause a momentary diconnection of the ground to the circuit which in turn migh result in a ringing effect on the relay operation.

The remedy is to connect the ground of the circuit directly with the bridge rectifier ground and keep the ground from the R1/R2/R3 resistors attached solely with the battery negative.

The corrected diagram may be witnessed below:

How to Set up the Circuit

Remember if you are using 741 IC then you must remove the red LED from the lower opamp and connect it in series with the base of the transistor to prevent permanent triggering of the transistor due to IC leakage current.

Do the same with the upper transistor base also, connect another LED there.

However if you use an LM358 IC then you may not have to this modification and use the design exactly as given.

Now let's learn how to set it up:

Initially keep the 470K feedback resistors disconnected.

Keep the slider of the presets towards ground line.

Now let's say we want the first relay RL#1 to operate at 13.5V, therefore adjust the LM338 pot to get 13.5V across the circuit supply line.

Next, adjust the upper preset slowly until the relay just toggles ON.

Similarly, suppose we want the next transition to happen at 14.3V, ...increase the voltage to 14.3V by carefully adjusting the LM338 pot.

Then tweak the lower 10K preset such that RL#2 just clicks ON.

Done! your set up procedure is complete.

Seal of the presets with some kind of glue to keep them fixed in the set positions.

Now you can attach a discharged battery to see the actions happening automatically as the battery charges with a 3 step mode.

The 470K feedback resistor can be actually eliminated and removed, instead you can connect a large value capacitor in the order of 1000uF/25V acrossthe relay coils to restrict threshold chattering of the relay contacts.

How to Set up the Circuit

Remember if you are using 741 IC then you must remove the red LED from the lower opamp and connect it in series with the base of the transistor to prevent permanent triggering of the transistor due to IC leakage current.

Do the same with the upper transistor base also, connect another LED there.

However if you use an LM358 IC then you may not have to this modification and use the design exactly as given.

Now let's learn how to set it up:

Initially keep the 470K feedback resistors disconnected.

Keep the slider of the presets towards ground line.

Now let's say we want the first relay RL#1 to operate at 13.5V, therefore adjust the LM338 pot to get 13.5V across the circuit supply line.

Next, adjust the upper preset slowly until the relay just toggles ON.

Similarly, suppose we want the next transition to happen at 14.3V, ...increase the voltage to 14.3V by carefully adjusting the LM338 pot.

Then tweak the lower 10K preset such that RL#2 just clicks ON.

Done! your set up procedure is complete.

Seal of the presets with some kind of glue to keep them fixed in the set positions.

Now you can attach a discharged battery to see the actions happening automatically as the battery charges with a 3 step mode.

The 470K feedback resistor can be actually eliminated and removed, instead you can connect a large value capacitor in the order of 1000uF/25V acrossthe relay coils to restrict threshold chattering of the relay contacts.

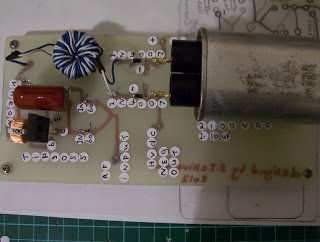

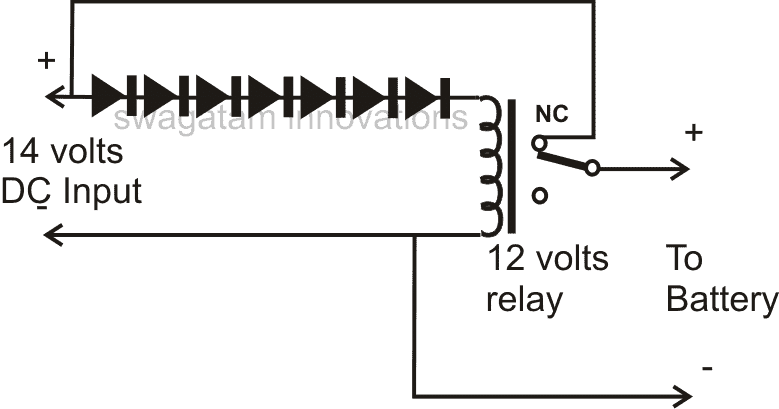

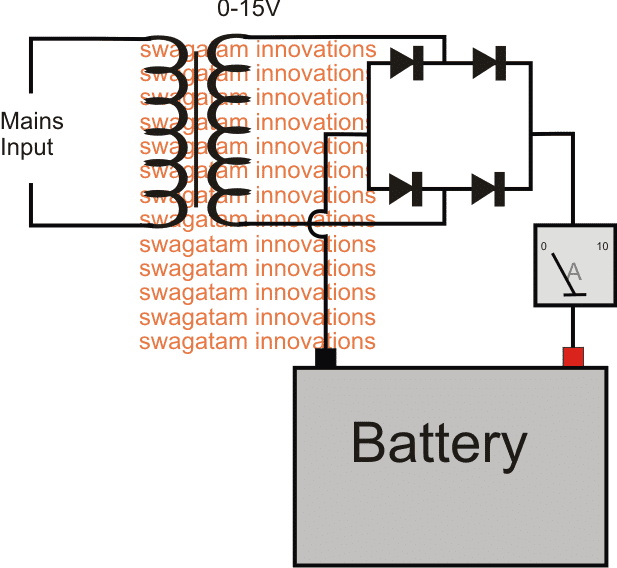

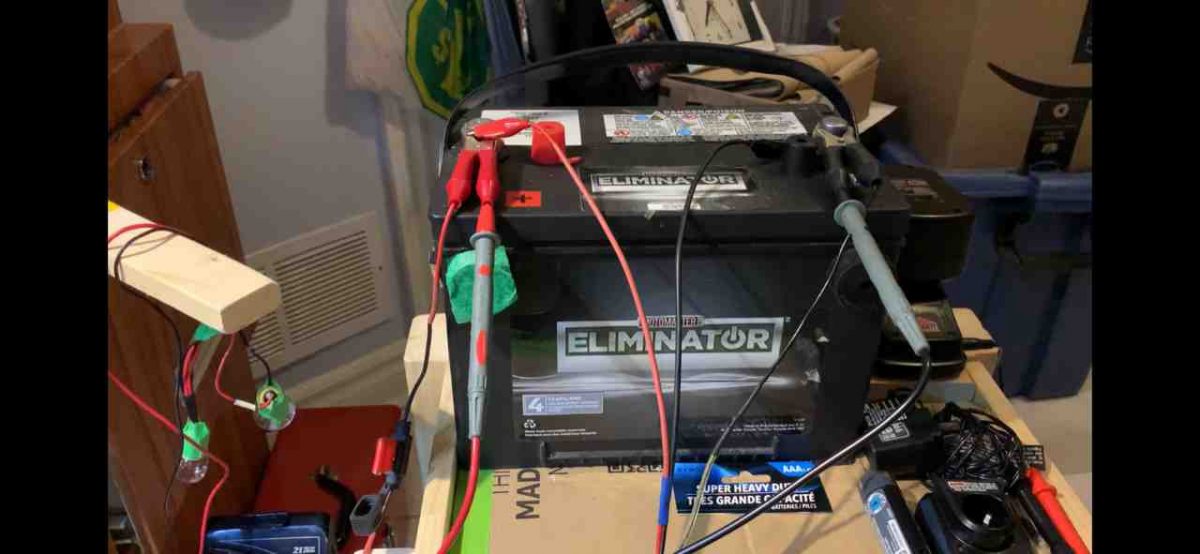

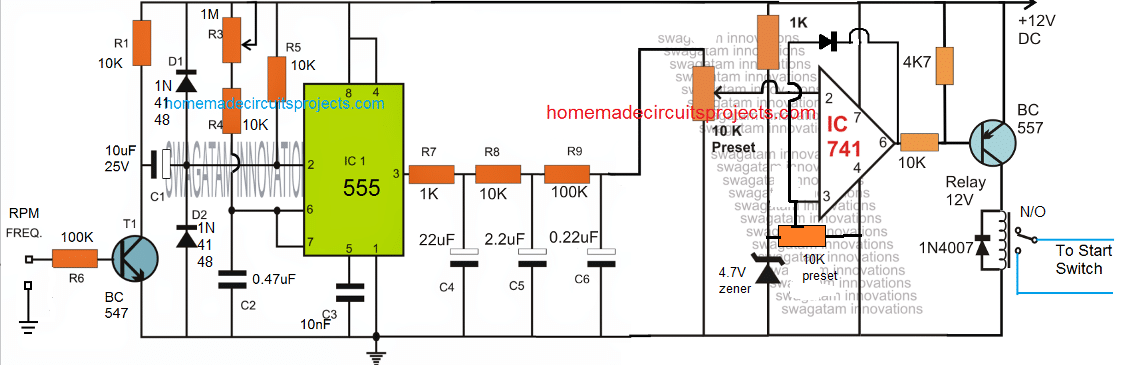

Make a Battery Charger in 15 Minutes

I have posted many battery charger circuits in this site, some are easy to build but less efficient, while some are too sophisticated involving complex construction steps. The one posted here is possibly the easiset with its concept and also is extremely easy to build. In fact if you had all the required material you would build it within 15 minutes of time.Introduction

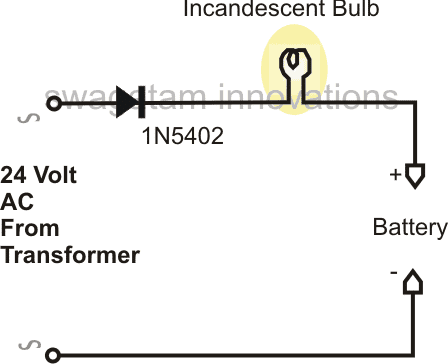

The concept is indeed hugely simple and therefore pretty crude with its going. This means that though this idea is too simple, would require appropriate monitoring of the charging conditions of the battery, so that it does not get over charged or damaged.Materials Required

To make this simplest battery charger circuit quickly, you would require the following bill of materials: One rectifier diode, 1N5402 An incandescent bulb, havingvoltagerating equal to the battery which needs to be charged and current rating close to 1/10th of the battery AH. A transformer having voltage rating equal to twice that of the battery voltage and current twice the charging rate of the battery. That means if the battery is 12V, the transformer should be 24V, and if the AH of the battery is 7.5 then dividing this by 10 gives 750mA which becomes therecommendedcharging rate of the battery,multiplyingthis by 2 gives 1.5Amps, so this becomes the required current rating of the transformer.Building this Simplest Charger Circuit

After you have collected all the above material, you may simply connect the above parameters together with the help of the diagram. The functioning of the circuit may be explained in the following manner: When the power is switched ON, the 1N5402 diode rectifies the 24V DC to produce half wave 24V DC at the output. Though the RMS value of this voltage may appear to be 12V, the peak voltage is still 24V, therefore it cannot be applied directly to the battery. To blunt of this peak value, we introduce a bulb in series with the circuit. The bulb absorbs the high peak values of the voltage and provides a relatively controlled output to the battery, which becomes self regulatory through the glow of the filament intensity of the bulb (varying resistance). The voltage and current thus automatically becomes adjusted to appropriate charging levels which becomes just suitable for the battery safe charging. The charging of the battery can be witnessed by the gradual dimming of the bulb as the threshold charging voltage of the battery isreached. However once the battery voltage reaches close to 14.5V, thechargingmust be stopped, irrespective of the bulb glow condition.

Circuit Diagram

Video Clip showing the charging process using a single diode:

Video Clip showing the charging process using a single diode:

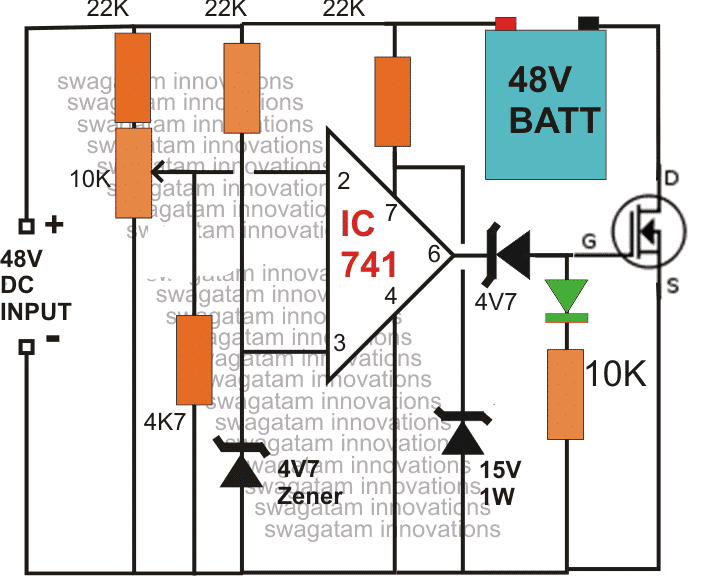

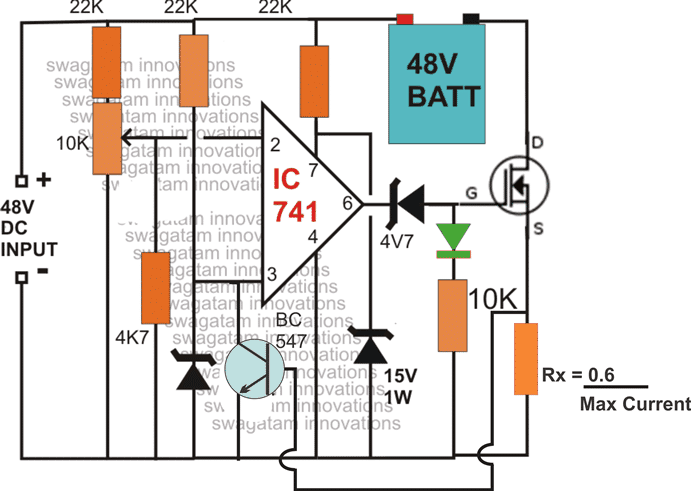

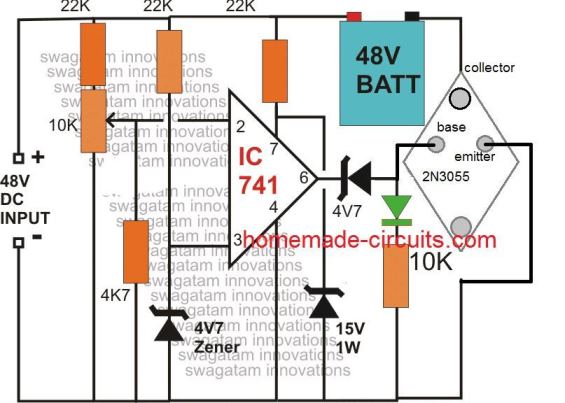

Simple 48V Automatic Battery Charger Circuit

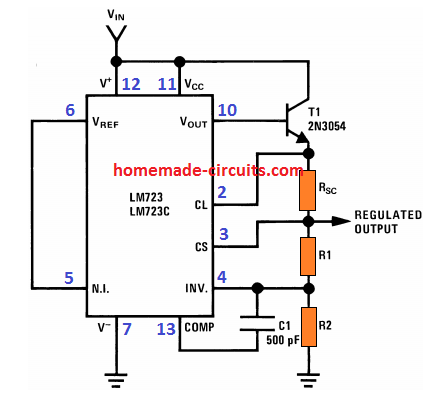

The proposed 48 Vautomaticbattery charger circuit will charge any 48 V battery up to an optimal 56 V full charge level, utilizing veryordinarycomponents. The circuit is highly accurate with its over chargecutoff features.CircuitDescription:

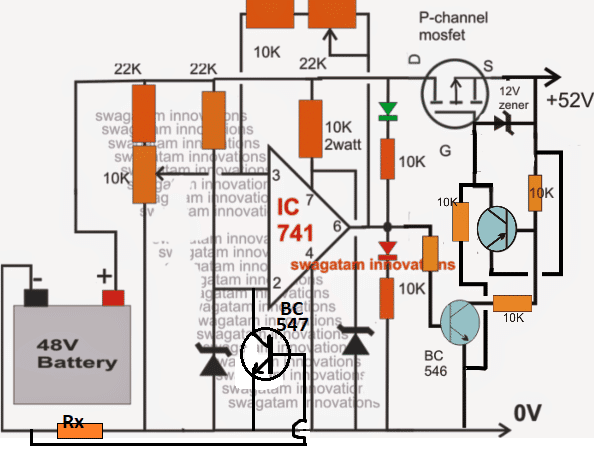

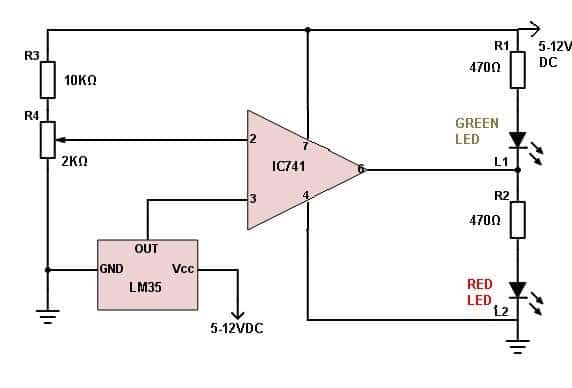

Asshownin the circuit diagram, the mainelementin the circuit is the opamp IC 741, which has been arranged as a comparator. Pin#3 which is the inverting input of the IC is referenced with a fixed voltage of 4.7V through therespective zener/resistor network. The other input isappliedwith the sensing voltage which isactuallythe voltage merged from the supply and the from the battery, in other words the charging voltage which is applied to the battery for charging. The resistornetworkat pin#2 along with the preset forms a voltage divider network which is initially adjusted such that the voltage at this pin stays below the voltage level at pin3, which is the reference voltage set at 4.7v by the zener diode. The preset is set in such a way that the voltage at pin#2 rises above the 4.7 mark as soon as the battery voltage rises above 50V or the fill charge threshold level of the battery. The moment this happens, the output of the opamp goes low switching OFF the mosfet, and cutting off the voltage to the battery. Initially as ling as the battery voltage and the over all voltage from the 48V supply remains below the full charge threshold level of the battery, the output of the opamp stays high and the mosfet us kept switched ON. This allows the voltage to the battery for charging, until the above explained threshold is reached which automatically inhibits the battery from further charging. The mosfet can be selected as per the AH rating of the battery. UPDATE: For converting this into a Solar version you can read this article1) Using Mosfet Cut Of

2) Current Controlled Version of the above Design

NOTE: The above diagrams mistakenly shows 48V as the input, the correct value is 56V.

Because the full charge level of a 48 V battery is around 56/57 V.

NOTE: You will have to connect the battery first and then switch ON the input supply, otherwise the mosfet will fail to initiate for the charging process. Make sure the green LED remains illuminated after power switch ON, this will confirm the charging status of the battery.

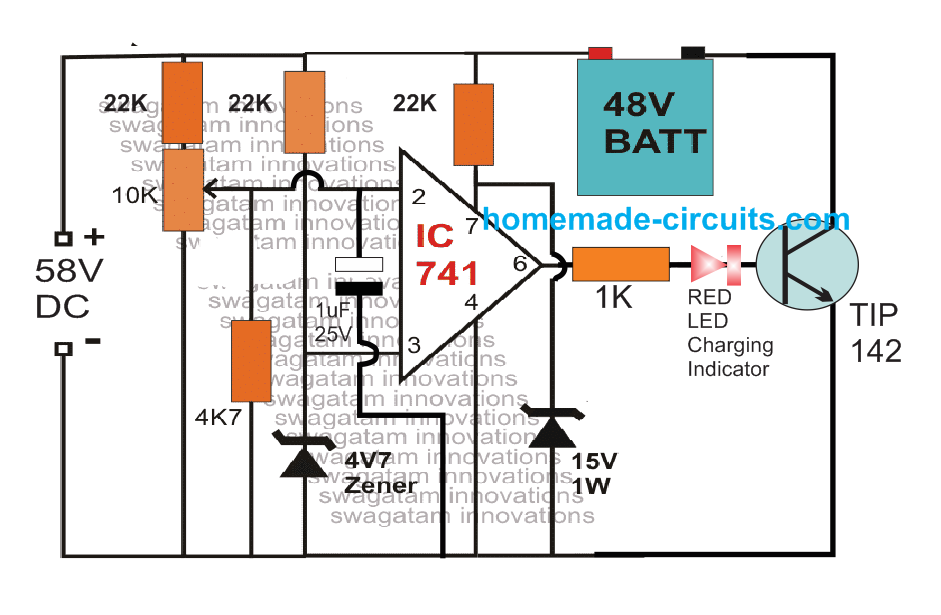

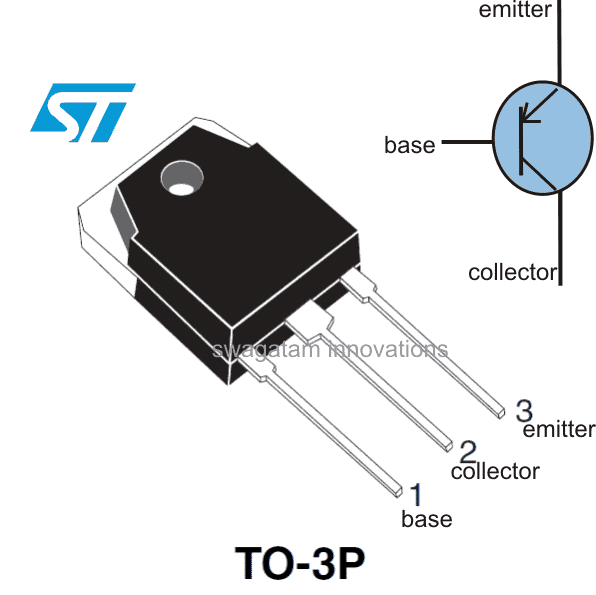

The above design can be also built using a TIP142 and a red led charging indicator.

NOTE: The above diagrams mistakenly shows 48V as the input, the correct value is 56V.

Because the full charge level of a 48 V battery is around 56/57 V.

NOTE: You will have to connect the battery first and then switch ON the input supply, otherwise the mosfet will fail to initiate for the charging process. Make sure the green LED remains illuminated after power switch ON, this will confirm the charging status of the battery.

The above design can be also built using a TIP142 and a red led charging indicator.

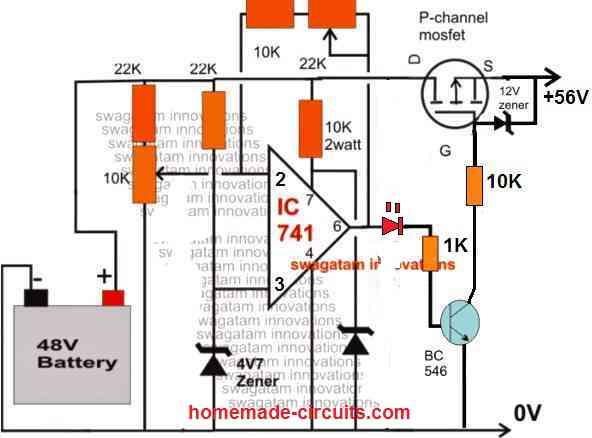

Simple 48 V 100 Ah charger Circuit using OP Amp and TIP142

3) Making a Fully Automatic Version

The above circuit can be upgraded into an over charge cut off, as well as low charge restoring battery charger system, for charging 48V batteries.

The modifications enables the circuit to switch OFF the battery charging process at the set over charge threshold and restore back the process when the battery voltage falls below the low threshold value.

The 10k preset must be adjusted to set the full charge level while the 22k preset for detecting the lower threshold of the battery.

3) Making a Fully Automatic Version

The above circuit can be upgraded into an over charge cut off, as well as low charge restoring battery charger system, for charging 48V batteries.

The modifications enables the circuit to switch OFF the battery charging process at the set over charge threshold and restore back the process when the battery voltage falls below the low threshold value.

The 10k preset must be adjusted to set the full charge level while the 22k preset for detecting the lower threshold of the battery.

NOTE: In the above two circuits, please connect the RED LED in series with the BC546 base.

This will prevent the op amp offset voltage from reaching the BC546 base and false triggering.

The above design can be further simplified as shown in the following image.

Notice that the input pins of the op amp are swapped in this design, which allowed the elimination of the extra PNP BJT from the circuit.

NOTE: In the above two circuits, please connect the RED LED in series with the BC546 base.

This will prevent the op amp offset voltage from reaching the BC546 base and false triggering.

The above design can be further simplified as shown in the following image.

Notice that the input pins of the op amp are swapped in this design, which allowed the elimination of the extra PNP BJT from the circuit.

How to Set up the above Circuit:

For setting up procedure, the sample power supply should be connected across the points where the battery is connected, the mosfet does not require any attention initially. DO NOT connect the battery while carrying out this procedure. Also keep the 22k preset link disconnected initially. Apply the higher threshold level across the above mentioned points and adjust the 10K preset such that the RED LED just switches ON. Seal the adjusted preset with some glue. Now reconnect the 22k preset link back into position. Next, reduce the sample voltage to the lower threshold value and adjust the 22k preset such that now the green LED just lights up, while switching OFF the RED LED. If you find no response from the circuit try using a 100K preset instead of the 22k preset. Seal the adjusted preset as above. The setting up of the circuit is over and done. Please note that during actual operations, the above circuit will remain functional only as long as a battery stays connected at the shown points, without a battery the circuit will not detect or respond.Feedback from Mr. Rohit

I have a 50-52v solar panel setup which is charging a 48v 78ah battery. What I want is when my battery is fully charged that is it reaches to 54v the battery charging stops and the supply which is coming from the solar panels is directed to another port from which we can charge any other device connected to the port. This charging should only continue till the battery is above 48v. Once it reaches 48v the battery again starts charging on solar panels and the supply to the other port is stopped. Hoping you will reply soon. My Response to the above Circuit Request You can try the last circuit from the following artcilehttps://www.homemade-circuits.Battery Charger Problems Troubleshooting Discussed

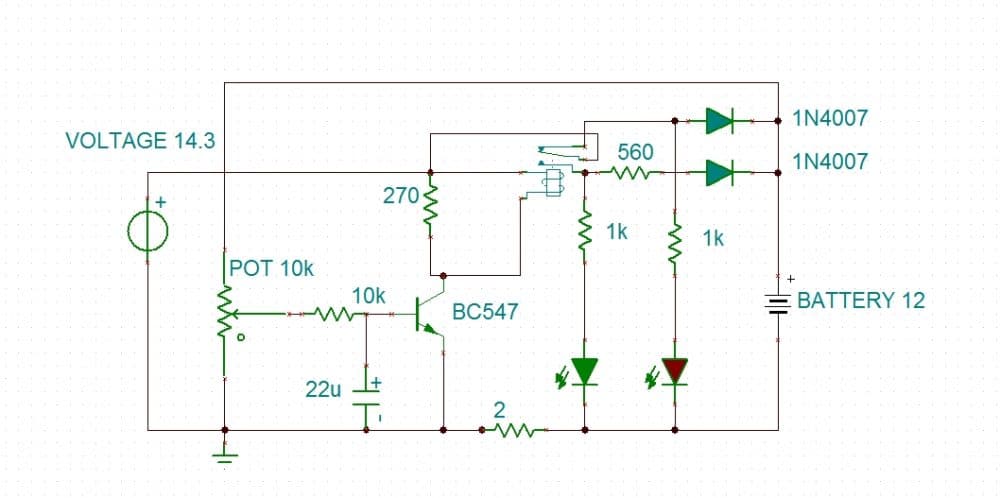

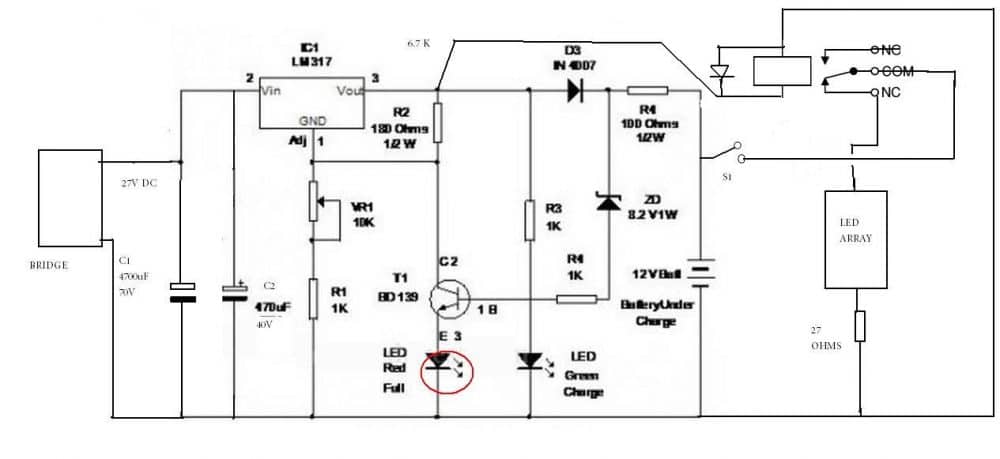

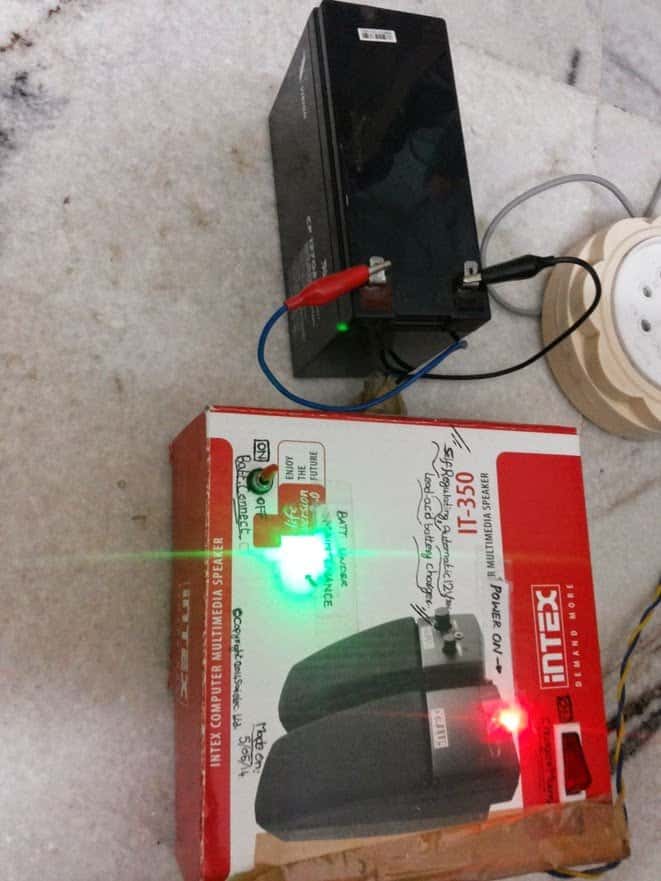

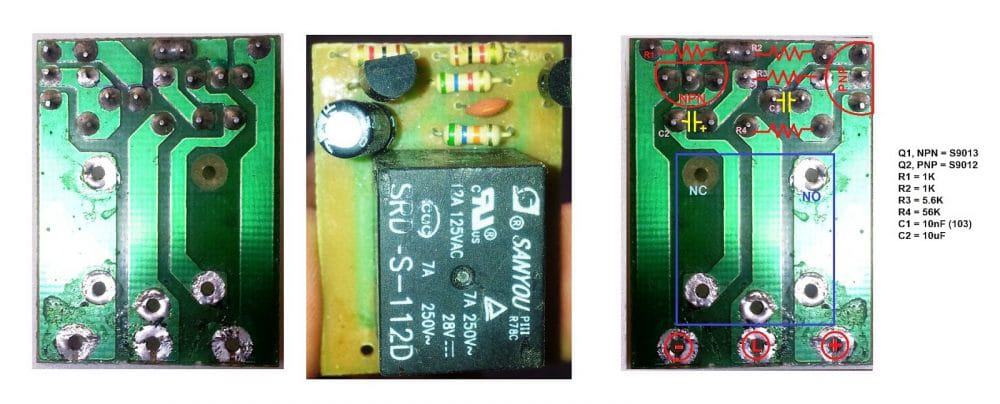

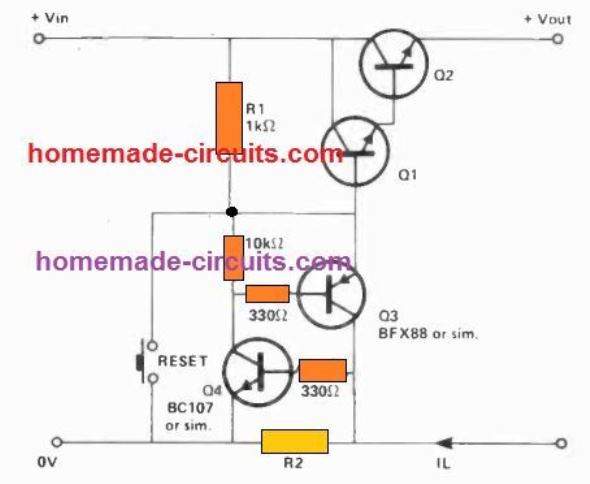

The included battery charger circuit was designed and built by Mr.Vinod Chandran, however there's some issues and problems with the circuit the troubleshooting of the same is addressed in this article. Let's learn the discussion between Vinod and me.Discussing a Transistor Battery Charger Problem

Vinod: I am attaching the circuit image of the charger with hysteresis feature. (with my modification.). This charger is working good. But i need your suggestions and confirmation. Swagatam: Using a transistor won't give accurate results, moreover the setting part would become very tedious.

The circuit is technically correct, if you can adjust the tripping point correctly, then it might just work.

Vinod: I am going to test this circuit.

I already build this in general board.

automatic cut-off is set in 13.6v now.

All i want to wait for the battery to discharge around 12v.

I will inform you the result.

Vinod: I made the charger (hysteresis) but there is a problem.

i will attach the image to explain the problem.

When i connect multimeter in that particular red dots, the voltage shows 16.8.(0.43 A) but when i disconnect battery from the charger and measured again.

then there is no problem.

the out put is 14.2. And the other pin of the relay(through the current limiting resistor) will deliver a clean output voltage of 13.9 (0.033A).

Why this is happening ?.

The only change i have made from this circuit is to grab the green LED and R1 from there and connect it after the D6.

Swagatam: Using a transistor won't give accurate results, moreover the setting part would become very tedious.

The circuit is technically correct, if you can adjust the tripping point correctly, then it might just work.

Vinod: I am going to test this circuit.

I already build this in general board.

automatic cut-off is set in 13.6v now.

All i want to wait for the battery to discharge around 12v.

I will inform you the result.

Vinod: I made the charger (hysteresis) but there is a problem.

i will attach the image to explain the problem.

When i connect multimeter in that particular red dots, the voltage shows 16.8.(0.43 A) but when i disconnect battery from the charger and measured again.

then there is no problem.